-

Posts

5,546 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by RGL

-

Type in "Hull plating small scale ships" into u-tube, there is a tutorial on how to do it, I found it last weekend, very simple.

-

No doubt it's all about packaging and shipping fees. Just would have been more simplified on a zig zag patter along panel lines, meh, too late, move on. Its a nice kit limited only by my own ability. The putty syringe seems to have solved it and nothing masking and overspray can't fix. Don't blame the tools etc. any faults will be my own.

-

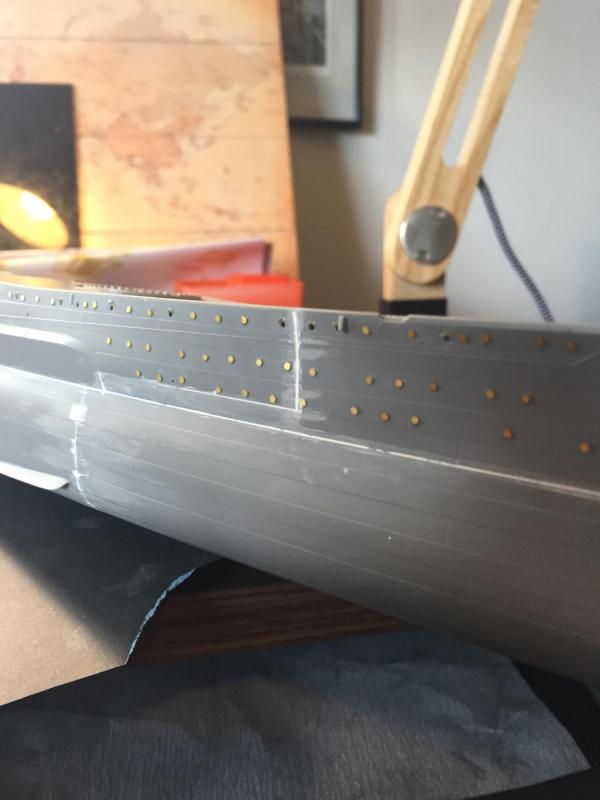

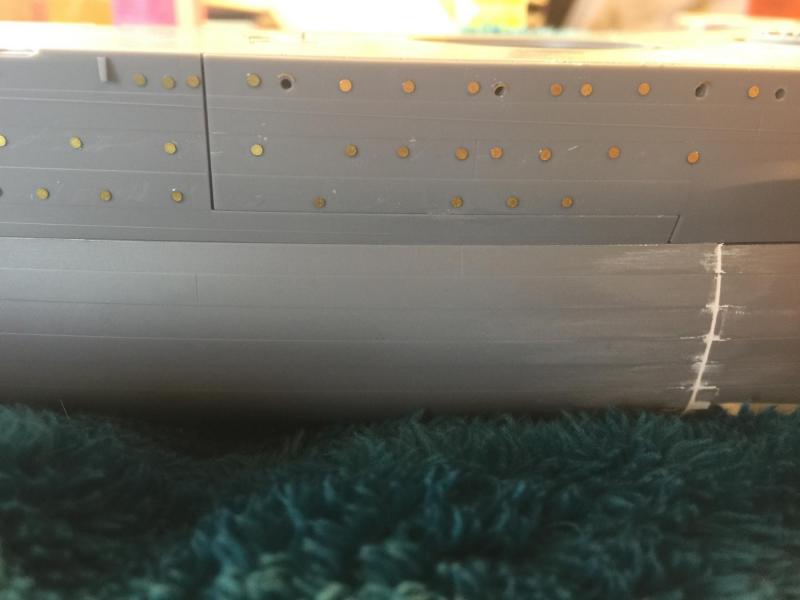

Bugger me, it worked! I expected having to spend days fixing this, but it was just a couple of hours work. I threw the old tool hull together so you can see the comparison. This swill be my practice piece for painting. Given how much I have spend on this thing so far I think it is worth having a mistake zone.

-

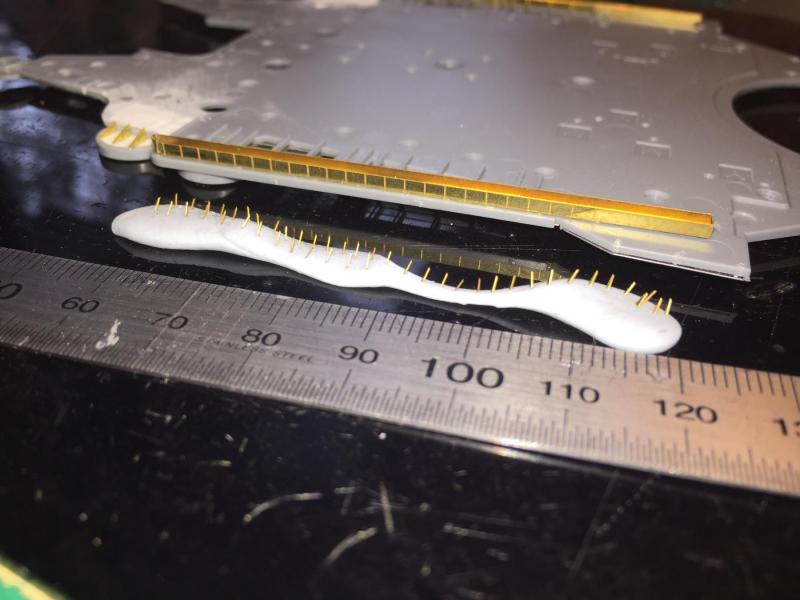

Finally some days off! The hull is now joined up, but I have no idea what Tamiya were thinking making the upper hull in 5 pieces as the gaps are huge. Given the size of the ship, it needs a LOT of glue, and it requires a fair bit of spot glueing with off cuts of PE to slide into the gaps. The centre deck area (I'm sure the ex mariners will have a name for it), comes in three pieces which join up to the hull nicely with some thin PE. In a moment of inspiration I found a syringe which I filled with Tamiya putty and ran along the gaps which will hopefully avoid a lot of sanding to avoid loss of molded seams. This is backed up by the prodigious use of masking tape Quite a few of the dead lights have fallen off due to this handling but can easily be replaced. Once all the seams are fixed up I can add all the drain pipes on the side, drill out the stanchion holes and fix up everything I can before even thinking about adding the forecastle and rear flight deck.

-

Slog, North Star is now producing these in 1/200 with resin and brass but you're all over this, amazing work.

- 244 replies

-

- borodino

- dom bumagi

-

(and 1 more)

Tagged with:

-

Thanks for the feedback gents, the intend to get the hull joined up, fill the gaps, and the use a Tamiya rattle can to prime, as their fine primer is excellent. Once that is bedded down I can start on the guns and superstructures, the numerous (I mean hundreds) of smaller guns, , and have everything ready to go for proper painting and weathering, the ships boats, aircraft etc, so my log will continue in that vein until it's time to buy and learn. Big build and large investment means being careful in what I do. BTW, Mr Taylor, challenge is set for you to try one!!!!

-

There is a build I'mfollowing on another forum that's quite good as it points out the bits that the instructions don't tell you about and is nicely weathered. When I get an airbrush there is a wealth of info on it, I know how to but there is so much good stuff out there now on the internet that did not exist back in the day that it's a whole new world. I think the secret is to be subtle. I imagine the hull will be battered and dirty but the Japanese were and are so fastidious the areas that were accessible would be as clean as possible or their seniors would have flogged them. I keep telling myself stop rushing.

-

Nah, I'll use anything, I used Humbrol for the weathering but this is a whole new world for me. The Tamiya Putty sands very nicely but goes off very quickly. This is the New Tool (post 2011), but I have the old tool for practice and they are exactly the same size. The only camera I own is my phone so if I had a good 54mm lense it would look better. My job sent me on a professional photography course last century and it's all about light (this was before digital), and I mainly then took photos of people who didn't know I was there.

-

Too early to tell, once I get the hull togeather and the gaps filled I'll feel a bit more confident. It is a very big kit. Keith, belated answer is no as there will be aircraft / boats in the road anyway

-

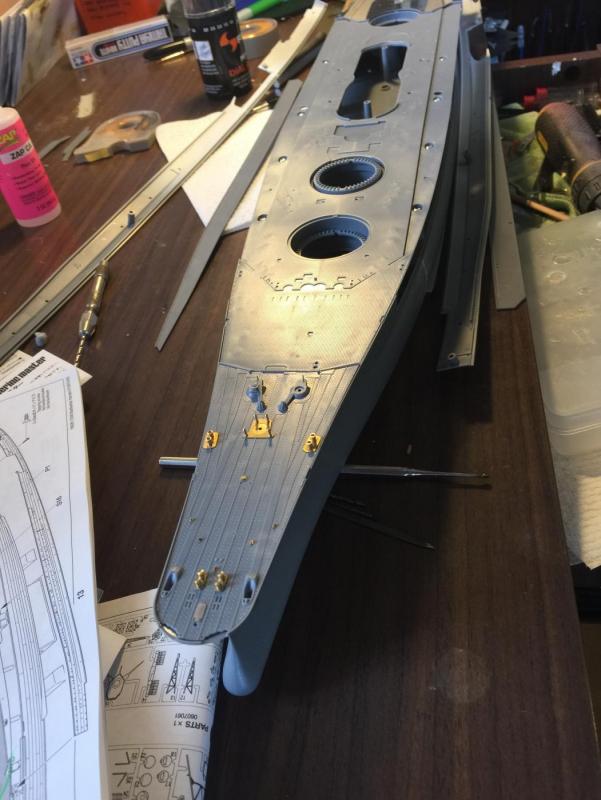

Now to start screwing the beast together. It is massive. The bow, hangars and main deck is down. I will get to the sides and forecastle later later next week then do the filling and sanding. The Rear aircraft deck will go on much much later.

-

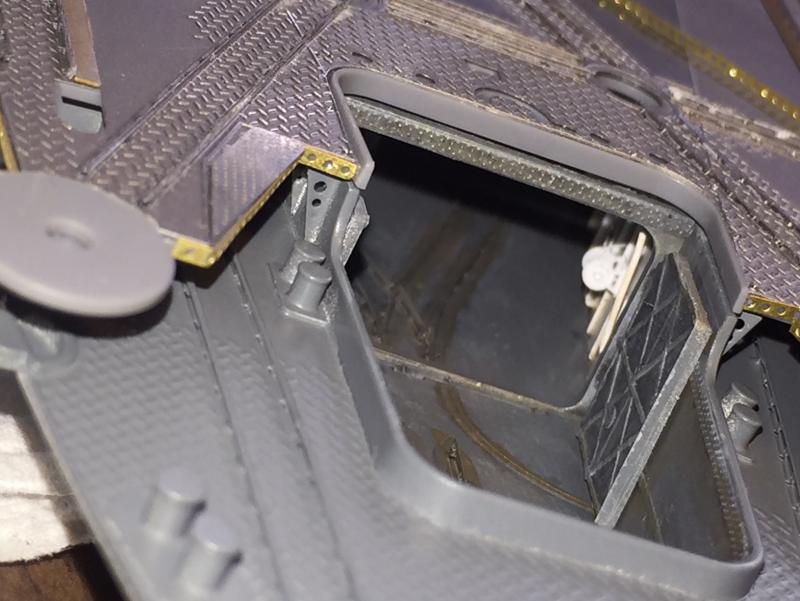

I have now finished the interior hangars. A little bit of weathering, rust, grease and drybrushing. Realistically not much will be visible.

-

You suddenly will hit that point and go, bugger, I'm finished, what now!

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

I'm at the stage where I really want to start putting the hull together, but I have to paint the interior boat and aircraft hangers first. I have given the 'inside bits' their first primer an base coats. I will weather the interior bits by hand and wait till later until I do the IJN grey bits. That way I can put the sides one and the deck. You can see in the foreground some perforated steel beams which are required on the rear aircraft deck, which is finally complete (2 weeks from the Ukraine to Oz is pretty good. I intend to give the base coat 12 hours to dry nice and hard before I do any work on it then I can put the hull together.

-

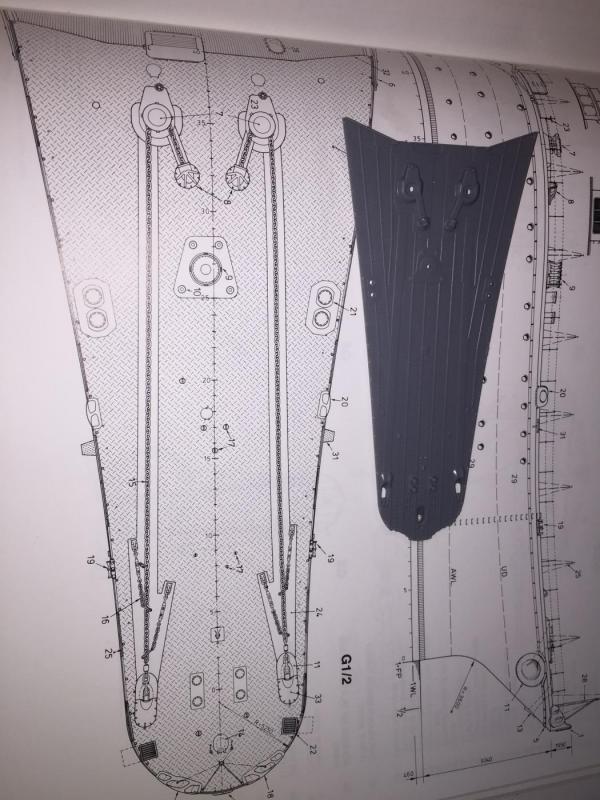

Moving along, I have done everything t the deck I can do before painting. There are marked places for the stanchions but I cannot drill them until I do up the hull. The Forecastle is a very nice mold. As you can see from the AOTS there is not really much to be done here. The Tamiya capstan and cable holder are fairly bland; and I have replaced them with the Chrysanthemum set which is just lovely. The front hawser hole is provided by Tamiya but the other brass is all Pontos. Now it's in its' box until painting time. What next?

-

Most, if not all their stuff is in 1/700, for the sake of my eyesight in latter years, I will avoid. I do like this Essex though!

-

Little update, the crane runners for the ships launches. The main metal pieces are 1 piece of PE, but the struts are each about 2mm x 1mm x 0.3mm. In order to place them as they are tiny triangles, it's a matter of placing them facing the right way in some blu-tack and running some CA in the grooves then using the tweezers to place them. Once placed, run some thin CA to seat them permanently, and watch some fall off, and repeat. There are 24 on each side and the kit provides 50, and I only lost 4 so a few tiny offcuts of old PE did the trick. There is very very little reference as to how it works so a bit of scratch building/imaginative interpretation as to how I will sling the launches much much later in the build. I am awaiting some perforated beams to place on some edges and this piece will be finished for all intensive purposes. I am now moving on to the deck, drilling and prepping areas that will be replaced by the Pontos parts plus a couple of hundred stanchion holes.

-

Not at all, I had no idea that's what they were called. That's how we learn. I don't think many people would get the other reference!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.