-

Posts

496 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by twintrow

-

-

Mr Mosco:

How would you like to jump from your current market share to no 1 wood shipmodel kit manufacturer in the country.

Two small modifications, at least initially.......1. switch from those pathetic wood blocks now supplied with the MS kits to those made by the Syren Co. Chuck is a reasonable man and if you can negotiate the deal, your customers probably wouldn't mind a mild price increase to cover the added costs. After all, that move alone would catapult you to one of the best.

2. While your at it, negotiate also to begin acquiring Syren rope as well. Again a modest increase in price would be acceptable.

Having done these two simple tasks, you will no doubt significantly increase your sales.Now be aware that Chuck will most likely have to increase his production equipment and staff, so allow for an upfront offset of those expenses.

OK now your turn Chuck. How son can you get tooled up for the increase in production? ;o)

Tom

-

It may have been mentioned but don't forget Tichy Train Group they have scale bolt heads w/washers, or alone. great pricing too. very nice folks to deal with. Check them out here

https://www.tichytraingroup.com/Shop.aspx?SearchValue=bolt+heads

Tom

-

-

-

Chris

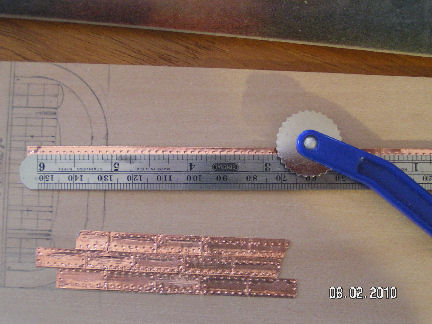

Using copper tape is much less expensive than buying individual plates. They are easy to make and the way a lot us do it faster. We layout a strip of 6 to 8 plates at a time. The adhesive on the copper tape is also far superior to that on the individual plates. The copper tape is generally used in making colored glass windows.

A ponce wheel (a wheel that looks like a cowboys spur and used in sewing, dressmaking) is needed to simulate the rivets. I measure out a lentgh of tape equal to 6 or 8 plates, then with the edge of my little 6" ruler score a line indicating the plates. Then lay it flat on a plate of glass or other solid flat surface, lay the ruler next to the edge and run the ponce wheel the length of the strip, then do the same on the other edge. To help with the explanation check out the attached photos. Hope this helps a little.

Good luck

Tom

-

Mike this may be a far out idea for you. I live in Sun City, Arizona, Sun City is what is known here as a retirement Community. That means if you are under 55 you can't live here. As a somewhat closed Community it has several, Recreation Centers, in these centers are Gymnasiums and various hobby workshops, among them wood working shops. These shops are run by retired guys expert in woodworking, cabinet making etc. and have magnificently stocked work spaces. Virtually every wood working tool you can imagine. I too was wrestling with whether or not to get a planer or thickness sander. Knowing it would be only occasionally used, I decided to ask the boys in the wood working shop if they would let me use theirs....they said NO, but would be glad to do whatever I needed done for me. They said to use the equipment myself I would have to undergo a training class at $9.00/hr for 5 hrs, then pass test first. Had strictly t do with safety an not wanting their tools destroyed by some amateur.

Anyway, and this would have been shorter if I had just said...see if there are any retirement communities around, or check for wood working clubs. They are all good guys just like us, but with less fingers ;o)

Tom

- mtaylor, mikeaidanh, Canute and 3 others

-

6

6

-

-

You can generally tell where a manufacturers priority lies by looking at the instructions. They are interested in manufacturing for money, or for the enjoyment of the hobbyists. The latter because they probably are hobbyists themselves. Take any of the Passaro builds from Model Expo vs any other manufacturer. Proves the point. So why buy from folks that are only interested in units sold rather than the customer. Admittedly ME could improve on the non-Passaro kits and for the most part they are better now than 5 years ago.

IMMHO

Tom

- mtaylor, skipper1947, Canute and 2 others

-

5

5

-

-

Excellent job B.E. very realistic look. It seems to me though that virtually every painting I see of square riggers the sails have a blueish tinge and show multiple patches. and in some photos as well.

Stark white sails just hanging on a model do not look good IMHO, and detract from the overall look of the model. So far I have avoided putting on sails for that reason. When I find the right technique maybe I'll try them then.

Tom

-

Cap'n Poison....That sure looks like a cement block......!

The drawing from the plans looks like a 12" double block (2 12" score) and a 12" triple block (3 12" score) and below those a single 10" block ( 1 10" score).

Now what is meant by "score".......

I've Googled the phrase...nothing, searched all my rigging books,,,,nothing. Underhill's Masting and Rigging...nothing, Admiral Smyth's "Sailors Word Book", nothing.

Cap'n Bob maybe try and contact company that put out the plans. They may know.Tom

- captainbob and mtaylor

-

2

2

-

I use my wife's discarded hair curler. It is stuck on High so she can't use it. I soak the wood for 10-15 mins. Open the jaws stick the wood in and close the jaws . The heat helps with the bend. The diameter is perfect for every curve I have needed so far (15 or so ships), and can be bent in any direction.

Brand new the curling iron is less than $10 USD.

-

OK Chuck solve the biggest mystery for me.....how in the heck do you keep your builds so clean looking???

I think mine is pretty clean when I go to take a photo, only to find the photo magnifies each minuscule dust particle by a factor of 10!! And that is after O blow it it and wipe it sown with a tack cloth.

Come on ....share, please ;o)

Tom

- SawdustDave, GLakie, mtaylor and 3 others

-

6

6

-

I ordered set and the magnifying lenses for $5.22 couldn't pass on those prices....I'll report back in a month and describe quality.

Tom

PS Thanks for sharing the link....I think ;o)

-

John:

1. Brass and blacken, because then you learn a new technique AND have an unlimited supply since you can blacken lots more than just wire.

2. If artistic wire, I'm guessing it will be shiny and then you will have to apply a matte finish somehow.

3. You may want to try and use your electric drill and learn how to make short lengths of line. You just need to take three )or four) strands and fix one end in a vise, the other in the drill an turn it on until it is what you want. Search MSW for rope making, there are a couple articles on the technique (probably better explained than I did too).

Tom

- Canute, mtaylor and Landlocked123

-

3

3

-

-

Paul:

My preference is Hobbylite. By Hobbyco. see http://www.ebay.com/itm/like/291074587074?ul_noapp=true&chn=ps&lpid=82

It comes in white or balsa color. Made originally for model aircraft and balsa but works well on any planking wood also. It is extremely lightweight, and sands beautifully. The ebay link I gave above sells it for $4.00 plus $2.00 shipping. That is about the lowest price I could find.

Unlike wood fillers, it is water soluble until dry. That means it is less expensive because if it does get a little dry you only need to add a little water to revive it. No odor and can be painted (not sure about staining).

Tom

-

USS Frolick:

The following quote is taken from the Nautical Research Guild article "The Philadelphia/New York Fair American. A Primary Source Chronology" by Clayton Feldman.....The catalog of the Rogers Collection of models indicates

that the Fair American model was built to a scale of 3/8 inch

to the foot and her dimensions are indicated as being: length

of gundeck of 68'-0", beam of 24'-0", and a depth of hold

of 9'-0". If the plans of the Model Shipways model of the

craft reproduced the lines at approximately one half full size,

and using the figure of 24'-0" beam as a guide, the scale used

on the model would be a bit less than 1/5 of an inch to the

foot or approximately 4.8 feet equals 1 inch. Using this scale

we come up with a revised set of dimensions, which would

indicate a length of gundeck to be 73'-0" and depth of hold

at station 6 as approximately 10'-6", while the beam at midsection

remains 24'-0".

- Canute and CharlieZardoz

-

2

2

-

I agree entirely John. I would, or rather will use the 3D printer when the price comes down to a hobbyist level. Problem is for now, the ones you assemble yourself and those at or around $1000, do not produce a suitable finish for modeling ships. Somewhere here there is a thread about someone making ship parts, sorry don't recall where or who, and those were very good looking parts. A more expensive machine as well.

As the market grows the price will come down. My 50" TV cost $1500 5 years ago, now they are going for a third of that. (Time for a 70", football starts in a couple weeks, good luck on selling the admiral on that).

of course, currently quite a few piece parts in kits are machine made, and even in scratch building we need to buy some parts ready made. Lets just build make what we can, buy what we need and enjoy the fruits of our labors.

Tom

- mtaylor and thibaultron

-

2

2

-

"Byrnes table saw along with a Sheerline 4001 lathe has higher priorities."

"Where will the charm and warmth of crafting be with machines doing our work?"

Dr Per surely you see the irony in your two statements....;o)

Tom

- mtaylor and Beef Wellington

-

2

2

-

-

-

Don't know if this has already been discussed I just found out about it.

Trying to talk local Home Depot in to doing a demo to see if it is worth it.

Tom

-

I wanted to make a model of the ship my ancestors came to America from Germany on. I knew the ship name (Pleasant) and the captains name and even have the signed manifest with my ancestors signature....but could find what exactly the ship looked like. So I knew they came over in 1732 so I looked for ships that transported immigrants in that time period. Turned out the Endeavour was exactly what I was looking for so I built the Endeavour and call it the Pleasant.

There is no one alive that can dispute my choice ;o) And my family members all love it. She flies the Family Crest and that is all they care about.

Tom

Model expo Constitution

in Wood ship model kits

Posted

OK Chuck and Marc let's look at this in a different way (Until I retired I created about 25 different companies most in areas others said couldn't be done).....let's look at Crown Timber yard and the Lumberyard, both create "packages" for scratch building models. They are not trying to provide lumber sets for all kits, just specific ones, slowly adding to their inventory.

Why not then have Syren start providing rigging materials only for say the Constitution, or the Confederacy. The parts list says how many of what sizes are needed. So start by customizing popular kits. It is also what the etched metal makers are doing for plastic and wood kits.

For example, I would love to have a set of Syren rigging materials (rope, blocks, deadeyes, etc.) for the HMS Prince kit I just acquired. I'll not be using crappy kit supplied stuff. I would be an injustice to the ship.

Just trying to stimulate the imagination a little to satisfy my own selfish needs, but I'll bet there are a few more folks out there that would like the same opportunity to buy new rigging materials for their kits. I know I can order what I need from Chuck ala carte, I'd rather it be a custom package.

IMHO

Tom