Jim Rogers

NRG Member-

Posts

1,381 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jim Rogers

-

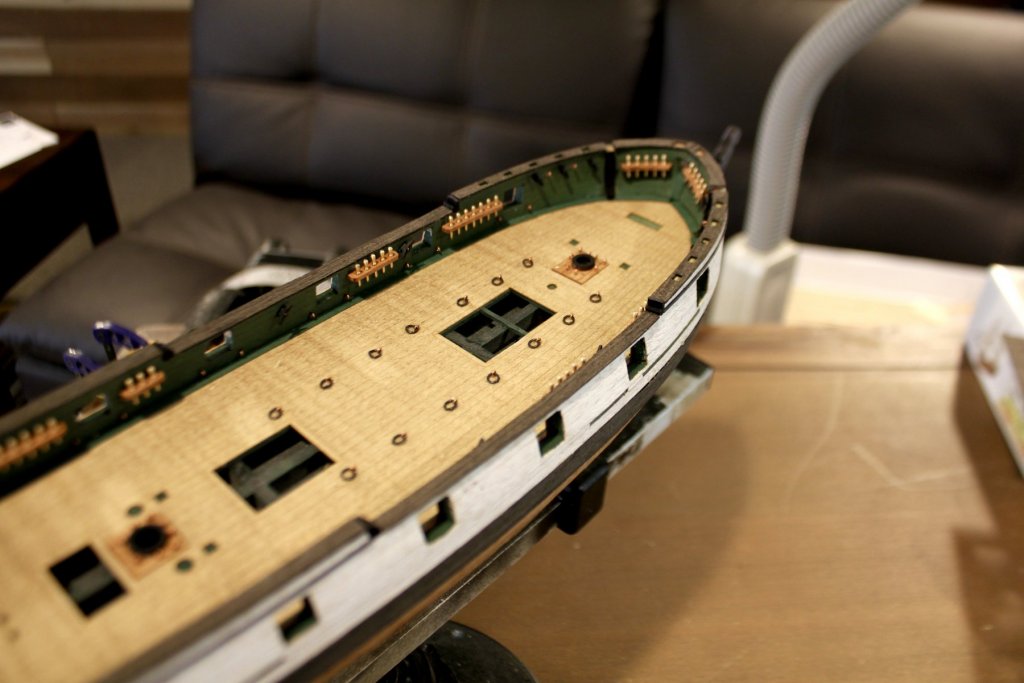

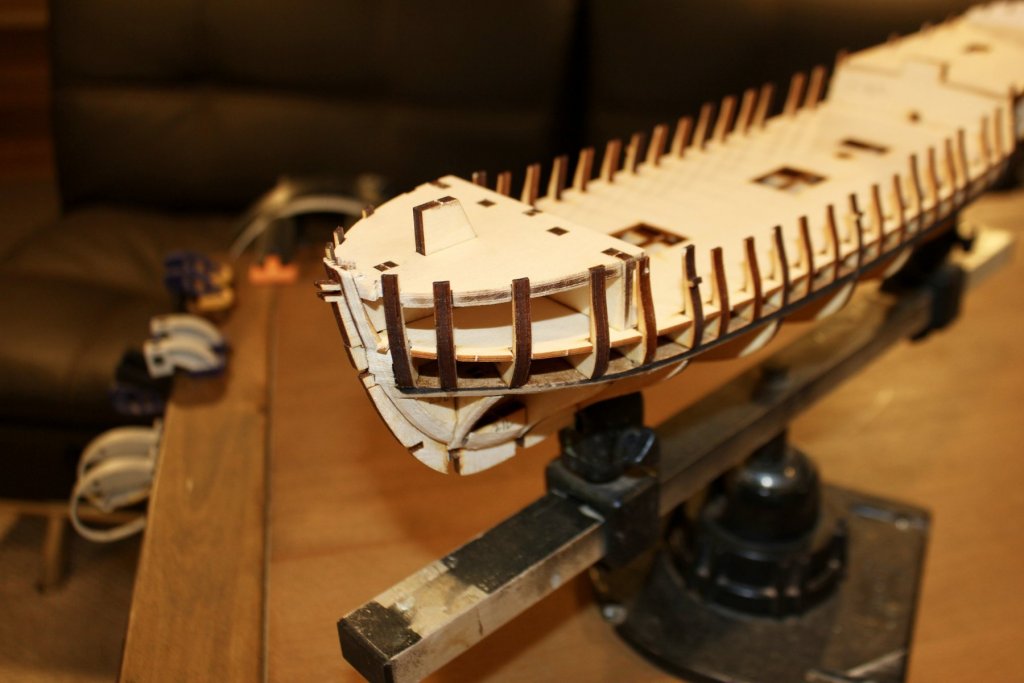

Update: 1. Finished Second planking 2. Attached interior and exterior veneers. Painted exterior a flat white and interior a flat green. 3. Got decks installed. 4. Received my Laser upgrade parts and got them installed. 5. Got belaying pin racks and pins installed. 6. Companion way and skylight installed.

-

Welcome aboard Richmond. You may want to look at Russian Manufacturer Master Korabel. They make a good product and I would consider them entry level.

-

Welcome aboard. Ships In Scale Magazine did an entire series on building that kit. You should be able to get the back copies. It will be a big help in your endeavor

-

Recommendations For A Good Milling Machine

Jim Rogers replied to Thistle17's topic in Modeling tools and Workshop Equipment

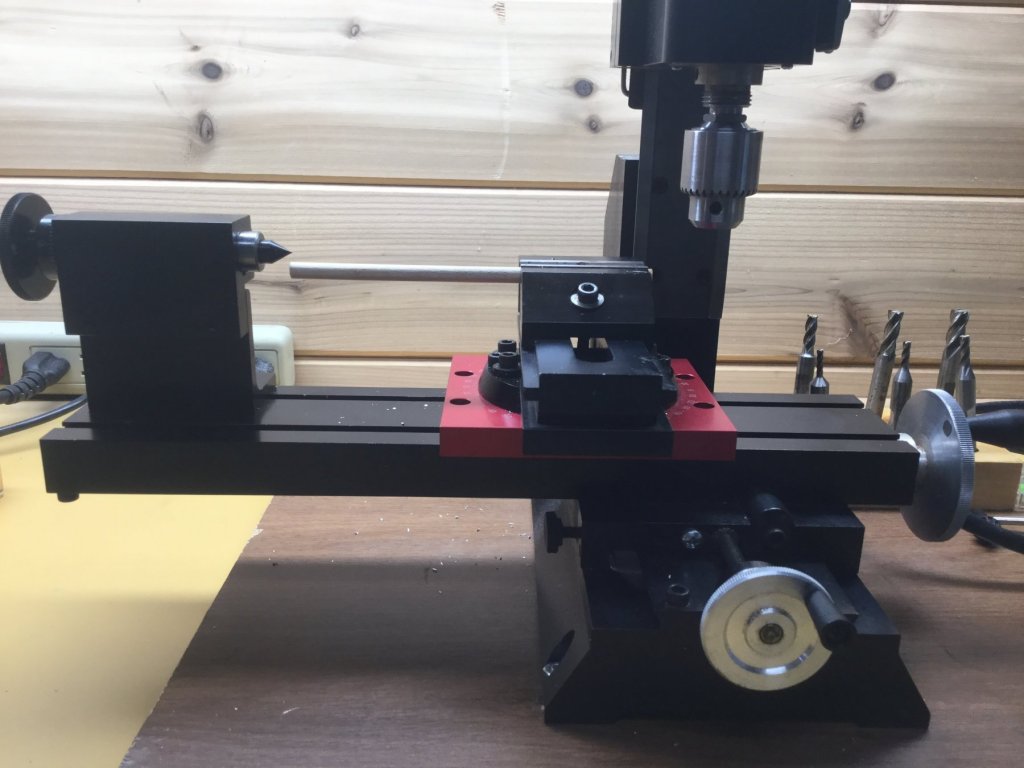

So I have received my Right Angle Attachment and my Rotary table. They send two L shaped useless brackets to use for mounting work. So do I get a drill chuck or 3 or 4 jaw set to hold my round stock? And is there something else I don’t know about that I’ll need to get before I can use this? -

Recommendations For A Good Milling Machine

Jim Rogers replied to Thistle17's topic in Modeling tools and Workshop Equipment

Got it. I knew I had something wrong. Ordering rotating table. -

Recommendations For A Good Milling Machine

Jim Rogers replied to Thistle17's topic in Modeling tools and Workshop Equipment

According to my communications and this photo sent to Sherline I am the only person to ever have this problem and they tell me they make no adapters to fix this problem. They told me to build an adapter. I find it real hard to believe they don’t have attachment to fix what appears to me to be a common issue. Right hand attachment plus rotary table with vise mounted on top does not align. Any suggestions -

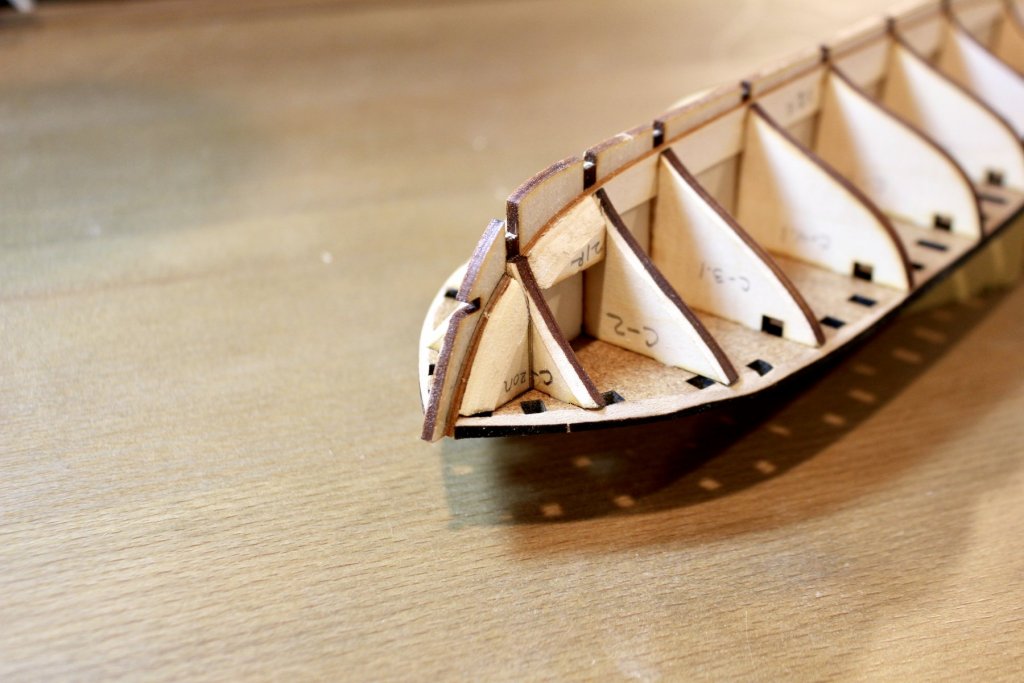

The decks and forward timbers are added next. During this operation you assemble a jig ( although it is not called this) to aid in lining up the forward timbers. It is called a conductor in the plans. The instructions have you remove it, wrap it in cellophane and reinstall after your timbers are aligned. I did this but really see zero reason. After the glue drys the forward timbers are really sturdy. Oh and they NEVER tell you to remove it.

-

One of the great benefits of the additional blocks comes during planking of the deck. Now you don’t have to be concerned about being over a bulkhead to attach decking planks as you have the entire surface for glue. I do this all the time, makes the build really sturdy.

- 119 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks for the history Viggen I love the context. Amazed how close my Model matches the museum model as I was just adding color where I thought color should be.

- 28 replies

-

- cannon jolle

- master korabel

-

(and 1 more)

Tagged with:

-

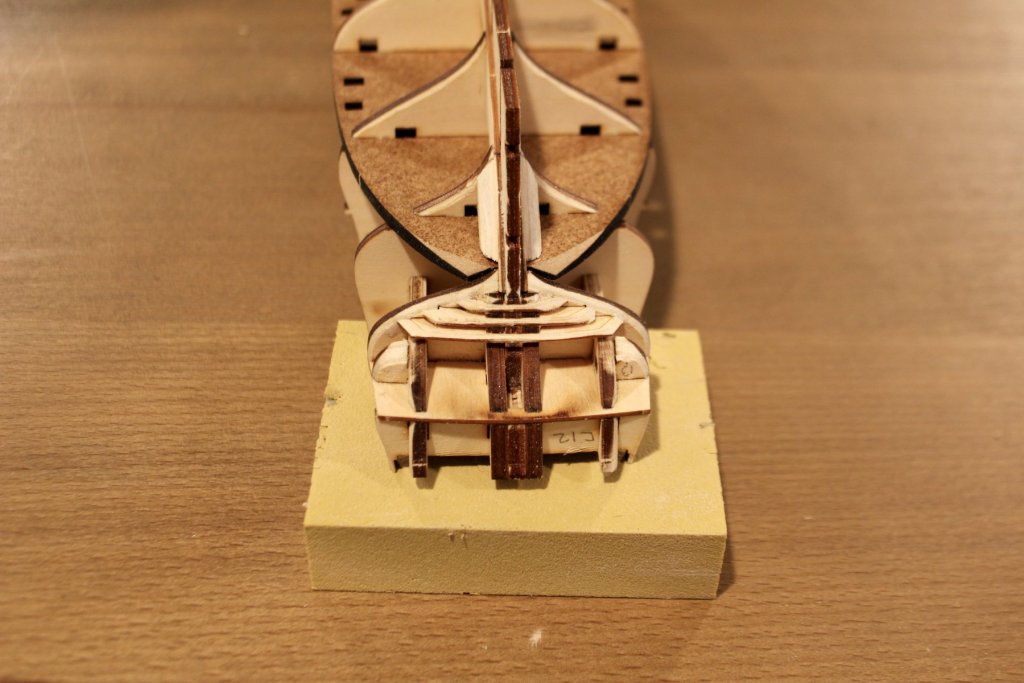

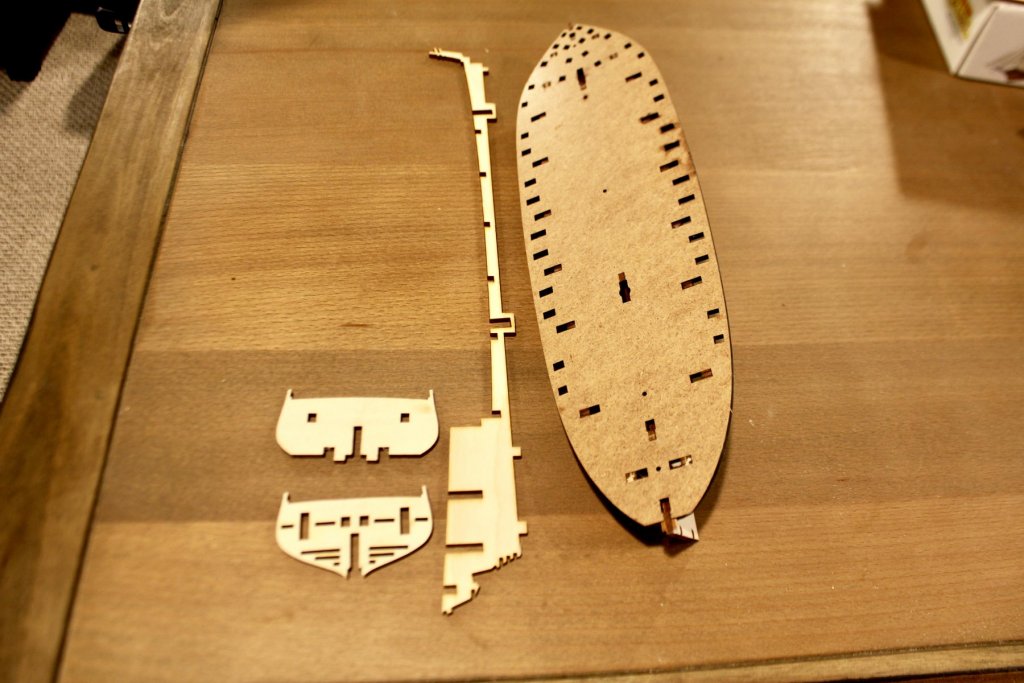

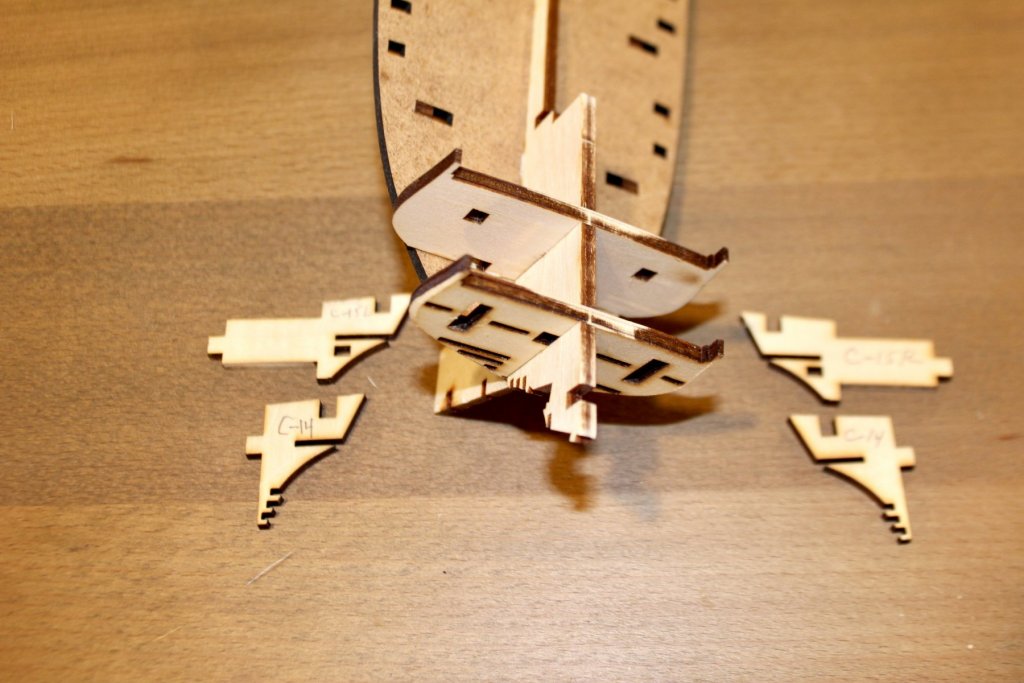

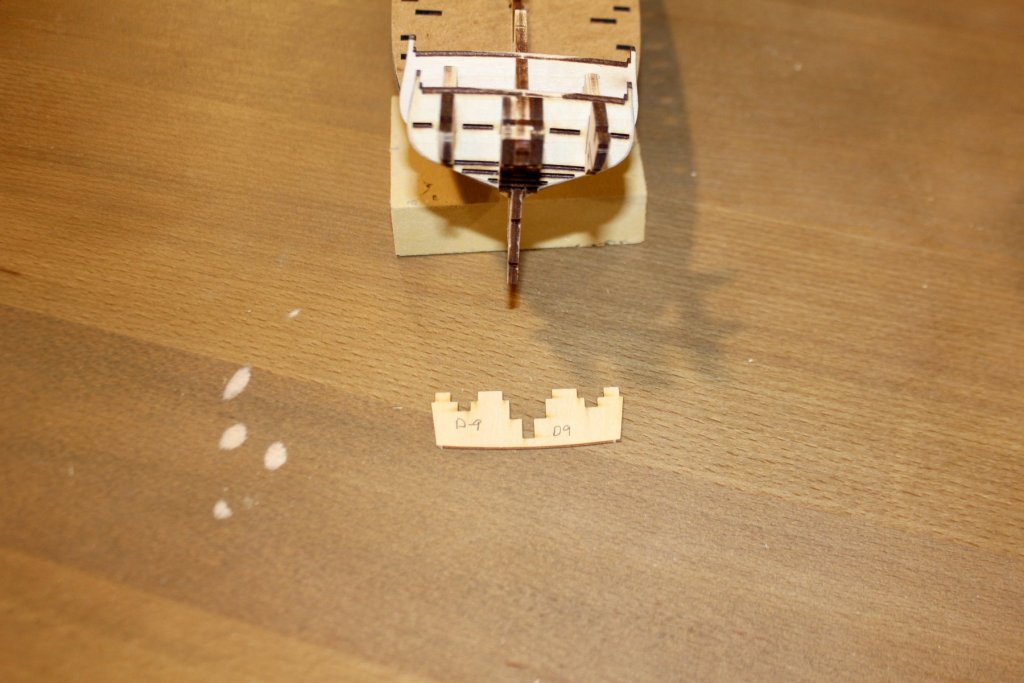

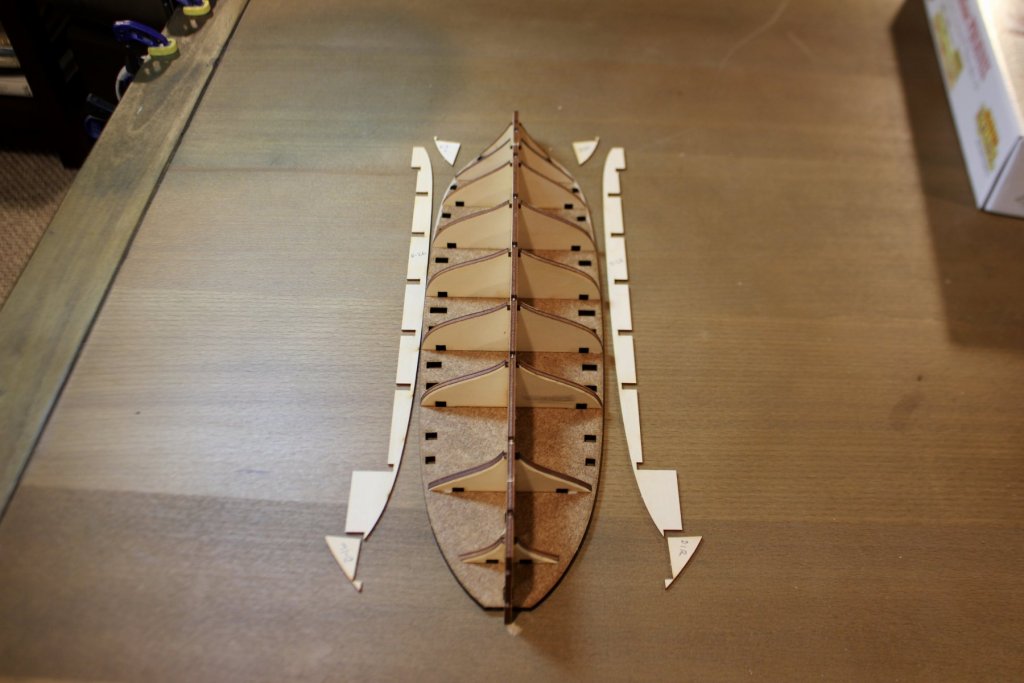

I am following the instructions so far. I have found one hiccup. You have to remove a chunk of the main upper support from the slot B9 goes in as it blocks the entire slot, but that is why we have Dremels. This is a nice little kit BUT you will learn ZERO skills that you don’t already have. Everything is cut so precise and fits so snug it goes really fast. I stop to let the glue set up otherwise I would be planking this puppy already. The figuring out what exactly they mean in the English translation can be frustrating. When I was mounting C9 they mentioned setting in a beam as in figure such and such. A beam means one thing to me a square chunk of wood, to them I finally figured out it was the upper support. I went through the box, examined each figure, tried to figure out where this elusive beam would go. Took a half an hour to settle on the upper support.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.