-

Posts

339 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rob S

-

Thanks for the insight David! I’ll take a look.

- 395 replies

-

- 395 replies

-

Henrik - I just noticed the nice bend in your bow cheek in the picture above. It appears to be shaped laterally. Did you shape the cheeks? If so, what is your secret? Every time I attempt to shape my walnut laths (2mm wide) laterally, the wood cracks even after prolonged immersion in water. I also see your grates look pristine. Any tips you want to share about assembling/glueing/tailoring them? My grates are brittle and don’t stay together very well. Thanks! BTW, I just came across your Hood build; very nice work! Rob S

-

- 395 replies

-

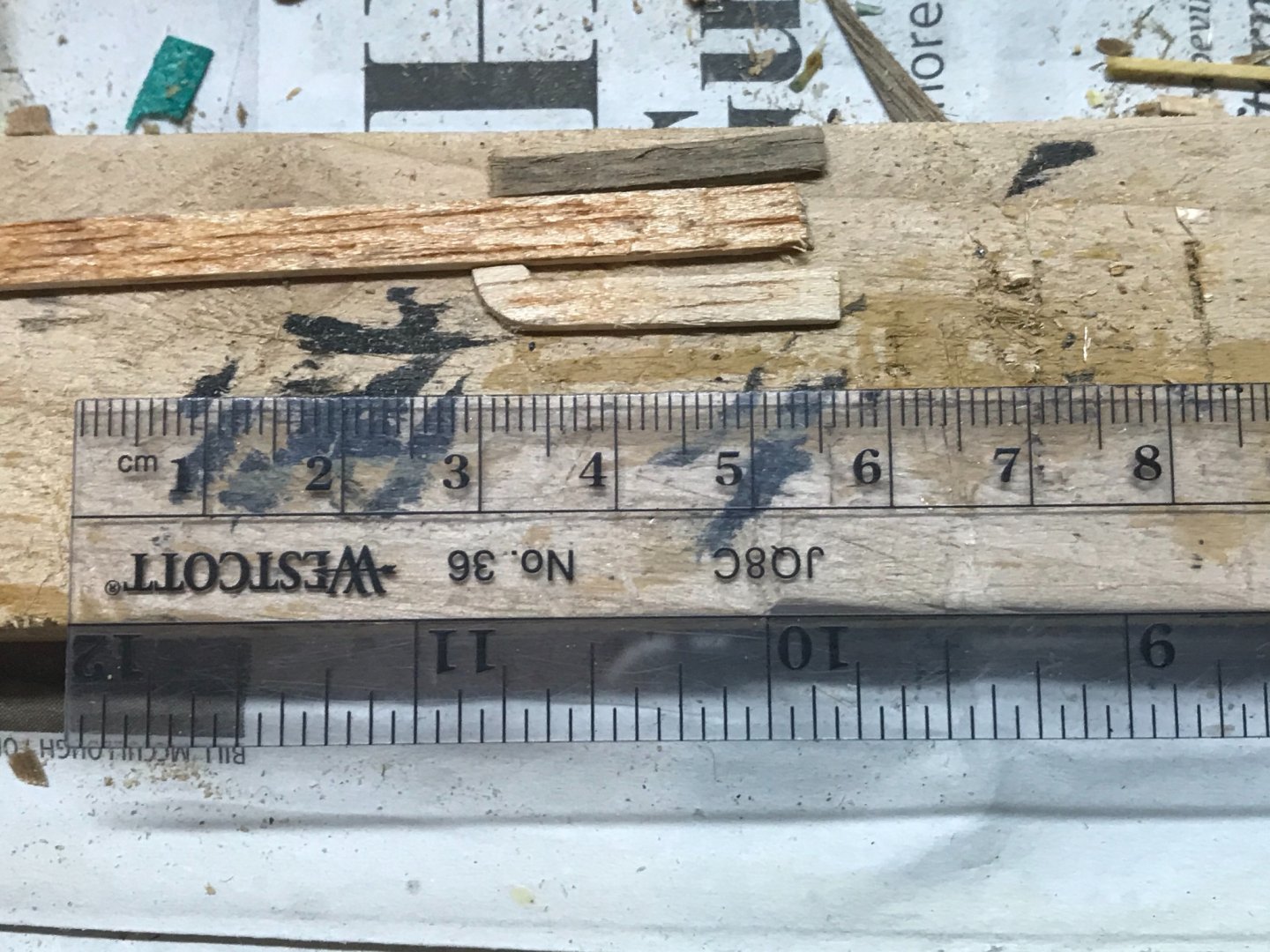

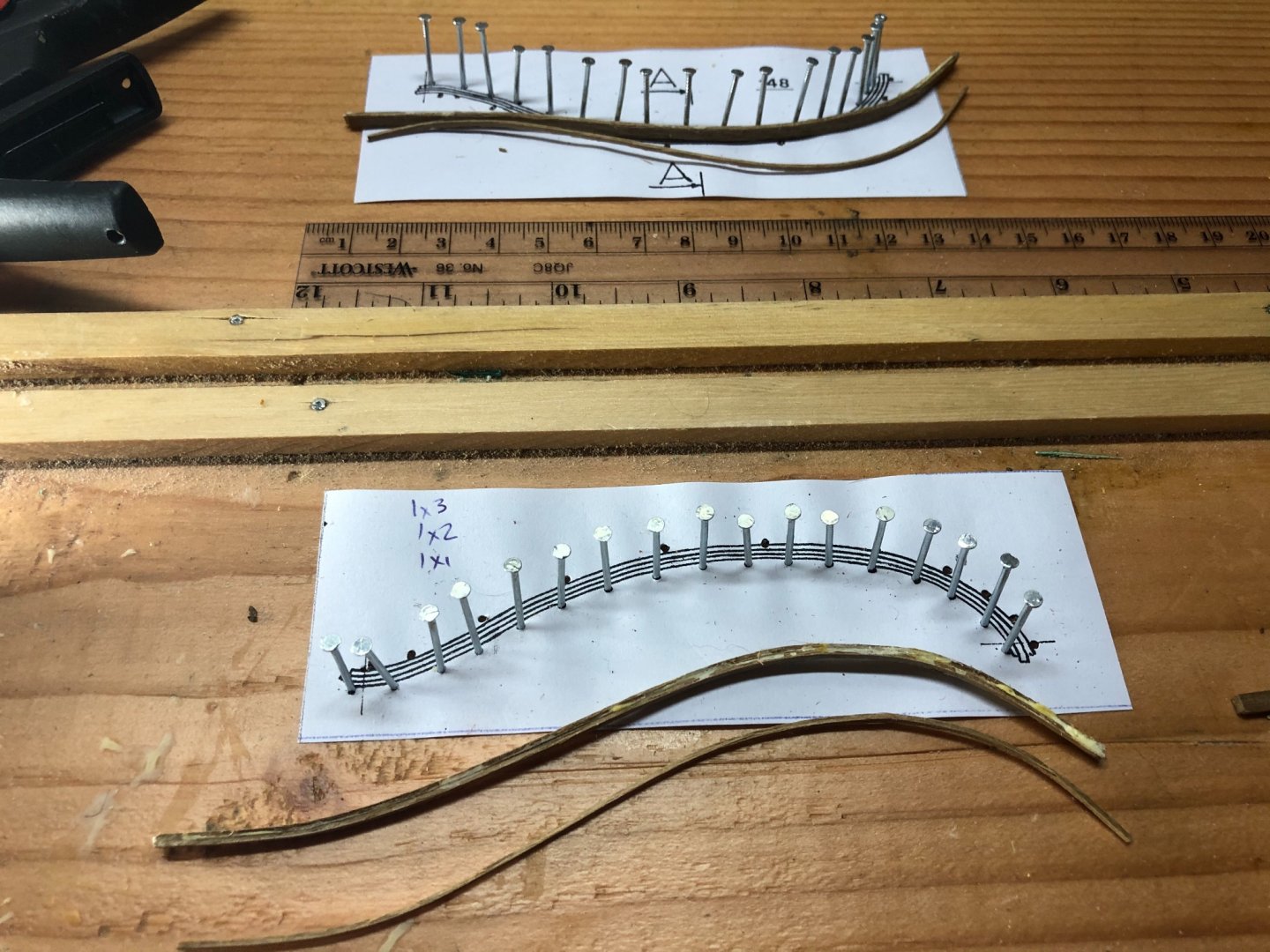

Continuing to assemble the bow finishing elements. Still can’t adequately bend the 1.5mm x 3mm walnut laths laterally without breaking them. This is after a 2 day soak and using an electric plank bender (see earlier section in my log if interested). I’ve come up with a non elegant, but working solution using a 5mm plank and cutting it down to 3mm and manually adding the curve. The original, unbendable walnut lath on top, the replacement 5mm lime lath (left over planking) and cut out/modified piece. The resultant attached piece is shown (unpainted).

- 395 replies

-

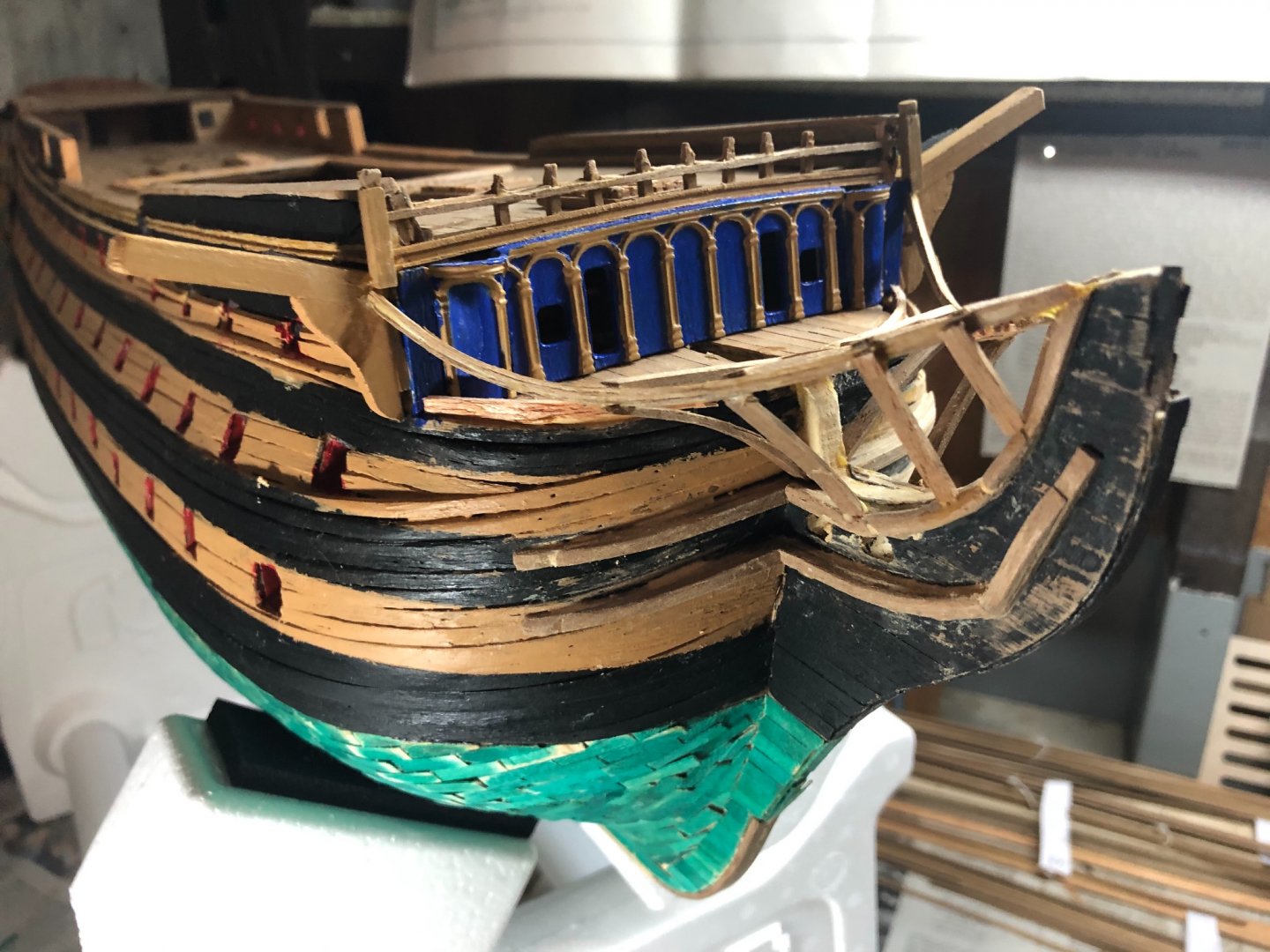

Bow progress as of this morning. Grate work is challenging as they fall apart and need continuing glue application. Especially when shaping them.

- 395 replies

-

- 395 replies

-

Thank you for the examples Gregory. In my opinion this is a better option for displaying by taking up less room but still looks good. The bow work is coming along and looking better, in my opinion.

- 395 replies

-

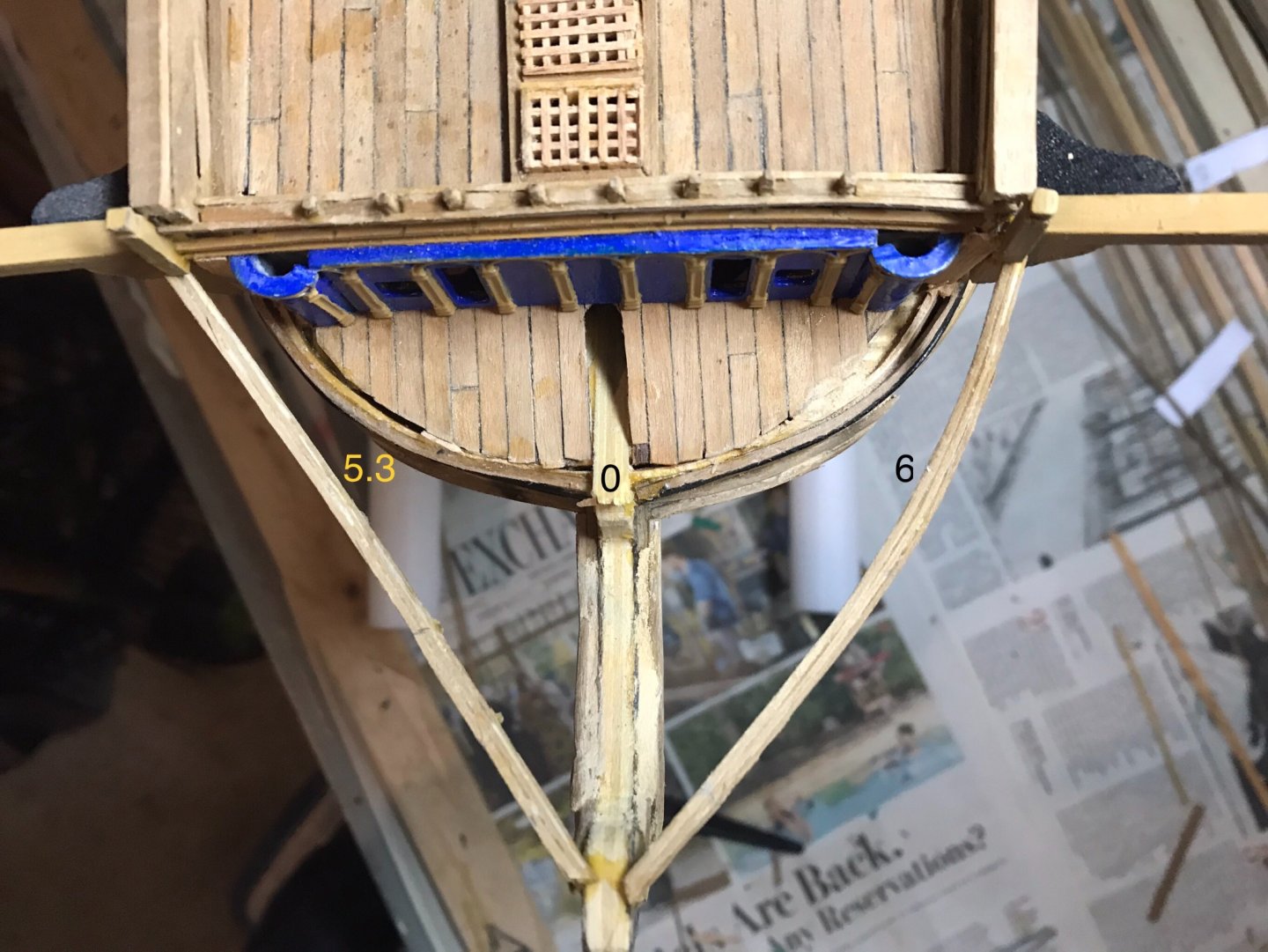

Here is the first step back. Symmetry is much better looking down, however the port main rail ‘bow’ appears more significant. This may be OK... depending.

- 395 replies

-

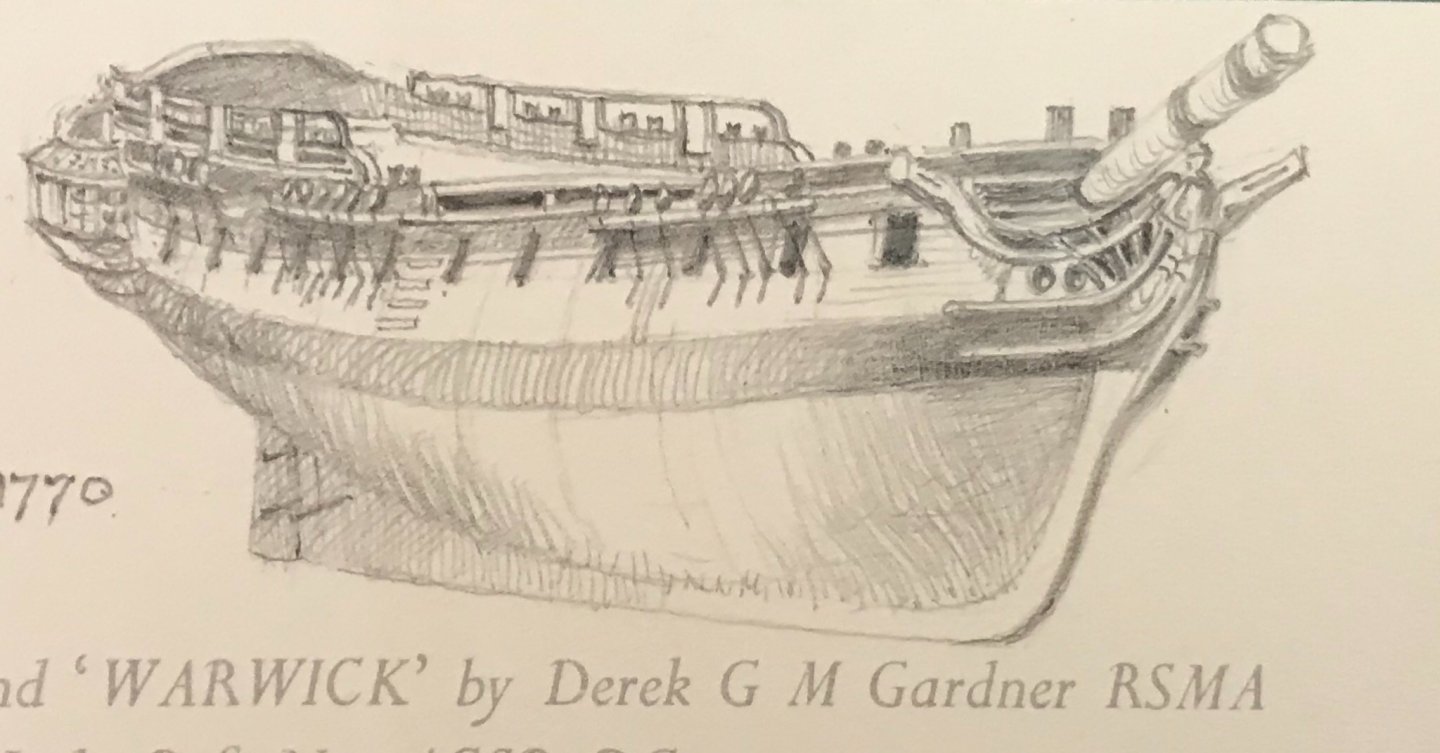

Thanks Gregory; appreciate the advice. However, I’m planning to finish the model ‘hull down’ per the below picture. Will that still be an issue in this case?

- 395 replies

-

Well, here WAS my bow section.... What a mess. I’ve since dismantled everything on the bow and am starting over including removing the main rails. The dismantling process went well and I’ll be able to reuse most everything. I’ve got some good bow section examples to study further and hopefully I’ll be able to laugh about this debacle later!

- 395 replies

-

Diana by Kyak - OcCre - 1/85

Rob S replied to Kyak's topic in - Kit build logs for subjects built from 1751 - 1800

This is a great build for a newbie to planking to see how it’s done. It’s amazing how some modelers make it seem so simple. This log helps one see the process in logical steps. Very nice! -

All modelers know that gluing/attaching some ship components are relatively straight forward through the use of ‘classic’ temporary means (e.g., nails, clamps, weights, etc.). What I’d like to know is those little secrets modeler’s use to attach those pesky/difficult items where a classic method isn’t readily appropriate. I’ve attached an example where the main rails on the Mamoli Victory were difficult to attach. You can see in the example by the red arrows the two places where the starboard main rail attaches. The right end simply sets on top of the beak head. However, there was no obvious (at least to me) way to temporarily hold both ends in place while the glue set. I did not have a clamp/area that I thought would hold either end in place. The area was too small for a nail to work. I couldn’t set a weight on top of the beak head to hold the right side in place. I was a bit stymied. Perhaps I just didn’t think it through enough...... In this case I ended up lodging a small screw driver in the bow area to hold the left end up while the right side simply sat on a bubble of glue. Very precarious and unstable. However, in this case it worked. Not the ideal way to get the job done. Are there other difficult to attach elements/components in your ship build(s) that required some out of the box thinking to temporarily hold the piece in place while the glue set?

-

- 395 replies

-

Here are the BEFORE pictures of the ‘finished’ bow cheeks using what I understand are the Mamoli directions. However, I’ve not added all the layers they suggest as the cheeks would extend 8mm from the bow surface at their widest point. These extend 4mm. Next is to continue sanding, add minimal filler and sand again. Then on to the main rails.

- 395 replies

-

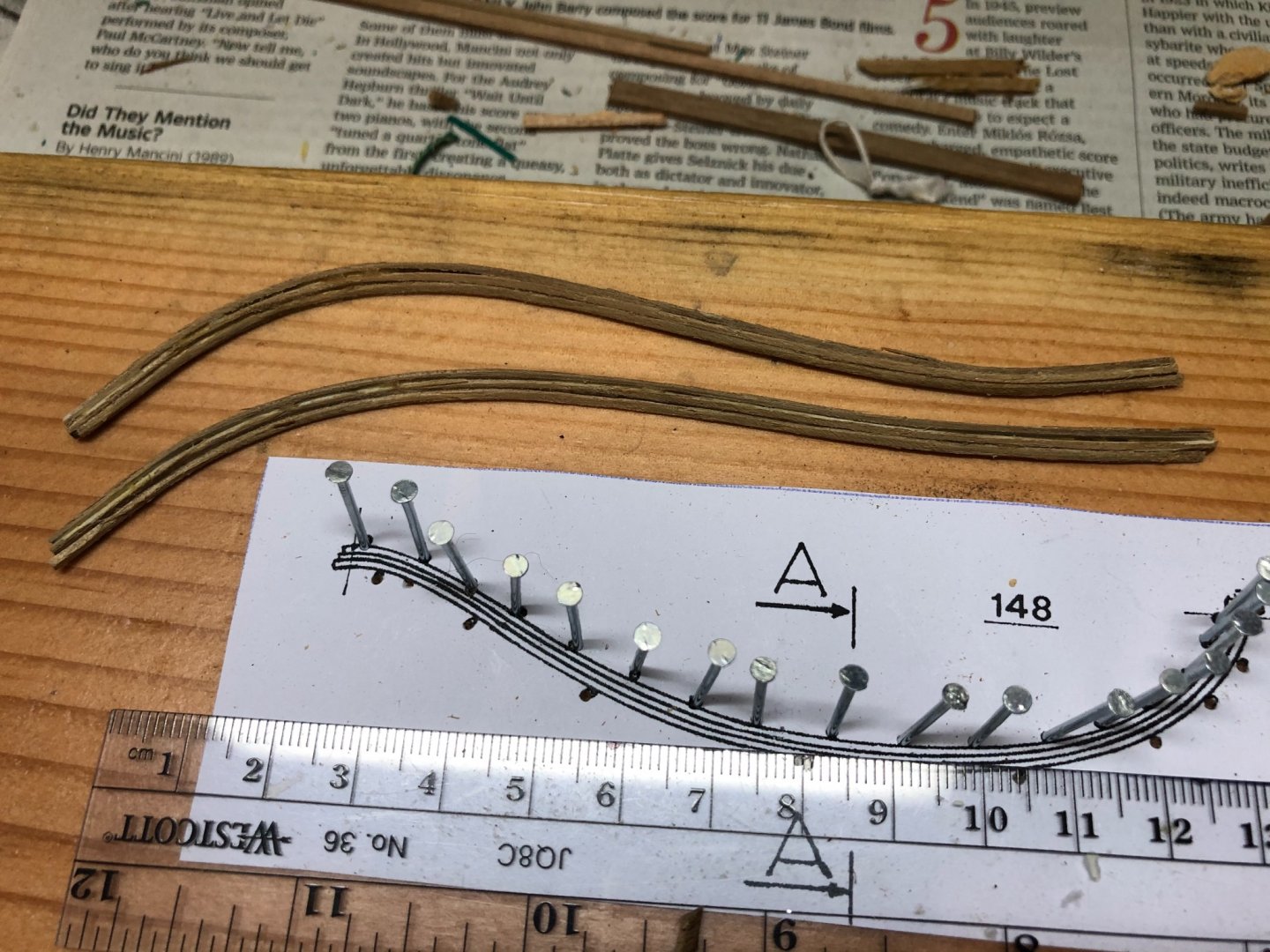

Still working the bow cheek build up. I’ve had trouble shaping the 2mm x 3mm walnut laths ‘against the grain’ and after looking in the forum help section was able to find a topic addressing this. While the wood demonstrated seemed to be a little less wide, there were some good suggestions. I actually boiled some water and put the walnut pieces in for about 10 minutes and was able to get a better bend with my shaping iron. You can see pictures below. I’ll resume the cheek build up in the next few days. I’m also working to chamfer the main rails created with the Mamoli jig. They were shaped, dried and then glued together. It’s not too easy holding these down, but slowly am able to take the edges off.

- 395 replies

-

Initial results were positive from the jig above. Now assembling the rail elements before the chamfer process.

- 395 replies

-

While awaiting laths to dry to continue building up the bow cheeks, I built the Mamoli jig for shaping the bow main rails. These laths are 1mmx1mm, 1mmx2mm and 1mmx3mm, shaped, glued together and then edges chamfered. Next, look up ‘chamfer’.

- 395 replies

-

Hi Henrik! Yes, correct. The Mamoli instructions call for an approach of building them up, layer by layer. No pre cut pieces I’m afraid. Hope you are well and thanks for asking:)

- 395 replies

-

Still working to build up the bow cheeks.. Slow going. I still haven’t found a good way to shape the walnut along the 2mm edge without breaking the wood. This is where my lack of experience working with wood is really obvious. However, I’ll continue look for a better way to shape these laths.

- 395 replies

-

Building up the bow cheeks using 2mm x 3mm walnut laths per the instructions. The 3mm wide portion of the laths is glued to the surface. These size strips are difficult to shape, particularly along the 2mm side. I’ve left these planks (2) to soak now for over a day after attempting to shape the first two with mixed results. These small walnut pieces will be built up and then shaped to form the upper and lower cheeks. Here is the starboard side progress. I’ve used a clamp to secure one side and had to nail a small piece of wood down to hold the other side down. It takes time because I have to wait for each strip to dry which in this time of year takes a day.

- 395 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.