-

Posts

339 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rob S

-

Thanks Emmet! Appreciate the kind words. I hope you are doing well and wishing you the best. Stay safe and I look forward to your return and continuing work.

- 395 replies

-

Yellow Ochre being applied to the gun decks. Some of the black paint is still wet and was re-applied after the masking tape removed some of it. Total of two-2.5 coats applied in each color. Some finer detailing still required. Good to see some color now being applied.

- 395 replies

-

- 395 replies

-

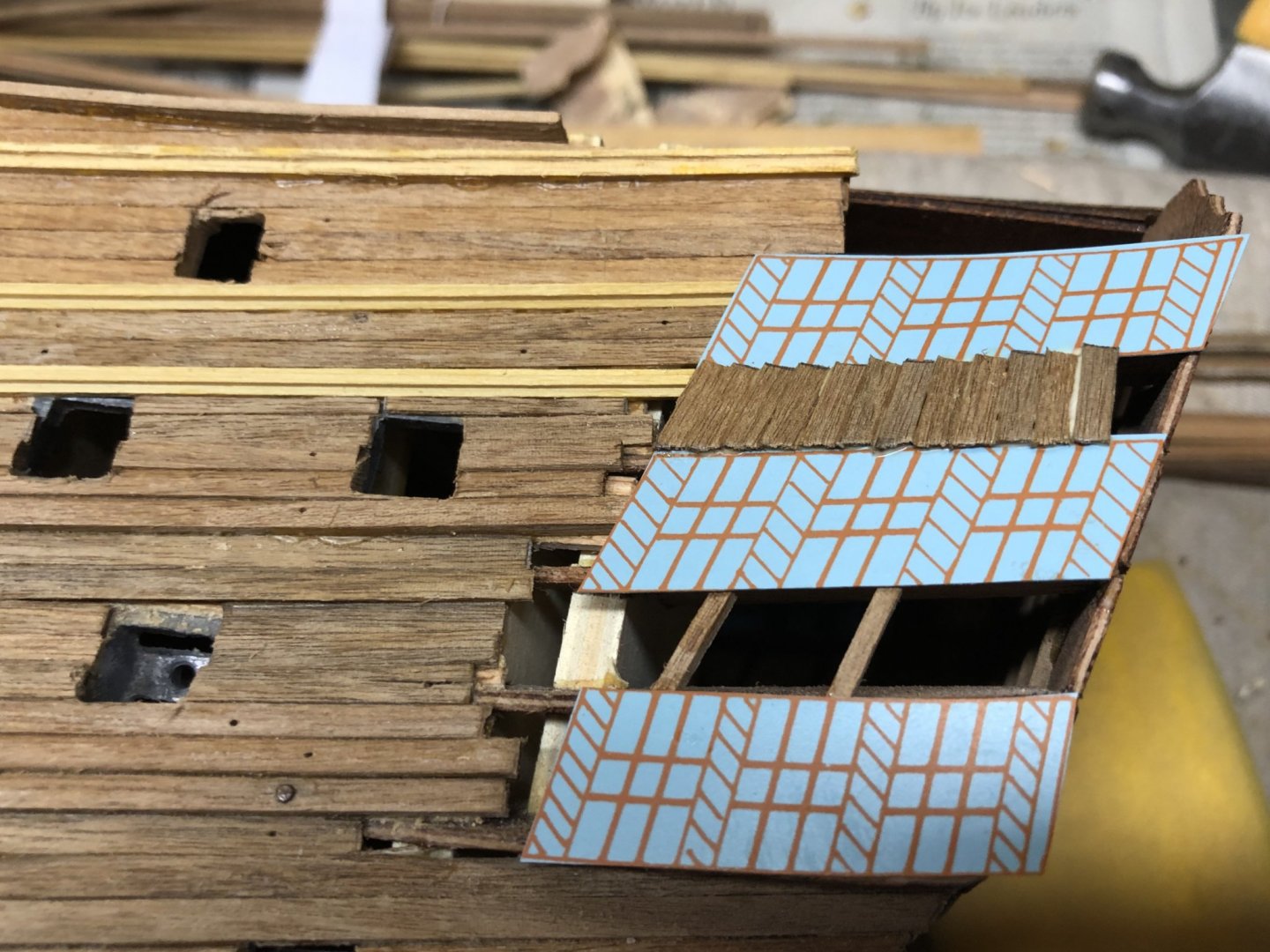

As I was reading through the instructions they read to implement steps a, b, c, d... and so on and then ‘before completing these steps, paint the transom ink black...’. Of course I had already implemented the preceding steps. Another lesson learned, be sure to continually read ahead... over and over again to make sure steps are completed in order. Good news is it wasn’t too difficult to paint the transom black and carefully painting around the blue windows. While I was at it, I decided to begin painting the hull black in the right places. Just starting now.

- 395 replies

-

Transom/stern ‘windows’ applied with an acrylic glue for wood/non-wood bonding. I understand there are better alternatives out there, but I realize I’m already over my head with the basic instructions/kit materials. We’ll see how it turns out.

- 395 replies

-

- 395 replies

-

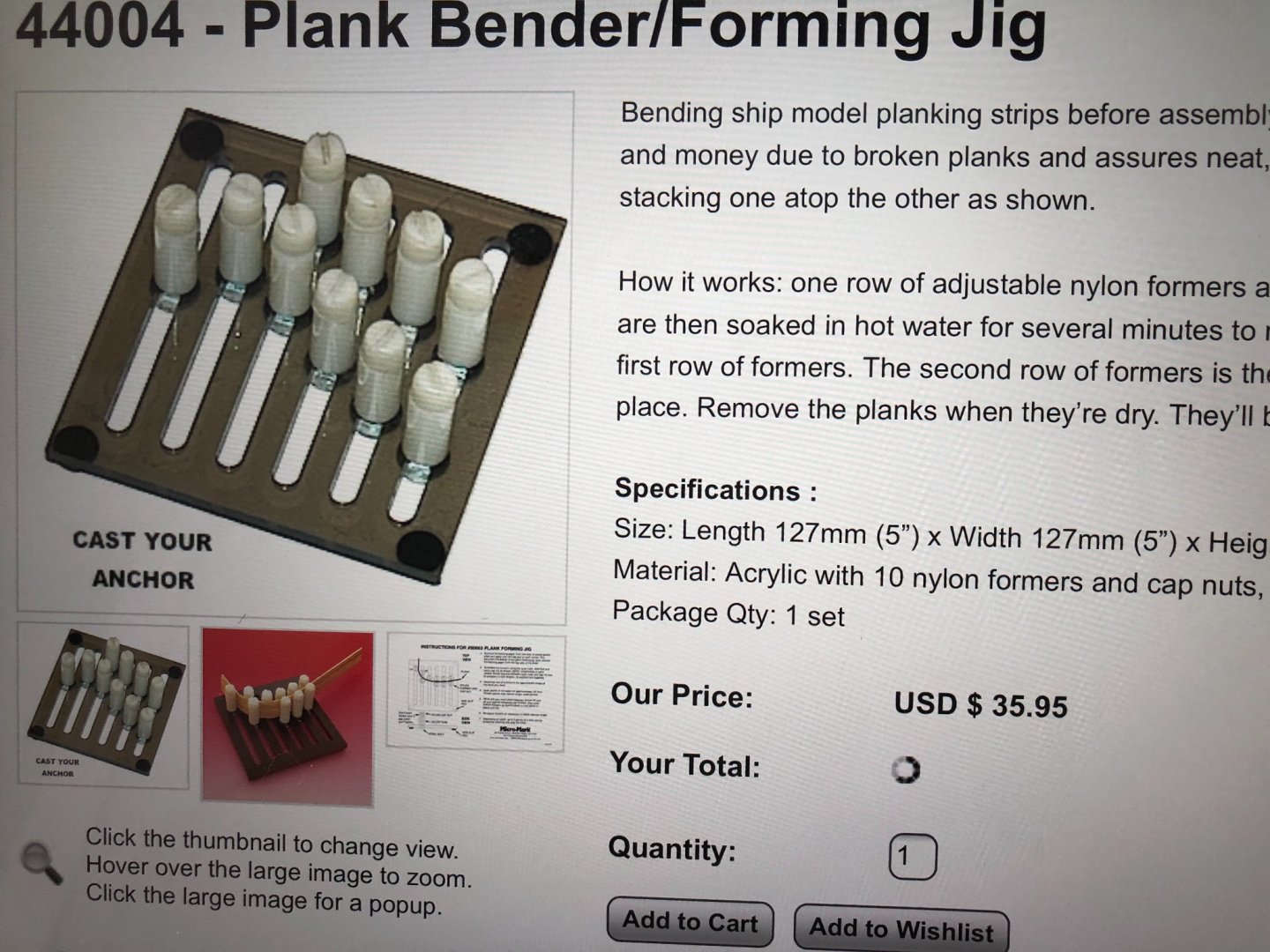

Applying 3mm x 1mm walnut laths to the bottom portion of the transom per the instructions. Note that although these strips are pliable, there is just enough tension in the small pieces to make it difficult to attach without first bending them. Small nails to hold the laths in place will split the wood, so I measured and then applied my bending iron to the planks, cut them and then dried them in my plank ‘shaper’ device. After dry, the pieces fit and stayed nicely with the wood glue adhesion. No other means of keeping them in place were necessary. You can judge the result for yourself.

- 395 replies

-

Now installed! Will be doing some light sanding in preparation for putting 0.5mm x 3mm walnut laths over them next.

- 395 replies

-

- 395 replies

-

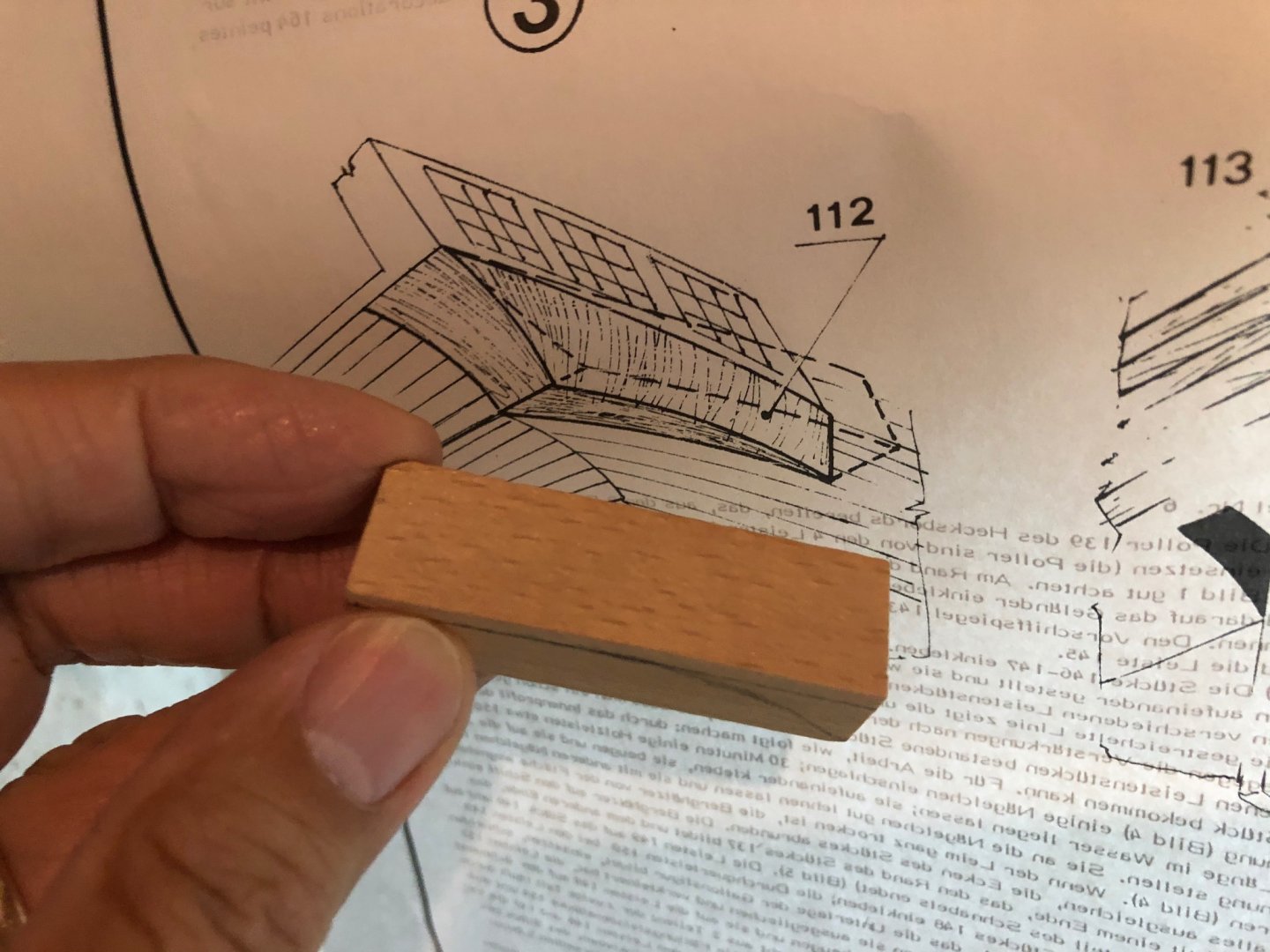

Well, I’ve been away from the shipyard for a little while as I transition to the Transom with associated finishing. I’ve been working to shape the bottom sections of the transom. You can see the piece of wood I started with (bottom piece) and where I currently am on the starboard side (top piece and associated picture). I need to shape the port side, install and plank. Then over to the more intricate portion of the transom finishing. It’s really fun (not) trying to interpret the instructions for all the small pieces of trim, etc. This will take some time.

- 395 replies

-

Hi Clive - yes I do. You can message me for details.

- 395 replies

-

Continuing the transom work. Instructions call for shaping a couple of small blocks to form the bottom portion of the starboard and port sides of the transom. I’m not completely sure the best way to mold the blocks so I intend to solicit help on potential techniques by starting a forum discussion. My initial thought is to identify/mark sections on the block, secure it in a vise and sand it with an electrical sander. I’ll use sand paper for the finer sections. Any other suggestions are welcome. Thanks in advance.

- 395 replies

-

Transom work on the port side. Instructions call for small, 1mm x 3mm walnut strips (about 11mm) between the cut outs. Doesn’t leave a lot of room for the strips to adhere to.

- 395 replies

-

Transom work has begun as I transition to instruction set ‘6’ of the Mamoli plans. The transom windows are on a thicker paper stock, cut out and glued to the sides. This will be the same for the aft windows. I’m sure there are more elegant solutions, similar to use of copper tiles for the hull, but I plan to stay the course with the as provided materials/approach.

- 395 replies

-

Thank you Nirvana! Appreciate the very kind words! Continuing the bow finishing activities. These clamps are extremely helpful. Seems like there are never enough!

- 395 replies

-

Continuing quarterdeck finishing... Should finish up the bow portion this week and then redo the cannon ball storage on the upper deck before turning to the transom.

- 395 replies

-

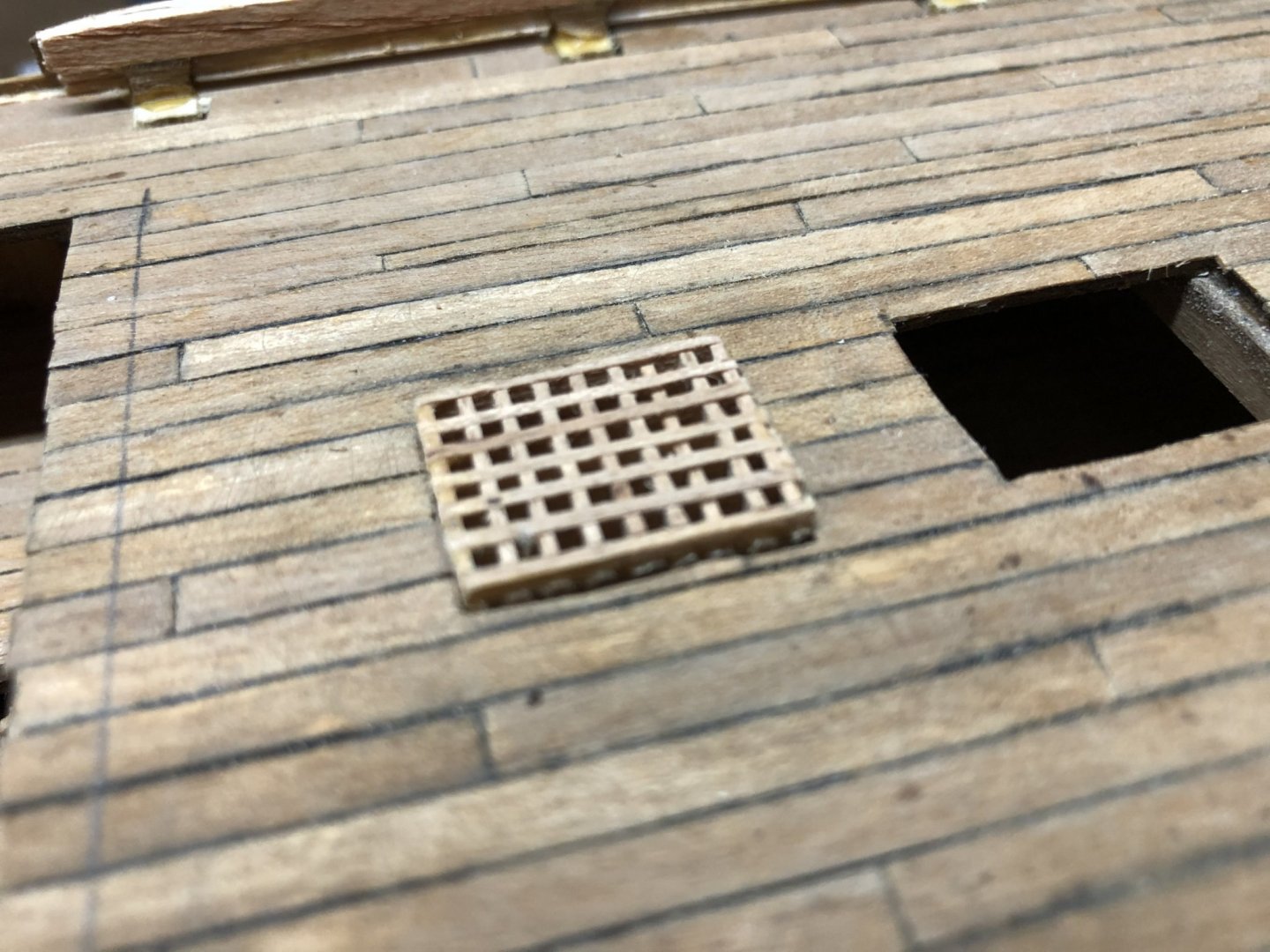

Slow going finishing the quarter deck moldings and running into a few issues along the way. Primarily we have a quarter deck support beam that is running across the aft steam grate on the starboard side. I’ve elected to leave it as is rather than cut it and later face a ‘load bearing’ issue. You can see the finished product.

- 395 replies

-

Thanks Emmet - understood. I will see what I can do. For messaging, simply select the member you want to communicate with and you’ll see a hyperlink with a ‘Message Member’ type link near the top. Then write your email/message. However, to respond you have to be in the forum. Select your name/icon and navigate to your messages where you select the appropriate thread and reply within it. You can’t respond externally. Hope this makes sense. Safe journeys!

- 395 replies

-

Quarter deck finishing at the bow section. The grates are difficult to work with especially when banding with the finishing moldings. The Mamoli instructions don’t always call out the molding dimensions so I’m using best judgement. I used the deck planking material for the molding parallel to the gang boards because the material wasn’t specified in the instructions (or I couldn’t find it).

- 395 replies

-

- 395 replies

-

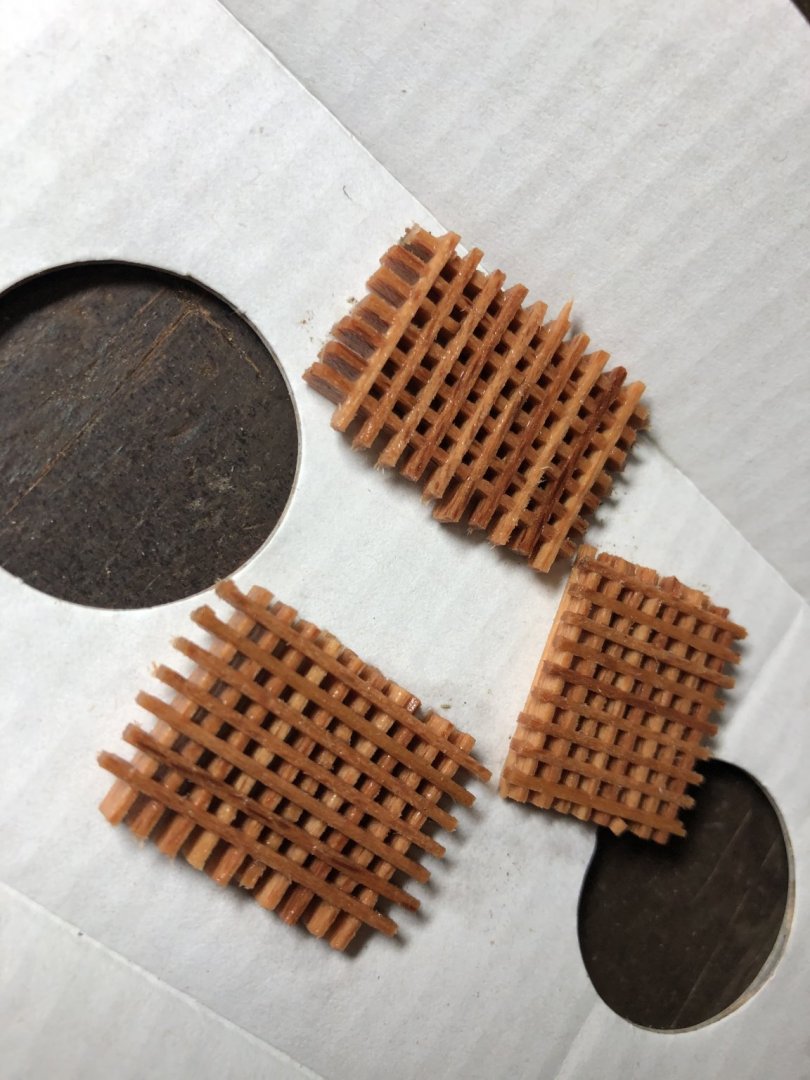

Now that the thrill of planking is largely behind me, I’m working the deck finishing aspects. I’ve included a few pictures of the grates as they progress from pieces to assembled components to the finished grate assemblies. The instructions call for you to assemble the grates, mix some glue in hot water and throw the grates in the glue/water mixture for a few moments. The glue is supposed to adhere with the grate pieces and make it easier to tailor them appropriately. However, after doing this and attempting to cut the grates down to size, the grate wooden sides/parts fall off.... so I’ve been adding some additional glue on the grate sides and then sanding them down once the glue hardens. This takes a bit of time and isn’t really as ‘sexy’ as the planking process is, but if done correctly look good.

- 395 replies

-

Upper deck grate moldings replaced and ladder repositioned. I’m having trouble putting the cannon ball fixtures on the brittle walnut laths. Will have to go even slower. Preparing the fore quarter deck grates.

- 395 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.