-

Posts

574 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by petervisser

-

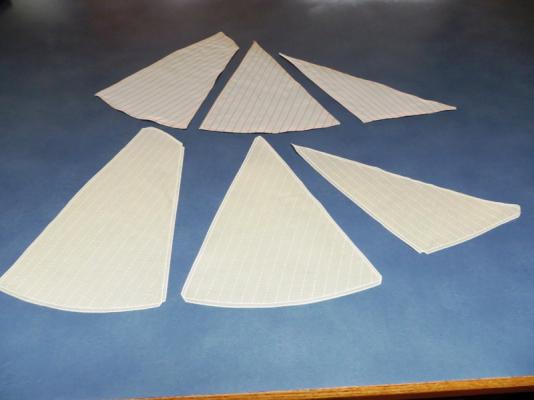

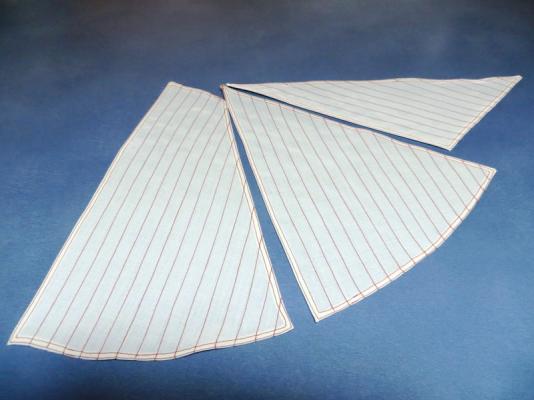

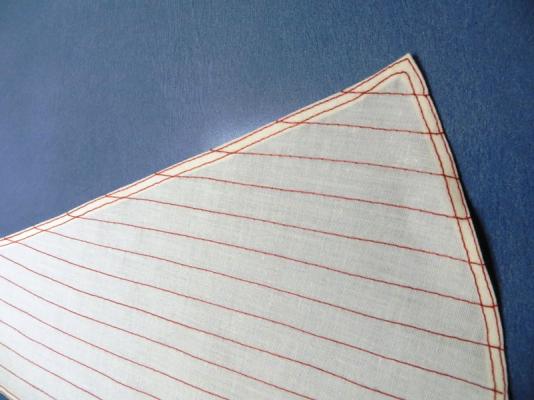

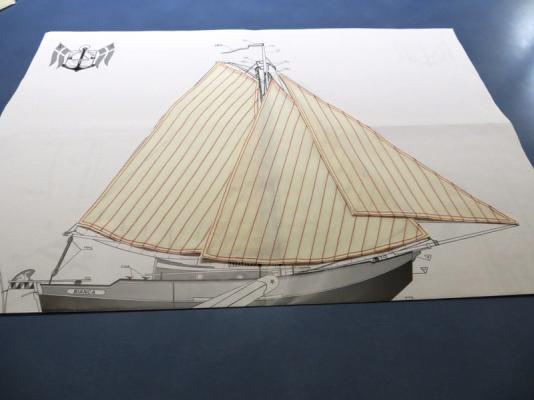

Another little update before work is interrupted. My wife has completed the sails. I have a bolt rope to attach still, but the hard part is complete. I am very happy with how they turned out so far and will have to make it up to her somehow. I'm sure she will fill me in on "how to" on this... Here are the "before" and "after" sails. The finished sails. A close up of her handy-work. A little teaser on the overall affect. I teased her a little this morning, telling her that my next model will be the Cutty Sark which has about 20 sails to be sewn. Her response..."Well, I guess I'm going to give you some sewing lessons" in a matter of fact tone... I'm thinking "bare poles" for that model. Peter

- 109 replies

-

- zeeschouw

- billing boats

-

(and 1 more)

Tagged with:

-

Yes Popeye, I am a lucky man. With my previous models I have hand sewn the sails, but they look a little unrefined. Passable, but they could look a little better. So this time I opted for some "professionally' sewn sails. I still intend to sew on a bolt rope which I can do myself. I enjoy sewing, but the machine is a little intimidating. Besides, if I am taught how to use it now, I will have totally forgotten how to do it again when the time comes. My next model won't have sails you see. The model will now take a little hiatus while the sails are being sewn. And I return to work in a few days which takes me away from model building. Oh well, the end is clearly in sight. Cheers, Peter

- 109 replies

-

- zeeschouw

- billing boats

-

(and 1 more)

Tagged with:

-

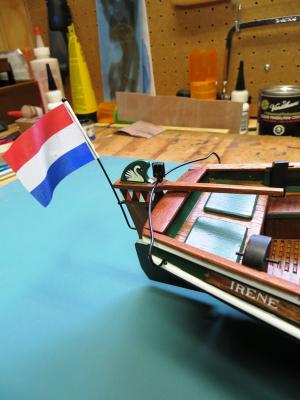

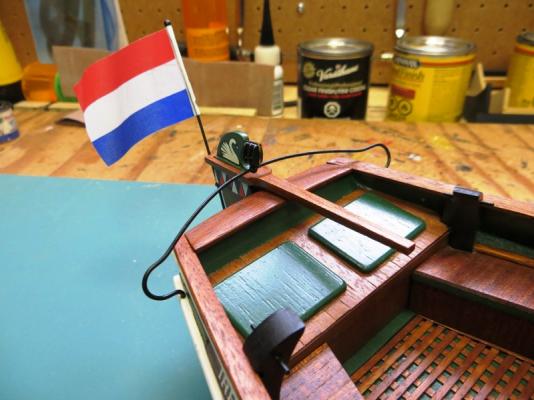

Attention zeeschouw fans... another minor update. I have been working on the mast and its jewelry along with the other spars. Just a matter of staining, varnishing and painting really, but it does take time to put it all together. I also managed to make an athwartship traveller for the boom. Believe or not, I managed it the first try. I was certain it was going to take several attempts at getting the right bends at the right size. The flag is also flying! I used the flag supplied with the kit and am pretty happy with how it turned out. So here are a few more pictures... The flag flying from the the stern. I used some varathane to soak the material and then wrapped the flag around several dowels to give it some curves and life. I used some scrap material to experiment with to find out what, and what not to do. A shot of the traveller for the main boom. A shot of the boat with the mast and spars ready for mounting. My wife has kindly offered to sew the sails on her machine. She's awesome! They are a work in progress so I will wait to step the main mast until I can get the sail bent on. Stay tuned...

- 109 replies

-

- zeeschouw

- billing boats

-

(and 1 more)

Tagged with:

-

Lilla Dan by Billing Boats - moved by moderator

petervisser replied to ronc's topic in Wood ship model kits

Hi Ron, I just stumbled onto your request of drawings for Lilla Dan. I completed this kit a number of years ago and yes, I still have the instruction book and the drawings. However, the sheet drawings are not in the best of shape and so they won't likely make great copies. If you like, I can get an estimate on how much it would cost to get copies made and into the mail for you. Let me know via PM. Cheers, Peter -

Hi Vince, Just a great job so far. I am following along closely as I also have this model waiting in the wings. (Un)fortunately there are several models ahead of her. However, I will watch your progress and take some notes. Cheers, Peter p.s. Thanks for the great photos as well!

- 593 replies

-

- royal william

- euromodels

-

(and 1 more)

Tagged with:

-

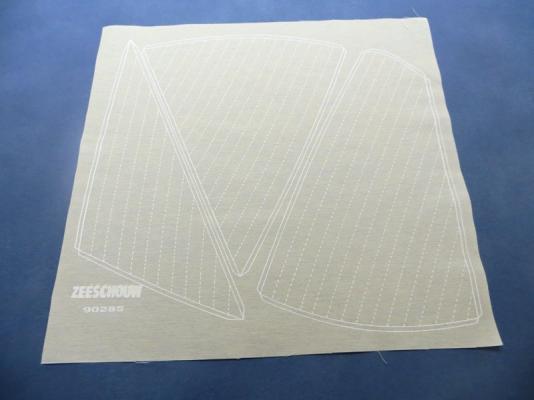

Funny you should ask Nils! I just put on her name boards and now she has a proper name. "IRENE". I named her after my sister. The kit's name is "BIANCA" but I don't know anyone personally by that name so I decided "Irene" had more significance. Here are some pictures with the new name board. Now I have to start work on the sails. I have put another coat of paint on the masts and they are drying in front of the gas fire. Billing has supplied a sheet with the pattern of the sails inked on them. However, the material is a bit too white and stiff. So I will use them as pattern pieces and use muslin cloth instead. I am hoping to get a sewing lesson from my wife who has a sewing machine and a serger. I will do a little experimenting and come up with the best solution. Stay tuned to this channel....

- 109 replies

-

- zeeschouw

- billing boats

-

(and 1 more)

Tagged with:

-

Thanks for the encouragement and nice words guys. Marc, the Amsterdam Maritime museum has a great selection of books. However, a few years ago, I tried buying some books there, but I could not actually enter the book shop. They had a counter person who would take the order and enter the shop to get it for you. I'm not certain if that's still the case, but you might want to think about the books you want before shopping there. The weather outside is awful with snow and sleet today soooo, I'm thinking I have free reign to hobby today! This is our first snow of the year really, so not much to complain about. Cheers guys. Peer

- 109 replies

-

- zeeschouw

- billing boats

-

(and 1 more)

Tagged with:

-

A quick little update guys while the paint on the mast and spars are drying. The rudder minus the flag is finally finished. Boy, what alot of steps for finishing this one piece. Cutting out the rudder, laminating the strips of mahogeny, fitting the tiller, multi-layers of different colour paints and lacquer, fitting the pintles and gudgeons and aplying the decals. It took days and days! The decals were a bit challenging because I had not done any for many many years. They were applied and then I coated them with a few coats of varathane. They're not going anywhere! Well here is the finished product and the rudder dry fitted to the transom... Cheers, Peter

- 109 replies

-

- zeeschouw

- billing boats

-

(and 1 more)

Tagged with:

-

Gil, Great idea in staining your rigging thread! An sollution for many of us with less than perfect rigging thread. I also like your fine detailing on the spars. Insprational! Peter

- 755 replies

-

- finished

- caldercraft

-

(and 1 more)

Tagged with:

-

Marc, Yes, I have the Billing Friese tjalk also! And I also have a kit of Lemster sailing barge that is produced by Mamoli. I am very fond of the Dutch sailing vessels and I saw lots during a trip to Holland to see family. We rented a small motor yacht and sailed the canals of Friesland. Many many vessels of all types to see and admire. Popeye, Unfortunately, Billing has decided not to market these kits outside of Europe. I suppose they think only people who are familiar with these types of boats would want to build them. That's unfortunate because these kits are ideal for beginners. They are easy to put together and don't take a great deal of time to finish. They also offer beginners a fun intro to the hobby and allow them to acquire some basic skills. I purchased my kits in Holland while on vacation. They make packing challenging! Kip, I managed to find them at Lee Valley! I am going to have to go back and look at what else is on offer. Lot of things to spend money on there... Today I painted a bunch of fittings and stained the mast and spar. Pictures to follow soon. Peter

- 109 replies

-

- zeeschouw

- billing boats

-

(and 1 more)

Tagged with:

-

Thanks for the kind words guys. They are much appreciated. Today I must go out and try to find some tiny drill bits. The hardware stores have 1/16" but that sems to be the smallest they sell. Where do you guys get your bits? Peter

- 109 replies

-

- zeeschouw

- billing boats

-

(and 1 more)

Tagged with:

-

Well, a bit more progress was finally made. I am working on the rudder and have finished the lee boards. I am also working on the mast and other spars as well. A bit of light at the end of the tunnel all ready. Here are some pics... The rudder is assembled and I am now giving it a few coats of paint. Here the lee boards are in place and rigged up. I have dry fitted the main spars. The gaff required a bit of bending in two different directions. A few dowels met their ends trying to get it right... The kit provided some plaques for the name on the stern. I have stained them and will add some letra-set lettering I found in my cache of goodies to give my model a different name. Tommorow I will stain the spars and paint some fittings in preparation to fixing the mast. Cheers, Peter

- 109 replies

-

- zeeschouw

- billing boats

-

(and 1 more)

Tagged with:

-

Beautiful model Danny! Well done. I hope you plan a glass case to protect all your hard work and fine rigging. Peter

- 59 replies

-

- caldercraft

- bounty

-

(and 1 more)

Tagged with:

-

A busy week in the workshop. I have prepped, painted and installed all of the deck fittings. Not that there were that many... This is proving to be a fun build and relatively quick. A nice change from a square rigger, that's for sure. Here are some photos of the progress... Cheers, Peter

- 109 replies

-

- zeeschouw

- billing boats

-

(and 1 more)

Tagged with:

-

After many months of idle tools and a neglected model, it's time again to get back to "work". I have begun by prepping a number of itens that make up the deck fittings. For the most part an easy task because all the items are laser cut and simply need to be popped out of the sheet and sanded. I had to modify a couple of parts as they did not fit as advertised. A little scratch building was therefore required to keep me honest. Here are the results so far. Tomorrow a few more parts to prep and then I can start painting! I have dry fitted the sliding hatch and skylight. A closeup of the sliding hatch and skylight. And here a shot of all the parts so far ready for a few coats of paint. Stay tuned... Peter

- 109 replies

-

- zeeschouw

- billing boats

-

(and 1 more)

Tagged with:

-

Very nice work ZyXuz! I remember doing my own cannon during my build of the Unicorn. I rigged the guns fully in the waist and quarter deck where they were visible, but simply afixed the breeching tackle to the guns that were under the deck. It saved a bit of time and effort. Keep up the excellent work! Peter

-

Thanks for all the detailed posts and pictures Gil. Plenty of great tips and tricks for all of us! Peter

- 755 replies

-

- finished

- caldercraft

-

(and 1 more)

Tagged with:

-

That is a superb Bounty you have on the go Danny. Wow, she is turning out very nice. All the best with the rigging project to come! Peter

- 59 replies

-

- caldercraft

- bounty

-

(and 1 more)

Tagged with:

-

Looking good Don!! Hey, if you need drawings of the running rigging, I have John McKay's large scale Bounty drawings I can lend you. I'm only home for another week so just let me know. Cheers, Peter

- 43 replies

-

- finished

- billing boats

-

(and 1 more)

Tagged with:

-

Hi Hamilton, If that is the North Star of Herschel Island I just want to point out that the rig is a dummy rig. Those sails are never set and the vessel motors everywhere. The "ship" used to live in Victoria for a number of years and I had seen it many times. It's really a huge stretch give it credit for the rig it displays. Sorry to be such a downer but really, it's just a boat with lots of sticks. Peter

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.