-

Posts

3,046 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by bruce d

-

Nice job Mustafa, looking forward to the next one.

- 54 replies

-

- mantua

- santa maria

-

(and 1 more)

Tagged with:

-

Hello George, What a great subject, well done. I saw an image of something similar on Thassos a few years ago but there was no date. I will watch if you don't mind? Καλή τύχη Bruce

-

La Real by sotter - 1:150 - from Dusek plans

bruce d replied to sotter's topic in - Build logs for subjects built 1501 - 1750

Looking good, mind if I watch? -

They are invaluable. Also, they are cheap: https://www.proopsbrothers.com/modellers-hobby--craft-kit-plastic-parallel-slide-clamp-130mm-x-50mm-large-3092-p.asp ... and available in smaller sizes... https://www.proopsbrothers.com/modellers-hobby--craft-kit-plastic-parallel-slide-clamp-75mm-x-40mm-small-3095-p.asp Their ebay store has multi-packs of 5 and 10 at discounted prices. I have no connection with Proops other than being a long term satisfied customer. HTH Bruce

- 395 replies

-

Hi Thomas, sorry for the delay in answering but it looks like you chose well. Your progress is good and you seem to be doing all the right things. The stern looks better after you thinned it down and the stem (that piece at the bow) looks alright to me (but I haven't seen the plans ). The stem is quite a big part of the distinctive appearance of these craft and I have spent quite a bit of time finagling the stem pieces on my Mediator.

-

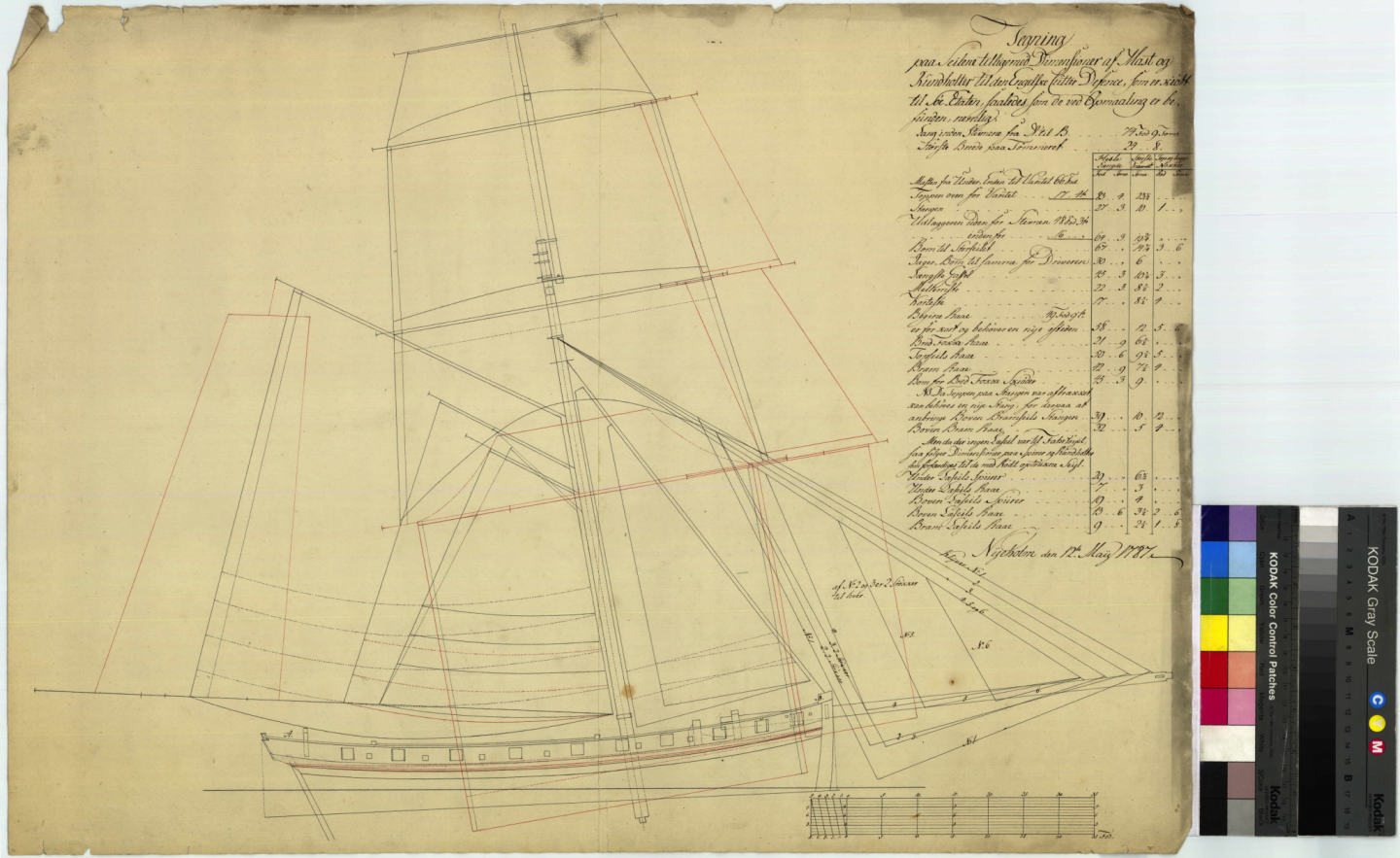

Yard height on 18th century Cutter

bruce d replied to michaelpsutton2's topic in Masting, rigging and sails

Hi Michael, Actually, the cutter is English, purchased by the Danes. Since starting this thread ... ... I have narrowed things down a bit more. There are a couple of files which I believe will help once I can return to The National Archives (I don't have the guts at the moment). HTH Bruce -

OK, have a look at this and compare the end grain of your wood with the examples in the video. If your walnut is quartersawn, you should be able to get good slices off the narrow edge. If not, you will have to experiment. Based on my own experience, and I am no expert, you will know pretty quickly if thin planks from the narrow edge are going to be any good. HTH

-

Hi Thomas, looking good so far. Just another unsolicited bit of advice: choose your filler to match the hardness of the wood surface. If one is harder than the other, sanding will be much more difficult because each stroke will remove more of the the softer material (whether it is the wood or the filler) and leave high spots and low spots. On the curved surface of a hull, the effect is even more pronounced. If anything, go for a filler that is softer than the wood. HTH Bruce

-

Yard height on 18th century Cutter

bruce d replied to michaelpsutton2's topic in Masting, rigging and sails

-

Chronos have very good aftersales service.

-

Thanks Mike, keel update soon. If it is of interest, here is the link to the thicknesser used for the tapering: HTH Bruce

- 43 replies

-

- mediator

- first build

-

(and 1 more)

Tagged with:

-

Depends what you want to do with the saw. Chop off saws are good at, well ... chopping off. The Proxxon FET saw ... https://www.chronos.ltd.uk/product/proxxon-fet-table-saw-240v-210576/ ... is pretty good at most small tasks that suit a conventional saw-table. I have one, it is consistent and once you get used to the fence and mitre seems well suited to a modellers typical needs. It also of course can chop off wood using the sliding mitre. You will undoubtedly hear that the best saw on earth is a Byrnes saw: I am sure this is true. Sadly I do not have one so can only say that so far I have been satisfied with the Proxxon. HTH

-

Welcome to MSW

-

Always looking for problems solved by others before I come to them in my build. Good luck and maybe you could ask if the numbers relate to some linen industry standard? That seems to be the case but I'm guessing.

-

Hello Mike, I think this fits the description ... https://www.linladan.com/products/the-flax-flower-hemstitch-yarn?variant=21884453748841 ... for the 874 but no sign of the 870. HTH

-

Hello Slowhand, just looked properly at your log for the first time. A very interesting subject and the way you are keeping your cool while navigating the what-scale-is-it-today game is admirable. I will follow along if you don't mind? BTW, my Scheppach bandsaw only had one weak spot: the tyre wear which never made sense. The UK after-sales support was always first class. I have now upgraded to a Metabo BAS261 simply because I needed to do some bigger stuff.

-

I love MSW. It has yet again made me think. So here is my question. If two pieces of wood are to be glued together, and one of the surfaces has been painted with acrylic paint, which glue gives the best result? Part two of the question: what if one surface has paper glued to it? (big hint: scarf joints, edges of planking)

-

By following this suggestion you will find the results of your wood, your glue and your sanding/scraping materials. All three affect the outcome and you may find that you just don't like carrying out a particular process despite liking the results other builders have produced. I sympathise, and a few experiments with the scrap wood from your kit will tell you a lot.

-

Laying out plans in a smaller workshop

bruce d replied to alde's topic in Modeling tools and Workshop Equipment

I admit when I got the first one I was wary of this but (maybe luck) mine stay put unless given a good wallop. -

Laying out plans in a smaller workshop

bruce d replied to alde's topic in Modeling tools and Workshop Equipment

My workshop has absolutely no floor space left so I couldn't use an easel as intended. The solution was a piece of 1mm steel sheet from the local blacksmith (£5) screwed to the wall above the workbench. It is big enough to take A1 size plans and magnets do all the work. For what it is worth, I have a policy of never putting shelves above a workbench (ask me how I know what can go wrong... ) and am very pleased with this arrangement now that it is in place. The picture below was taken immediately before beggining work on my Mediator and I assure you the bench does not look so clear now but the wall is unaffected by events below. A new trick I discovered: a short steel ruler is now always stuck on the plan with magnets, always there when I look for it. Also, the small LED lights with magnetic bases originally for use on the mill and bandsaw are very handy to attach in any position above the workbench so I am ordering a further one, a bit bigger. HTH, Bruce -

Prynhawn da pawb - (Good afternoon all) from Wales!

bruce d replied to SweepHall's topic in New member Introductions

Welcome to MSW, looking forward to the Bounty. -

Welcome to MSW!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.