-

Posts

3,051 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bruce d

-

Hmmmmmm. If the tiller is in place, where does the Queen sit? The many layers of protocol surrounding HM probably dictated that no tillerman's bum shall point at the Queen, so a couple of lines past her elbows may have been the deal.

- 185 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Capitulation of warship between centuries?

bruce d replied to Baltic_submariner's topic in Nautical/Naval History

My opinion: Armour. As the ships got better armament and engines, the close quarter fighting of the previous centuries simply could not develop. After the fight between Kearsarge and Alabama, the navies of the world knew that future battles would look different. Captains could use their engines to keep away from their opponent and hammer away with long range weapons. So weapons with even longer range were developed and armour to protect the crews who manned the weapons. Prior to this development, the outcome of a battle between wooden ships was usually determined by casualties inflicted; even a dismasted opponent would be fired upon until surrendered. After the introduction of armour and long guns the correct approach to fight a metal ship was to disable or sink the opponent. I expect others may have something to say 🤐. -

Hello retiredpm and welcome to MSW from the UK. Lots of good advice here, it might be a good idea to say where you are (just which country 😁) so members can point you to appropriate suppliers etc. Beware! People like me will suggest you buy every tool available and then make a few more! I think once you decide which kit feels like a good fit for you the subject of tools will begin to come into focus. It's always a good idea to browse through the build logs and see what appeals to you. Above all, enjoy the ride. Regards, Bruce

-

Hello Bob and a warm welcome from a very wet Sussex. Polaris is popular, there is always room for another should you decide to start a log for the balance of your build. Regards, Bruce

-

That is a good looking boat. Well done, I think the grain in that base-piece works perfectly. 👍

- 50 replies

-

- model shipways

- 18th century longboat

-

(and 1 more)

Tagged with:

-

NRG Capstan Project

bruce d replied to tlevine's topic in - Build logs for subjects built 1751 - 1800

Show off. 🤐 -

Kubota-San, I am so glad I found this thread. I love the way you approach each task. It looks great. 👍

- 126 replies

-

- victory models

- amati

-

(and 2 more)

Tagged with:

-

Hello from sunny Southern California

bruce d replied to boatsNbeers's topic in New member Introductions

Hello from the UK and a warm welcome to MSW/NRG. That is an interesting array of subjects, looking forward to a build log, ✔️ -

I am doing just that, one at a time. Known here (and elsewhere?) as NVR switches, for 'No Volt Return' I believe, and most look something like this: Back to the boat: it is worth waiting for. So glad to hear you intend to leave it bright.

- 433 replies

-

- open boat

- small boat

-

(and 1 more)

Tagged with:

-

Hello nehemiah, and a warm welcome from the UK. Glad to have you aboard. Mark has given good advice, and it applies to all the steps you will face when building: no matter what you come up against, someone has done it before, maybe they posted it in a build log 😇 with a few tricks to help the next builder. Bruce

-

Hello Jean Pierre and a warm welcome to MSW from the UK. Very impressive skills, I am sure your work will raise many questions! Bruce

-

Swann Morton chisel blades.

bruce d replied to harlequin's topic in Modeling tools and Workshop Equipment

Tim, I know what you mean. But, since I have a couple of Xacto handles, I was wondering if the SM chisel blades would fit them. -

Swann Morton chisel blades.

bruce d replied to harlequin's topic in Modeling tools and Workshop Equipment

I see the blades have their own fittings that don't fit standard #3 or #4 handles. Do they fit anything else? The fitting looks quite bit like the one used on their orange plastic 'hobby utility knife' which, IIRC, is interchangeable with Xacto blades/handles. It would be handy if they fit something already in my toolbox! -

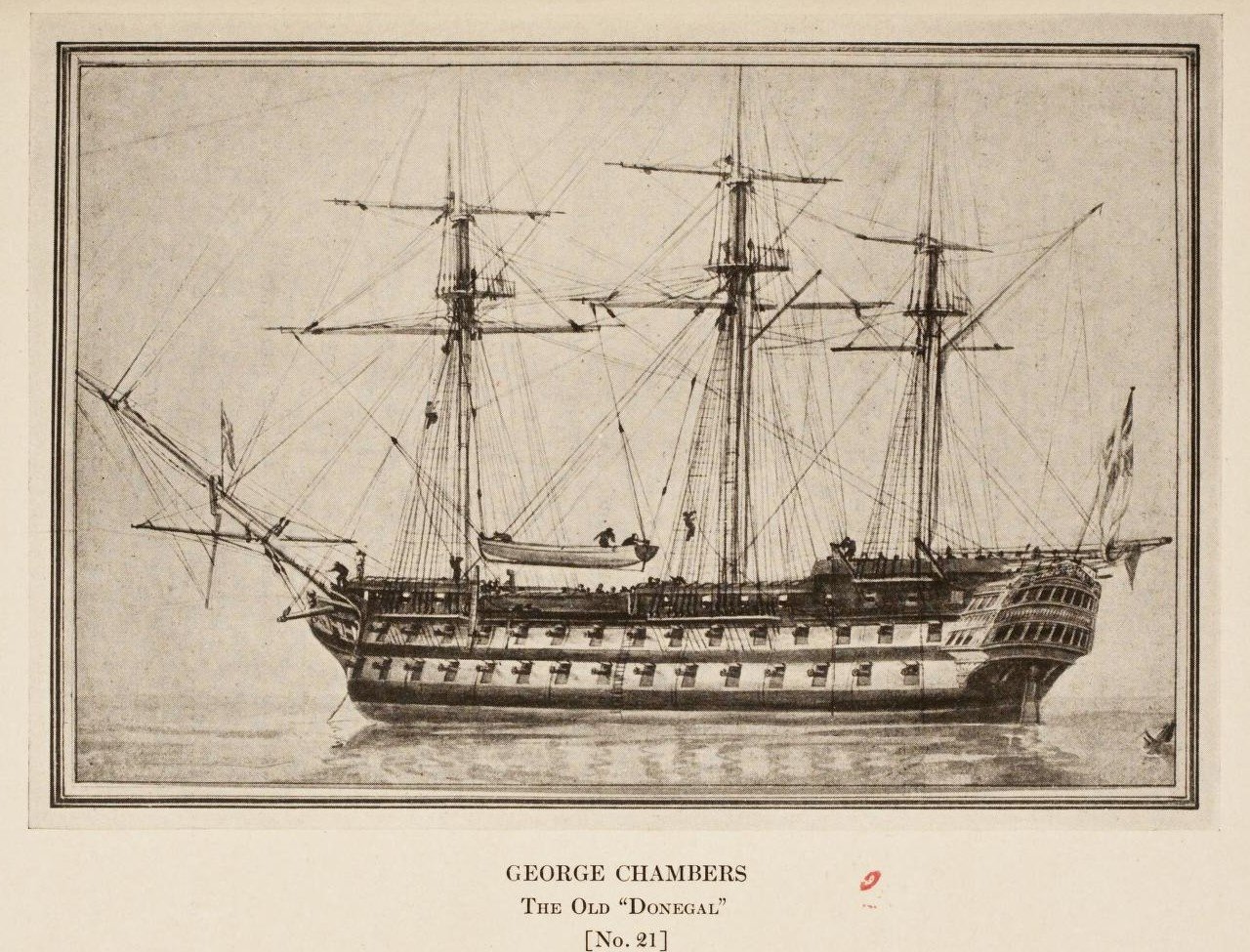

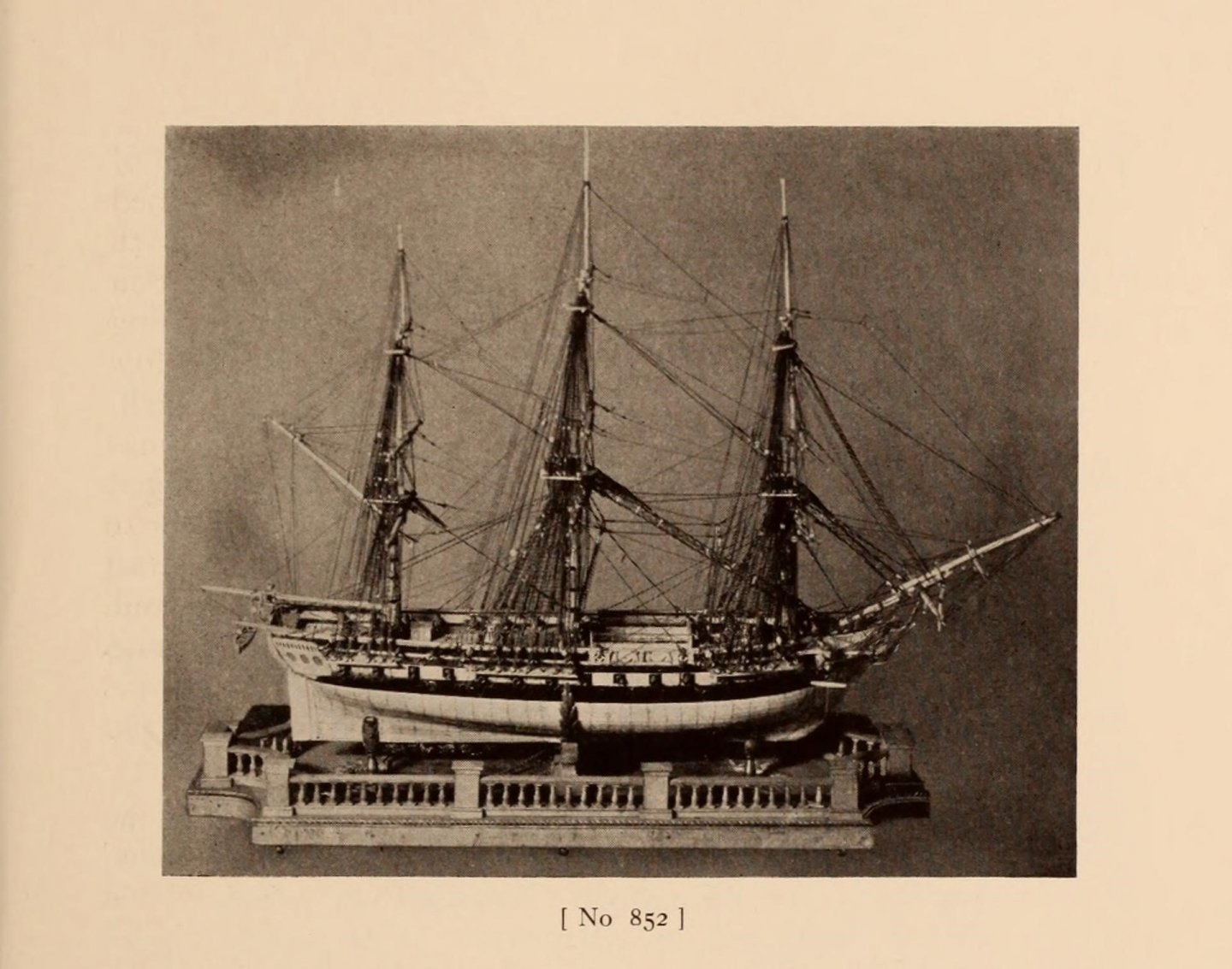

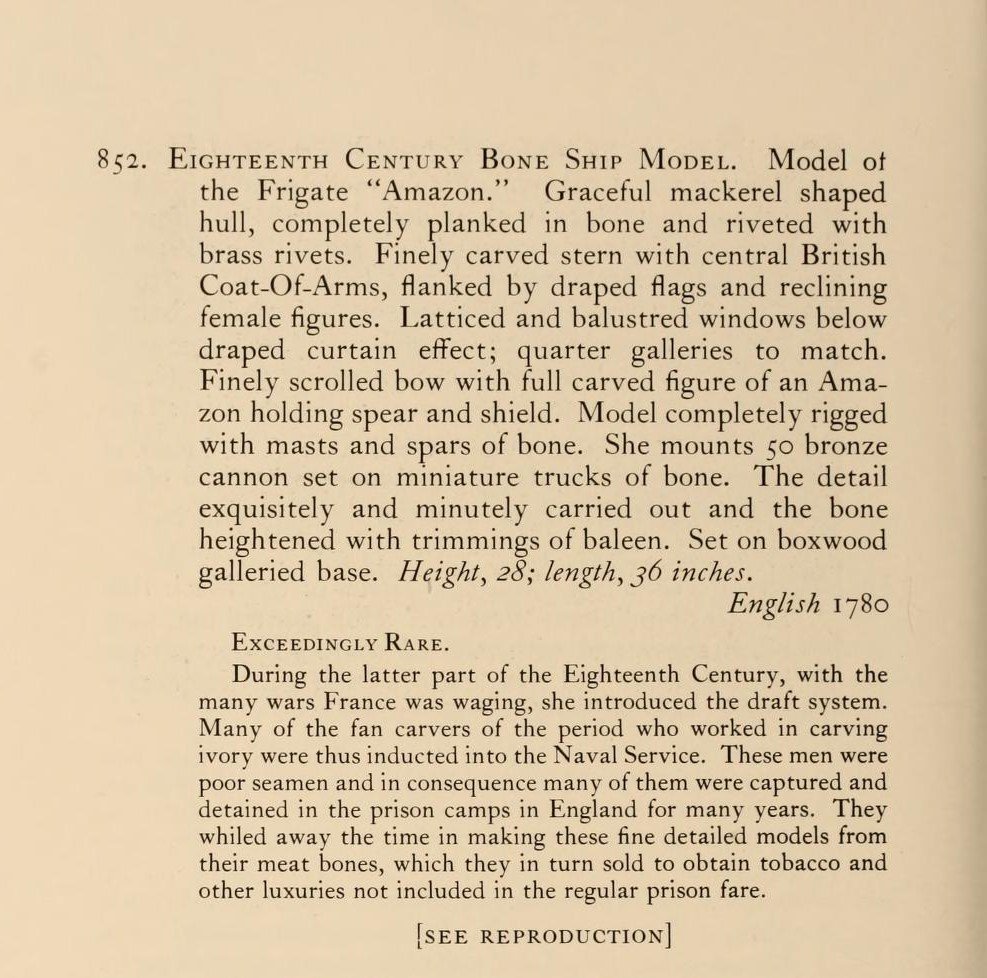

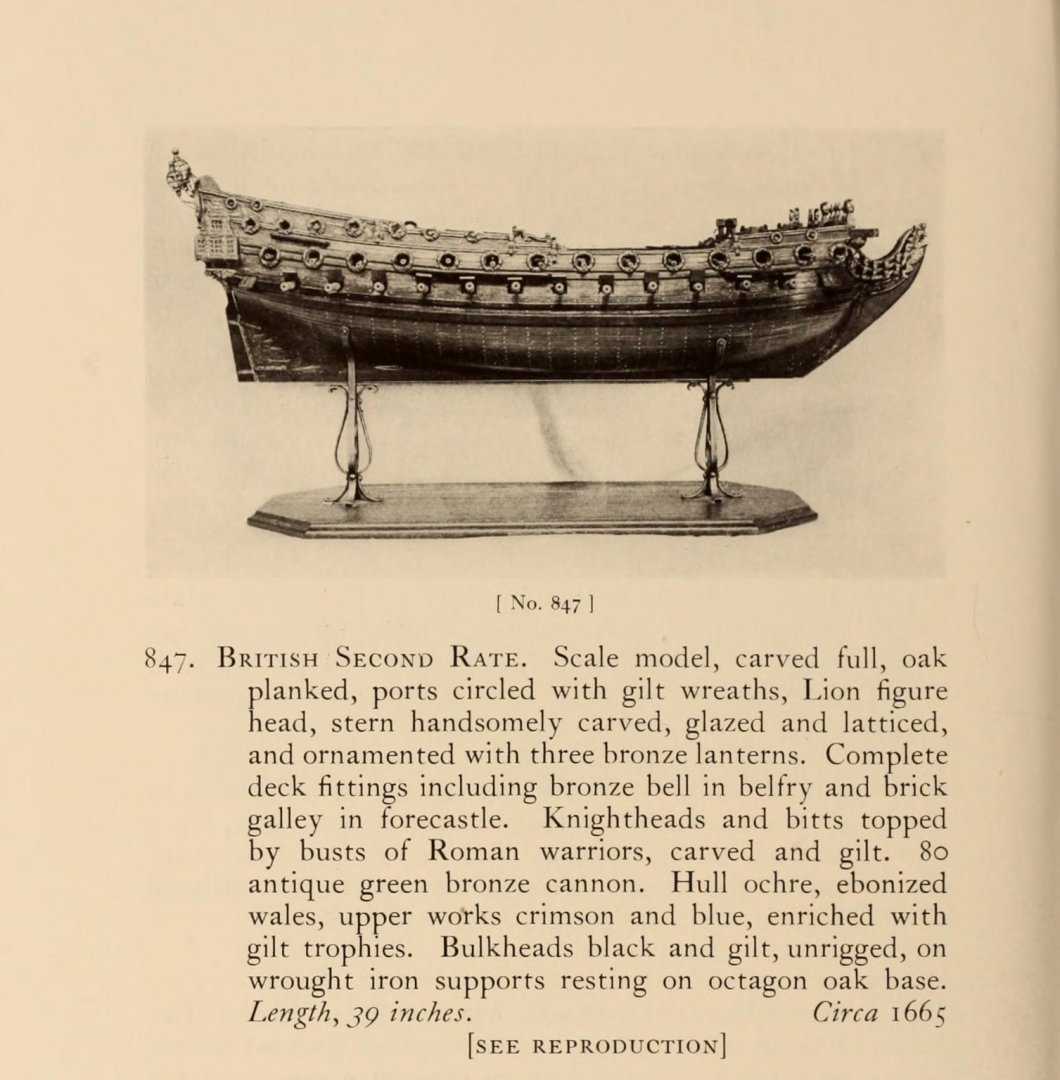

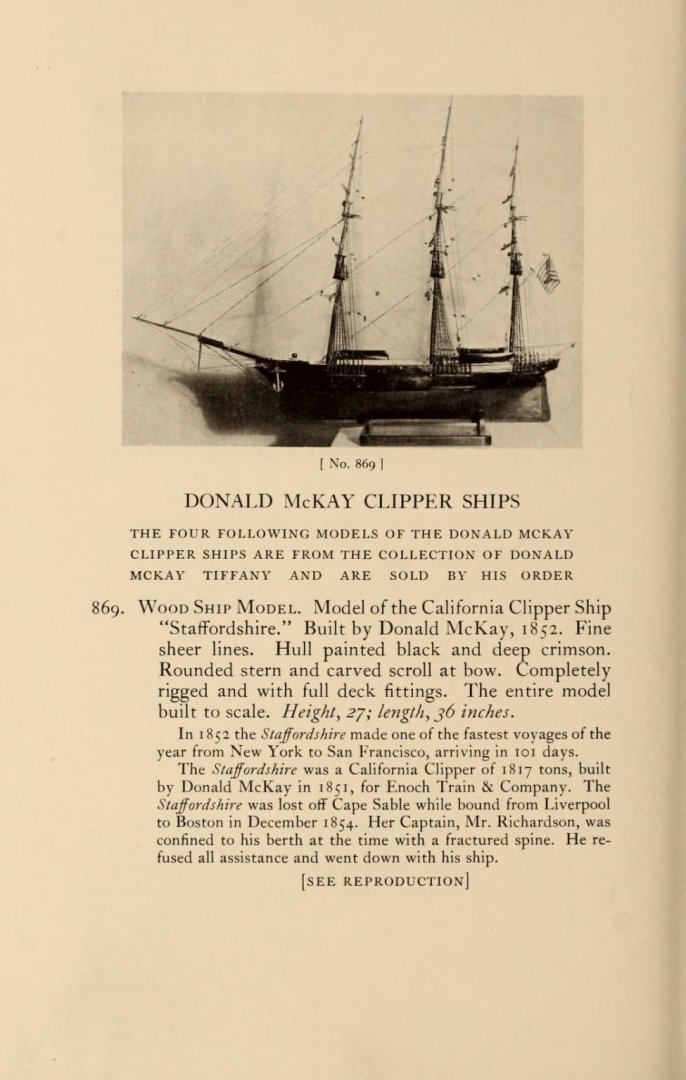

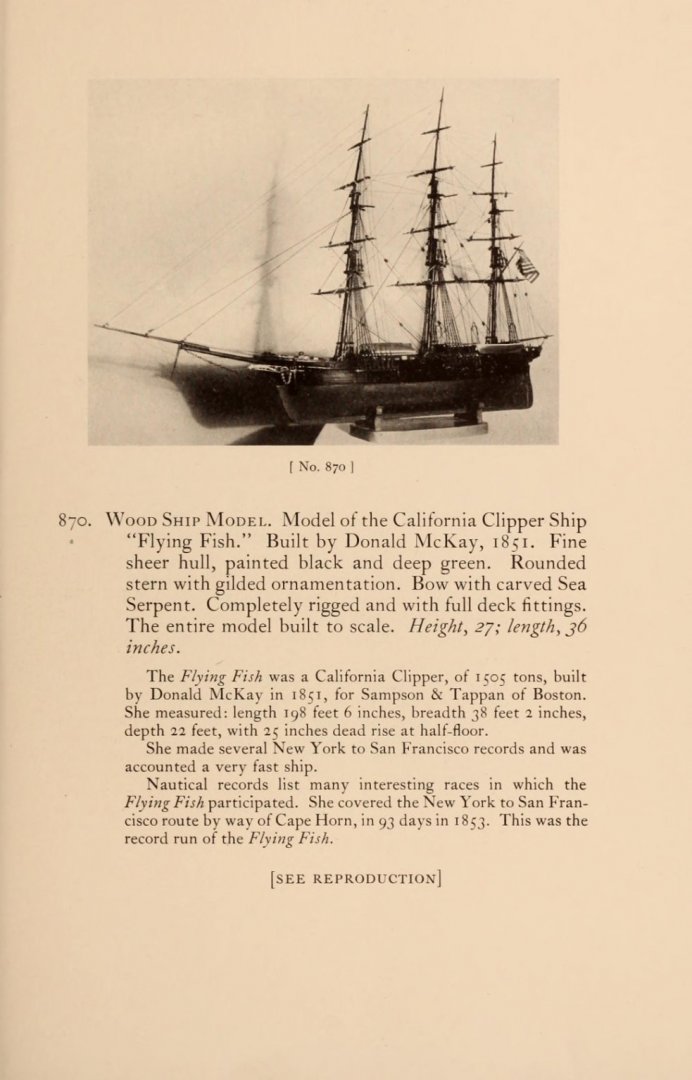

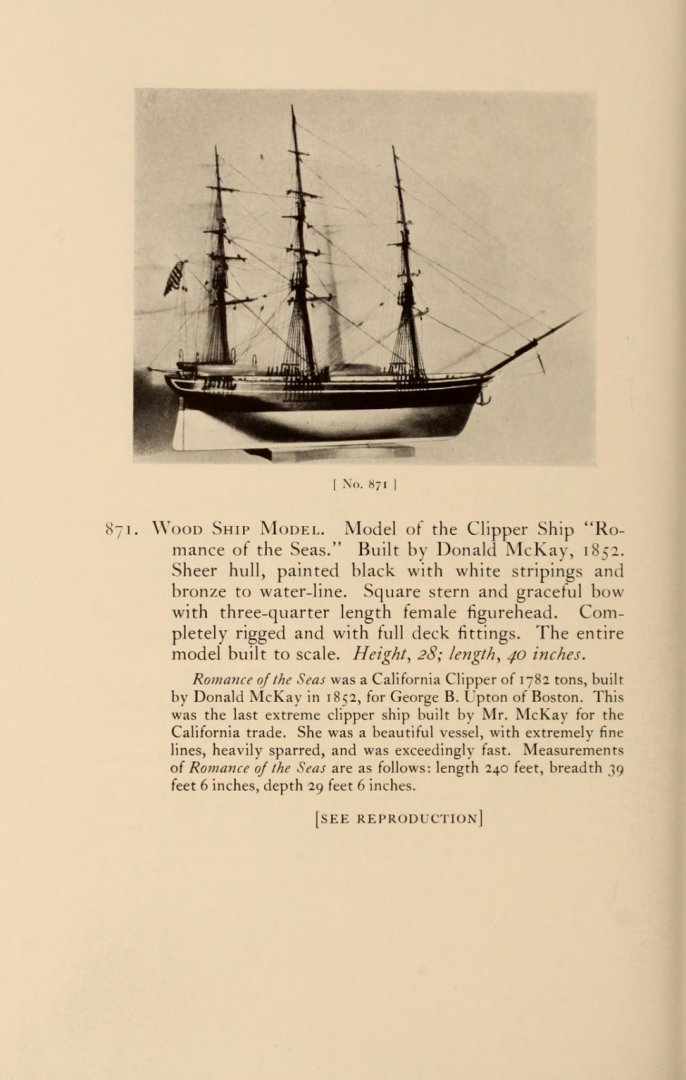

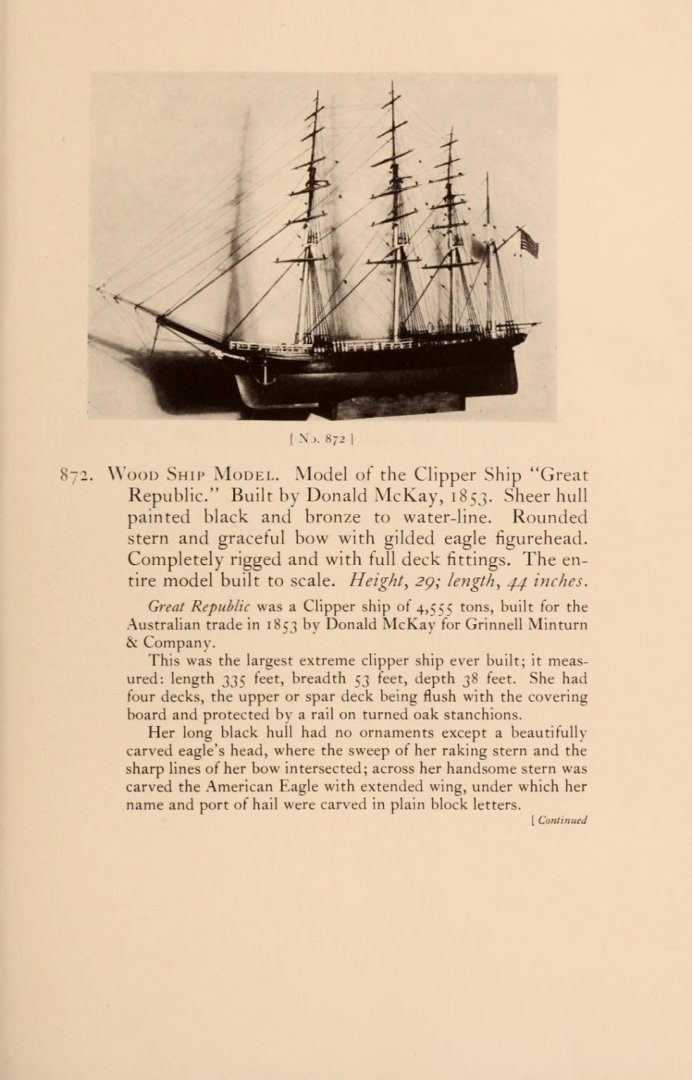

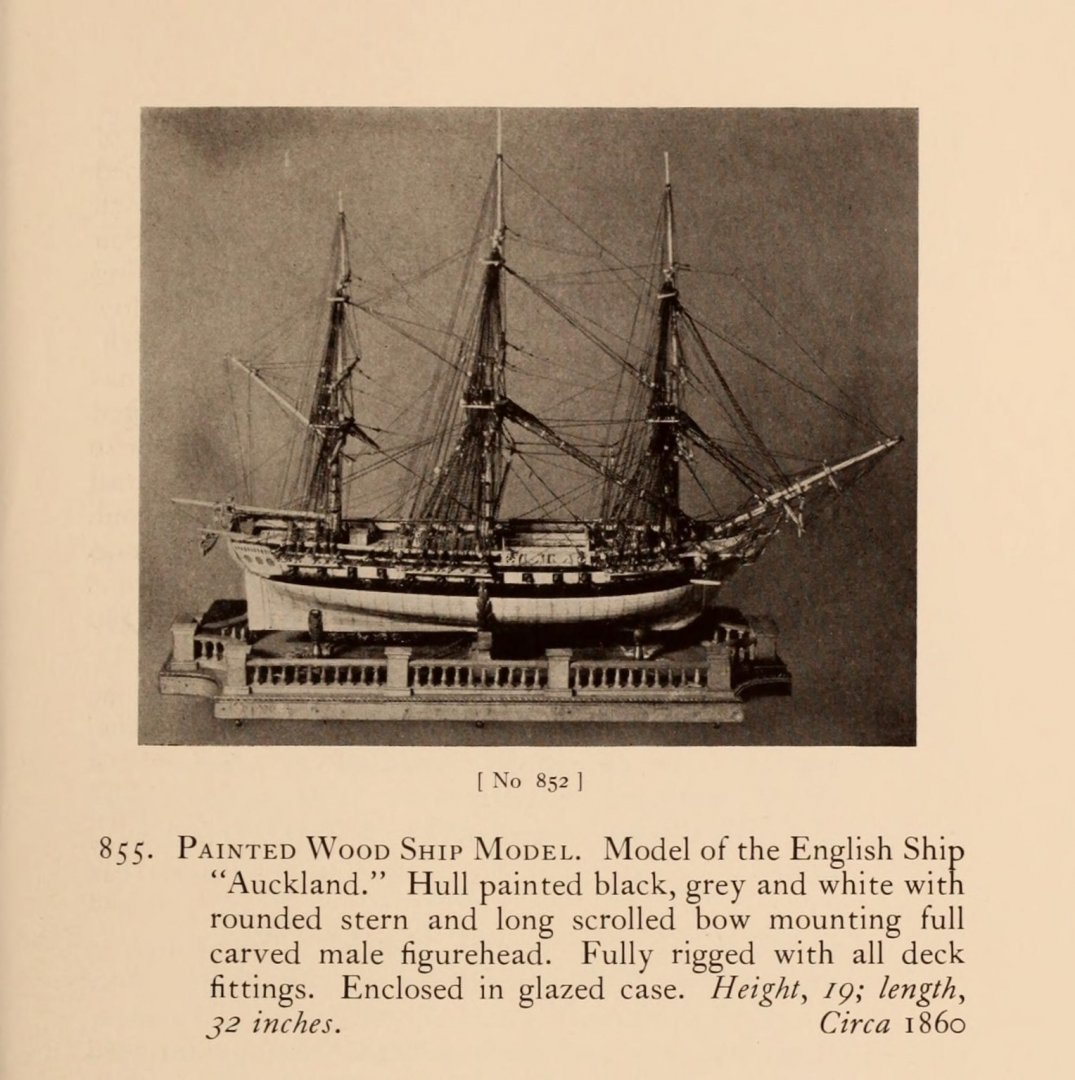

A 1926 auction by the American Art Association included several nice model. Here are some of those illustrated in the catalogue. Amazon Described as British second rate circa 1665: Four models from the McKay collection: Staffordshire Romance of the Seas Great Republic Aukland:

-

Welcome to MSw from Sussex. Good looking models, looking forward to a build log. ✔️ Bruce

-

Evening all - first post

bruce d replied to TheNavyWouldNotHaveMe's topic in New member Introductions

A warm welcome to MSW from Sussex. Your models look good, hope to see more. -

Quite right. Victor, you will fit right in here at MSW. A warm welcome from the UK. The models look great, can we look forward to seeing a build log?

-

Platts eyot - Historic maritime site destroyed by fire

bruce d replied to Kevin's topic in Nautical/Naval History

Not going to 'like' that one, but thanks for bringing it up. That is sad, sad news made worse by the loss of one of the Dunkirk Little Ships. I used to go there and I can tell you the image of 100 firefighters + equipment using that footbridge is scary!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.