-

Posts

564 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Robin Lous

-

I kindly disagree with brass being the better choise. Aged brass still looks yellowish, while aged copper looks more brown. the green copper oxidation comes very close to the green bronze oxidation. Imho copper is the better choise to work with, or at least...I tried to do it with brass and I wasn't happy with the results. I'll start with an oil and blowtorch treatment...inspired by my Titleist Vokey Oil Can wedges (golf clubs). Always welcome to help me empty a bottle of Cognac.....or any bottle for that matter. Yes...I shake the bottles (paint...not cognac!) until it start to hurt my wrist...and a bit more! A good way to speed this up is to hold the bottle in one hand and slam the bottom of it hard with your other hand...several times. Robin

- 473 replies

-

- greek bireme

- dusek

-

(and 1 more)

Tagged with:

-

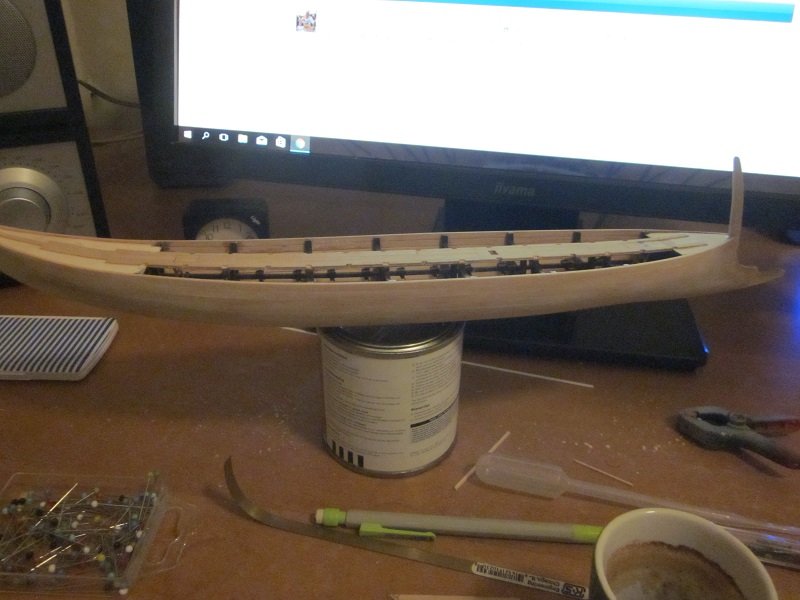

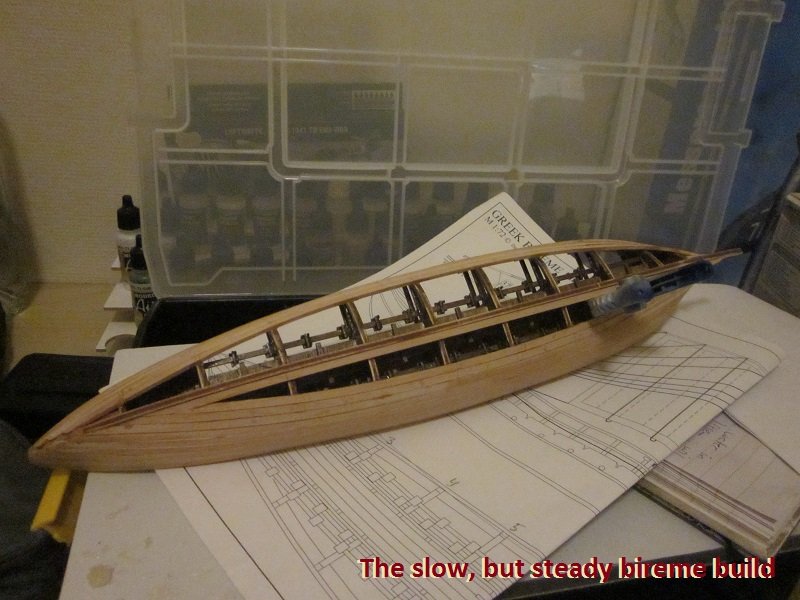

With the hull planking done (it's finally a ship!), I'll now continue with making the (planked) forecastle. Final news... The Admiral picked up the 0,15mm thick copper sheat for me, so I can start experimenting with...how to make copper look like bronze. For the ram btw. Not yet designed, but I have ideas about it already. So...next will be the forecastle. A neat little project I think. More soon, Robin

- 473 replies

-

- greek bireme

- dusek

-

(and 1 more)

Tagged with:

-

Lovely! The wood - white - black colour combination looks great! Robin

- 44 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

Nah...not after several layers of wood stain and a final layer of varnish. Not sure I do a bathtub test when I finished the hull, but it is tempting!

- 473 replies

-

- greek bireme

- dusek

-

(and 1 more)

Tagged with:

-

It's a Dutch brand I think...Alabastine. It's a wood paste, available in several wood colours. Meant to fill small gaps, holes and cracks in furniture. A bit too thick to use for the small gaps we have to deal with, so I thinned it down with a little water. It works well and it's easy to sand smooth again. It dries very quickly, but still need to wait a few hours before sanding. Robin (working on the last 2 planks atm)

- 473 replies

-

- greek bireme

- dusek

-

(and 1 more)

Tagged with:

-

Thanks and....tough luck! I still must do the few remaining planks on the other side, but I won't post about those. With a busy week...it will take at least until sunday before I can start working on the "in between" drop in frames. Treated myself with a new Proxxon toy for that...the DS 230/E Scroll saw! More soon, but it will take time. Robin

- 473 replies

-

- greek bireme

- dusek

-

(and 1 more)

Tagged with:

-

Planking trials and tribulations are history now...only a few near the keel on one side, but I won't bother you guys about those. This was the part that scared me most, so it feels good I managed to do it. When I finished the other side, I'll protect it from dirty fingers and other woes with cling foil...and move to the next step. Several nice things to do next. Finish the deck planking, make the "in between" frames I mentioned before, stain the inside of the hull, drill the holes for the lower oars, start with the rigging attachment points, the forecastle, centre deck railing, wale(s), rudders, ram...and more! A whole score of jobs I'm looking forward to. Funny...I hardly need the plans or manual. Much of what I do next is scratch build or heavily modified...and those plans are bubbling in my head for 2 months by now! More soon! Excited! Robin

- 473 replies

-

- greek bireme

- dusek

-

(and 1 more)

Tagged with:

-

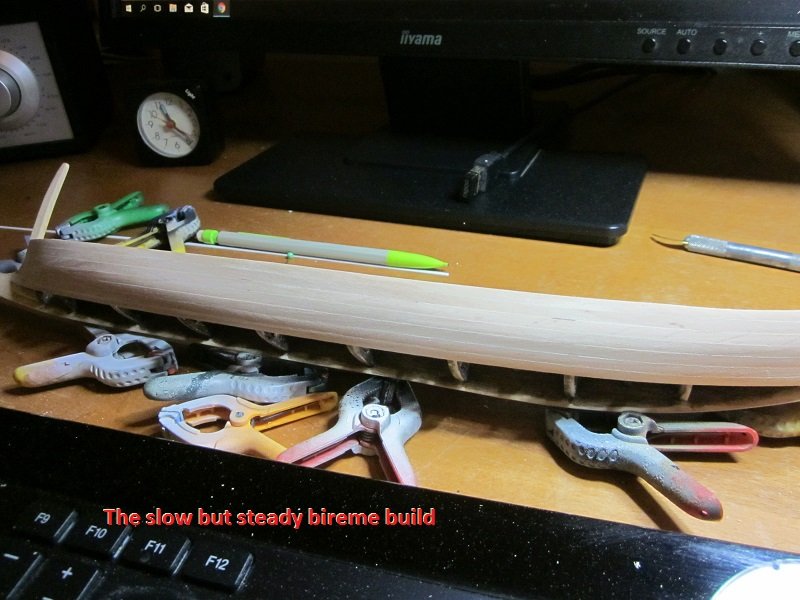

Oh that sounds all too familiar! But so far the Admiral here is in full support of my wood adventure...she even asks about the progress I make. Never happened with plastic! Although...today I had to explain why her white blouse got ruined by a dirty steam iron. Tip: always clean the iron after you use it for plank bending! Robin

- 305 replies

-

- deagostini

- vasa

-

(and 1 more)

Tagged with:

-

Oh dammit! as if the monthly Christmas isn't enough already! Nice stuff you got there. Robin

- 305 replies

-

- deagostini

- vasa

-

(and 1 more)

Tagged with:

-

Glue efficiency (most useless topic ever!)

Robin Lous replied to Robin Lous's topic in Modeling tools and Workshop Equipment

I just won't tell my sailors the ship is a floating bomb, but I'll put up a few no smoking signs -

Glue efficiency (most useless topic ever!)

Robin Lous replied to Robin Lous's topic in Modeling tools and Workshop Equipment

How a topic posted just for fun and for no purpose whatseover...can become quite interesting Cheers guys! Robin -

Ah well...never a dull moment with a Riva Robin

- 414 replies

-

- riva aquarama

- amati

-

(and 2 more)

Tagged with:

-

I posted this photo of testing cherry wood stain before. Centre popsicle stick and the basswood plank test...1, 2 and 3 layers (sanded). I think it's a safe, but nice. Photo MIA The other colour is "dark smoked oak" it's too light for the pine tarred lower side of the hull, so I got myself a can of ebony wood stain instead.

- 473 replies

-

- greek bireme

- dusek

-

(and 1 more)

Tagged with:

-

There purchase records of Athenean (trieres) shipyards for large quantities of red and yellow ochre. Likely used to paint or decorate trieres (the ships...and/or the sails)...or maybe just buildings. nothing is certain. When things become uncertain or obscure...common sense and artistic freedom enter the scene I'll stick to wood staining. This will result in an orange wood tone. Something like the colour of the Argo penteconter reconstruction. So...I play safe Robin

- 473 replies

-

- greek bireme

- dusek

-

(and 1 more)

Tagged with:

-

I have no experience with Vallejo textile paint, but it sounds good...any textile dye will do I guess. Best make several test swaps before you do something you'll regret. Also worth trying...wash the painted swaps one or more times...to see what happens. A somewhat faded look can be very nice. Avoid overly bright colours. Try to mix red with brown and maybe a bit black for the darker stripes. When you wash dyed fabric with 2 colours...be careful...the colours can bleed/blend. To set textile dye...wash with water with some vinegar. Looking forward to your build! Robin

- 12 replies

-

- Painting viking sail

- Viking ship sail

-

(and 1 more)

Tagged with:

-

Glue efficiency (most useless topic ever!)

Robin Lous replied to Robin Lous's topic in Modeling tools and Workshop Equipment

-

Beautiful drakar! I like what you did with sails tied up and lowered yard. The way you kept the oars in line...nice idea! (I might copy that ) Robin

-

Yet again...thanks for the peptalk gents! I slowly get the hang of the planking job.... It's maybe a small ship and considered a starter kit, but I don't think the planking is easy on this one. Of course it's my first and I have nothing to compare it to, but the hull has an odd shape. The raised stern and the bulbous bow make it challenging. Most planks need bending in both directions (bow and crook) and some need to be warped (twist). It's a lot of bend...fit...bend...fit...bend...fit, before a plank can go on. Careful bevelling is also needed and some panks are tapered near the bow. I doubt two finished Dusek biremes (not seen many) are planked the same way. Only 2 planks (each side) are oddball (woof! woof!) planks. Plank 5 needed too much tapering to make it to the bow...it ends halfway the forecastle, but plank 6 runs smoothly underneath and it won't be visible because it will be hidden underneath a wale. (sheer luck!) And the plank next to the keel. I needed a straight one there to neatly finish the bulbous bow. All other planks run from the stern to the bow...from the top to the keel. Looking forward to sand the whole thing smooth! And I was happy to find thin (0,15mm thick) copper sheet on the internet. It's for the ram sheating. I already have 0,15 brass sheet, but copper ages (forced) much much nicer...and with some magic it will look like bronze. That's pretty much impossible with brass I think. Getting there! Mind over matter! More soon! Robin

- 473 replies

-

- greek bireme

- dusek

-

(and 1 more)

Tagged with:

-

Decks look great! It's also nice to see the barrels came with blast bags. Well done Hasegawa! Robin

-

Glue efficiency (most useless topic ever!)

Robin Lous replied to Robin Lous's topic in Modeling tools and Workshop Equipment

Uhu (owl) is a German glue brand. The "Hart" is a clear, strong, fairly quick drying wood glue. Resistant to water, oil and grease. It was recommended by 2 nearby hobbyshops and a ship building guy I met in one of those shops. Being new to wood building I followed their advise. I also tried PVA, but I like this better. For ease of construction when planking on the frames I use the Hart in combination with the Zap a gap CA. Hold in place for a few seconds and done..no clamping needed. I was just wondering about the amount of glue I used, but for no real reason, other than. When I build plastic a small bottle of plastic cement seems to last forever. I use much more glue building wood. Easy to explain of course it's welding versus glueing. Like I said...I was just bored -

After weighting the tubes in use and new tubes....I used 28 grams of Uhu Hart and 4 grams of Zap-a-gap. The weight of my build is now...58 grams The Zap CA is pretty much 100% efficient...or at least hardly any waste. But the Uhu Hart? Much of it stays on the coctail sticks, glue tray, my fingers, pants, desk and whatever. Just guessing, but I think I waste at least 50%. So...on my ship...4 grams of CA and about 14 grams Uhu. How much of it evaporates when drying? I think it's about 50%....so 58 grams of ship is made of about 9 grams of glue and 49 grams of wood. Uhmm.....about 15% of the ships weight is cured glue. I was bored Robin

-

omg! The thought alone!...unbearable! I'll never start a Vasa, Victory, Vounty or Vutty Vark! (all big ship names start with a V, right?) I'll stick to things with oars More soon! Robin

- 473 replies

-

- greek bireme

- dusek

-

(and 1 more)

Tagged with:

-

Guys...I come from Planet Plastic...when you don't show something new at least once a day...you're MIA and probably dead. So...it feels a bit strange for me to not post something new daily. With wood things don't work that way, but I'm not used to that yet. 14 planks done...worked my bum off to get that done...but it feels like I did so little Sigh! Robin

- 473 replies

-

- greek bireme

- dusek

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.