-

Posts

339 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rob S

-

Looks like an informative place. Great Just Great

Rob S replied to rudybob's topic in New member Introductions

Welcome aboard Rudybob. You will certainly have a lot of material at your disposal. Glad you are here! Rob S -

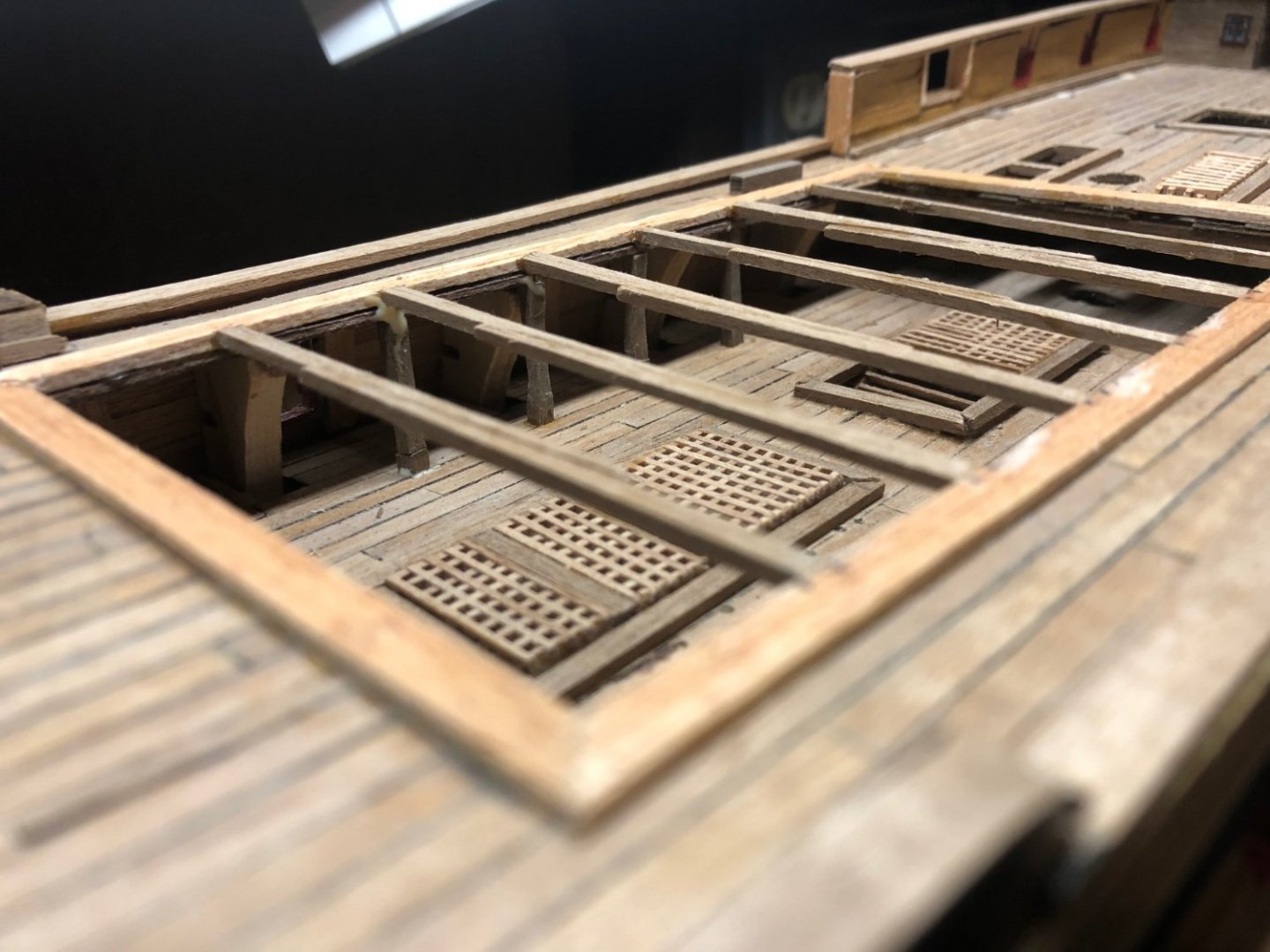

Next step. Putting the small indents in for cannon balls is difficult because of the wood condition.

- 395 replies

-

Beginning fabrication and installation of the Topsail Sheet Bitts and Main Topbowline Bitts assemblies. Working with the small parts is trying given the wood is old and brittle.

- 395 replies

-

- 395 replies

-

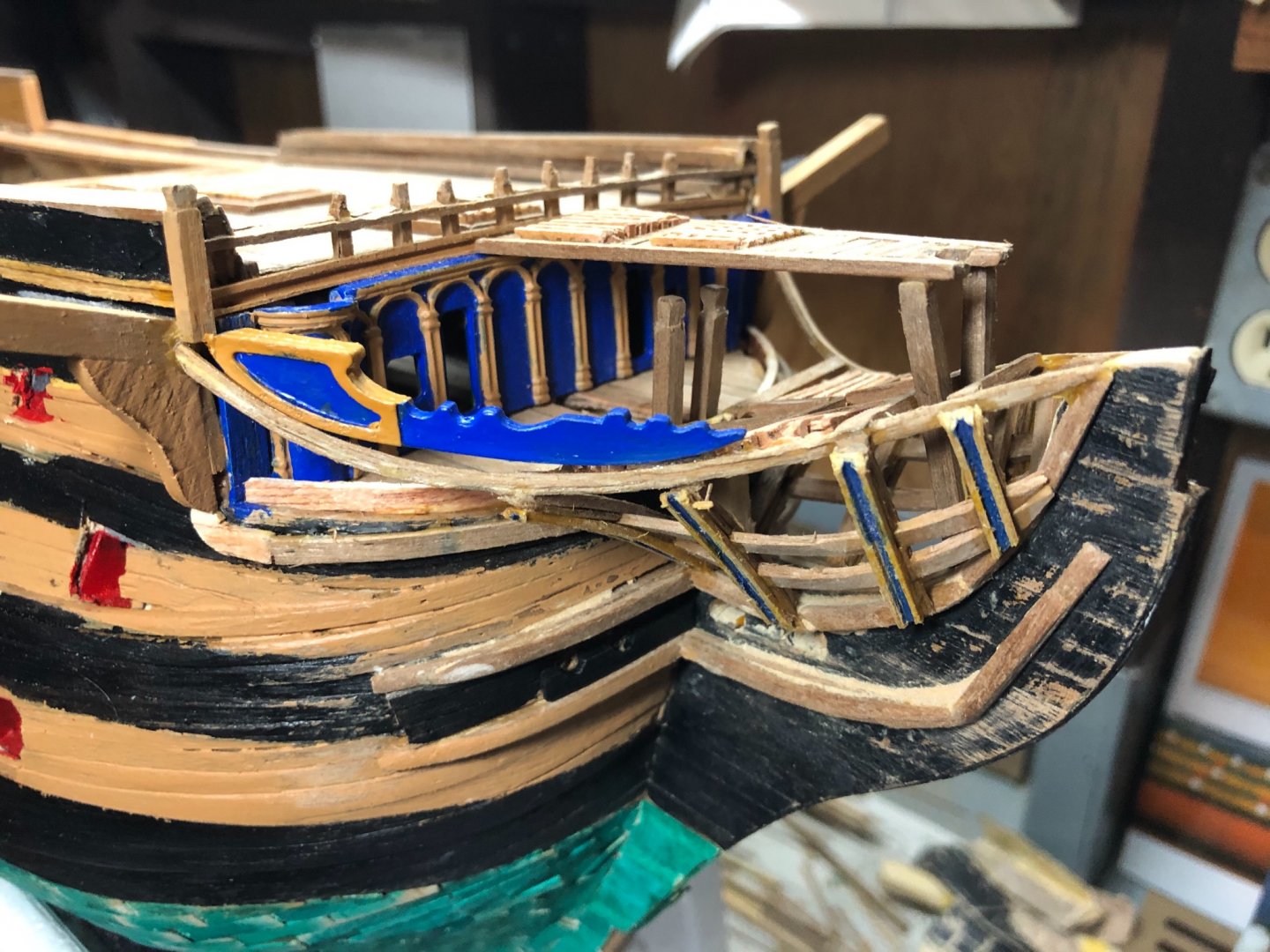

Starting the 4 x ladders connecting the quarter to upper decks. A nice pair of serviceable needle nose pliers really help.

- 395 replies

-

Looking closer at these ladders I realized they were installed upside down…. Will need to remove, sand, reposition and the reinstall.

- 395 replies

-

- 395 replies

-

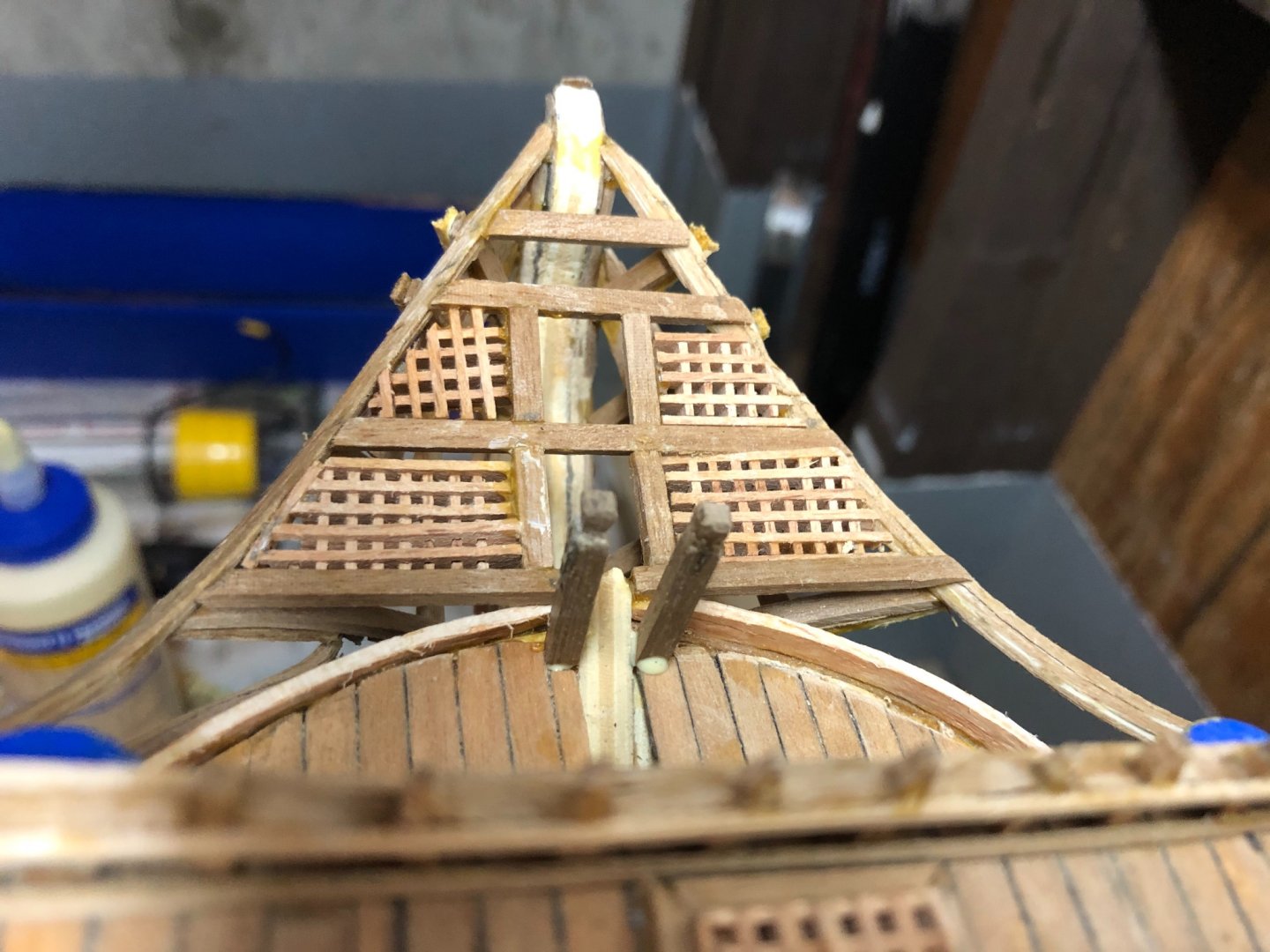

Columns continuing to go in. The gap between the upper deck and Scarphed Skid Beams is not uniform, necessitating tailoring each column for the 1-2mm gap difference.

- 395 replies

-

Thank you Henrik! Your Aggie is coming along nicely. Well done!

- 395 replies

-

Continuing adding the 20 columns between the upper and quarter decks. They are roughly 20mm tall with variances between 1-3mm. I’ve included a photo showing the progression from unfinished 20mm x 3mm x 3mm block to the finished column. I start by cutting the blocks with a small, fine saw, with a bit of sanding at the ends. Then, I mark the 3mm points top and bottom with a pencil. I then use a razor to cut slits along the 3mm lines and then shave the center of the block with the razor. The last step is sanding. Not perfect, but works for me.

- 395 replies

-

Beginning the finishing of the upper and quarter decks. I’m not very good at creating the small column structures from 3x3mm blocks 20mm or so in length as you can see below. Will be looking for more reliable methods for creating them.

- 395 replies

-

Time to start restarting the shipyard as the temperature dips below 40 degrees Fahrenheit and we are moving into Nov. Now working to finish the quarterdeck which requires a lot of precise, detailed work. We’ll see how it goes.

- 395 replies

-

Hello everyone! Hope you are staying safe and healthy and that you/yours have been safely vaccinated. Summer is nearly upon us and I'm taking this opportunity to step away from the shipyard for a bit to enjoy the nice weather and do some outdoors type activities. I've been briefly in/out of the shipyard to complete the bow area and will be in the later summer/early, GLW, ramping up working on finishing the quarterdeck area moldings, etc. I'm also reading 'Nelson, a Dream of Glory' by John Sugden to get a better understanding of Nelson's earlier years and exploits. So far, fascinating reading. Please be sure to have a safe and enjoyable summer season and keep up the good work on your models! Rob S

- 395 replies

-

Still working on the bow finishing and have painted and installed the starboard false rail. These rails are made of lead and you can see where they don’t seamlessly interface with the main rail. The lead will break if I attempt to bend it, even a little. My thought will be to shape and put a piece of wood in the gap. I’m not aware of any more elegant type solutions. Lesson learned may be to fit the false and main rails while shaping the main rails to minimize that gap. There is a larger gap on the port side.

- 395 replies

-

- 395 replies

-

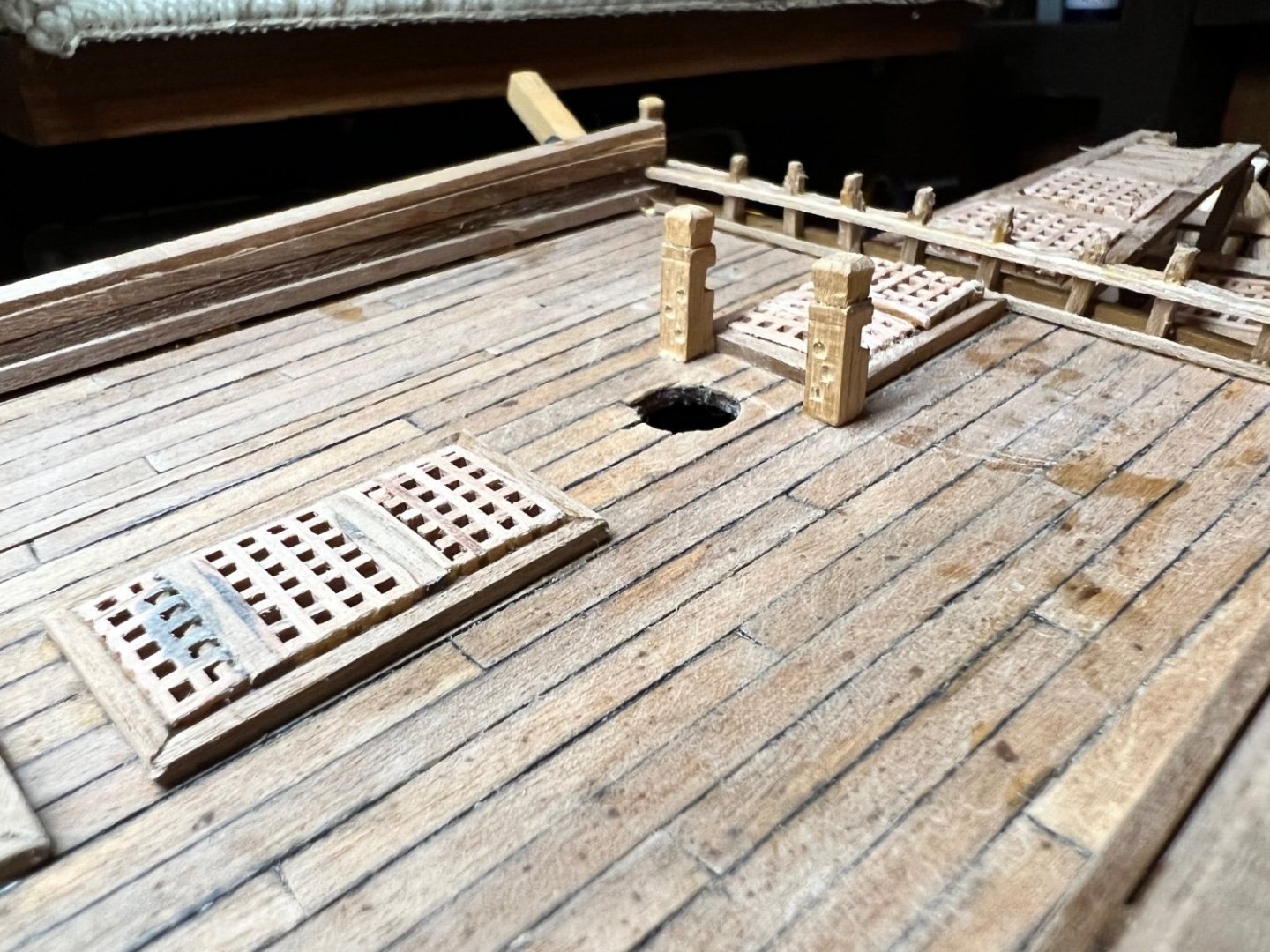

Marine’s walk with accompanying grate (1 of 2). I’ve tried a new approach to mitigating the grate brittleness with associated breakage by gluing the side grates (see pencil point for one) on each of 4 sides and then I was able to successfully tailor the sides without the whole thing falling apart. Still some additional work to get it to properly fit. Next pictures will show the completed item installed.

- 395 replies

-

Working some of the detail as I complete the bow area. The knightheads are 3mm x 3mm walnut laths that I used a small chisel with the laths held in a vise. The grates did not turn out as I had hoped.

- 395 replies

-

- 395 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.