src

Members-

Posts

2,300 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by src

-

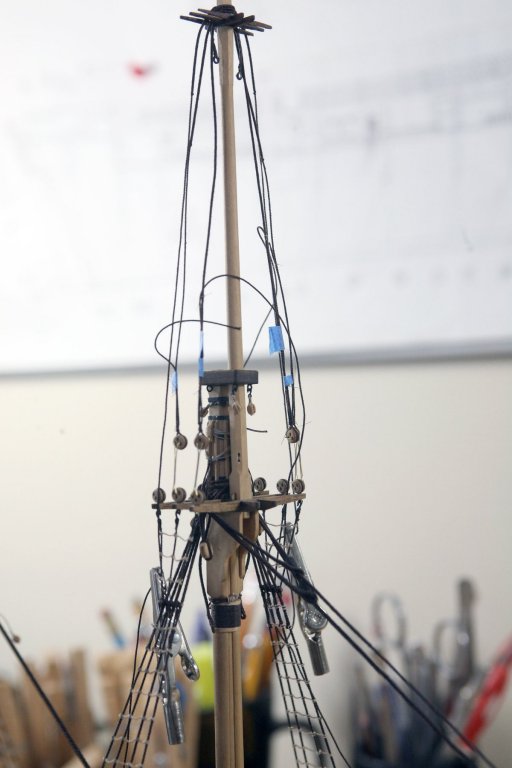

Woo! Hoo!!! After many months of my build sulking in the corner feeling like a red headed step child I finally have some progress to show. Not much but its something. I started in on the Fore Top Mast shrouds as well as some of the various and assorted blocks for the running rigging. It took me a while to make sure I had everything on the masts before I started the next set of shrouds. I I didnt do that when I started teh lower masts and struggled getting the various collars rigged with the mast in place. Hopefully I got everything this time. I marked the lengths of the shrouds this time and tied the deadeyes on off the ship, it was easier but I am not sure if they will come out at the same length when I rig the lanyards, I hope they do, I dont really want to re-do them. I figure if they are all within 1/4 diameter of each other nobody will notice. Now, to try catching up on all the builds that have got away from me in the last week and a half since I have visited here. Sam

-

Hang in there Dennis, it will come to you. We have all seen what you have done with your other builds. I do want to know though, where did you get those Ginormous clothespins??? I could use those in my day job!. Sam

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

That binnacle is quite the little project Rich. Looks good there. Sam

- 1,135 replies

-

- model shipways

- syren

-

(and 2 more)

Tagged with:

-

Well done Carl, and in just a little over a month too. Sam

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

Thanks Dennis!! Now that the job site craziness is over I can see if he is here. I have managed to tie on a couple of blocks today and get a handle on where I left off in February, jeez that seems so long ago. Thanks for all the likes and well wishes, now lets see if I cant make some progress here!! Sam

-

Wow, all three of you are doing a great job! Making em wish I had time to add a second build to my table. Sam

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

Lord Mark, Getting caught up here. The Death Star sure makes a nice layout for carving. Cant wait to see the finished product. Sam

-

Dennis, Back stories are always good. I like the decals the way they are. A bit of wear and tear works. Sam

- 171 replies

-

- krabbenkutter

- authentic models

-

(and 1 more)

Tagged with:

-

Outstanding Piet! I especially like that there is variation in the gun smoke. Too many times we try to make things exactly the same when there should be variation. Well done. Sam

- 378 replies

-

- java

- pacific crossroads

-

(and 2 more)

Tagged with:

-

Mike, I had a scale drawing from, I believe, the NRG home page. I forget where I found it now, but when I scaled it to 1:51 they came up off. Also the carriages did not sit properly to my eye. As far as being difficult the only thing you need to be prescise on is the center hole and the outer diameter on the tool. I was able to find drill bits that were the right diameter. Once the raw steel was in my chuck I just drilled the center out for both the axle diameter and the truck diameter, then ground it on the sander like I described. I get that it sounds like a lot of work, if it seems like too much then turning your dowels down on the lathe will work. I might be being overly picky but I was concerned if I tried to drill a dowel out for the axle I would never get it centered properly and would also end up splitting the dowel.That just me, I have seen several builds where the builder pulled it off quite well. Aww jeeze! I just realized something, I could have drilled the dowel out on the lathe and then sliced them!!!!! Sam

- 136 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

Mike, I tried to edit the above post but for some reason could not. There is more information on the preceding page of that link. THe actual work took more time to figure out than it did to actually make. If you need further information let me know and I will expand on the details. I was trying to not take up too much time on your build log. Sam

- 136 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

Mike, this post has some pictures that should help with explaining the cutter I made using my wood lathe Since there is only a few wheels I just used some mild steel pencil rod. If you wanted to go a bit further a piece of tool steel or drill rod will work better but with out a metal lathe its much harder to work with. The teeth were cut with a small disc grinding attachment on a die grinder but a dremmel would work too. To make the bevel for the gutting angle I chucked the material in my drill motor and spun it against a running disc sander, that kept it pretty true. Not machinist true but close enough. After that I cleaned everything up with needle files. Best of luck , Sam

- 136 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

Mike, You could always turn the dowels down to the size you need. A lathe would be the easiest but a drill motor and some sand paper will work. If you were to rethink scratching a set I would be happy to share some pictures of the cutters I made when I did my carriages. They were not difficult but did require a lathe to get the drill bit centered. Sam

- 136 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

Mike, Larger trucks might do the trick as would taller axles. The trunnions on the barrel should be drilled below center, when I first mounted mine I had them upside down. If yours are the same, flipping themover would give you another 1/32' or more. Sam

- 136 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

And Dennis is in the race!! Nice progress gents. Every time I see a picture with a scale reference I am amazed at how small some of those details are. I get a headache just thinking about it. Ooops! Sorry Carl, my popcorn box slipped.... Sam

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

RIch, I am always in awe of the builders who can do that with their drills! I just make uneven tooth picks when I try that. Well done, Sam

- 1,135 replies

-

- model shipways

- syren

-

(and 2 more)

Tagged with:

-

Mike, I posed the same question back before the crash, unfortunately that forum discussion is long gone. It also shows you just how long I have been tinkering with this kit! The general consensus was that Constructo has created a bastardized carronade. My suspicion is that when they created this kit they looked at what parts they stock this picked and chose until they had what you see in your kit. I threw them away and created my own. THis was before Chuck was making carriages. Today I would have bought his. I like the looks of the larger Syren carriage, although it still looks a bit low in relation to the ports. I recall reading somewhare that in the neutral position the muzzle should be about centered in the port. Regardless, the Syren kits are far better looking than what Constructo supplied. Best of luck. Sam

- 136 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

RIch, so sorry to hear that. I hope you are feeling better. Sam

- 1,135 replies

-

- model shipways

- syren

-

(and 2 more)

Tagged with:

-

Carl, looking good!! Especially the top picture with the WWI anti ship missile. As far as beams and roof loading we are good. No rum in my bag, brought some Don Julio 1942 tequilla though. Sam

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

Lou Rigging one of those claw contraptions right now. Shhhh! Mark will never notice as we dip into his bucket. I would love to join in the build, but I can barely get time to work on the Enterprise, much less start a new build. She Who Must Now Be Obeyed also has a project or two for me. Greg, what are the little bumps on each side of the stern deck in that last picture? Sam

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

This looks like a fun build, although, Greg, calling Carls wit cheap, that was low.... I'm gonna join Lou up here in the rafters, safer that way when MY cheap wit rears it head. Sam

- 1,090 replies

-

- showcase models

- vendetta

-

(and 2 more)

Tagged with:

-

Formula = 1/2 bottle dried black drib of white drab of tan three caps of thinner shake thoroughly strain through carpet remix with flip flops and add dawn as an emulsifier. Confirm proper balance of color (and body) by sticking foot in sink. (Sam Runs back to his corner and hides) at least you cleaned it up before the cat(?) gibs got to it. Better luck next time. Sam

- 171 replies

-

- krabbenkutter

- authentic models

-

(and 1 more)

Tagged with:

-

Mike, yea those carriages are.......interesting. I scratched a set for mine, that was an exercise also. Chucks carriages should work. At least you can adjust the ports to fit if you are willing to wait until your replacements come in. For cutting out the ports I found a set of hobby rasps at micro mark that made the process at least tolerable. Sam

- 136 replies

-

- enterprise

- constructo

-

(and 1 more)

Tagged with:

-

Piet, my apologies, in was imprecise in my choice of words. What I was commenting on was my experimenting with the BJB tints in a polyester resin we use for fiberglass at the shop I work at. What I should have said is the BJB tints DISPERSE well in the polyester resin. So sorry for the confusion. Yoy sea looks great!! sam

- 378 replies

-

- java

- pacific crossroads

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.