bartley

NRG Member-

Posts

424 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bartley

-

Looks great, Paul. The treenailing, the dullish red and other features make it look "authentic". some I have seen from very accomplished modelers look a bit "plastic" to my eye. John

- 274 replies

-

- Cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

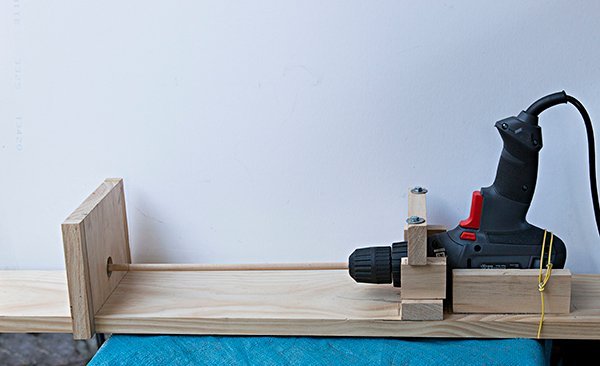

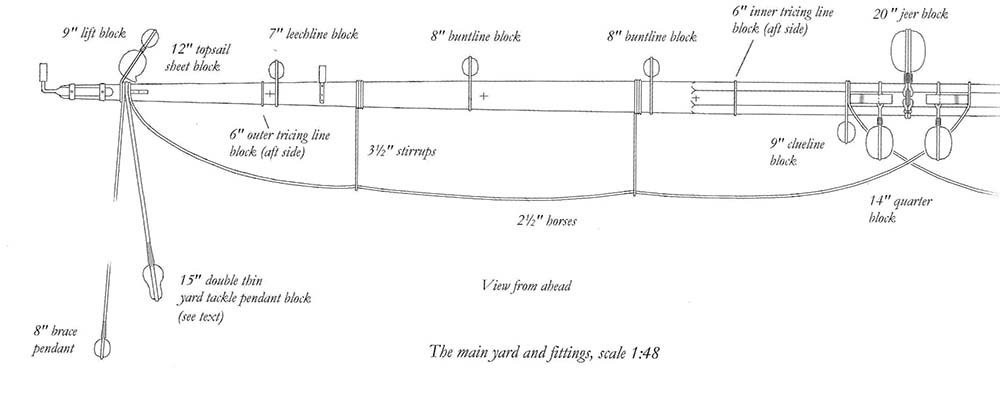

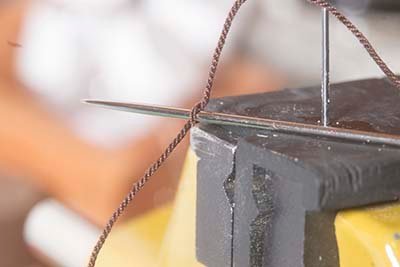

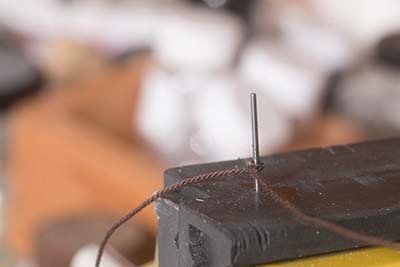

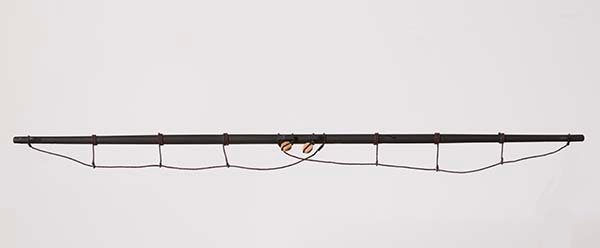

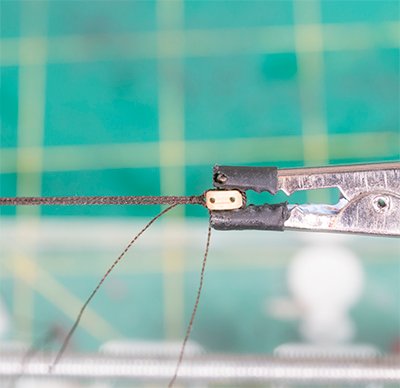

Post 65: Construction of the Yards. Work on Cheerful has been slow of late since we have only just returned from a six week holiday to the north of our state. And now we are embarked on some major renovations. Nevertheless, I have found time though to start work on the yards, The yards were turned on my home-made lathe. It may be of interest to know that we did originally consider the Proxxon DB 250 lathe which we were able to assess at our local supplier. However, we felt there were some limitations: 1. There was no provision for a central support. 2. The speed control seems to be a simple rheostat so the torque at high speed was very poor. 3. The bed length is quite short and the much vaunted hollow headstock was, we felt, limited because if the work-piece was extended more than a few centimeters into the headstock considerable whipping occurred even on round dowels. 4. The tool rest is very short and the adjusting handles obstucted the tools. I felt I could address some of these issues andconstruct a superior tool using a simple power drill as shown here. I use a switch mode power supply to control the drill speed and find that this provides quite uniform torque. A colleague has adapted my design by incorporating a belt driven motor and obtains even better performance. A feature of this design is that the length of the work piece is not an issue and the tail-stock (which consists of a roller blade bearing) is hollow and can be clamped in any position. The original idea was to extend longer work-pieces through the tail-stock. I now find that using a central bearing obviates the need to do this and I now only extend the work through the tail-piece in order to turn small diameter ends of spars and masts. The present task is a case in point. Since the central region of the yards is octagonal the central bearing insert was made octagonal using the FF 230 mill. After turning the yard: the stop cleats were fashioned from 1/8" sheet After painting black the stirrups and footropes need to be installed. In his monograph Chuck suggests the stirrups should hang below the yard by 11 /16 “ This equates to17.5 mm. However, the plans show a much shallower distance than this. I spoke to Chuck about this and he said that he obtained conflicting advice on this issue and on the model he “split the difference”. David Antscherl in his book suggests that the footropes should be 3’ below the yard and that this can be achieved with stirrups of 2’ 9” This equates to 17.4 mm at the model scale. This seems excessive since my waist is only about 3' from my feet! In the end I elected to make my stirrups hang 12.5 mm below the yard. The Stirrups are made from 0,63 mm rope by first forming a loop by using a needle to draw the end through the main strand then tightening this around a 0.8 mm drill bit . The loop was sealed with shellac and a small seizing added These are then suspended from the aft end of the yard using a copper wire to keep them at the same length Finally the horse was threaded through the lools and seized to the yard as indicated in the plans.

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

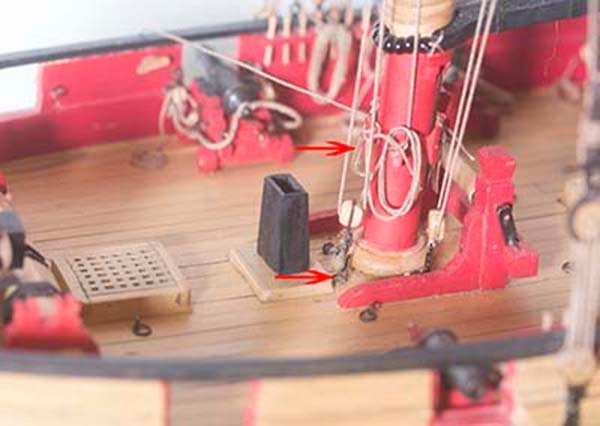

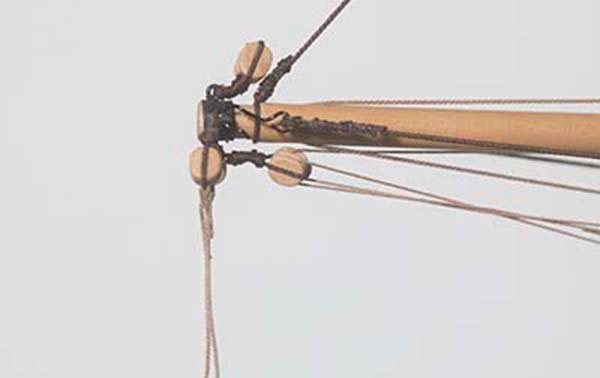

Post 64: Topmast Stay Chuck points out that these were not always rigged but he chooses to rig one himself and I propose to do the same. I will also rig the topmast back stays as it would seem to me that the physics demands neither or both to balance the forces. Also if the topsail is rigged then most of the time the pressure would drive the mast forward and demand back stays be fitted even if te leeward one is slackened in practice. So the topmast stay starts with a seizing to the end of the bowsprit: this tip of the bowsprit is a pretty busy region. You may recall that four blocks were fitted here much earlier: and there are also two hooks for the bowsprit guys and now this new seizing. (Incidentally the ropes attached to the 3/16 single blocks will form the braces for the main yard. They have been sitting there fro a couple of months!) The stay then travels through a block seized to the topmast: Then down to a tackle block here: This tackle passes through a block hooked to the base of the mast and is finally cleated at the front of the mast, as shown by the red arrows here: The main yard will be next but there is quite a bit of work to do on that. John

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks for your comments on the weathering, Glenn. I take your point that the effect here is much more subtle than the applications that I am used to. Even so with the cannons, I weathered hem off the ship and I had to "handle" them later to attach them to the carriages and fit breaching ropes. Not handled with fingers of course I have som3 foam tipped jewelers tweezers. Nevertheless I did give them a spray of Dulcoat. I couldn't see any difference in the appearance before and after. but as you say in cases were the fitting is already installed coating is not possible but thenit wont be subjected to further manipulation. Thanks for the explanation of your approach. John

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Great Build Glenn! I would be interested to know if you needed to protect your weathering. In my previous modeling life involving vintage rolling stock and vintage aircraft we made extensive use of washes and weathering powders to simulate rust. We found that we needed to use a varnish such as Dulcoat to protect the weathering powder otherwise later handling would abrade the weathering. Did you feel you need to do this? Unfortunately these models were made for the museum and I am unable to reproduce photographs of these models. John

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yes Allan, I use shellac a lot as well. But this pH scale is not easy to get your head around. It is common to think that the difference between pH 6 and pH 5 is "not much - its only 1 in 5 or 20 %" but the scale is logarithmic. This means that when we go from pH 6 to 5 the acid concentration goes up by a factor of 10 and if we go to 4 i tgoes up by a factor of 100. It also means that going from6 to 6.2, the acid concentration doubles! The message is that a small difference is significant. It is also not so easy to measure particularly close to neutrality and for things that are not soluble in water, so some quoted figures may be questionable. Confusing, I know but the closer to neutrality the better. John

-

Post 63: Topmast shrouds Ratlines are now complete and all knots sealed with shellac. The topmast shrouds are run in pairs from the top mast They then run down though the cross trees In preparation for the tackle to secure these a 1/4" block needs to be seized to each shroud and another to a hook finally the tackle is then rigged to eyebolts on the chain plates Next up the topmast fore stay. Chuck points out that these were not always rigged but it seems to me that if there were a sail rigged on the topmast yard then some support of the topmast itself would be required. John

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

For what its worth I have done a quick chemical analysis of Super Phatic. For those in the know I used Attenuated Total Reflectance Infrared Spectroscopy (like most exclusive clubs, we scientists invent this special language to keep out the rifraf!). This technique is quick (ten minutes). It cannot usually unequivocally identify a substance but can eliminate some possibilities. So, It is not CA and it is not PVA. It looks like an acrylic modified with polystyrene. There are other techniques which could confirm this but not really worth spending my time on really. John

-

Dying/coloring rope; sources for purchase of quality rope

bartley replied to Tomculb's topic in Masting, rigging and sails

Make your own is, in my opinion, the answer to many of the issues raised. To a certain extent you can control the appearance to suit. Gutermann Mara comes in such a range of colours that dyeing is unnecessary, and, as I pointed out in my Cheerful build, you have matching seizing thread in sizes from 0.1 to 0.3 mm. John -

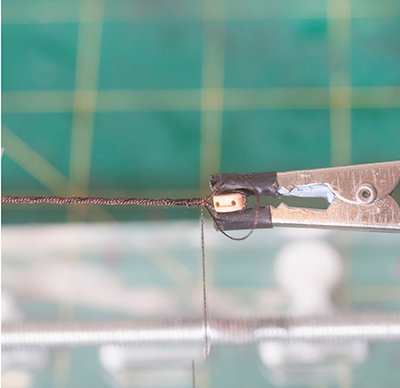

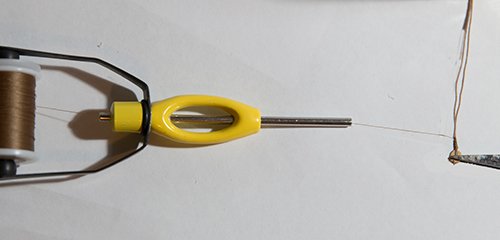

Seizing revisited My Cheerful has been on hold for a while since we have just taken our annual holiday. My other hobbies have also interfered with my shipbuilding. In the past I have used various threads (16/0 fly tying line, 50 wt sewing thread, etc). However, since I am now making my own rope it suddenly dawned on me that it makes more sense to use the Mara thread I use. It obviously matches perfectly and comes in a variety of sizes. For example: Mara 220 has a diameter of 0.109 mm Mara 150 has a diameter of 0.135 mm Mara 120 has a diameter of 0.14 mm Mara 100 has a diameter of 0.17 mm Mara 70 has a diameter of 0.19 mm Mara 30 has a diameter of 0.30 mm For comparison: Gutermann C Ne 50 Cotton has a diameter of 0.128 mm Here is an example of its use in seizing: 16/0 fltying line is still thinner. The diameter is hard to measure accurately. The old technique of wrapping 10 or 20 turns around a dowel is difficult with any thing less than about 0.3 mm in diameter. It is quoted in one source at around 0.05 mm. although my calculations based on the Denier given by the manufacturer produces a value of 0.105. Even so for small rope I might keep using it. John

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Yes, Glenn, I had a conversation with Chuck about this and in the end it turned out to be to do with my scan of the plans. I don't know why. It has never happened before or since! Anyway my grid turned out to be exactly the same as the plans anyway so I went with that. By the way your rope coil method is very elegant. Interestingly enough I had that method of Peta_V in my files but had forgotten about it. The idea of using two pegs of different sizes is a good one . This is how I modified Tom Laura's. method in the end rather than use pins as he does but I still had to use two pins at the top to get the loop to work. John

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Cleaning Brass Casting Residue

bartley replied to Jonathan_219's topic in Metal Work, Soldering and Metal Fittings

Brass is an alloy of copper and zinc while bronze is an alloy of copper and tin and sometimes other metals. So, both will react with pickling compound but it is designed to remove oxide coating. However, as Mark says the contaminant may simply be wax and if so a bit of heat is worth a try before going with a chemical treatment. -

Cleaning Brass Casting Residue

bartley replied to Jonathan_219's topic in Metal Work, Soldering and Metal Fittings

Brass is an alloy anyway so "alloy of brass" is a kind of funny term. Anyway if it is brass, you might try a pickling compound like Sparex but be careful it does etch the surface if left to long. Maybe try brushing it on and then stopping the reaction with bicarbonate of soda. John -

Hi Glenn, Looking good! Your faking down (rope coils) looks good. How did youdecide to do these in the end? I used a modification of Tom Lauria's method but it is a lot of fuss and a smpler method would be good. John

- 778 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

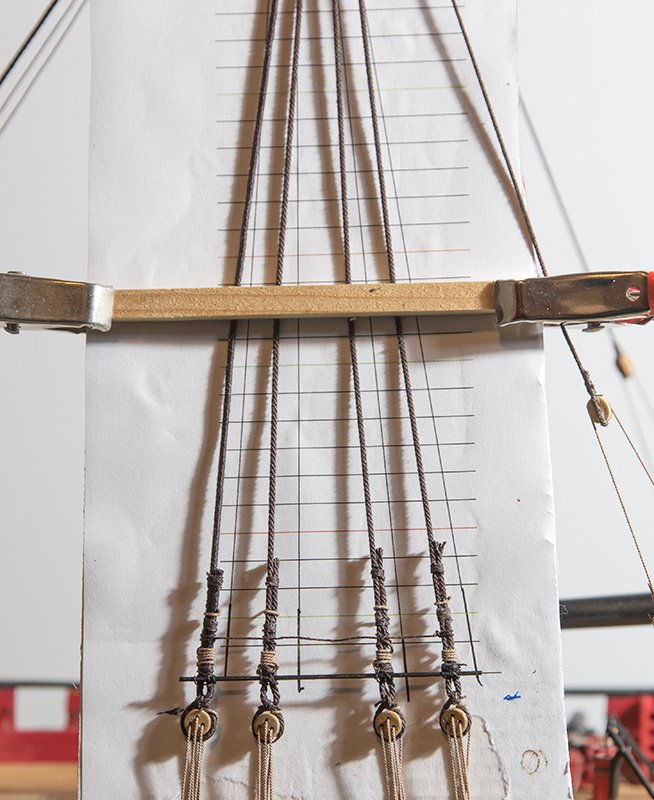

Post 62: Ratting Down For some this is a tedious job but there are only a few to do on this ship. The first issue is that there is some kind of perspective distortion on the plans which results in the spacing of the ratlines decreasing towards the top. I spoke to Chuck about this and he agrees that the spacing should be the same all the way to the top. It is a ladder after all. Therefore I drew my own grid in Illustrator with a spacing of 12inches which corresponds to 6.32 mm at this scale. In order to avoid the "hourglass" effect I did two things. First I camped the shroud to the card grid neat where I was tying. I discovered this technique somewhere on this site but I can't remember where to give proper credit for the idea. The second thing I did was to first tie at an interval of twelve then six then three. As we know on the real ship eye slices were used on the outer shrouds. Ed Tosti's book on Young America illustrates this well but it is difficult to do at this scale. The essence of this technique is that the line on the outer shrouds travels inward towards the middle shrouds. I simulate this by using a cow hitch on the outer shrouds and clove hitches on the inner ones. The problem with a cow hitch Both exit stands need to be held under tension. If only one is under tension the knot slips. Indeed this is the purpose of the knot as I well know from using it as a leg rope on cows art milking time. I digress. So, on can make it more stable either by following it wit a half hitch or by passing the free end back through the coils, This is what I have done here. The port side is nearly complete. Only the starbord to go John

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I agree wholeheartedly, Bob. I have worked in the chemical industry and so know a little about these chemicals. All acrylics are made small monomers which are derivatives of acrylic acid. However, as members of the general public we do not meet these because we only see the polymers (in fabrics, paints, plexiglass etc). It is generally only the workers in the industry who are exposed to these acrylate monomers. However, CA polymerises by contact with moisture in the air and the bottle actuually contains the acrylate monomer. These acrylate monomers are highly volatile, have an unpleasant odour, are lachrymatory (make us cry) and about 5 % of the population have an allergic reaction to them. Others develop an allergy after a period of exposure. I agree avoid CA as much as possible. John

-

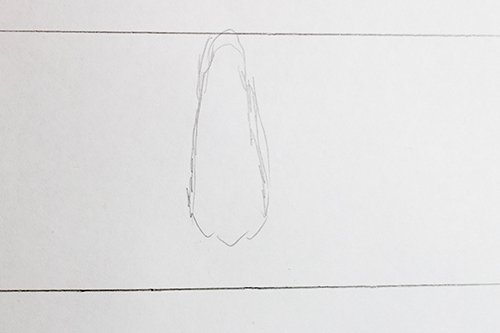

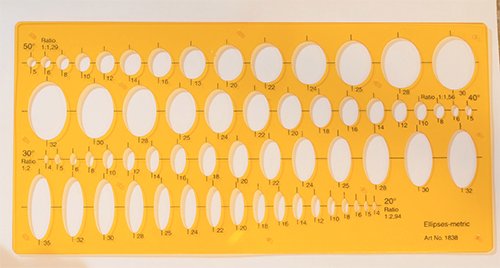

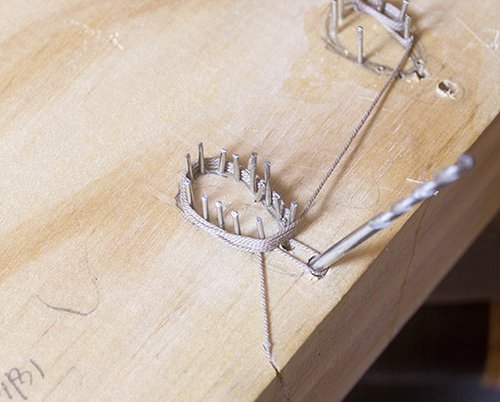

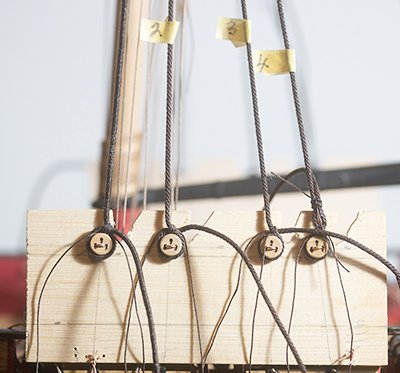

Thanks for your comment, Sea Hoss. First let me acknowledge Tom Lauria who originated this method. Tom uses an ellipse from a template such as this. As I said I prefer a less symmetrical appearance so first I draw up a rough sketch of the size and shape I want to achieve: I would make two or three of these of slightly different shape since on a working ship these coils are neat but not identical. Then i drill holes and insert pins as Tom does and continue with his method. John

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Post 61: Faking Down Before the ratlines get in the way I decided to at least attach some rope coils. I use the method of Tom Lauria. I find that that his oval jig produces coils that are a little too symmetrical for my taste so I slightly modify the shape of the jig to make it a little more pointed at one end. After painting with diluted acrylic medium the coils are allowed to dry and then cut from the jig. and here are some attached to belaying pins I am not entirely happy with how the look, but the more I make the better I get. The only trouble is they use up more rope than you would think and my light brown rope is fast running out! John

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Miniature Russian carving tools

bartley replied to druxey's topic in Modeling tools and Workshop Equipment

Bill Could you please provide me with Mikhail's Email address. John -

Tidying Up the rigging. Now that the shrouds are on, its time for a final tightening and trimming off some of those "dangly bits". Here is the for'ard region tidied up a bit. \ John

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

By the way, I sailed for a day on the square rigger in the foreground down in Cornwall some years ago. There was no way that their deadeyes were in line. They thought it was a strange thing to expect. Apparently the shrouds stretch differently and it is more important to tension the rig to account for this than keep the deadeyes level. John

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Post 60: Rigging the Shrouds Though I have done this on my previous build, I cheated and used three horizontal seizings. This time I decided to do it the " proper" way with a throat seizing as described in Chuck's monograph. I had some discussions with him about the details of this since the book by Lees and others suggest that the shroud should run anticlockwise around the deadeye but in Chuck's diagram they are clockwise. His point was that neatness was the main point and that for a right handed person it was easier to tie the throat seizing on the right hand side and so I elected to do it that way. Incidentally, there is a detailed discussion of all this by Ed Tosti here. I also used Ed's method of keeping the deadeyes level: I think this is actually overkill for only four deadeyes!! Chuck does it freehand and, it retrospect that would be just as good. In my view jigs only work if you can keep the tensions on each shroud equal. I found this easy enough for three of the stays but difficult for the fully served stay at the forward end. Anyway here is the final result, John

- 160 replies

-

- cheerful

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.