-

Posts

1,995 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Trussben

-

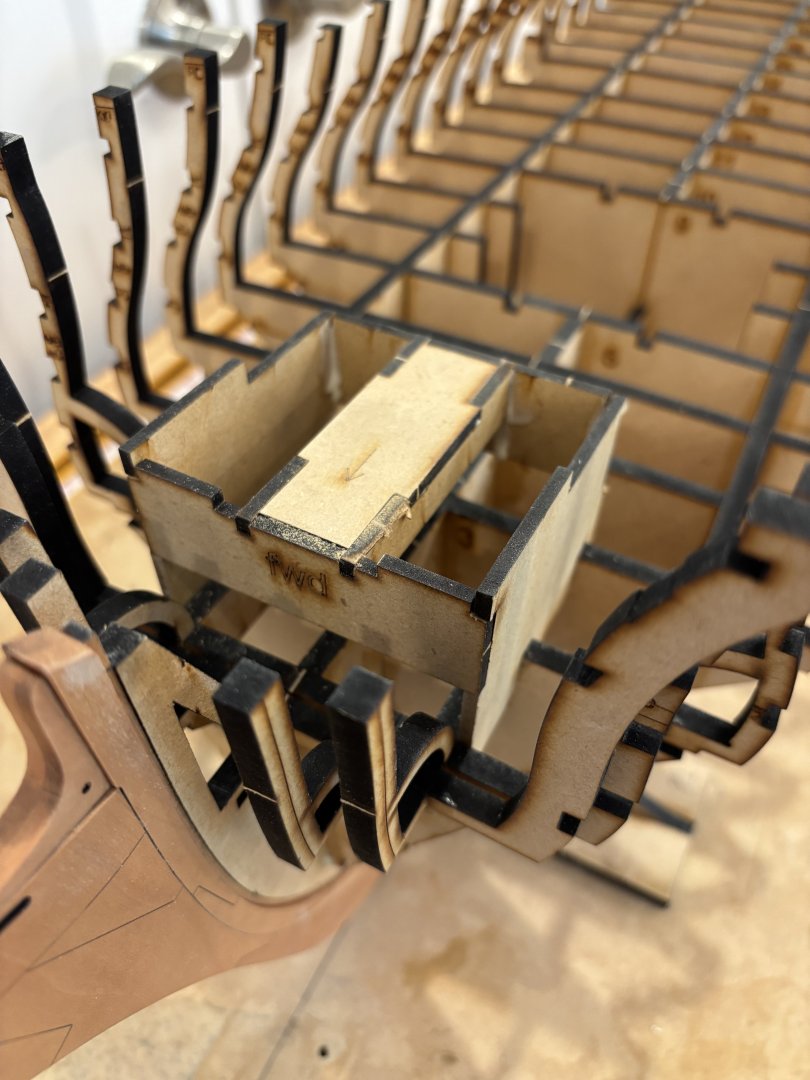

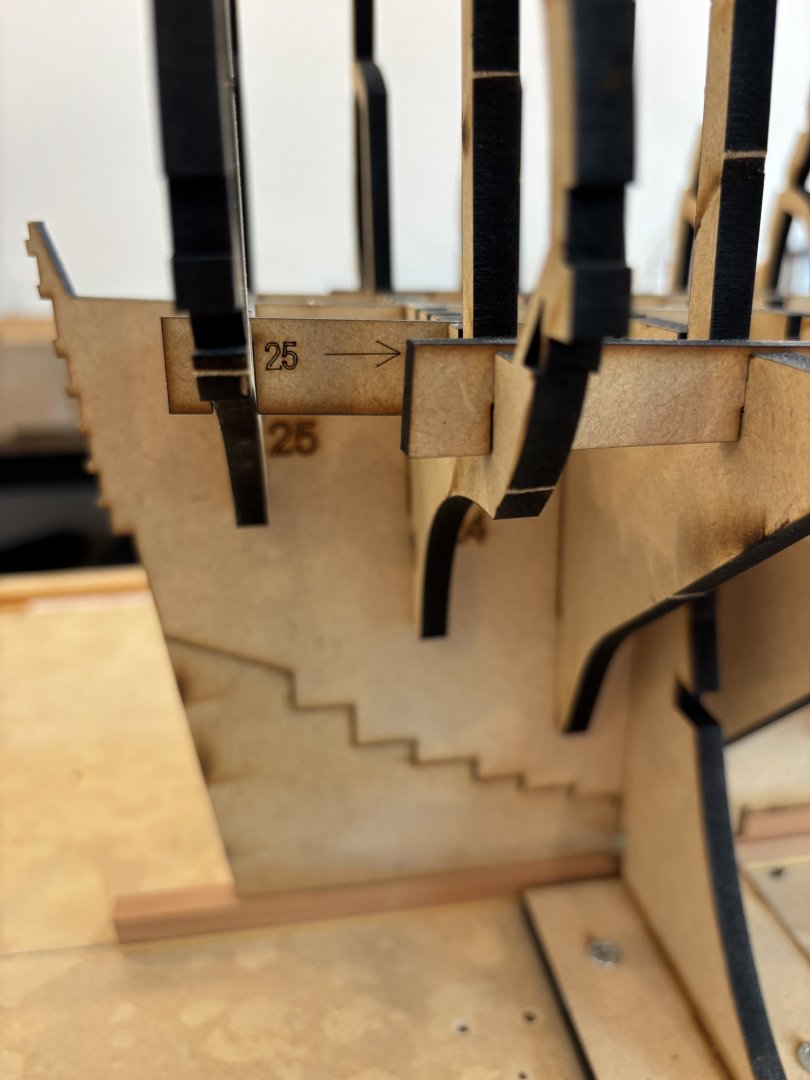

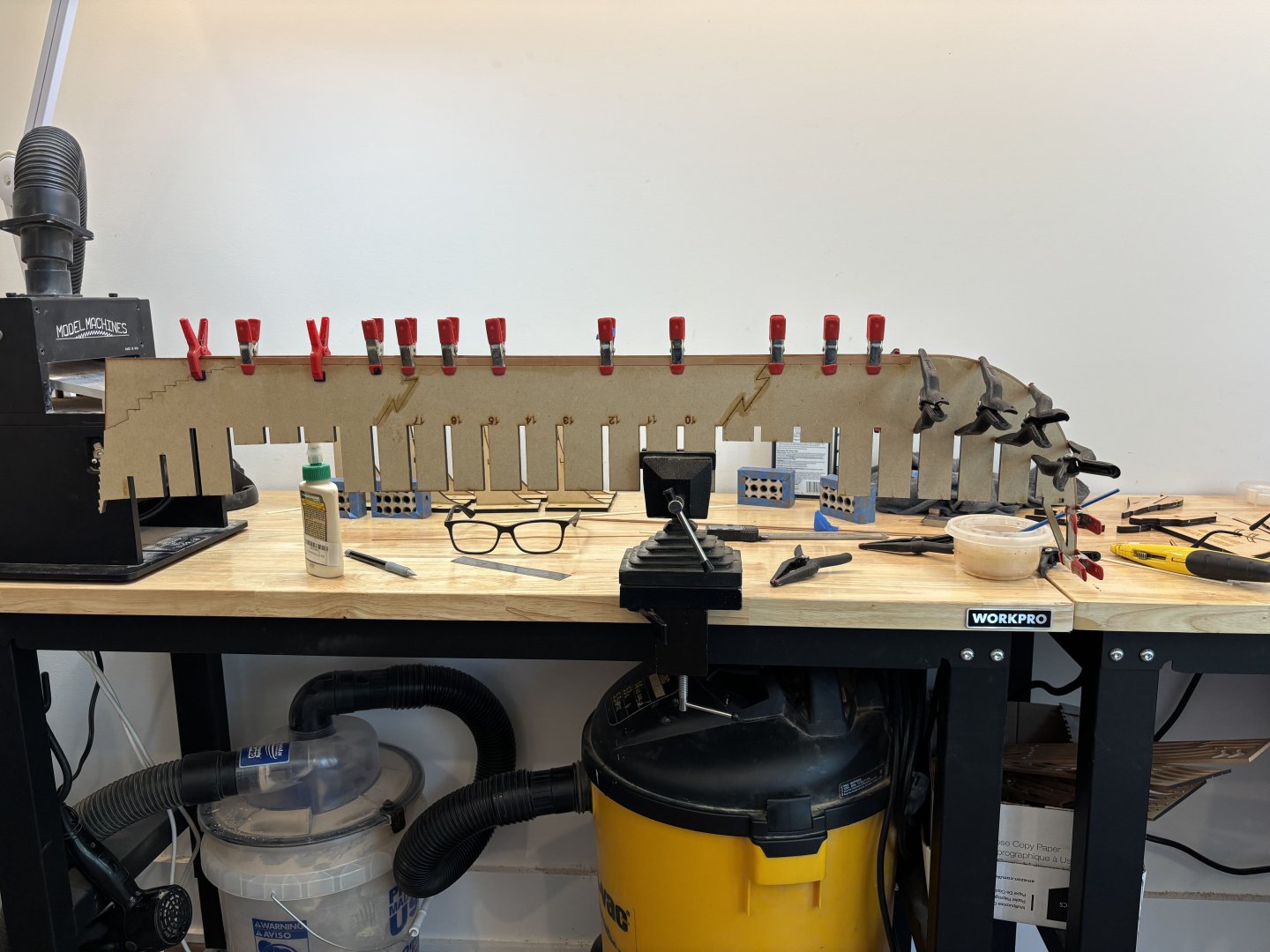

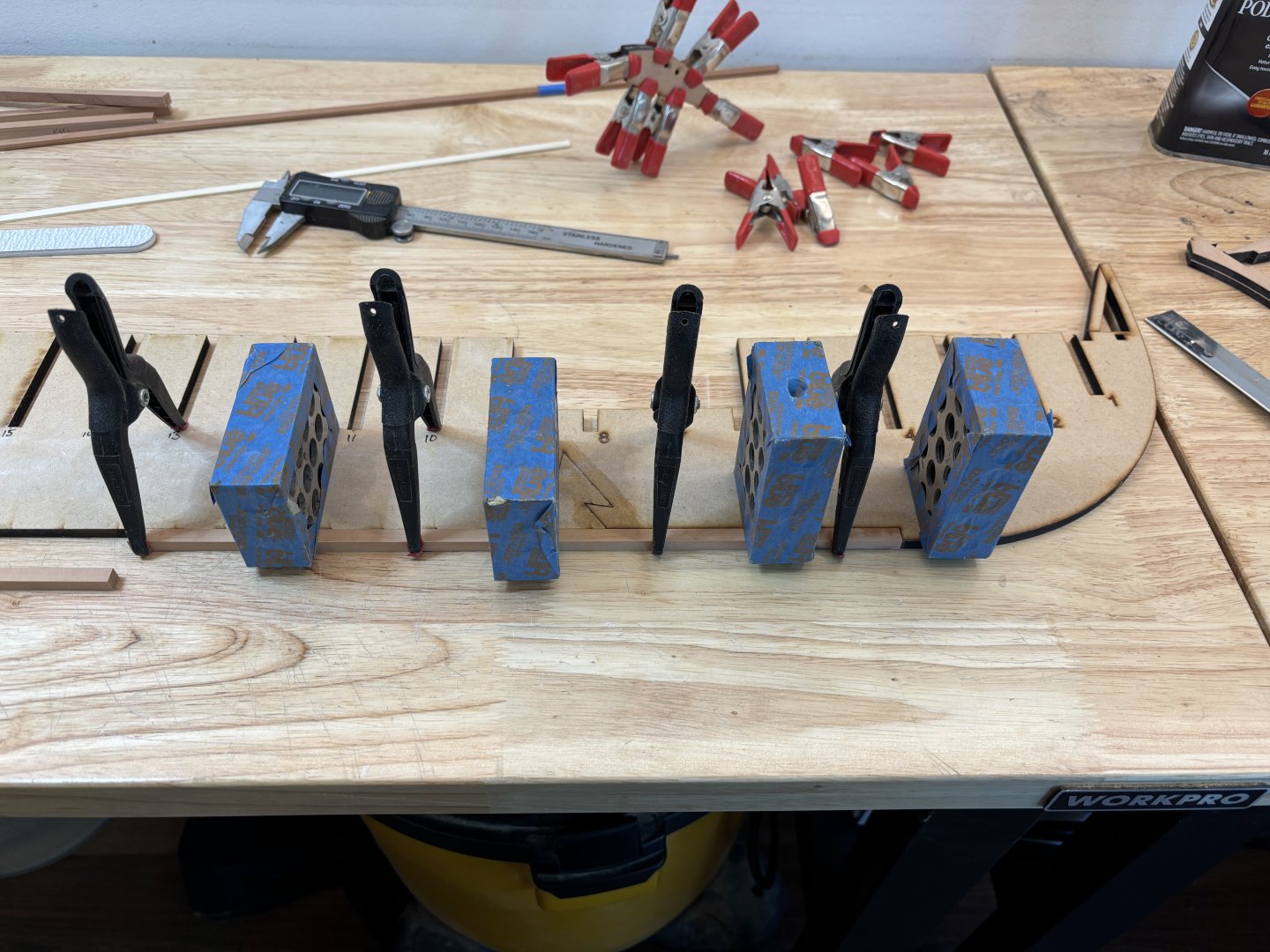

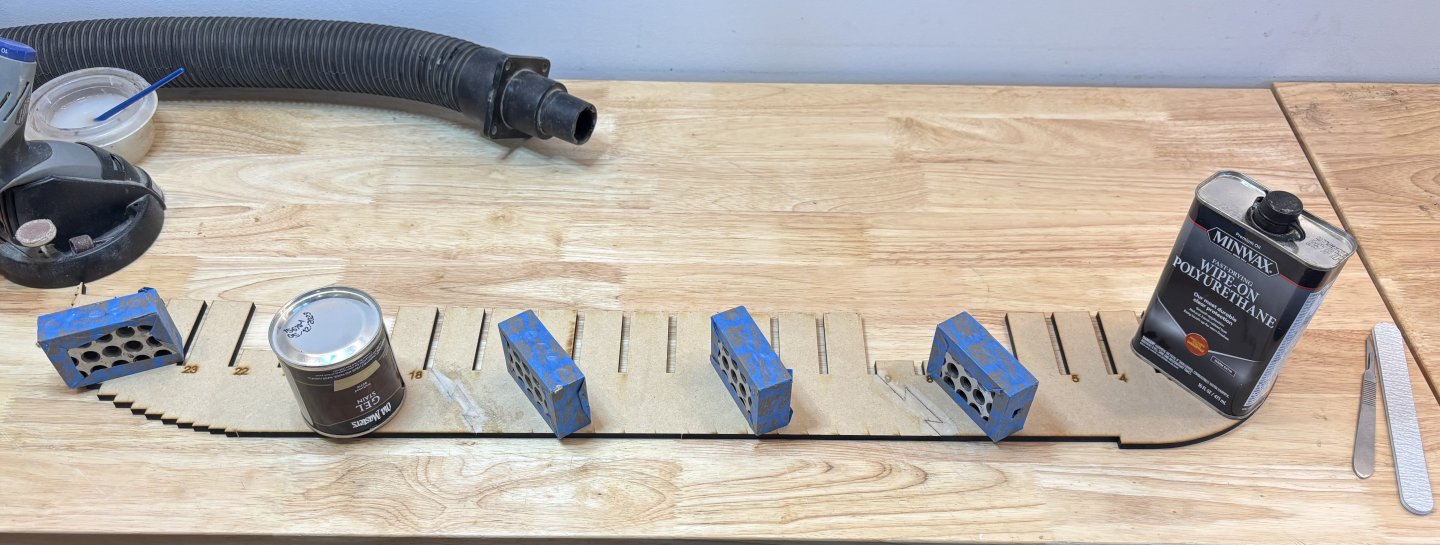

Only a couple more jig pieces to be installed, these MDF parts sit on top of the previous jigs and give more support to the bulkhead extensions at the level of the upper gundeck, they get screwed into the lower jigs to keep them securely in place. These MDF sections as you can see also contain all of the gunport framing parts.

-

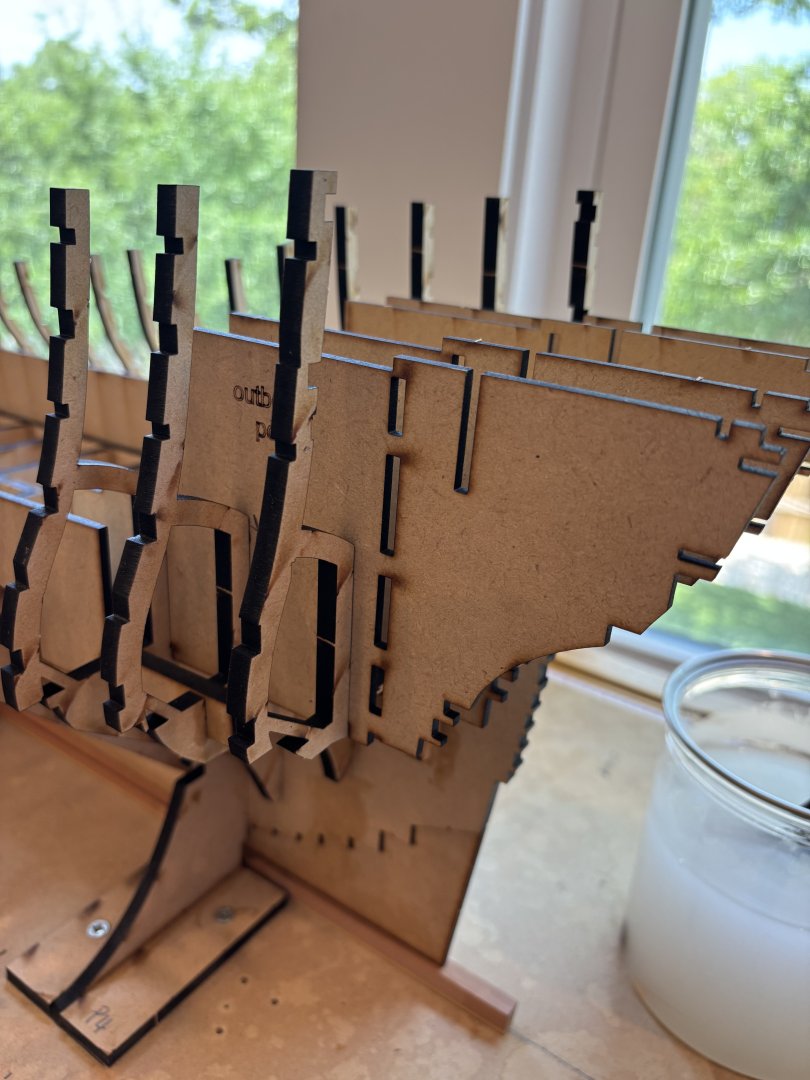

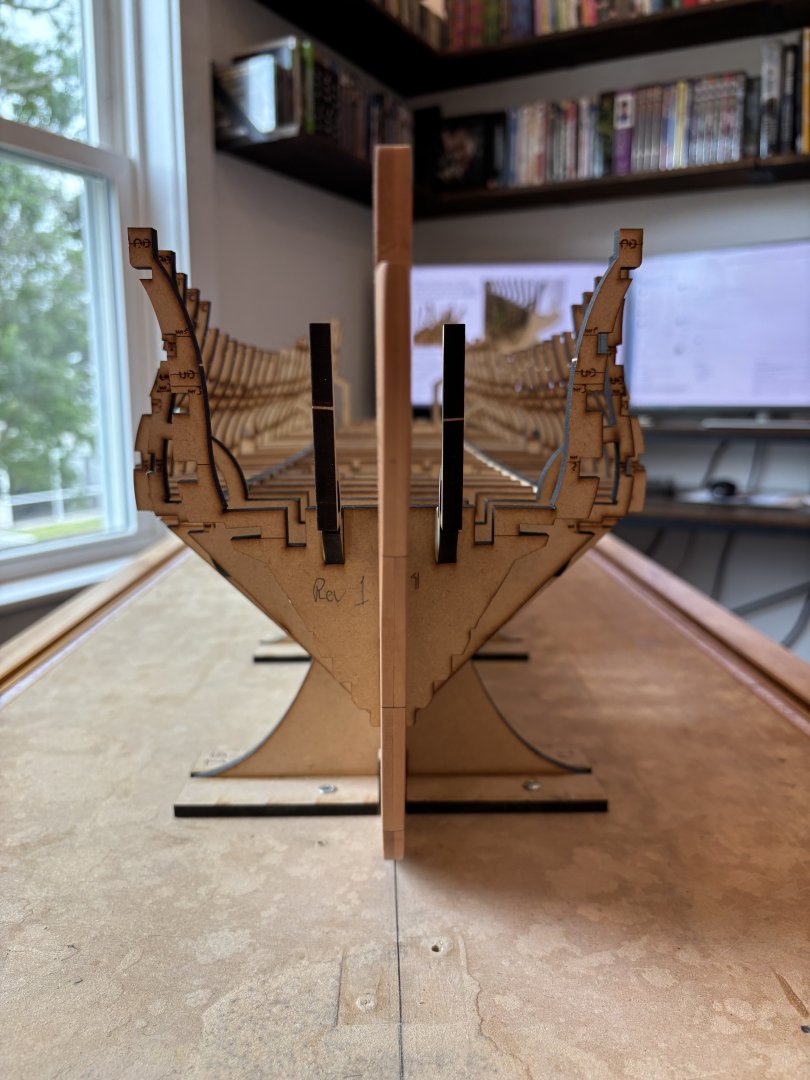

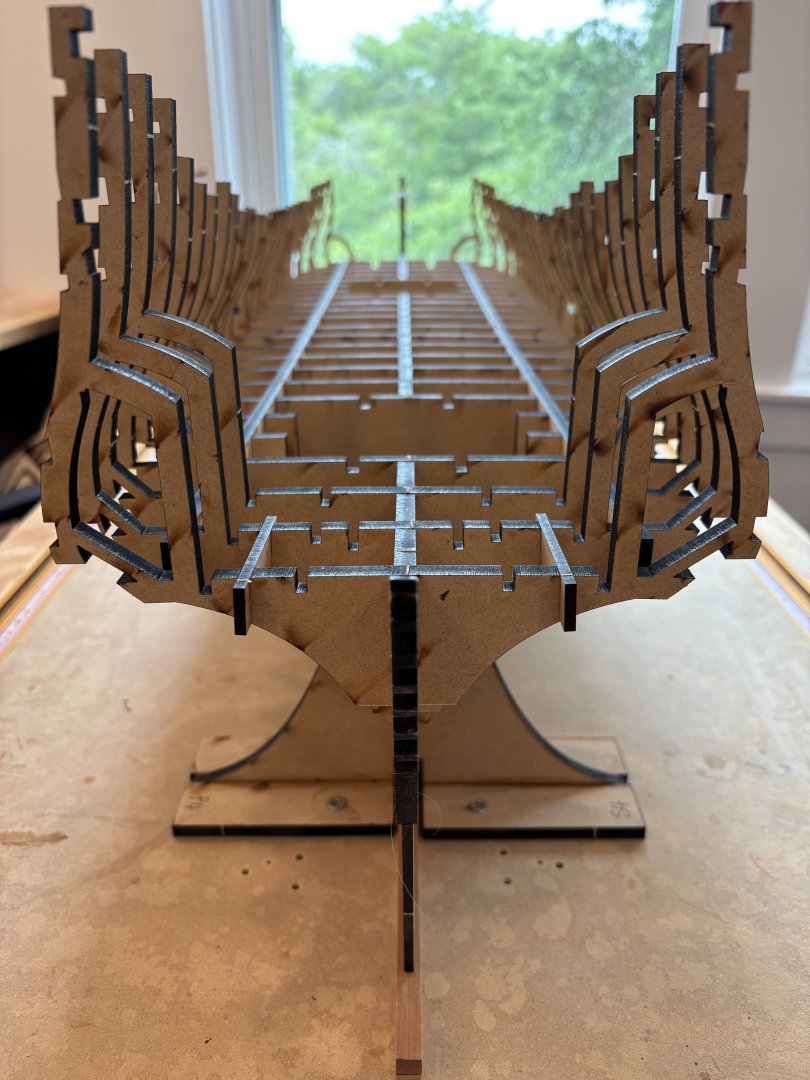

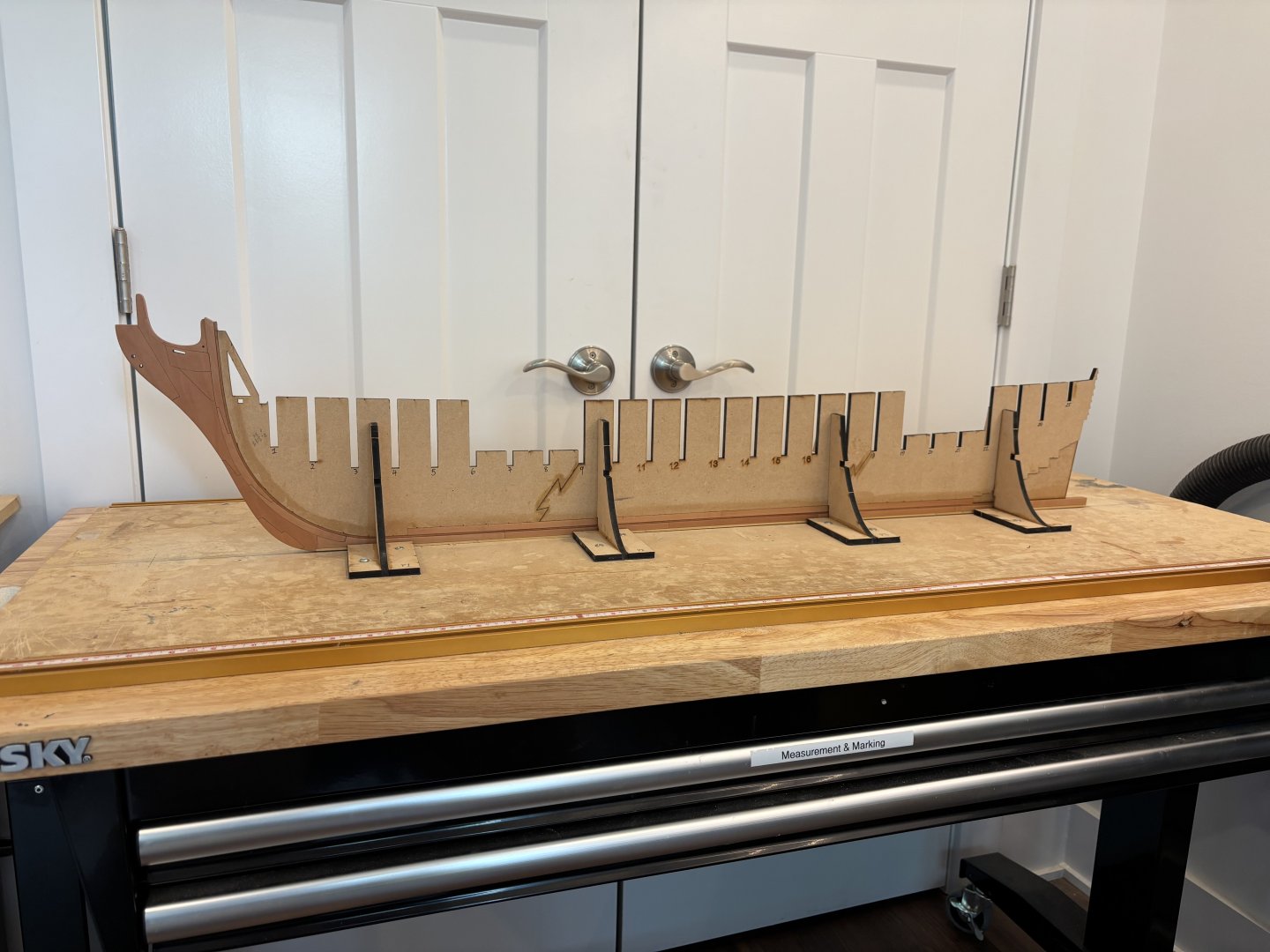

All of the bulkheads and stiffners have been glued to the former and themselves, this thing is now rock solid and a very sturdy platform for everything thats to come. I have begun installing all of the jigs that will support the upper parts until the model has been planked on the outside, these jigs are NOT to be glued to the model as they will be removed later for all the internal work, here you can see the forward one.

-

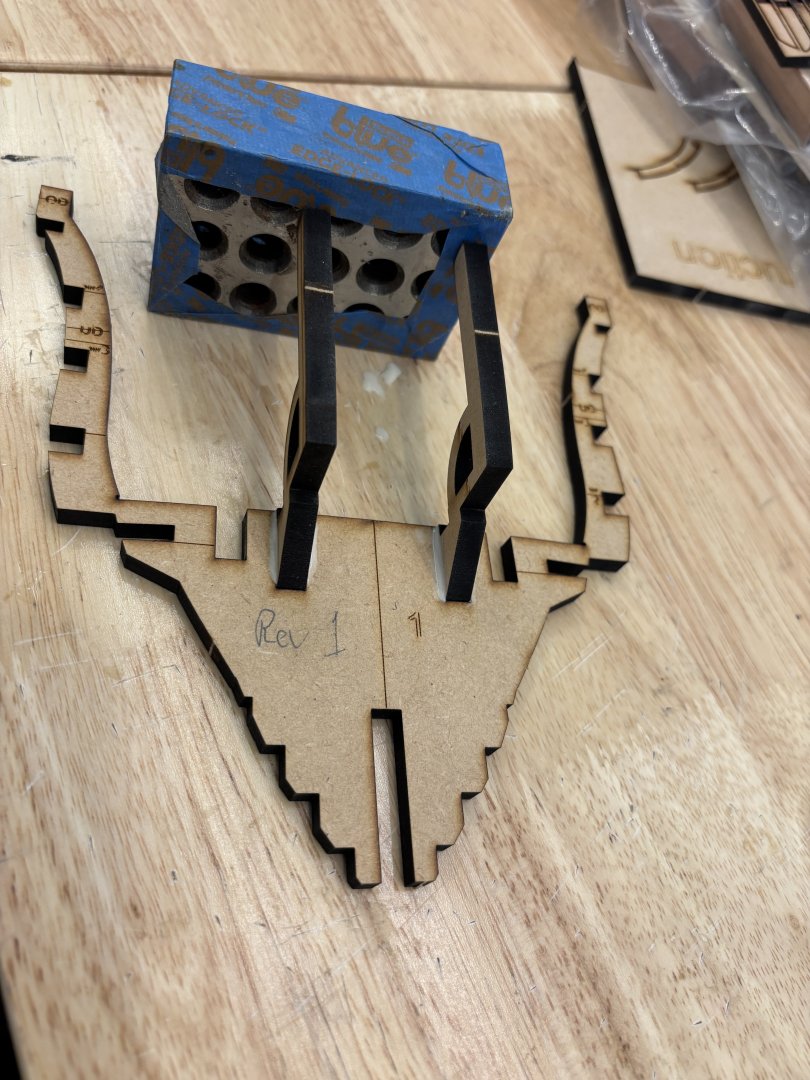

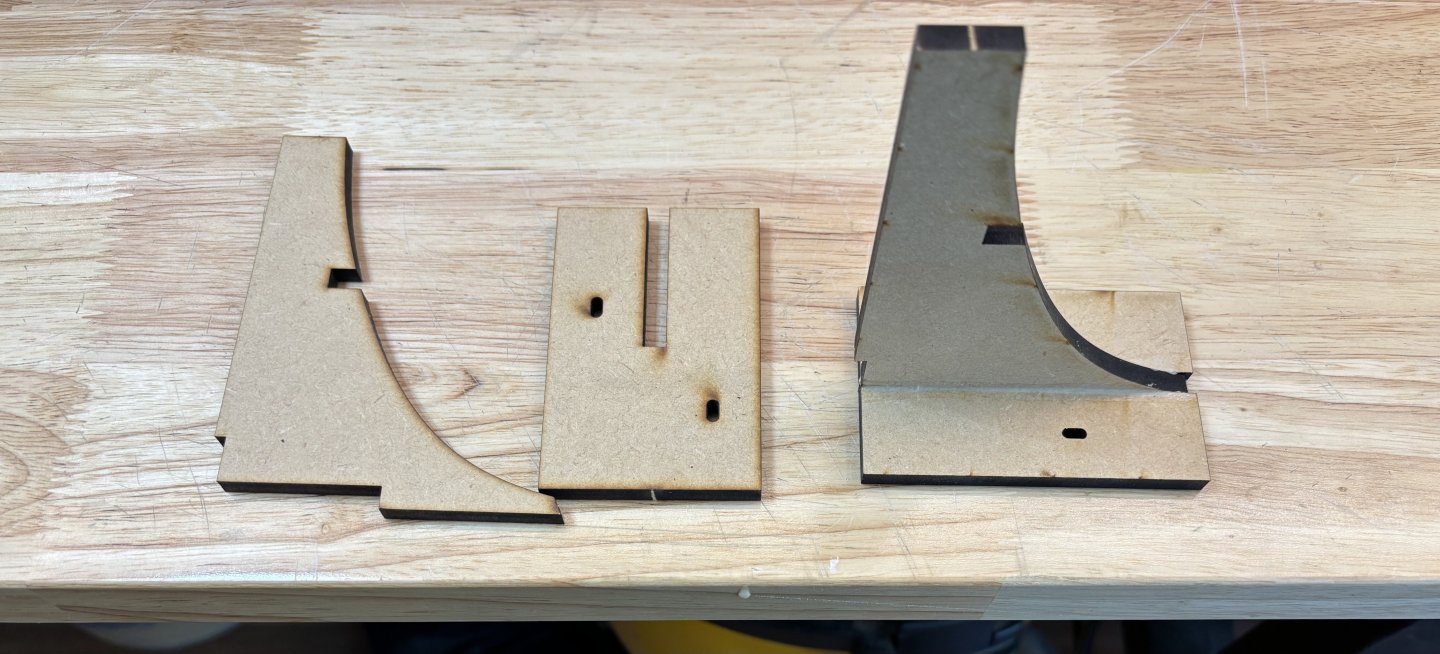

Last bulkhead to be installed is for just forward of #1, it is for the beakhead support, it also has two verticals for the bow and it locks bulkheads 1/2/3 together for more stiffening. There should be a 1/16-1/32” gap between it and bulkhead #1. With all these parts now installed, the entire structure is very very stiff with almost zero movement anywhere and is now ready to start having glue applied to it, kudos to JJ for his design and laser cutting to make this as solid as it is.

-

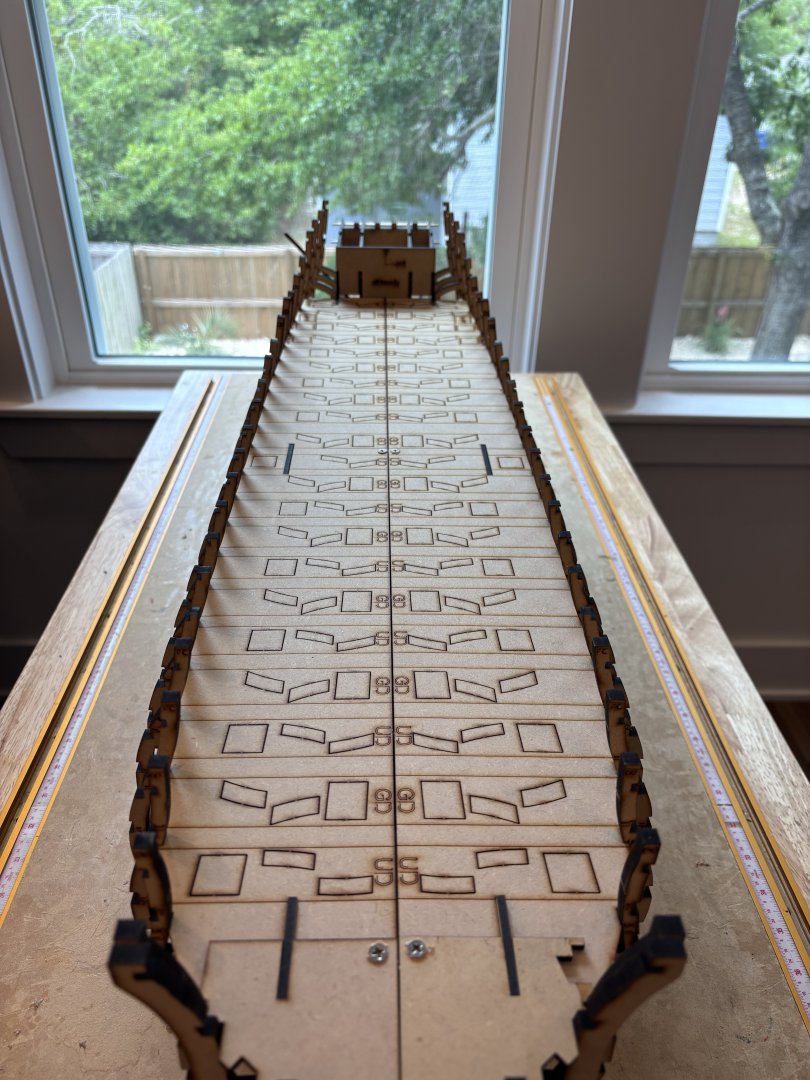

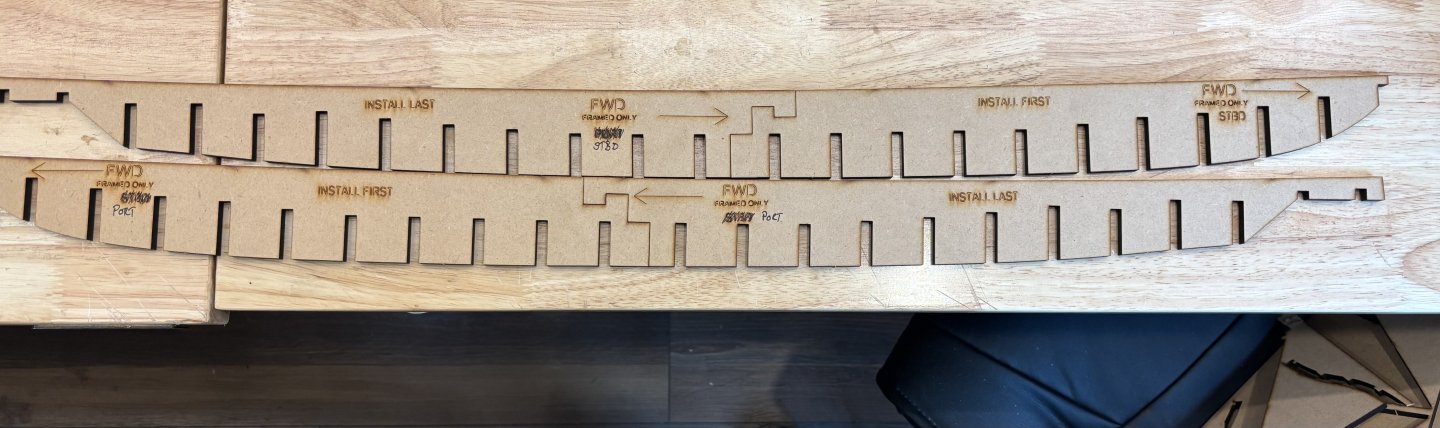

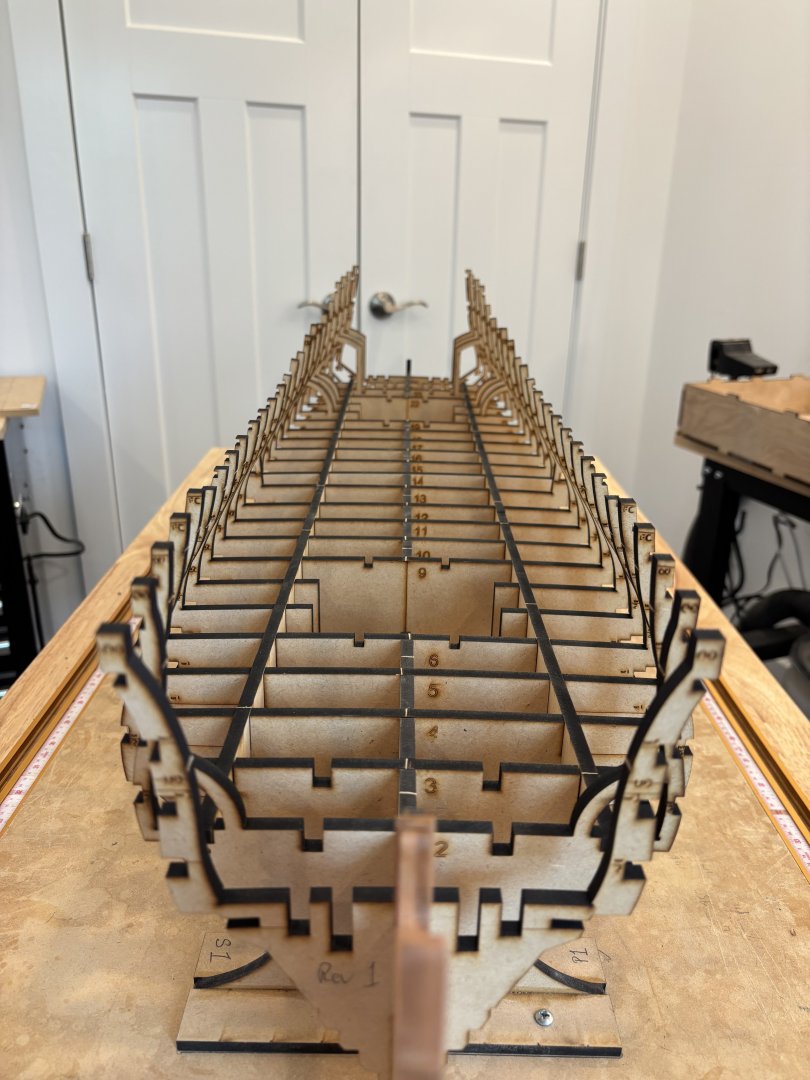

All of the bulkheads were removed from their sheets and dropped into position on the former, no adjustments were needed to any of them to make them fit! No glue has been used so far and you can see the longitudinal stiffeners being installed - fore sections first and then the aft ones, after these clipped into place with a little persuasion the entire structure has really begun to get more solid. More bulkhead and stiffner work to come before glue goes anywhere near it.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.