-

Posts

4,284 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Baker

-

Roter Löwe 1597 by Ondras71

Baker replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

Indeed -

Batavia. The curved planks on the stern are a protective layer of soft wood against shipworm. An early form of copper plating.

- 324 replies

-

- Sovereign of the Seas

- Airfix

-

(and 1 more)

Tagged with:

-

Goedemorgen buurman 😉

-

Treenail update, The weather forecast has been the same here for several weeks : rain and occasional showers... So a lot of time to drill holes and add treenails... After all the treenails have been applied it is time to scrape and sand. Pieces of old Stanley knives are used for scraping. The original and the model (picture of the original is thanks to @firdajan) After sanding, the hull was cleaned with a wet cloth. The starboard side is ready. Wales still needs to be done, probably also with treenails, and bolts??. I sent this question to the Mary Rose museum, but no response yet Thanks for following

-

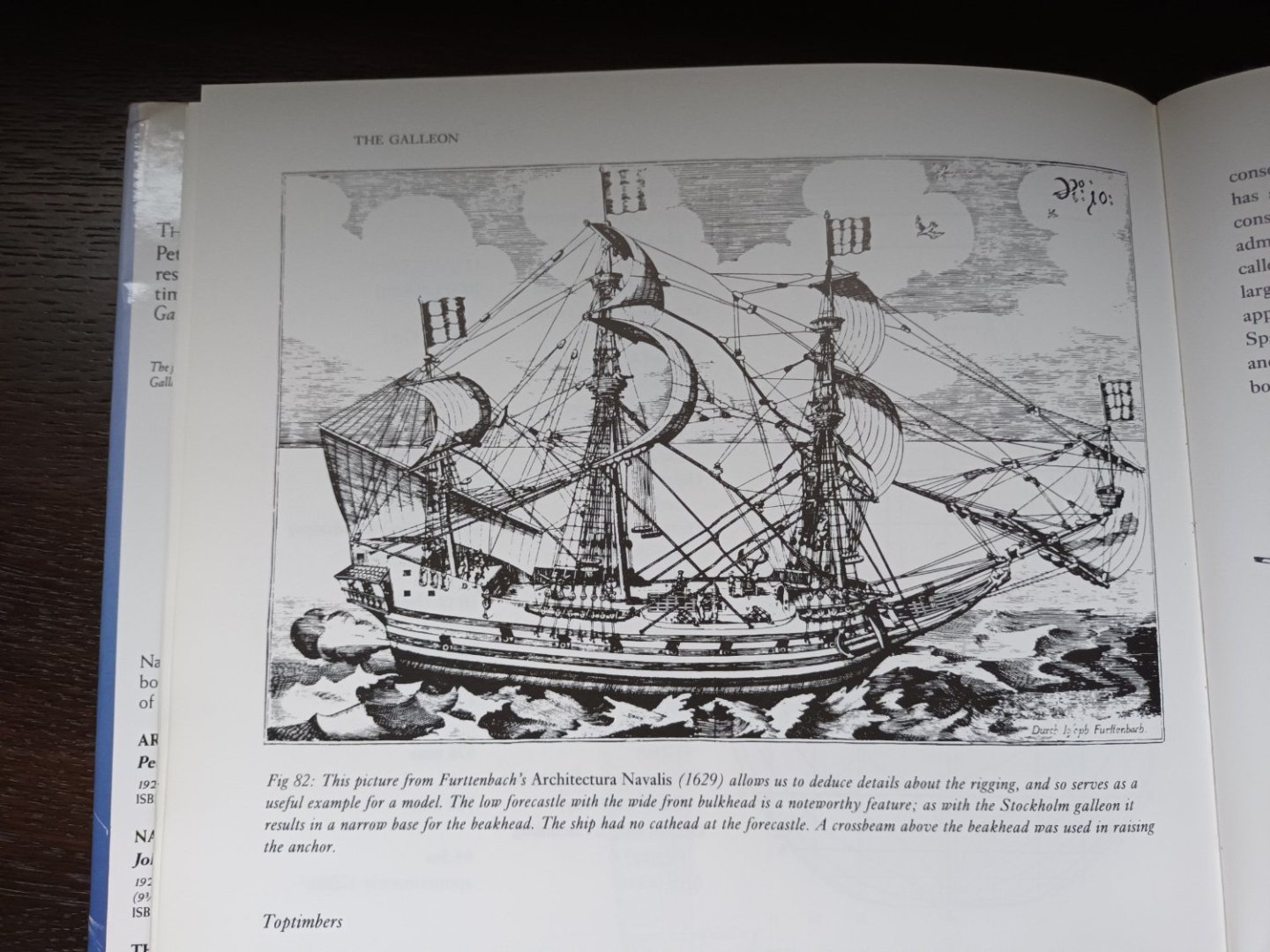

To late, but. A certain Mister Furttenbach had the same problem 300 years ago. Now this drawing is an example in rigging for many 😉

- 1,508 replies

-

- Le Soleil Royal

- Heller

-

(and 1 more)

Tagged with:

-

There is little information about colors on ships from this period.And certainly not about merchant ships. I would leave the colors as they are, looks good

-

How much would an unbuilt Airfix St louis kit be worth?

Baker replied to shipman's topic in Plastic model kits

https://www.hismodel.com/articles-detail-814 price : 82,61 euro out of stock...☹️ -

All this could end up on the mast top i think. Not on the deck.

- 1,508 replies

-

- Le Soleil Royal

- Heller

-

(and 1 more)

Tagged with:

-

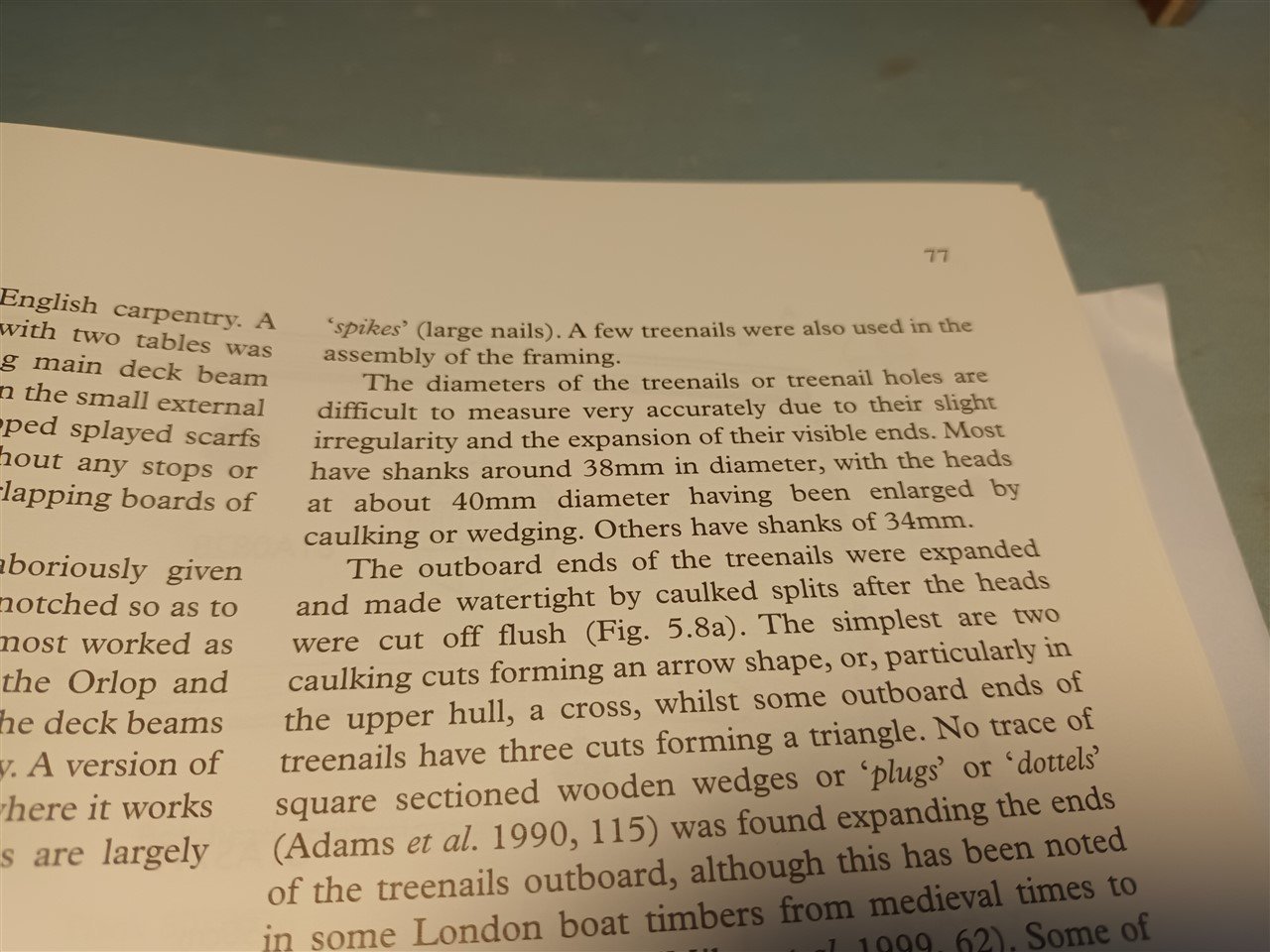

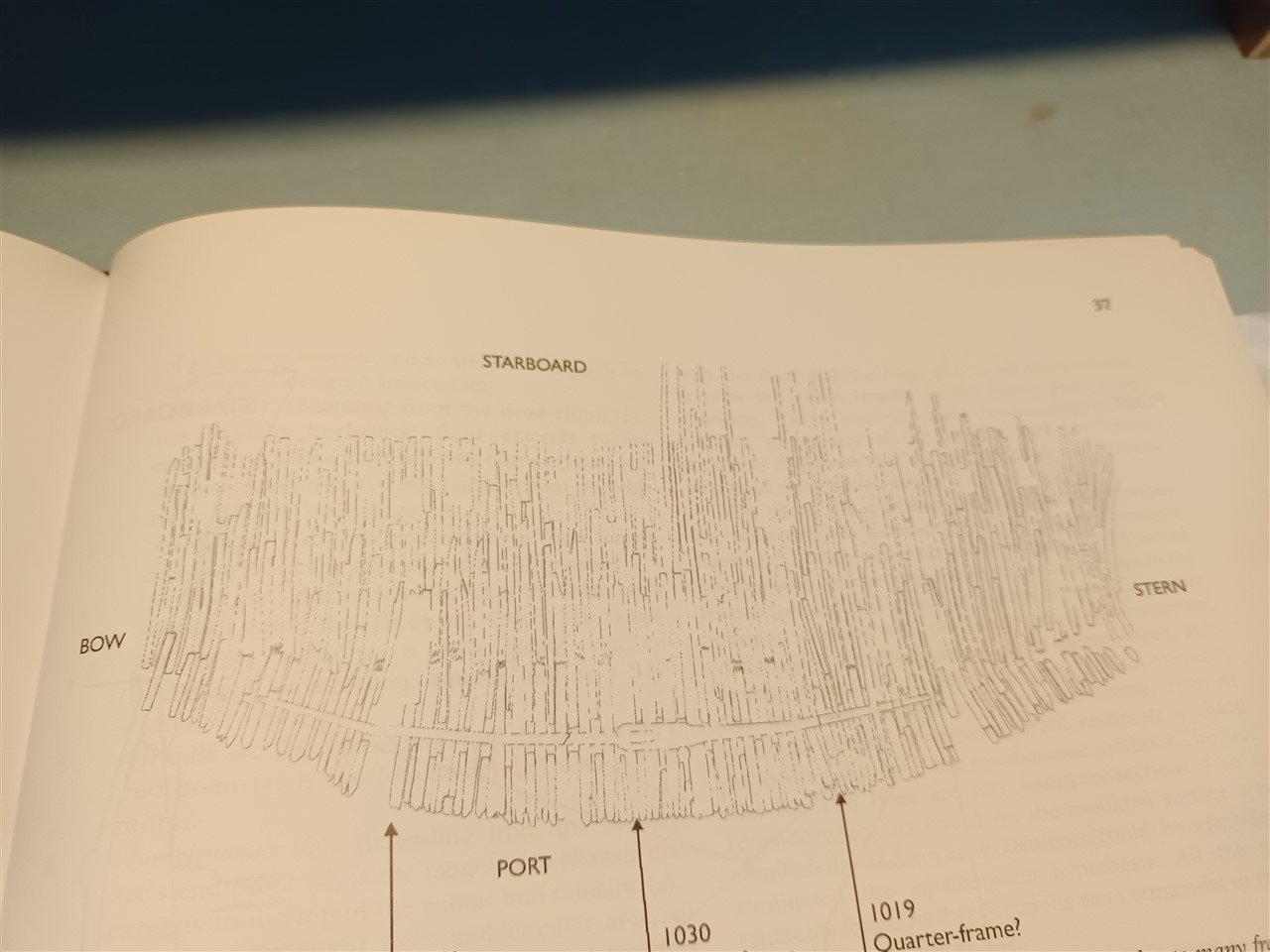

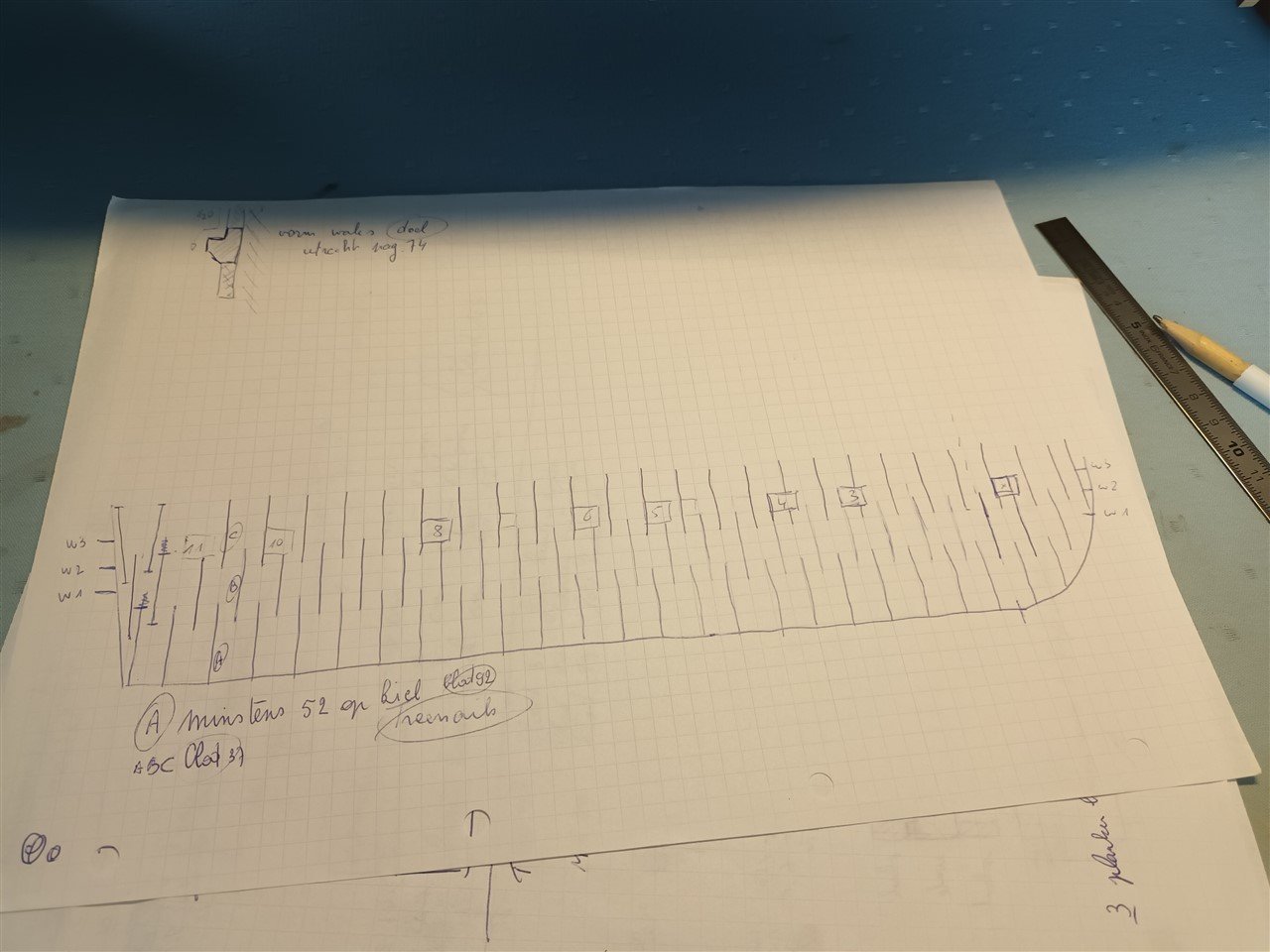

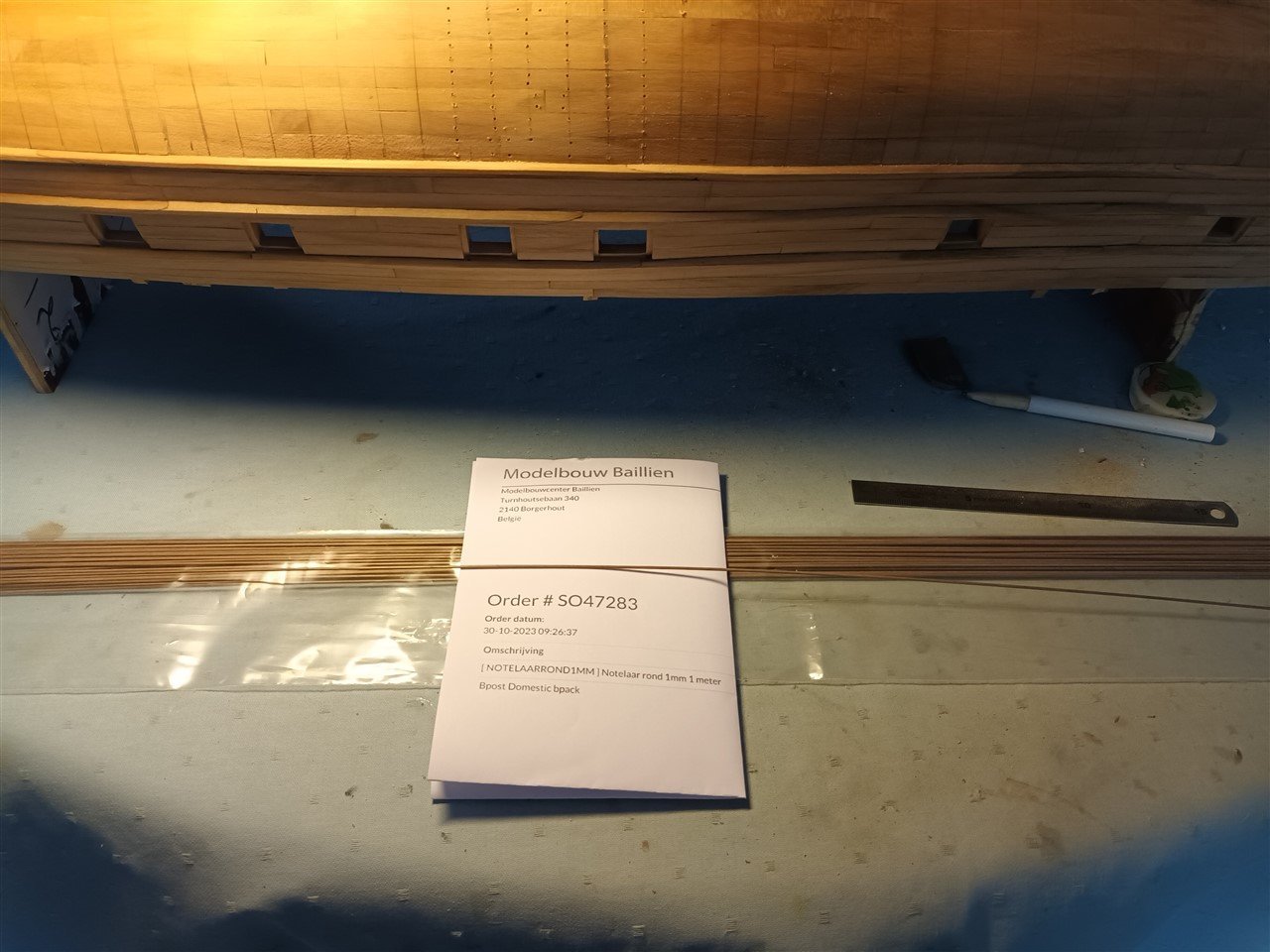

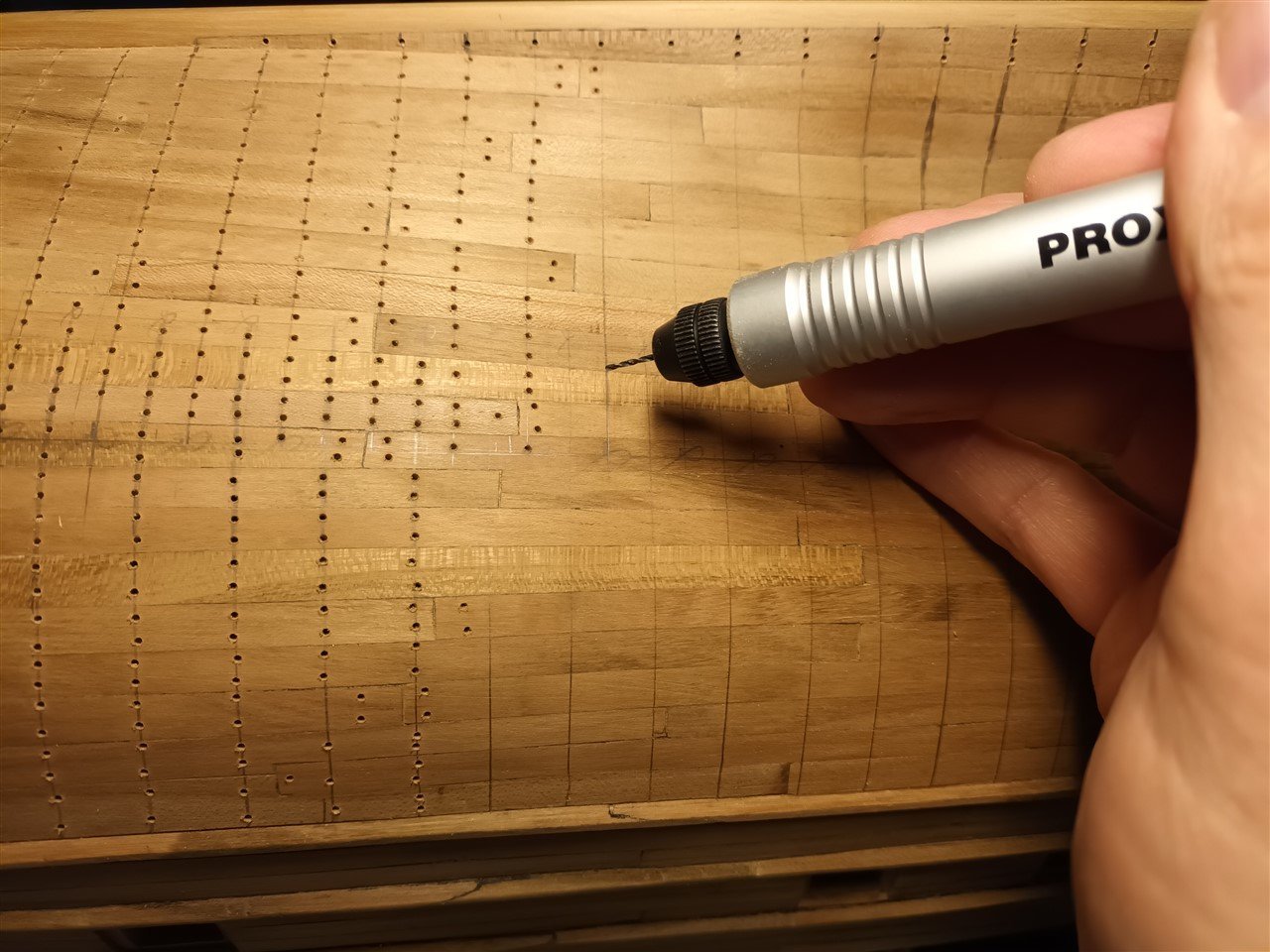

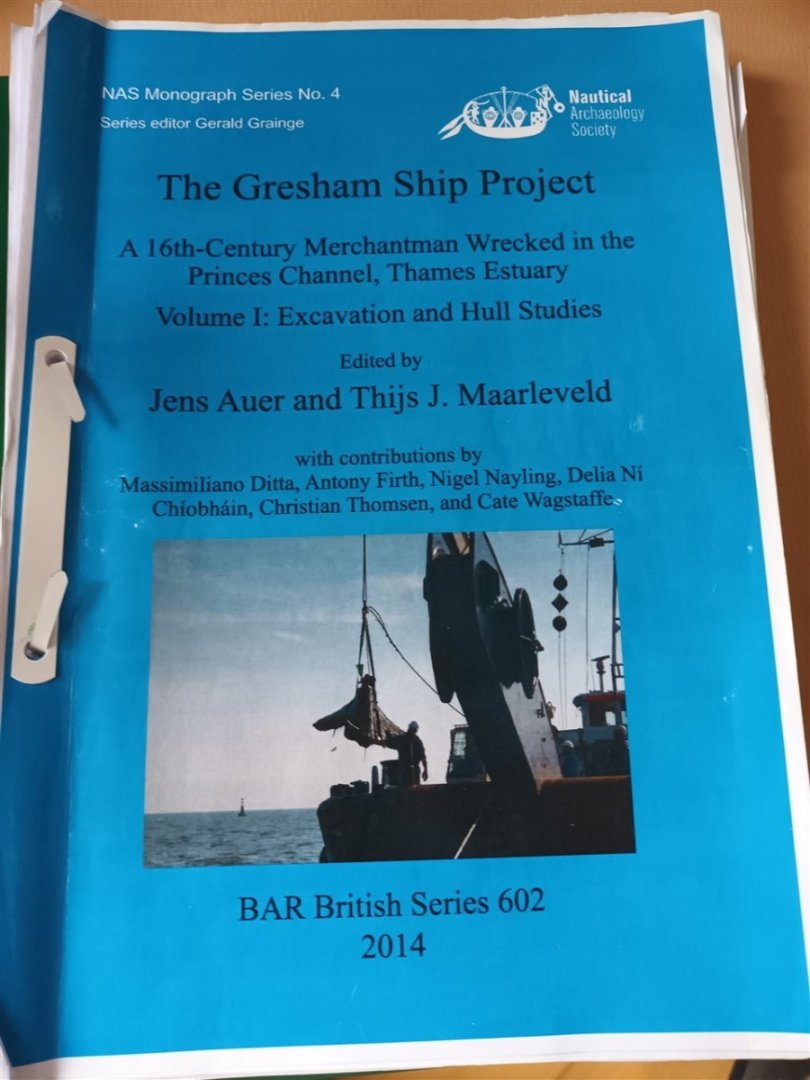

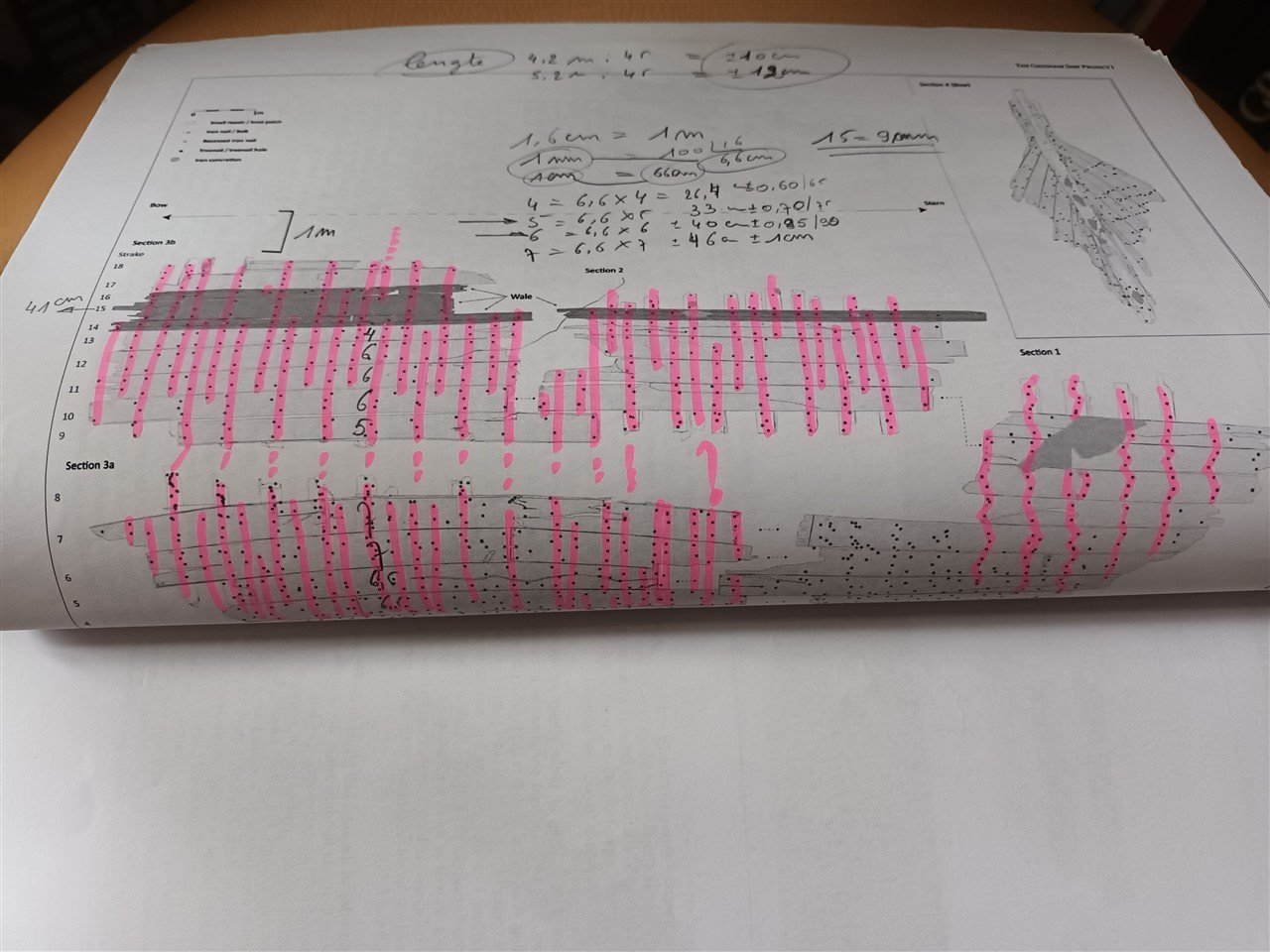

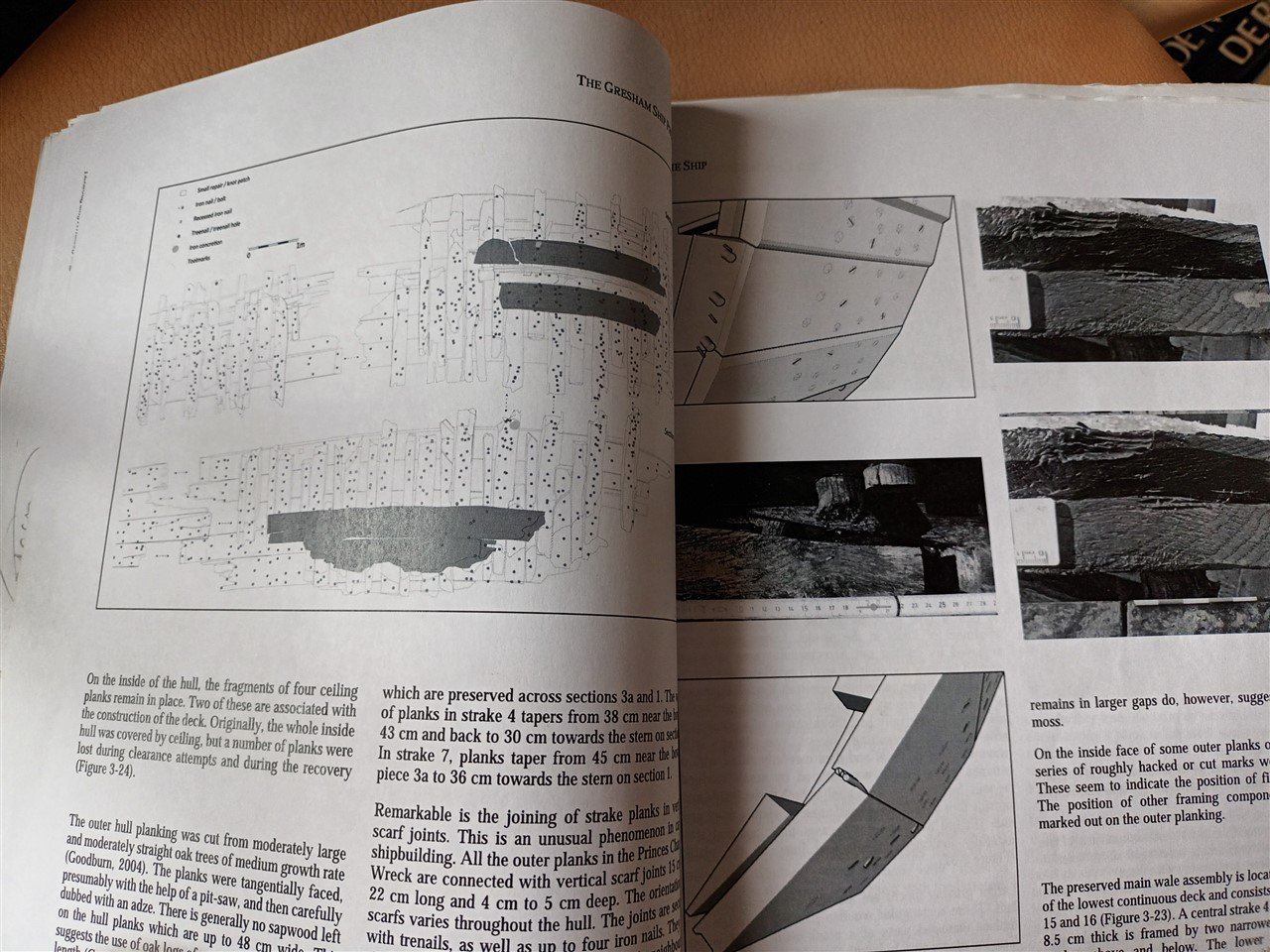

Treenails... There have been many discussions here on the forum; Treenails, yes or no. For me: yes. It's a lot of work, but for me it adds value. The idea is to add the treenails and then paint the hull with diluted Tamiya paints. This worked last time with toothpicks and ramin wood, but the cherry wood does not provide enough contrast. That is why I purchased walnut strips with a diameter of 1 mm, these provide sufficient contrast with the cherry wood to be able to paint over later. There is not much information for the Mary Rose, only the diameter of the treenails. The frames also do not have an ordered structure to create a treenail diagram. Therefore, back to the method on my previous model. This creates a schedule that has some structure. This will not match the real ship at all. but it looks good (to me). The Mary Rose info, Further in the book it says : We will investigate this further later... My treenails are indeed 0.2mm too thick. But I couldn't find smaller strips in walnut and 1 mm drills are cheap here The frame diagram Plan B The strips : ordered on monday, delivered on teusday. There should be approximately 5500 to 6000 holes between the keel and the first wale. This work requires new tools Drilling Adding the treenails (and my very first hammer, still in service) Work in progress

-

Revenge 1577 by Loracs - Amati - 1:64

Baker replied to Loracs's topic in - Kit build logs for subjects built from 1501 - 1750

I think your painting gives a very special and beautiful result. At the time the Revenge was built, wood and iron were used.No brass 😉 The most common colors where red,green and white

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.