-

Posts

1,194 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by CPDDET

-

Finally got around to making the other half of the gooseneck for the foremast. Its been a while coming, LOL I began with a .125 square brass bar and milled it down to .085 Then used a #66 bit to drill a hole for the through bolt that would hold the two halves together Then drilled another hole into the face of the bar and two more holes into the side of the bar Then, using a file, joined the two holes to form a slot Checked the fit of the two halves Then drilled a hole straight down into the bar to accommodate a piece of brass rod that will be used to attach the gooseneck to the boom I attached the two halves with a .8 mm bolt and nut and trimmed off the excess Then used a jeweler’s saw to cut the gooseneck from the bar Used CA to glue the brass rod into the back side of the gooseneck This is a picture of the finished gooseneck mounted (simulated) on a brass rod with a piece of dowel for the boom. The boom can swivel port to starboard, slide up and down the brass rod and the gooseneck will allow the boom to lift after the downhaul is set

- 389 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Welcome! Lots of great modelers here. Looking forward to seeing your builds Dave

-

Split ring making process

CPDDET replied to Dave_E's topic in Metal Work, Soldering and Metal Fittings

Always nice to get ideas/ advice from a master like yourself. Thanks! -

Welcome! While you will find a treasure trove of information here, we all will benefit from your experience as well. Dave

-

Split ring making process

CPDDET replied to Dave_E's topic in Metal Work, Soldering and Metal Fittings

They are very susceptible to side shock -

Split ring making process

CPDDET replied to Dave_E's topic in Metal Work, Soldering and Metal Fittings

-

Split ring making process

CPDDET replied to Dave_E's topic in Metal Work, Soldering and Metal Fittings

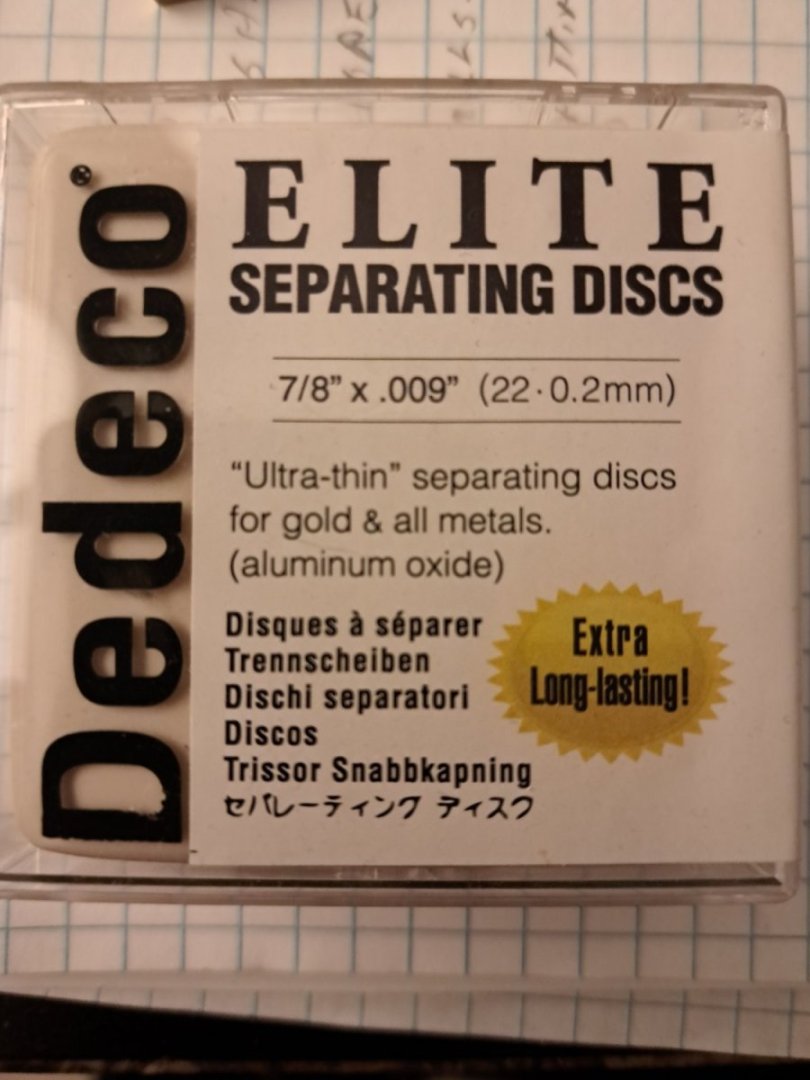

My mind is still dwelling on this, crazy huh? Another cutting method might be a very thin cutoff disk in a dermal tool? I have some of these disks, very thin and quite fragile. But they cut beautifully. I'll check the name and post it. -

Split ring making process

CPDDET replied to Dave_E's topic in Metal Work, Soldering and Metal Fittings

After some thought it may help to dab a bit of CA on the dowel after wrapping the wire. This would aid in holding things while making the cut. Afterwards just drop the dowel and wire into acetone to dissolve the CA. -

Split ring making process

CPDDET replied to Dave_E's topic in Metal Work, Soldering and Metal Fittings

Hmm. Cutting with any kind of nippers will not provide a truly flat surface to butt against each other, if that's desirable. Never tried using a fine tooth jewelers saw or razor saw but that might work. But would have to make the cut while the wire is still wrapped around the dowel or drill bit shank. There would also be some loss of material (the kerf of the saw blade) causing you to end up with a smaller ID than desired. However, using a slightly larger dowel / drill bit shank could compensate for that. Perfection may not be attainable? -

Split ring making process

CPDDET replied to Dave_E's topic in Metal Work, Soldering and Metal Fittings

I find wrapping wire around the shank of a properly sized drill bit works best for me. The real challenge is keeping the diameter of the wire to scale. If the actual ring was made from 1/2 inch diameter, round, metal stock, then at scale the diameter would be 1/128 inch? Probably 36 - 40 gauge wire? -

Welcome to the group!

-

Bryan, welcome to this very rewarding and sometimes frustrating hobby. I'm sure you will find all the help you need here. Dave

-

Good evening from New Jersey USA!

CPDDET replied to Funkingonuts's topic in New member Introductions

Welcome, Mike! -

Welcome Paul, good to have you aboard.

-

Welcome Tom, I'm sure you'll find help and some interesting build logs here. Dave

-

Nice, clean crafting on your first model. You look to be a natural! Dave

-

Welcome Mark, lots of help to be found here. Dave

-

Welcome home, sailor!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.