-

Posts

1,995 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Trussben

-

That looks beautiful Chuck, you are raising the bar yet again.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

She looks great Rusty, have you decided on the final finish you are going to apply to that gorgeous pear? Maybe even oil it like Chris did on his Confed - that looked sublime IMO. ben

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks for all the likes. Rusty - I have been at home for a few weeks so have managed to spend some time in the shop, that will soon come to an end but I hope to get the port framing completed before I go back on the road. Erik - sorry to hear the benches are so expensive, you could try and make one, instead of drawers just make 2-3 shelves instead, wouldn’t be too hard I think. ben

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looking real good there Ryland, nice tight joints.

- 263 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks for looking Bob.

- 64 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yep Chris, I have started the Rough fairing process before I start the port framing layout, you can see the flexible holly battern I use to check fairness as I go.

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

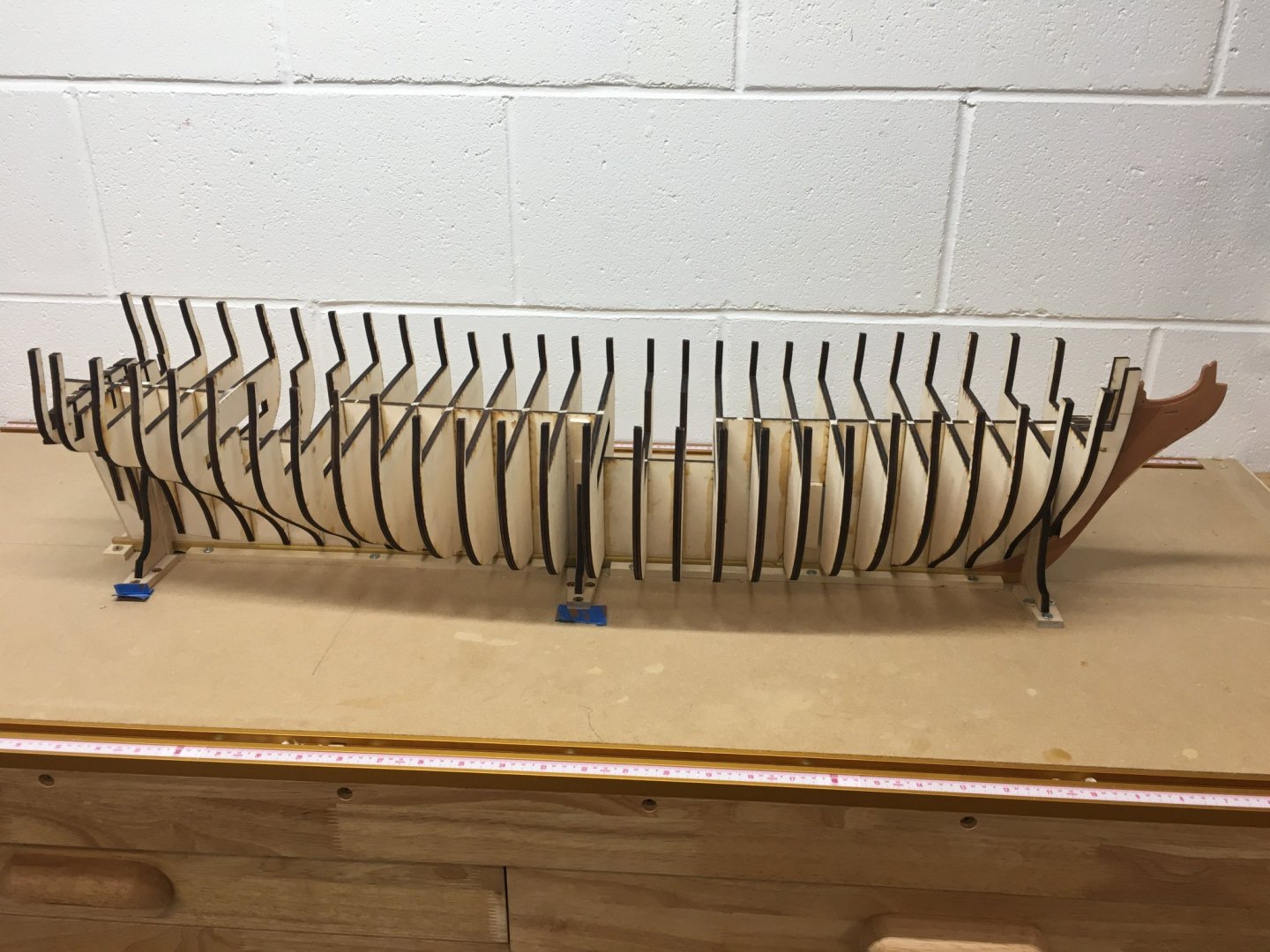

I have completed the keel and started glueing the bulkheads together, here you can see them sat in place. ben

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

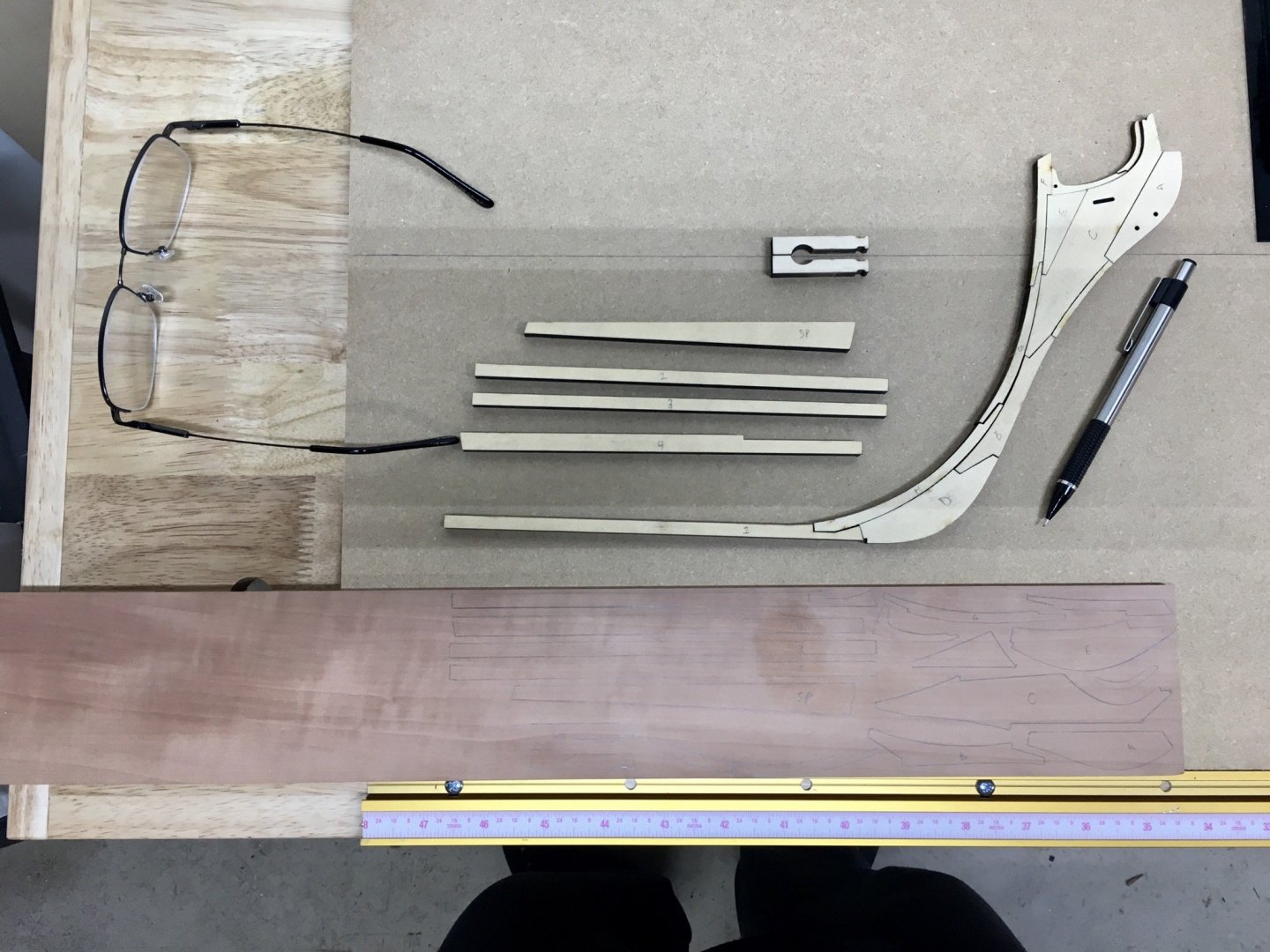

Thanks David and Rusty, I decided to make up both the AYC and my own Pear/Box knee of the head to look at the difference in color and grain appearance and I have decided to go ahead with my decision to make the framing in Pear. ben

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looks really good Ryland. ben

- 263 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi So I'm going to go ahead and start a build log of the Winchelsea, It will based off Chuck's designs with a few modifications of my own. My main reason for building her is because she was once captained by Pellew and I intend in the future to build another of his ships, a 1:48 fully framed model of the 44 gun Razee Indefatigable and it would be great to have both models together in the same scale. I will not be planking in AYC as I have a goodly stock of Castello Boxwood and prefer it on a model of this size, also stem/stern framing and keel will be of Swiss Pear with other wood highlights, maybe I will use the cedar on things that wont be seen easily and use the fruitwood gel stain that Chuck has discovered to blend it with the boxwood to minimize usage. I did purchase the Bulkheads and starter packages from Chuck and will certainly be buying his cast resin set when they are available. The first job I have started while waiting for planking to dry on Pegasus is to make a new build board for this "BIG" ship, it will be approx 38" long without rigging and will need good support while framing, planking and finishing, so I decided to go and buy another 'cheap' 5foot workbench from Harbor Freight for $100 and modify it to suit. First it was put together and lift casters added so that I can quickly move and spin the bench whichever way I need it. Second was to add 4-foot T-tracks and a nice large 1/2" MDF buildboad to the top. Third was to install the keel and bulkhead former holders ready for the backbone. The 4 drawers are great for holding parts/tools and the bottom shelf for materials which keeps an entire build together on one table instead of being spread about my workshop. Here is looking forward to an interesting build and I should start on the bulkheads later this week. ben

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hey Rusty, just catching up and I think I see that your stern framing is still a bit wrong, see doctored picture showing where the upright and the back of the port should go to in yellow and the red shows where the bottom sill of the QG door should slant, this will affect the QG door a bit I think. Maybe you can get away with just filing the correct angle into that existing bottom framing to get it correct. Also I think you have your foremost gunport a little bit too far aft, the plans show its foreward aft edge on the aftside of bulkhead W, yours appears quite a bit further back than that, should be real easy to fix. BR ben

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Au natural for me, the friezes are enough of a contrast with the hull.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

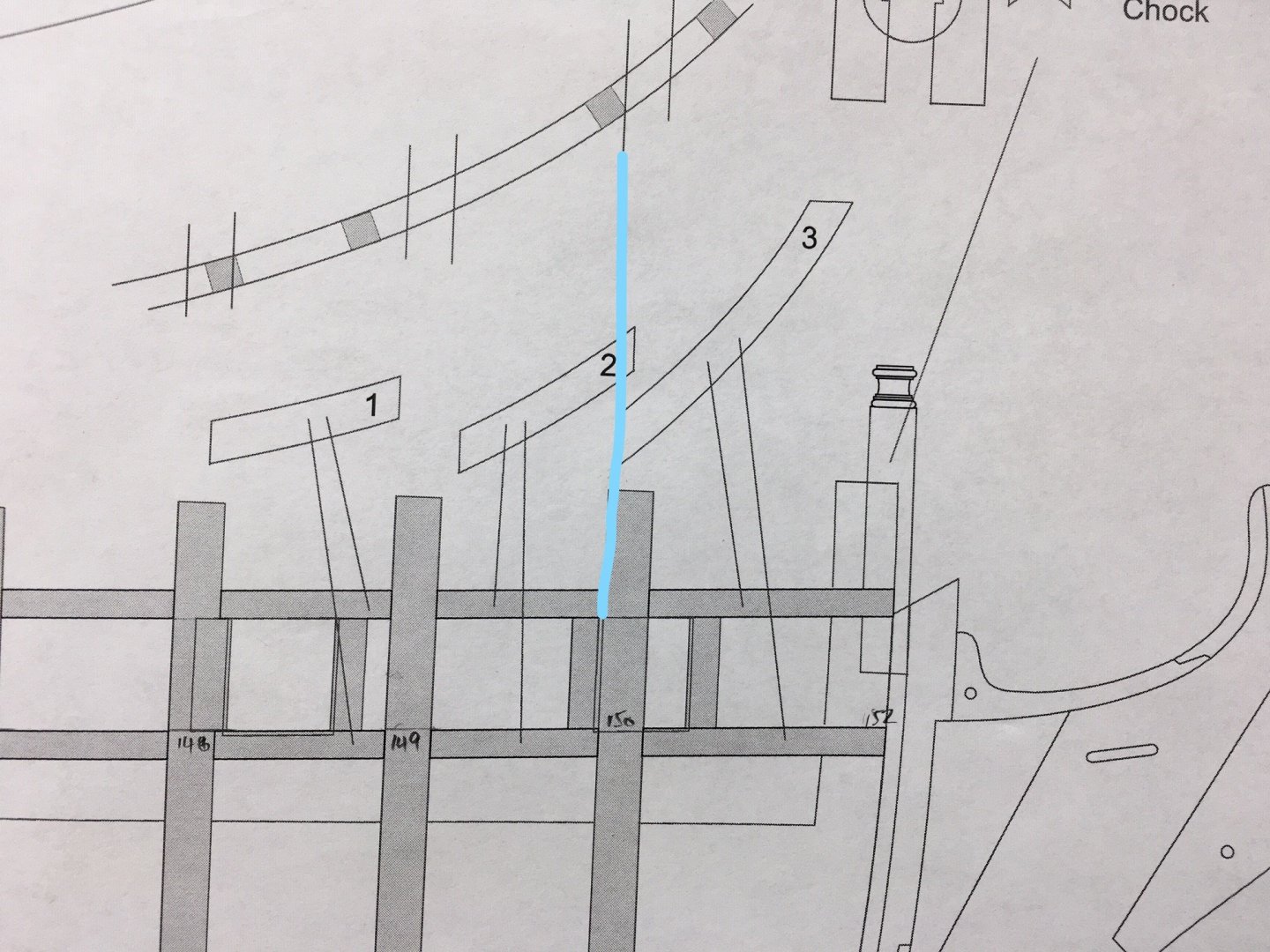

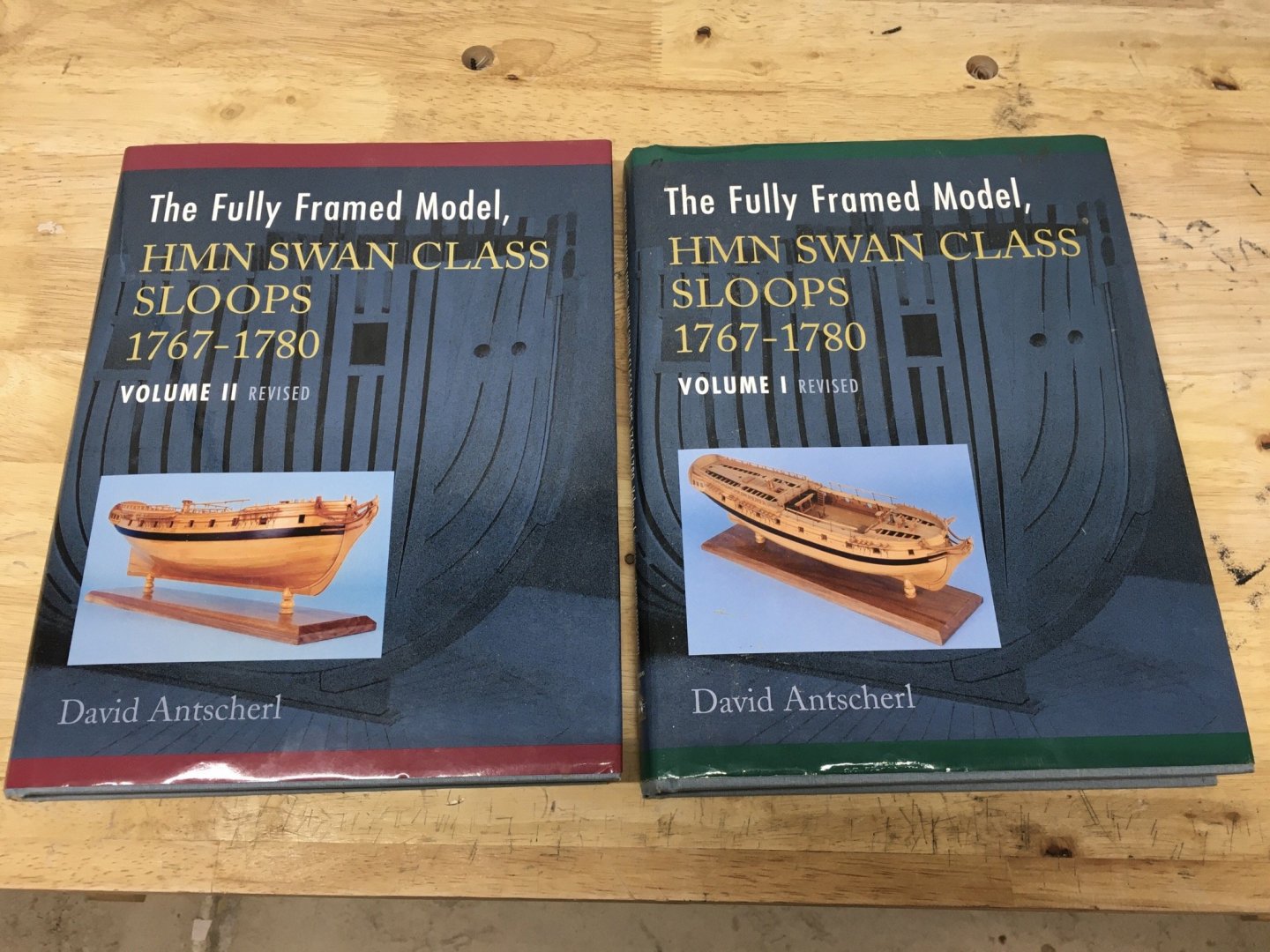

Hi Lyle, TFFM stand for “ The fully framed model” which is a set of 4 books written by David Antscherl and Greg Herbert and they are available from Seawatch books, who are one of the sponsors of Model ship world and you can find a link to their site on the main page. The set of books is an excellent reference for many things in model ship building and in my opinion a must have for any serious model builder looking to move into scratch building. ben

- 889 replies

-

Work continues on upper planking to the sheer strake, this is a “fun” one to make and blend into the other planking. ben

- 889 replies

-

Port side has been marked and started drilling for treenails, have to draw some boxwood down, wow this is tedious work.

- 889 replies

-

That is correct as per TFFM, 7/8”. Strakes at this point at 3” thick getting thinner as I go further up to 2” thick.

- 889 replies

-

Work on Pegasus has begun again, the first 4 strakes above the wales have been installed and now I’m treenailing while I can see the framing positions. I’m using boxwood for treenail material drawn down to #18 hole on Byrnes plate, and I’m glad that it’s pretty subtle so far. ben

- 889 replies

-

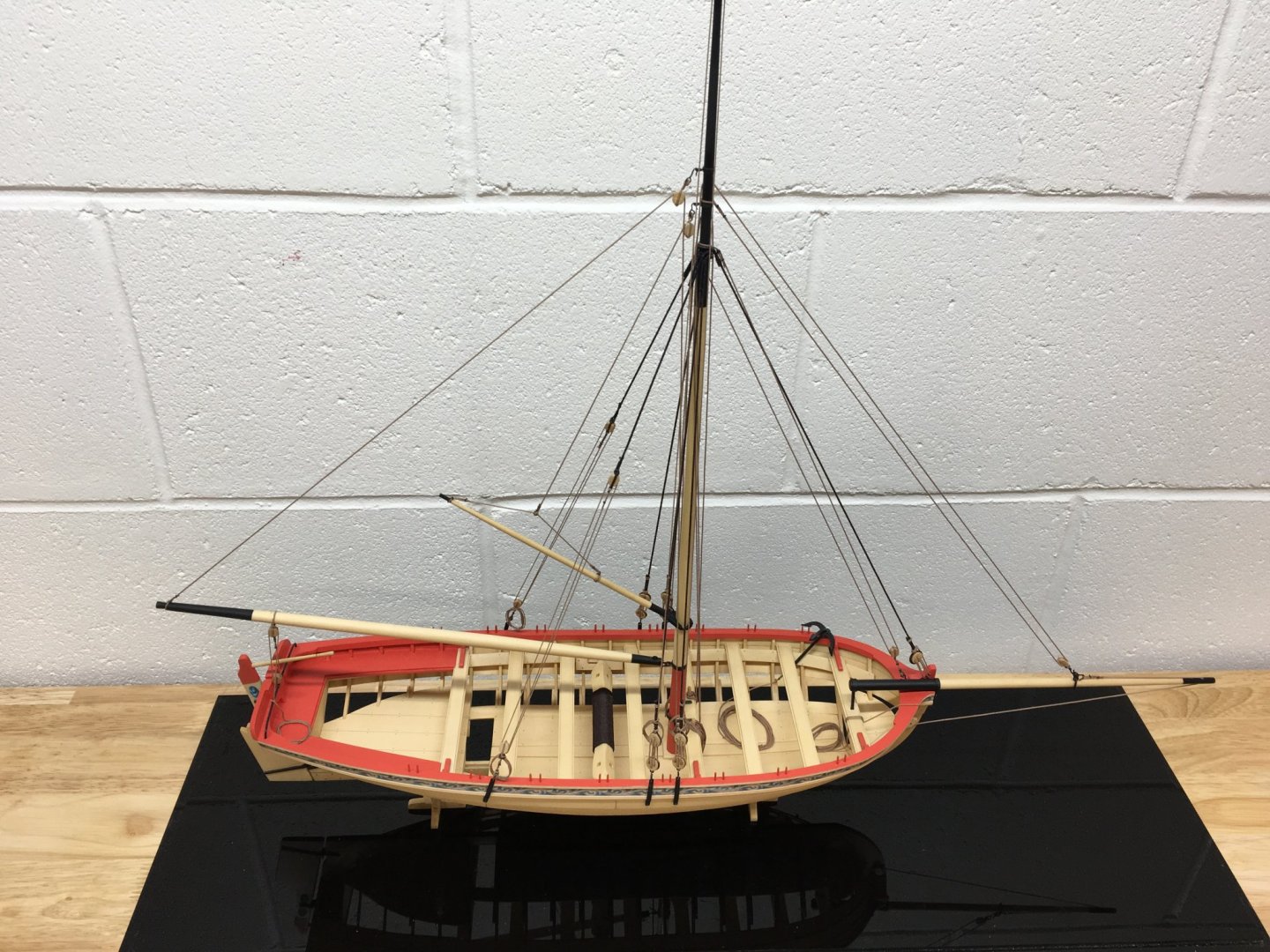

Wow, Thanks for all the likes and comments. Here are the last pictures of my longboat build with the flag attached. Im really impressed with how this kit from Chuck came out, it was a huge amount of fun to build, quality parts of the highest order, excellent instructions - Overall I think Chuck will sell thousands of these, just hope he can keep up with demand 😎 ben

- 64 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Rigging was completed with all rope coils etc... Windlass was wrapped and grapnel installed. Not going to install any oars or windlass bars. I tore the tissue flag as I was taking it out of its baggie, hopefully Chuck will be able to supply me with another, otherwise this project is complete and in its case. Thanks again to Chuck for designing and supplying this awesome kit. Back to the Pegasus build and maybe line up something else too. ben

- 64 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hey Rusty, looks like Ike we have the same thing in mind, if I build her I will use Pear for the Stem, Knee, Keel, sternpost and rudder, ebony for the false keel, and Cedar for most of the rest - a la my Pegasus build, I love that color combination. look forward to seeing your progress to give me inspiration Ben

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Nice to see you start Rusty.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

No Jeff I didnt, the little time I have I prefer to be building ships rather than cases I buy my cases from here. https://www.casesforcollectibles.com/

- 64 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.