bartley

NRG Member-

Posts

424 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bartley

-

Thanks, Chuck. I have done another morning's fairing now. When I think its done I will post another photo. John

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

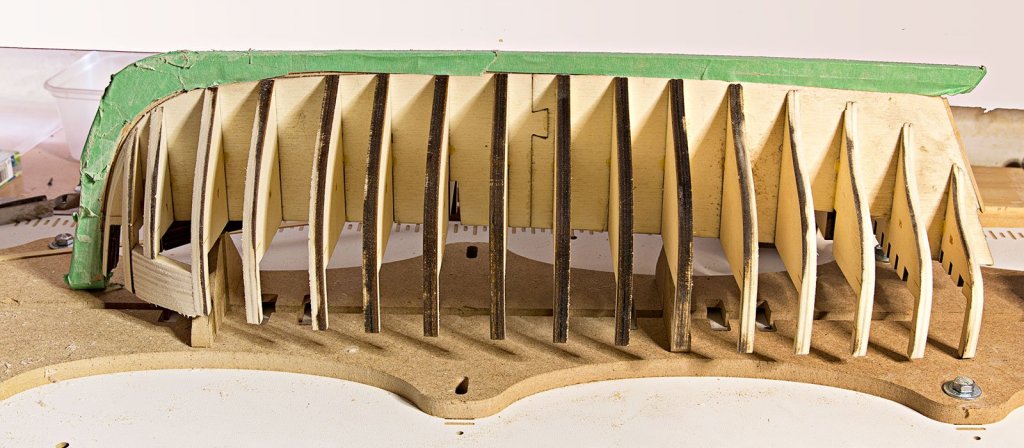

The starboard side at least is looking close. I notice from Chuck's pictures that there is virtually no lasr char left anywhere so maybe I need to go a bit further? John

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yes, Griphos, this is the boxwood kit. Bought a while ago when boxwood was cheaper than it is now! John

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

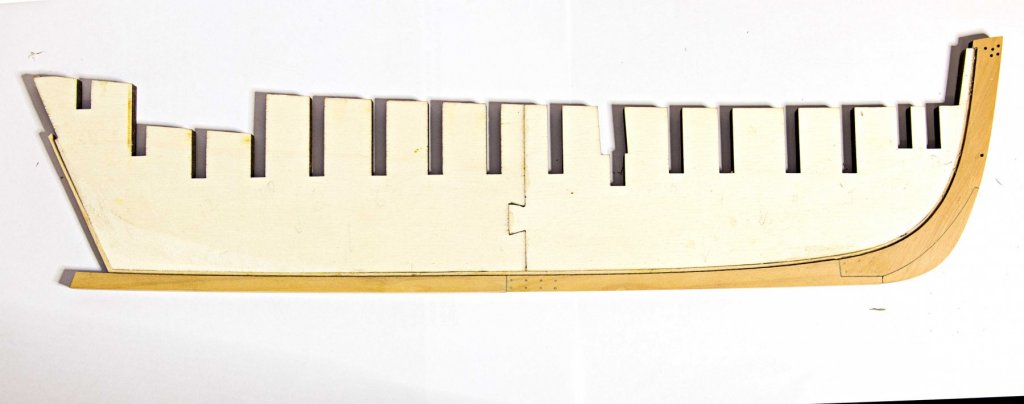

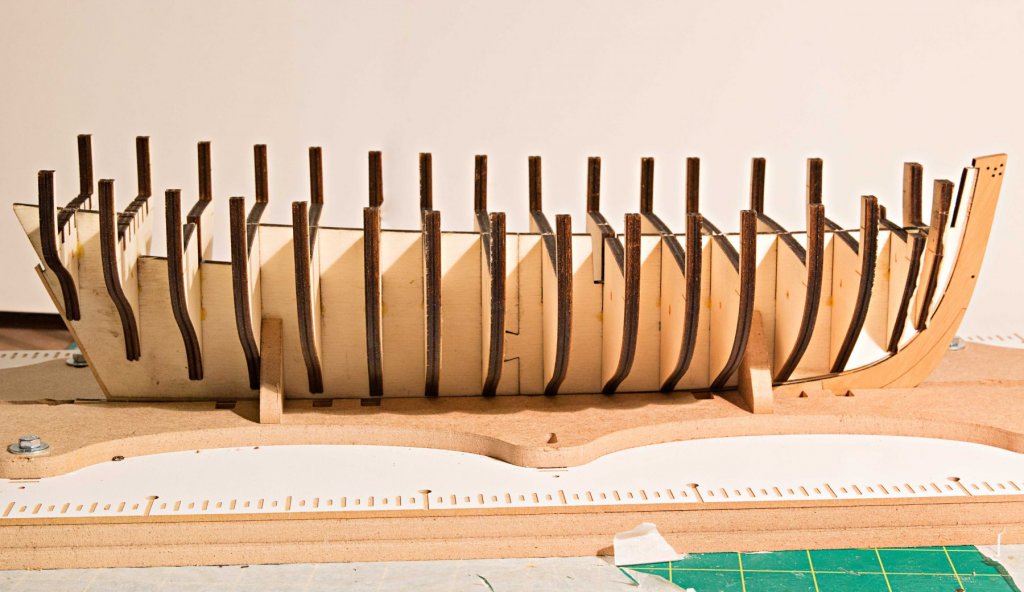

After a false start in which I snapped off the bow extension when removing the bulkhead former from the sheet! Things seem to be going well now. The two sections of the bulkhead former were glued together and the rabbet strip glued in place. The stem pieces and the keel were sanded on their faces to remove laser car but the edges were left unsanded. The treenails were simulated as described by chuck using a 0.5 mm drill and filling with neutral filler. After a coat of wipe-on-polly they were glued to the bulkhead former and fitted well with out the need for fettling. As recommended by Chuck no laser char was remove from the bulkheads and all fitted firmly. Care was taken to retain each one square in all directions. The bow and port filler blocks are added. Next comes, for me, the challenging process of fairing the hull correctly I think I have a way to go yet but trial battens are beginning to look close. I am taking a rest now. I think patience is the key here I am a little concerned about taking too much of the stern as others report it getting too narrow here. John

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Pity, Mark, but yes time to move on. Perhaps It helped when I did this that I am a chemist. But there are physical things like cleanliness of the plate and it has to be really flat during exposure. I clamped mine to a piece of thick glass. I don't know what Micromark use but I used brass shim to etch onto. They probably use ferric chloride as an etching solution but I used ammonium persulphate which is a bit less aggressive. Another time perhaps. John

-

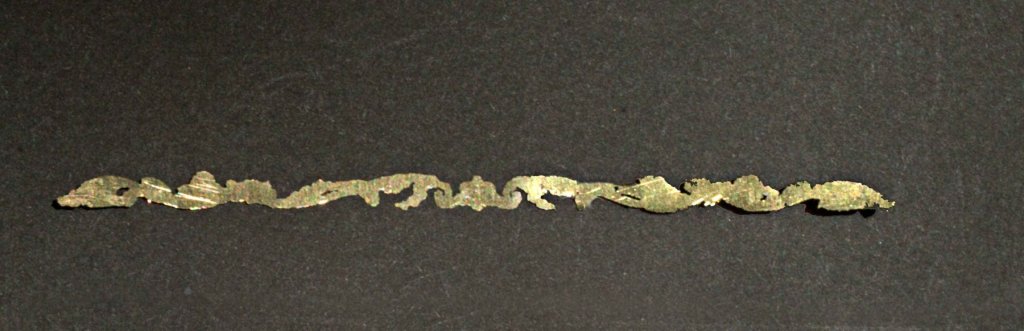

Mark, This was a frieze I made using the circuit board etching technique. It is about 6 cm long and at the time I thought it was OK but it is pretty flat for a frieze although after it was done I painted some etchant in places on top to give some texture. It was originally much flatter than this. However, my carving techniques are much better now so I can now produce better looking friezes that way. Even so you can get an idea of what the resolution was like. In fact I made some about half this size but don't have photos of them.t have any photos

-

I will be interested to see how this goes Mark. Particularly with respect top the resolution. I thought that I had invented this technique using Circuit board film. Clearly there is nothing new under the sun! However, the circuit board film works the opposite way from this Micro Mark stuff. You Iron it on and then the CLEAR stuff washes away. So I suppose that is a positive image and yours is negative. The resolution of my method was quite good I made some friezes with leaves etc. But I think your detail will be finer. I hope it goes well. Regards, John

-

Yes indeed. Ultraviolet light is past the blue end of the visible spectrum. Red is at the other end (and infrared is past that end) Yellow is in the middle of the visible spectrum (between red and blue) so you should be pretty safe with red. Even the yellow light probably shouldn't emit much uv but I would stick with red if you have it. Incidentally I have done some of this etching but I just bought my stuff from my local electronics shop. I printed on one side only but I taped some polystyrene to the back so that it floated face down in the etching solution. It worked OK but printing on both sides would be a much better idea. John

-

I think the person who used a slot through the yard to house the cleats was Jesselee. Regards, John

-

Michael, None of us is in Doris' league. However, in my limited foray into this art I have discovered that there is quite a difference in flexibility of the baked clay depending on the brand. The brands available in the west are Fimo, Premo and Sculpey For thin strips Fimo and Premo remain quite flexible but Sculpey III is very brittle John

- 1,035 replies

-

- royal katherine

- ship of the line

-

(and 1 more)

Tagged with:

-

I know that when square-rigged ships were in port, or when sails were furled, the upper yards were lowered by 2 to 3 m. But why did they do this? Was it to decrease windage or was there some other reason? John

-

Jim, Here in Oz I by ZAP CA. There are four grades which vary in viscosity: Pink is Super thin and dries in 1-5 sec Green is Medium and dries in 7- 10 sec Yellow or SLO-ZAP dries in 30 sec There is also a purple bottle called Safe ZAP which is supposed to be "fumeless" and is medium viscosity. I have not tried this one. The viscosity obviously affects the drying time but it also influences the gap filling ability. John

- 51 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Caroline's bottom

bartley replied to GrantGoodale's topic in Building, Framing, Planking and plating a ships hull and deck

Druxey The term “coating” may need to be treated with some licence, especially in the language of 200 years ago. In the book on Marine Antifouling from Woods Hole the statement is made “In the 18th century, wooden sheathing was filled with copper nails whose heads touched each other.” The article does not, however, say that this was called “Pease”. You are correct, Druxey, when you say that the typical green colour, which we see on copper rooves only forms in air. It is probably mainly copper carbonate but the chemistry of the oxidation of copper is complex. Copper oxide is certainly brown but copper chloride which forms in sea-water is bluish geren when in its hydrated form. Anyway, perhaps the more interesting fact is that although this treatment would possibly have prevented the attachment of barnacles and the build up of algal slime, it would not have prevented the ingress of Toredo worms which would attack the wood between the nails. In fact, first copper plating suffered from a similar deficiency since the worms were able to penetrate the gaps between the plates. Later a layer of canvas or felt was attached to the hull before the plates were attached so that there was no bare wood for the worms to attack. In fact, I have seen these worms “in the flesh” as it were. In a previous life I belonged to the Brisbane 18 Footers Sailing Club located on the Brisbane River. In the early 1980’s we refurbished our wharf involving, among other things, removing the 80 year-old wooden piles and replacing them with concrete ones. In spite of the original piles being made of Australian hard-wood, the section below the low tide mark was riddled with holes made by Toredo worms. We could not at first see the worms themselves but when the piles were cut in half the worms were visible and could be prised from their tunnels. The largest were about half an inch in diameter. They had a domed carapaceous head and jaws but the intestines and other body parts had no covering of any kind. I can only describe this part of the animal as resembling a piece of snot. The largest were about a foot long. The tunnels were parallel to the grain and seem to be lined with some kind of calcified material, perhaps to prevent them from collapsing. These worms apparently never emerge once they have invaded the timber and spend their whole lives in the sane piece of wood. How boy Toredo worm meets girl Toredo worm I am not sure but adversity has never been a deterrent for this kind of activity. Incidentally, for those who have never seen an 18 foot sailing boat, it is worth having a look on the web. They are an unrestricted class of sailing boat and there are only two rules – The boat must be 18 feet long and the race starts at two o’clock. There have been many developments over the years but they are always grossly over-canvased and capsize at the slightest provocation. John -

Caroline's bottom

bartley replied to GrantGoodale's topic in Building, Framing, Planking and plating a ships hull and deck

Druxey, This topic is old now but I read somewhere (not sure where now) that "pease" was a fore-runner to copper plating and was indeed round headed copper nails put into the hull at intervals below the water line. These of course turned green in salt water and were referred to by sailors as "pease" which is the Old Enlgish spelling for the plural of "pea" John -

For what its worth, Rod. The way I do this is to put diluted PVA on the rope loop just before I tighten it onto the block. This means that the INSIDE of the seizing is soaked in glue. I have never found that the cut off end pulls through. John

-

SeaWatch Books - Unreliable?

I ordered a book from this Company on 25 January. I have never received it an my six emails about this issue remain unanswered. Does this company still exist?

John

-

You might also consider using a non acidic PVA (white glue). Products like Weldbond are quite acidic. The downside is that the non acidic variety takes longer to dry and I dilute only by about 30 % John

-

Mike, I just noticed your post about the slings. On my plans for Royal Caroline The cross trees actually protrude about 0,5 mm above the support beams so that there is a 0.5mm gap between the top and the cross trees assembly (enough for ropes to pass through). Of course I did not notice this subtlety and so I have the same issue as you. Regards, John

- 843 replies

-

- niagara

- model shipways

-

(and 2 more)

Tagged with:

-

Ken, On the camera issue - I had this problem with a Canon SLR a few years ago and unfortunately it turned out to be the computer in the camera. Expensive! Sorry to be depressing. Yes, I have used that method for coils myself. I got the idea from Shipbuilding for Dummies and ir works well. Your build is looking good. John

- 424 replies

-

I had a recent order which was in the pipeline from Crown Timberyard when the "Store Closed for Maintenance" sign appeared. Being concerned about the status of my order I emailed them and received a reply from Julie stating that they were indeed undertaking maintenance but they had also experienced an unexpected illness for one of their children. She said that they were dealing with all orders which had already been placed. Indeed my order arrived a couple of weeks later and was of they usual high quality. I know that Jason also has a "day job' but it is a pity that they don't provide a bit more information about when they expect to open again - if ever

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.