-

Posts

1,964 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Trussben

-

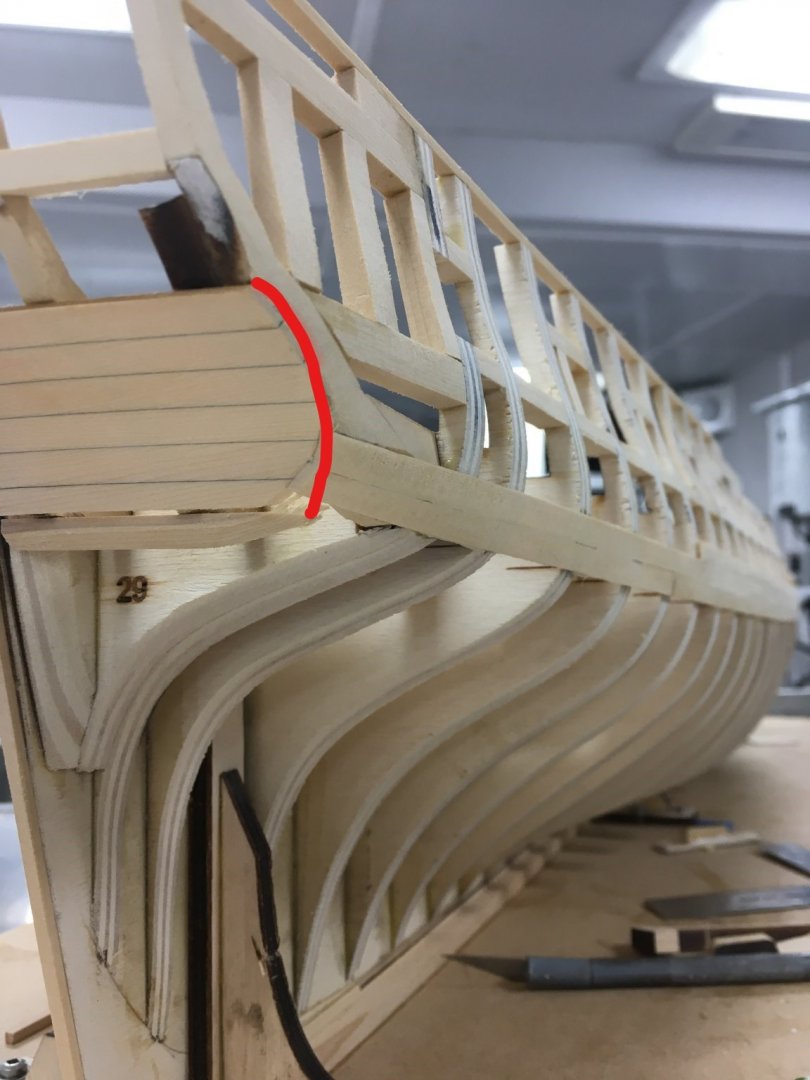

Well here is my port side frame reveal completed, in the end it turned out to be 23 frames that i could fit between the bulkheads. I did the treenails with 20lb black line and reversed the pattern aft of the deadflat frames. I'm so happy with how this came out in the end that I'm considering building one on the starboard side as well but we shall see. ben

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Rusty. Fred - it’s really not that complex once you have it planned in your mind what you are trying to achieve. I hope to have the reveal completed this week as I’m installing frames and treenails as we speak. ben

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Chuck/Mike and all the likes. Here is the shadow box installed and spray painted flat black, I’m currently cutting the frames out of Swiss Pear sheet that I milled down to 11” thick, maybe get that done and this completed in the next few weeks. ben

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

If anybody out there is still looking to buy Holly, try these guys in US. https://www.domexhardwoods.com/ ben

-

Stern framing completed and transom looks like everything is where it should be, I will now add the QG supports and begin installing the frame reveal shadow box. ben

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

SOOO SWEEEET! I love it Rusty.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

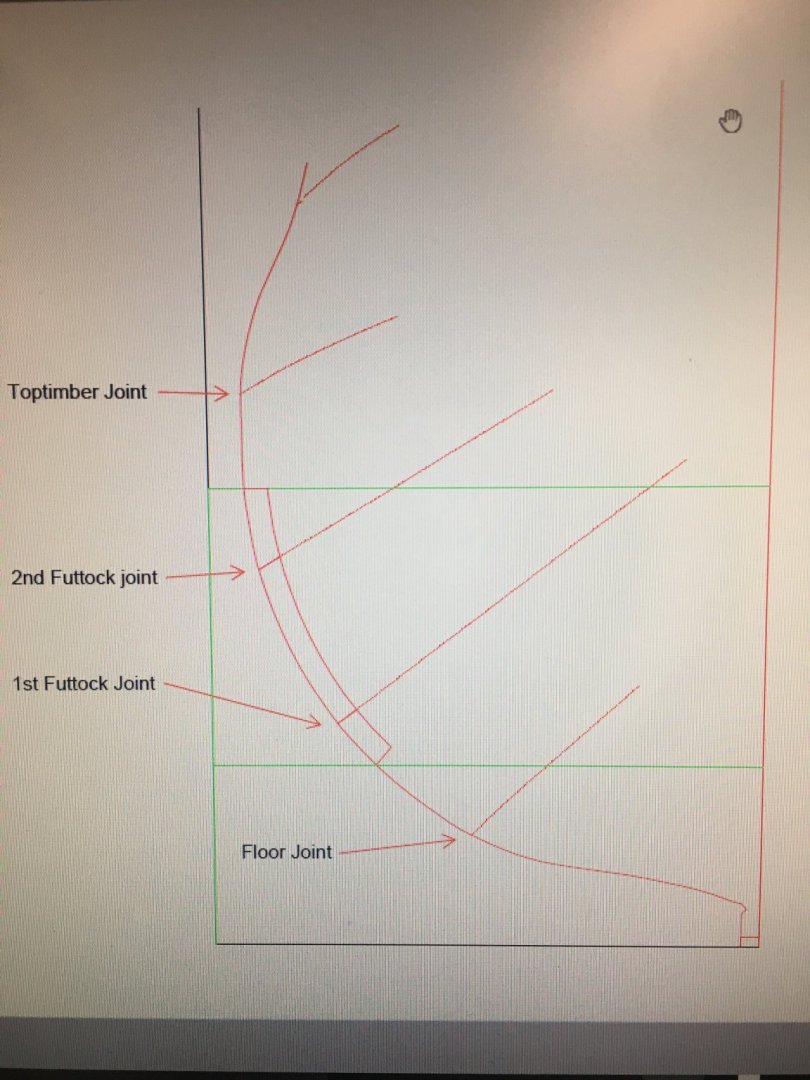

Thanks All, After manipulation of the NMM plans in Autocad I have now also completed the design of the hull framing parts and where their joints will be. I need to make a load of these and construct the shadow box, I’m not going to make actual chocked joints - just simulate them and highlight with black monofilament line treenails. This could take a while. ben

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

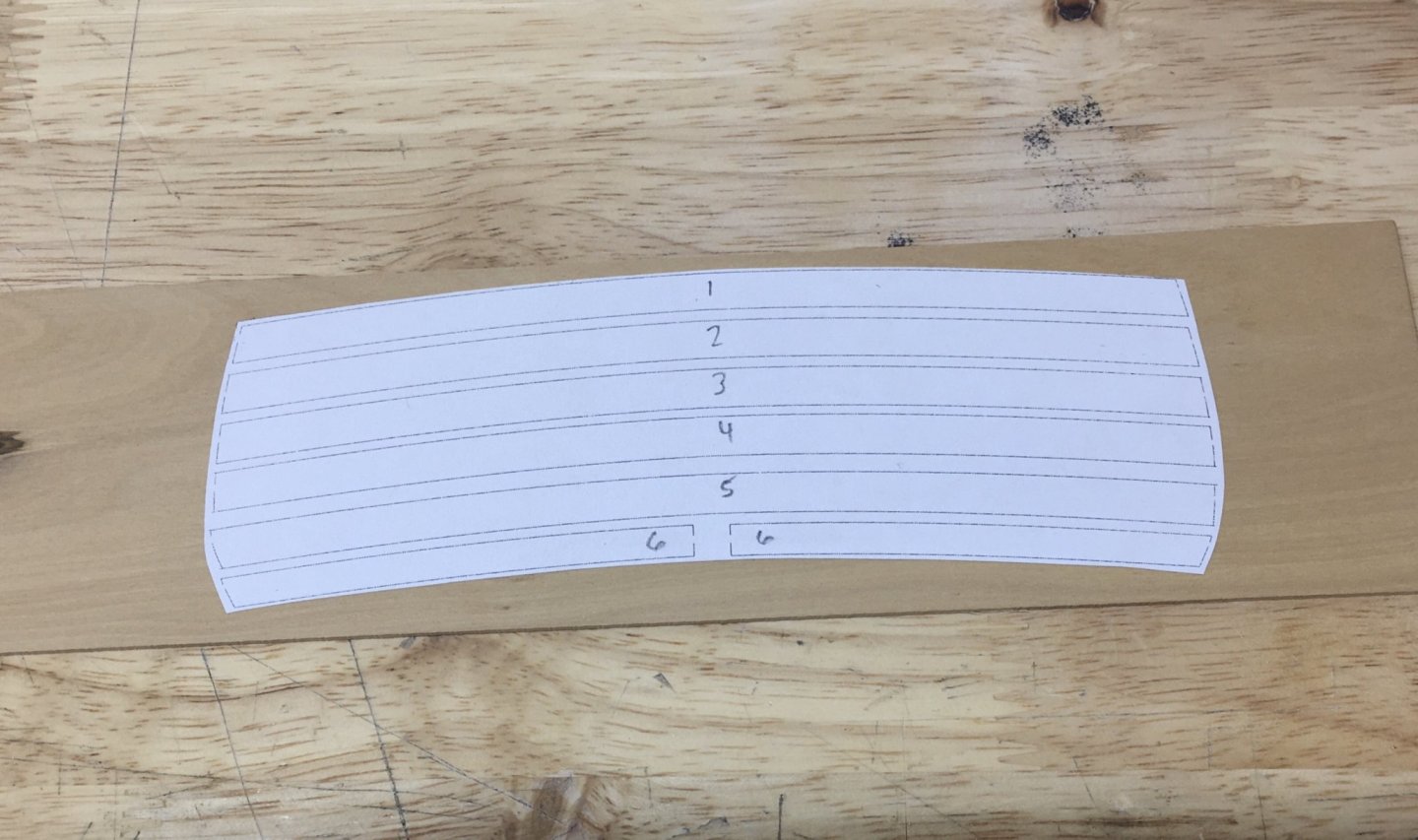

Here is what I have cooked up for my Winchelsea build to add a little difference to it. I intend to add a frame reveal to the model, much like Chuck's one on his Confederacy or David's one on the Comet. Midships is the obvious place to put a reveal so as to simplify the design work and make construction easier, so I have decided to make mine between the bulkheads of station frames G thru 5, Also it will be just below the wales to allow for two strakes of lower planking above and several below it. It will be quite a large reveal so as to show the first and second futtock frame joints, I will have to construct a shadow box behind it to be painted flat black and the simulated frames will be made of swiss pear. According to "Steel" and the "Shipbuilders repository" table of scantlings, a 32gun frigate of the time would have had 11 1/2" wide second futtock framing, molded 9" with a room and space of 27 3/4", I intend to simplify this a little with 11" wide framing with 3" between them, and it works out that I can fit 23-24 frames in the reveal. I will finish the design side of this soon and start building it when I have completed construction of the stern framing. ben

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

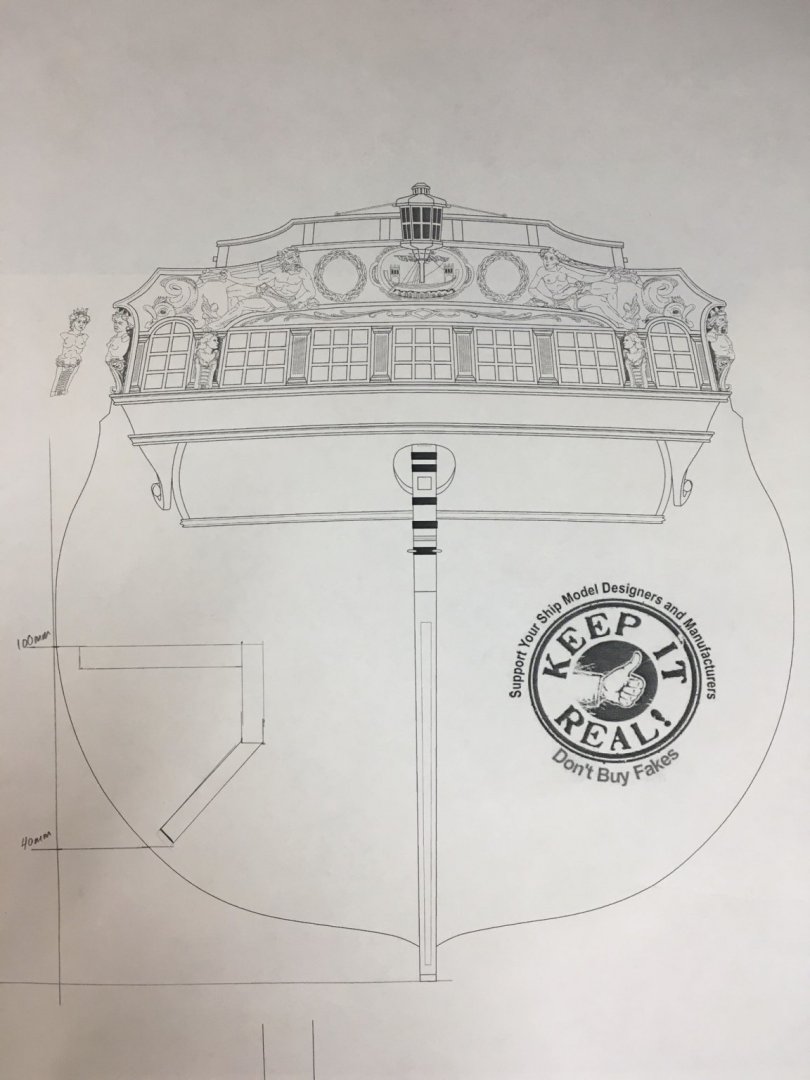

I’ve begun lining up the stern framing and adjusting everything before glueing using the patterns and plans supplied by Chuck, everything is lining up nicely and looks real good. ben

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Rusty, I have a feeling you will like the recipe I have in mind. ben

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Port layout and upper/lower cill framing complete, no issues were encountered with this process, and I have begun installing the port sides. Next up will be adding the stern framing and I’m also cooking up something special to add to this model which will change the original design somewhat but hopefully it will add to the whole. ben

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

That looks beautiful Chuck, you are raising the bar yet again.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

She looks great Rusty, have you decided on the final finish you are going to apply to that gorgeous pear? Maybe even oil it like Chris did on his Confed - that looked sublime IMO. ben

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks for all the likes. Rusty - I have been at home for a few weeks so have managed to spend some time in the shop, that will soon come to an end but I hope to get the port framing completed before I go back on the road. Erik - sorry to hear the benches are so expensive, you could try and make one, instead of drawers just make 2-3 shelves instead, wouldn’t be too hard I think. ben

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Looking real good there Ryland, nice tight joints.

- 263 replies

-

- Medway Longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks for looking Bob.

- 64 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.