-

Posts

686 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by lb0190

-

I wrote it and erased it two times... Mabe after I finish this beer.

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

I keep biting my fingers in effort not to comment on this topic. One time I was at the National Muzzle Loading meet in Friendship Indiana and..... NO, NO I cannot do it, must run as fast as possible form this topic....

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Hi Popeye, I found a saw blade for my x-actor handle but to the teeth were too course and ripped the wood. I hope to find another saw blade with more TPI. I recall having one many years ago, but recent searches have been unsuccessful. YES! You do need another beer and in effort to help you I'll drink one (or maybe two) all in the unselfish interest of helping one of the Niagara club members!

-

Thanks Sjors, When I started this method, I was not too sure how it was going to turn out. I thought about cutting short individual planks and staggering them, but eventually realized the deck is so busy, that level of detail would not be noticed be many. I'm satisfied with the current outcome, so it's full steam ahead...

-

Hi Rich, I started out mounting planks the entire length, but eventually realized I was torturing myself doing this. Since most of the runs were eventually cut for the gun ports, a little voice in my head told me I could cut the planks into three or four more manageable lengths providing the ends terminated over a gunport. The dremel really helps save sanding time, but one slip and what did I do!

-

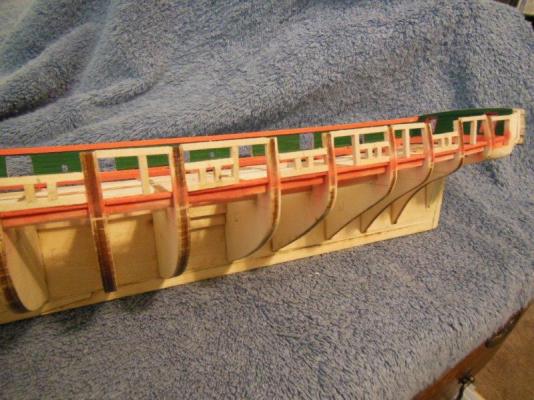

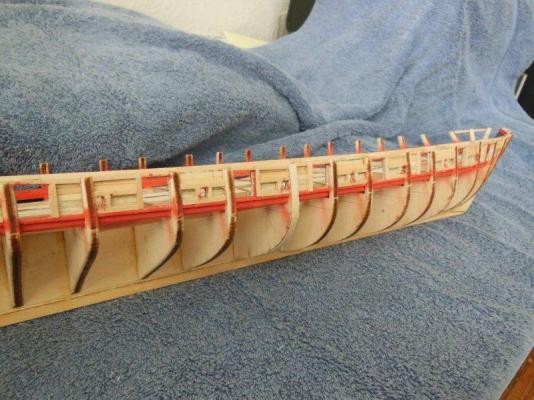

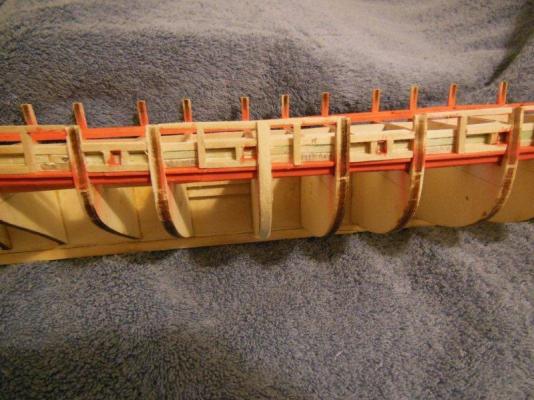

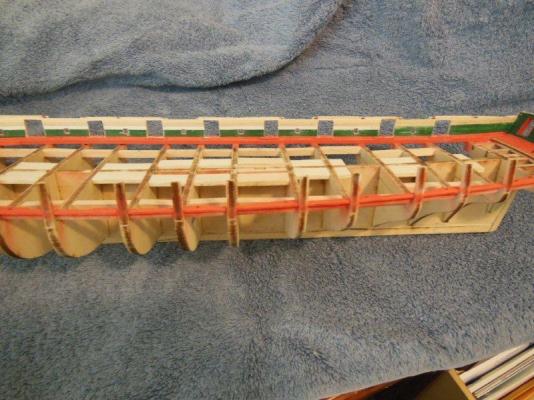

Yesterday I started cutting out the port-side gunports. I thought I would show the process I'm using. Once the inboard bulwarks are planked and primed, I use a rotary tool with a pointed cutting bit. This allows me to plunge cut into planks and hog out the majority of wood. The bit can grab the wood and dig deeper than intended if you do not keep a firm grip. After hogging out the majority of wood, I use emery boards and jeweler files to remove the majority of remaining wood. I leave a small amount of wood that will be removed when I repeat this process once the hull planks are in place. This is also when I do the final squaring of the the port openings. Sweep ports are worked the same way, but I use a small needle bur grinder (as seen in the photo) in place of the bigger cutting bit.

-

Good morning Popeye, Thanks! The top plank is 1/16" and the lower planks are 3/64". Hopefully I'll finish glueing the bow planks today and start cutting in the gun ports tomorrow. I'm anxious to start planking the hull but a little nervous how it will turn out due to being single planked. If I have not learned anything else with this build, I now know the next kit will have a false deck, two layers of hull planking and wider planks! My biggest goal in life is to be able to enter a post in MSW without have to edit numerous times...

-

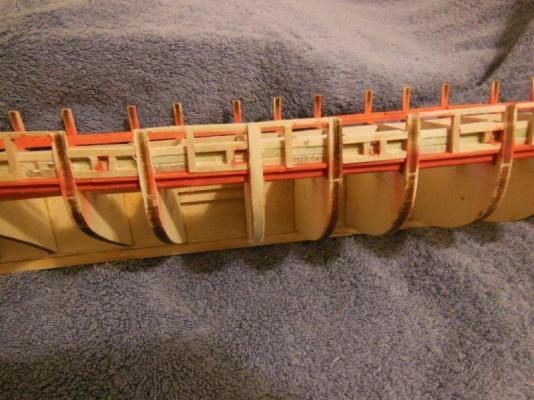

I've made some progress this week on the port side bulwark planking. I have a bow plank clamped in place and drying from being soaked in hot water. I hope to soak another plank tonight so I can glue the remaining two in place and then start cutting in the gun/sweep ports, followed by sanding, priming and painting.

-

Augie, One word comes to mind... Majestic!

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Hi Rich, Just thought I would drop you a short note to let you know I'm still thinking about you in your hunt for employment and still keeping my fingers crossed, plus I have an idea for your consideration. Most in-person interviews I've participated in eventually get around to asking what do you do for leisure, hobbies etc. Have you considered carrying photos or digital photos of your ship in varius stages of construction? In my opinion it shows a lot of positive attributes about the builder; patience, technical skills, craftsmanship, passion, research capabilities, dedication, etc.. While some of the above may not be directly related to the technical aspects of your line of work, it certainly says a lot about you as a person.

-

I used to always have a Far Side yearly calendar on my desk at work. It helped make an insane day bearable (no pun intended) Here is my favorite:

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Joseph, Your build is coming along very well. I suspect the toprail problem is a kit issue, but should be an easy fix. I'll have to do a trial fit to see if I have a similar problem. Adding the toprail really gives your ship a more finished and defined look. I agree with you on the gun/ sweep port framing being a challenge, but it looks like your doing a great job!

-

Augie, I have not posted much for a while but when time permitted I would quickly check in on your build. Your build certainly does inspire.

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Hello all, First, thank you for all of the well wishes. It's been quite a while since my last post and I've manged to get a little work done, so it's time to post a few photos. I'm 95% complete on the starbord inside planking. I have a lot of paint nicks to touch up and just general clean up work to do that I'll hold off on for a while longer. The gunports as well as the sweep ports need squared up but I'll do that after the hull planking is in place and the ports are cut in from the outside. I gave up on trying to air brush the inside planks and simply brushed on the paint. It was too difficult to mask off for spraying. I brushed on 3-4 very thin coats and the results were OK. My next steps are to frame in the port gun/sweep ports and then mount the inside port planks. Weather has been very hot, limiting my time in the garage, but mornings and evenings allow a few hours each day. I hope everyone is well and enjoying the season.

-

Hi Robbyn, You may also want to experiment with a small fan set to a low speed (and maybe at an indirect angle) to help move the fumes away from you.

- 773 replies

-

- san francisco ii

- artesania latina

-

(and 1 more)

Tagged with:

-

Thanks guys. Today has been better. My back issues are almost gone and I've managed to install a few planks. I'm at the point where I beleive installing the planks without paint is an easier process so long as the first plank (lowest one) is painted to provide an area to mask from. With a littler luck I'll have the starboard side planked this weekend and maybe some of the sweeps and gunports trimmed in. I'm learning a lot from from moving fwd on this side before framing in the port side. The port side should go together much faster (gawd, I hope I did not jinx myself)...

-

Today I reinstalled the plank I removed the other day, plus I sprayed three more planks that I planned on installing tomorrow. Unfortunately the spray results were awful. My airbrush is very picky about being very clean. The least amount of residual dried paint (as in specks hard to see) clogs it up and throws splatter. When it works right, it does an amazing job but the cleanup takes longer than the actual painting. I took a cleaning shortcut the last time I used it and apparently the airbrush gods were not too happy with me. It's not a big deal, I'll sand them down, repaint and then install. This will be another lesson learned, number 110,000,002. Well..., this week has primarily consisted of complaints, whining and a few expletives thrown here and there with very little ship building. Now that it's out of my system (almost out – still gotta fix those darn planks with the bad paint job) it's time for some fwd progress.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.