Jim Rogers

NRG Member-

Posts

1,381 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jim Rogers

-

Have to agree with Lou. Paint it flat black. Now would also be a good time to invest in an air brush and learn how to use it.

- 209 replies

-

- constitution

- revell

-

(and 1 more)

Tagged with:

-

Very,very reasonable. I have spent more for a lot less quality.

- 421 replies

-

- medway longboat

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I was a Torpedo Technician. I tested and maintained Lightweight Surface Torpedoes for 25 years active duty. Then I got hired on at Keyport, WA (Torpedo Town USA) and over the years got promoted to GS13 in charge of all the Torpedo facilities around the world.

- 367 replies

-

- model shipways

- niagara

-

(and 1 more)

Tagged with:

-

Yes that would be Torpedoman ‘s Mate Chief.

- 367 replies

-

- model shipways

- niagara

-

(and 1 more)

Tagged with:

-

Mix some of the Cedar sawdust with white glue and use that as filler. It will be sandable and same exact color. The other thing to remember is that parts on boats shift at sea so small gaps would be expected.

- 367 replies

-

- model shipways

- niagara

-

(and 1 more)

Tagged with:

-

I went online and had on of the vinyl label guys make one for me. Just chose the smallest font they had.

- 53 replies

-

- rattlesnake

- model shipways

-

(and 1 more)

Tagged with:

-

Oscillating Wonder Cutter

Jim Rogers replied to Jim Rogers's topic in Modeling tools and Workshop Equipment

$399.95 I’ll keep my number 11. -

I have found that anything you plan on painting metallic should be primed or painted white first.

- 209 replies

-

- constitution

- revell

-

(and 1 more)

Tagged with:

-

Oscillating Wonder Cutter

Jim Rogers replied to Jim Rogers's topic in Modeling tools and Workshop Equipment

It was advertised in a MicroMark email. I believe it is out of the start up phase if a company has it up for sale. -

Furniture looks great. I especially like the companionways.

- 145 replies

-

- model shipways

- charles w. morgan

-

(and 1 more)

Tagged with:

-

Has anyone used one of these?

-

Just type in Master Korabel and they come up.

- 216 replies

-

- masterkorabel

- ships

-

(and 3 more)

Tagged with:

-

These small boat kits are top of the line nice. I have built three of them.

- 216 replies

-

- masterkorabel

- ships

-

(and 3 more)

Tagged with:

-

Nice. I have been looking for figures going to give Amati a look.

- 48 replies

-

- 18th century longboat

- model shipways

-

(and 1 more)

Tagged with:

-

I usually seize the .008 to the top heart then run it through the bottom heart at least 4 times. I then take a toothpick and a small dab of CA to hold in place. Once it is set I seize the bitter end to the line running between the hearts.

- 242 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

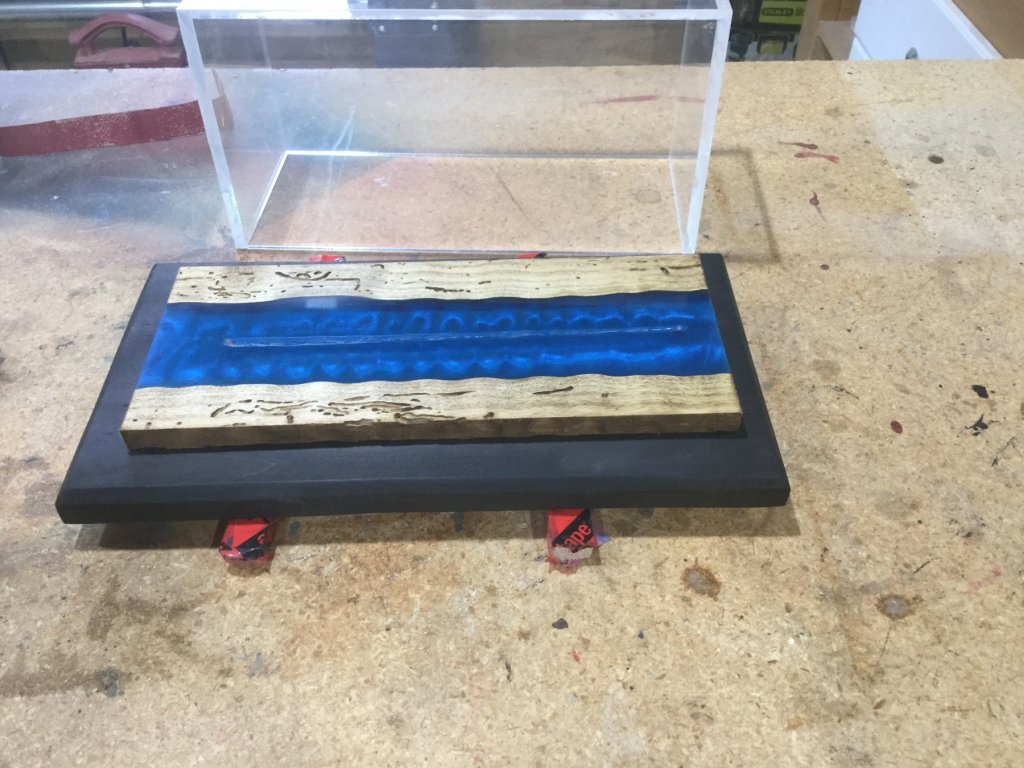

Sent it through the planer, polished it, mounted on blackened Maple, made acrylic case, added water action. Done

- 28 replies

-

- cannon jolle

- master korabel

-

(and 1 more)

Tagged with:

-

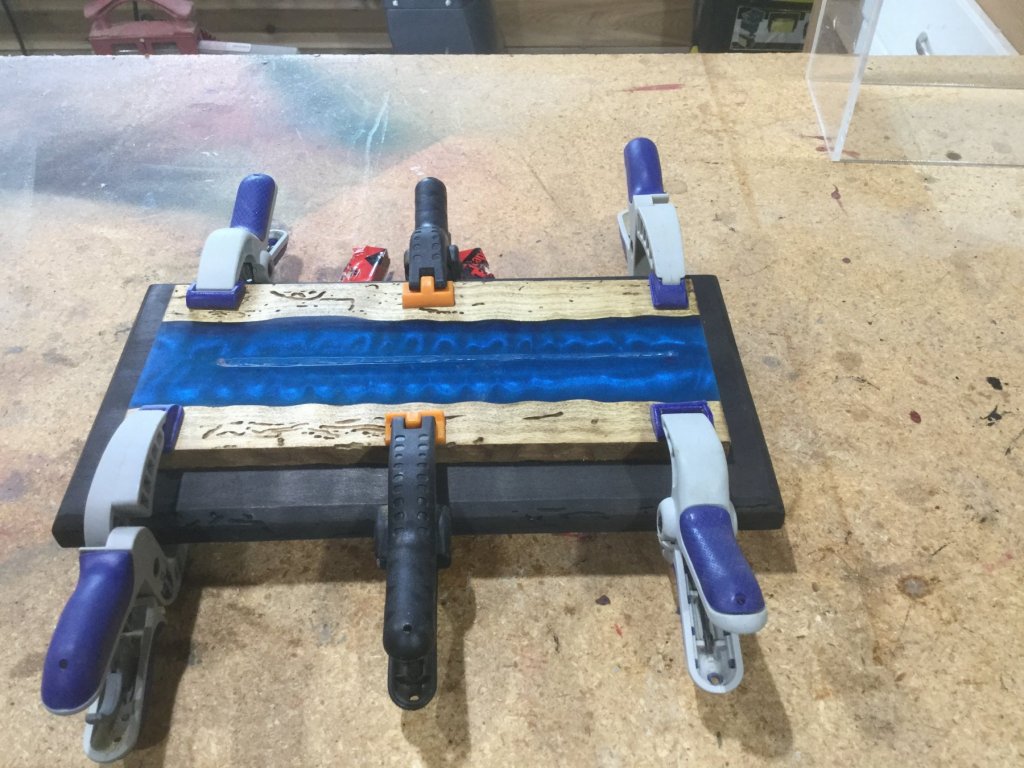

Lessons learned: 1. Don’t need the pre made groove. That is why God made a router. 2. When I poured the resin I brought right to the top of the wood. When I removed the clamps the resin had dropped about 1/8 inch. It has seeped under the wood. Next time I will mix a small batch and seal by painting it on between the bottom and the wood, and then pour the next day.

- 28 replies

-

- cannon jolle

- master korabel

-

(and 1 more)

Tagged with:

-

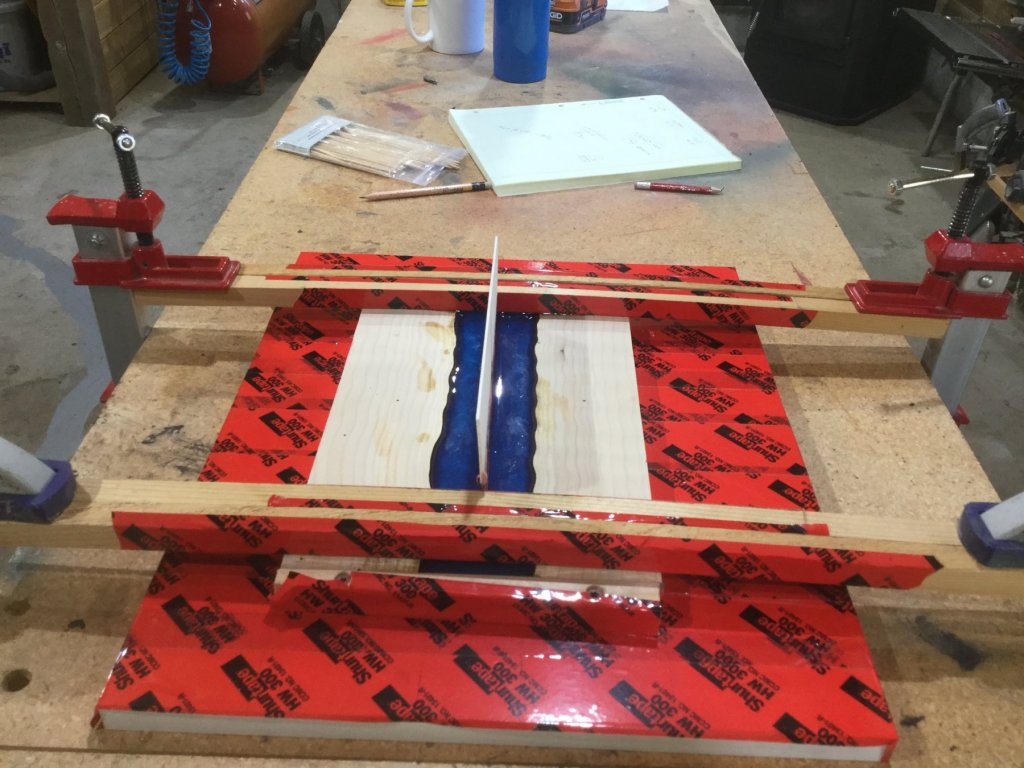

Next I laid it all out, checked clamping plan, and coated layout board with sheathing tape. The resin was mixed with Black Diamond Blue Cobalt powder and then poured. The sheet of wood in the middle is where the keel will rest. It is also wrapped with sheathing tape.

- 28 replies

-

- cannon jolle

- master korabel

-

(and 1 more)

Tagged with:

-

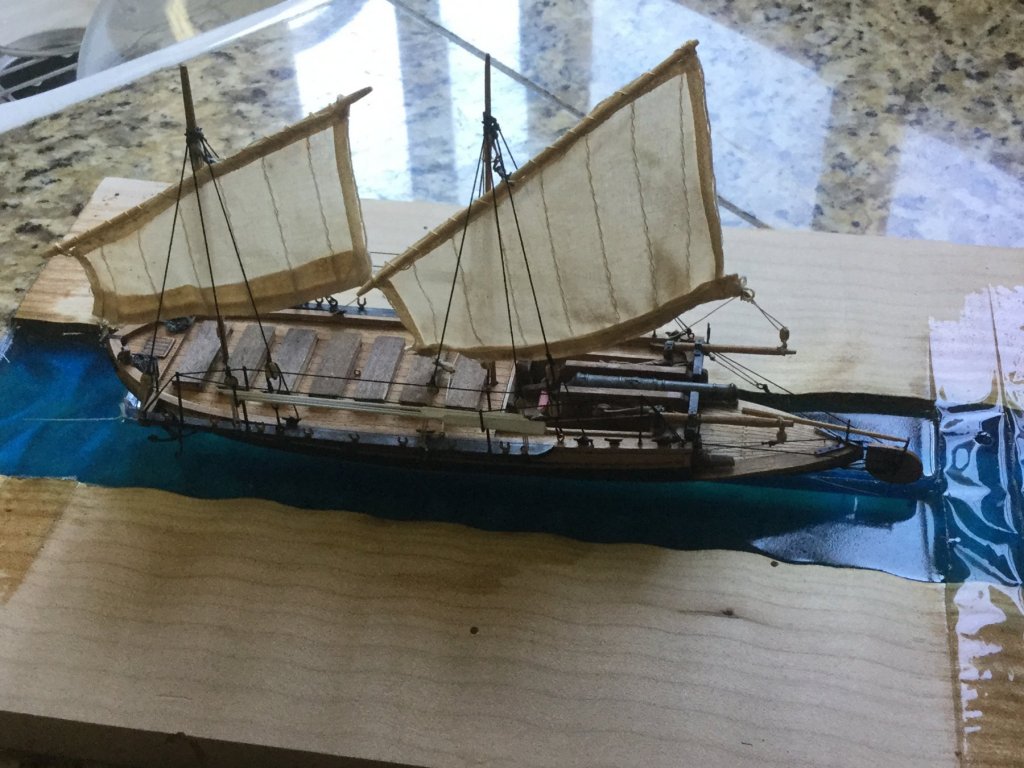

It took awhile for the sails to arrive from Russia and they were about 1/2 too long. Not being a seamstress and not going to tear apart the boat an re build I just rolled up the bottom. As I was sitting there looking at the model Imdecided it needed a base so I decided to experiment with a River Run Resin Base. First I purchased a live edge piece of Quilted Maple and cut it in half.

- 28 replies

-

- cannon jolle

- master korabel

-

(and 1 more)

Tagged with:

-

The translation leaves some to be desired. Truth be told I wrote technical documentation for Lightweight Torpedoes for the Navy and bad documentation drives me nuts. BUT the saving grace is the written word is accompanied by a good pictorial. Read, look at pictures, re-read. I found it strange that there were no fighting tops, just crosstrees so I added them.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.