-

Posts

6,706 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Keith Black

-

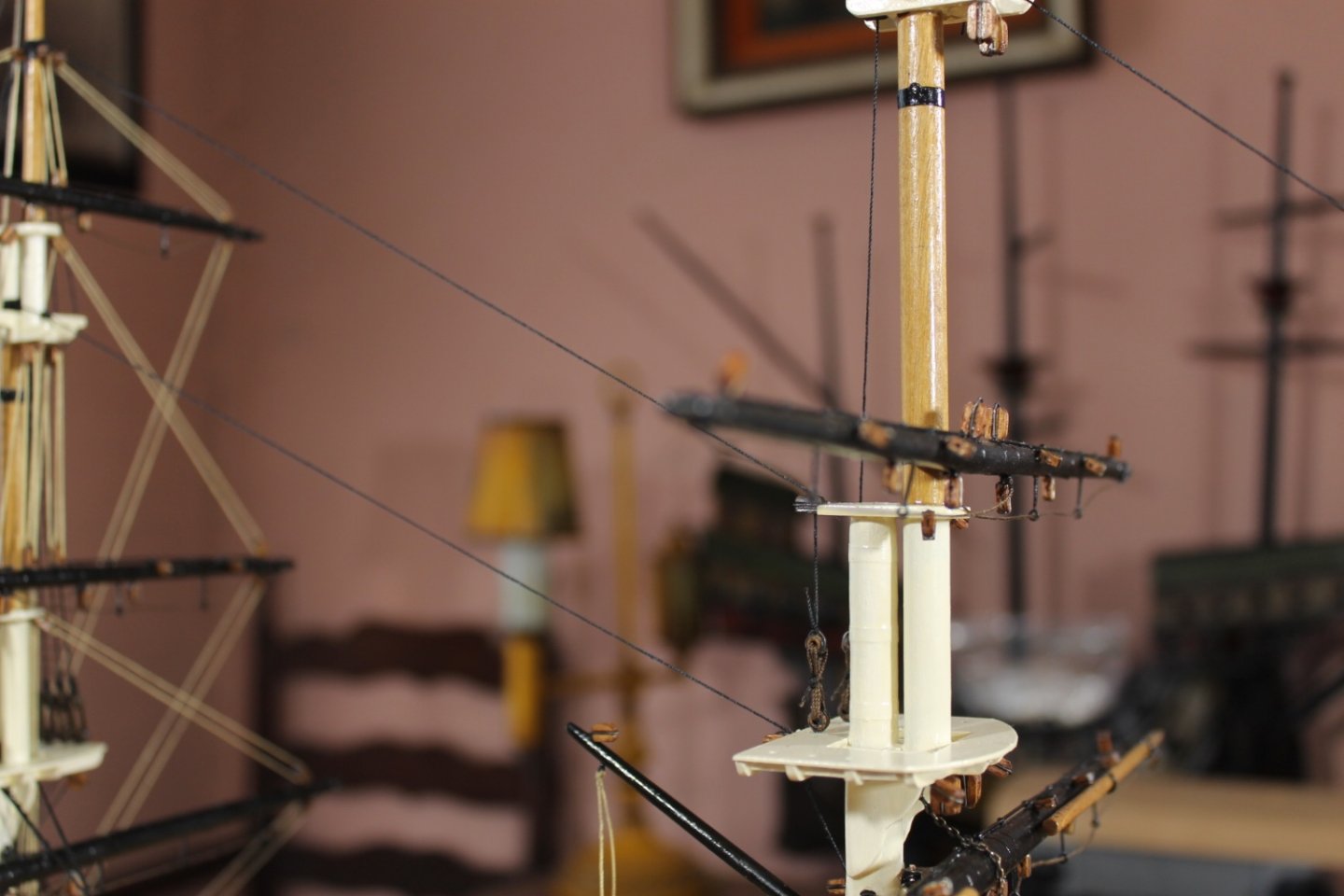

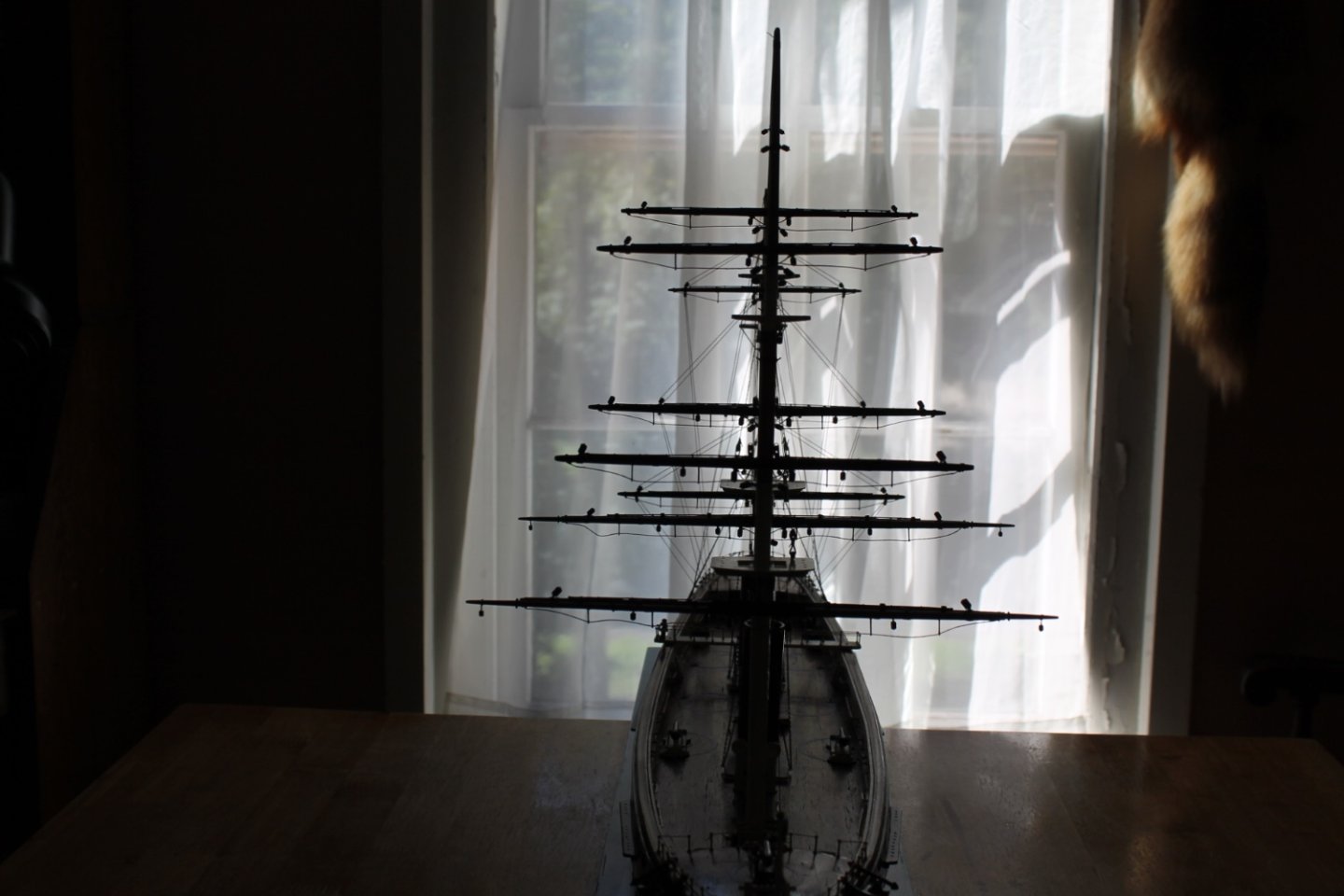

Mark and Andy, thank you for the photography tips and Lyle, Kevin, Keith C, Brian, KeithAug, and Gary, thank you for your kind comments. I finally got a decent photo of the bulls eyes albeit only one pair. This taken with flash, using flash seems to be the only way I can get a good sharp close up. When I enter the room I use as the shipyard, before turning on the lights and starting work, the Tennessee greets me silhouetted in one of the south facing windows. There really are nine yards, the mizzen topsail is eclipsed. God bless and thank you to all for the likes and for following along on my journey.

-

11 anni di modellismo d'arsenale

Keith Black replied to MICHELE PADOAN's topic in New member Introductions

Michele, welcome to MSW. Your work is beautiful, glad to have you aboard. -

jake, welcome to MSW. Glad to have you aboard.

-

Keith C, in this instance I agree. Forgive me as I'd gone brain dead regarding navigating in extreme northern climes.

-

Graig and Keith C, the problem I'm having is understanding how the helmsman could take advantage of the compass if the compass wasn't in his line of sight. I equate driving a car without being able to see the road with the ship's helmsman steering the required compass heading (road) without being able to see the compass? If he's dependent on the navigator to relay a "three degrees port" command to maintain course seems awkward at best. Steering to a needle makes much more sense to my pea brain. I do apologize for being so thick headed about this, I'm just having a difficult time comprehending the arrangement of having a navigator acting as a middle man relaying course corrections. If you guys are sick of hearing me yap, just say so because I'm getting tired of hearing me yap.

-

I guess this means no penguins, lions, tigers, and polar bears.

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

Craig brings up an interesting point that I've always wondered about. How often was the compass or compasses checked? If compasses were set to either side of the ship's wheel as in the case of the Tennessee, they were constantly monitored. But if a compass is stowed inside a cabinet or in an out of the way location, how often was it checked? If there wasn't a compass at the ready I would think the course would have been more zig zag than in a straight line which would have added sailing time to a voyage. I suppose that a lot of course correction would have been dependent on the direction of the wind and how steady the wind blew from a given direction. So, was the compass only checked when the sails were reset to accommodate a change in wind?

-

Glen, congratulations! That is so cool and you managed to stuff a herd of Longhorn in there too. Wait a minute, WAIT A DOGGONE MINUTE, your next project..........the Ark!

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

Giuseppe, welcome to MSW. Glad to have you aboard.

-

NAIAD 1797 by Bitao - 1:60

Keith Black replied to Bitao's topic in - Build logs for subjects built 1751 - 1800

Bitao, each new post is more impressive than the last. Your model is a testament to your skills as both craftsperson and artist. -

Congratulations, Glen. She looks right smart and right at home, perfect.

- 194 replies

-

- Bottle

- Treasure Fleet

-

(and 3 more)

Tagged with:

-

Jerry, welcome to MSW. Glad to have you aboard.

-

I love the BBC show Escape to the Country, what part did she settle into, Keith? The mast work is beautiful.

-

See page 7 of the below link and note the binnacle on the left was used by the British Royal Navy in 1839. The base was 18 inches square and 24 inches high. http://www.balogh.com/binnacleflyerad.pdf

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.