stuglo

Members-

Posts

707 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by stuglo

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

Perfectly clear. Thank you. I have vols 1,2 and 4- so I'll have to complete the set.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

A step middle of chock will solve the problem .Thank you. At the risk of being pedantic, I assume a small step on either side so narrower piece sits above in the middle?- 475 replies

-

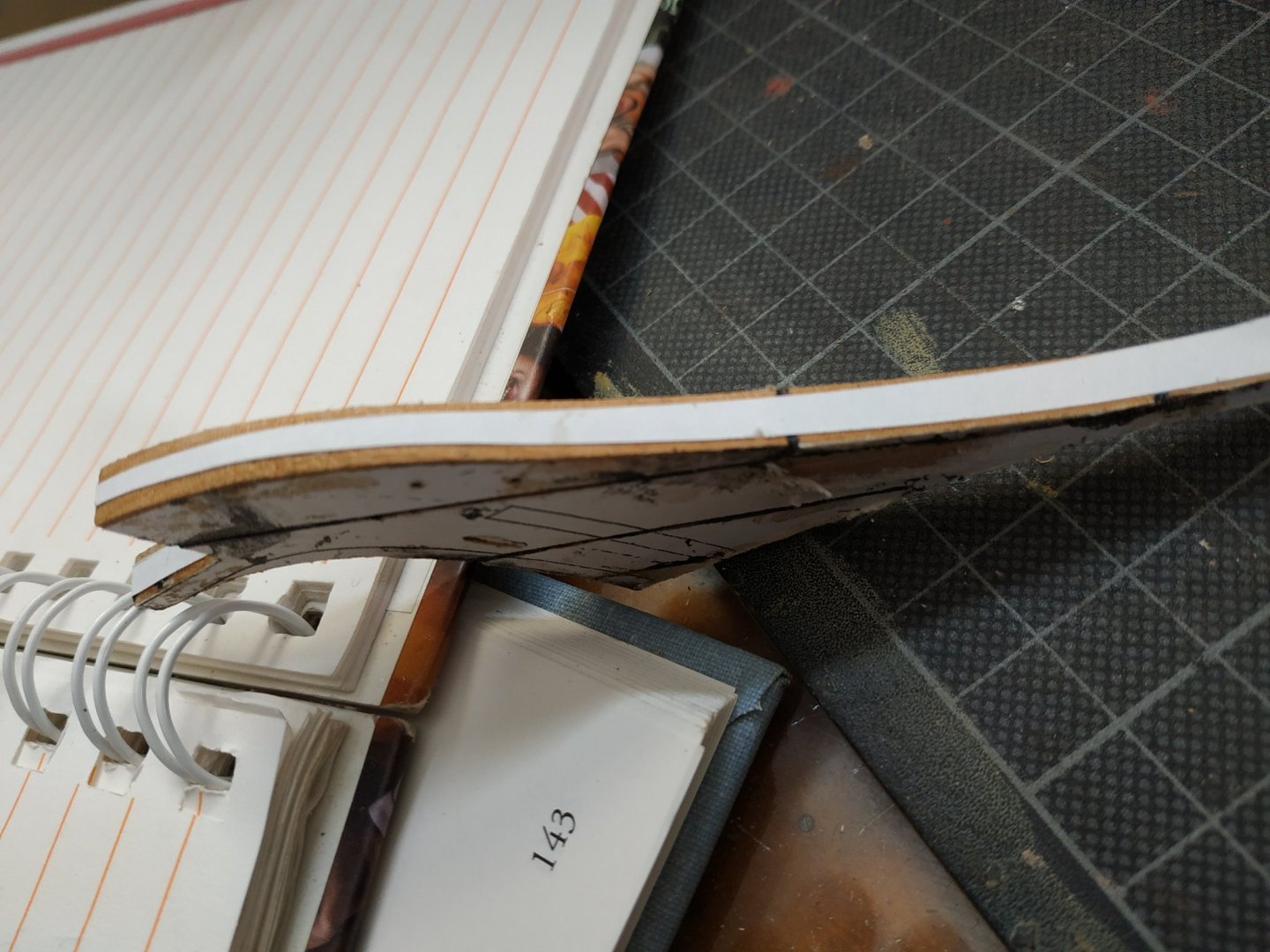

This is a great device, but the upper flange supplied is too small and allows slippage of the large sleeves. A simple fix is shown in picture- a jar top.

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

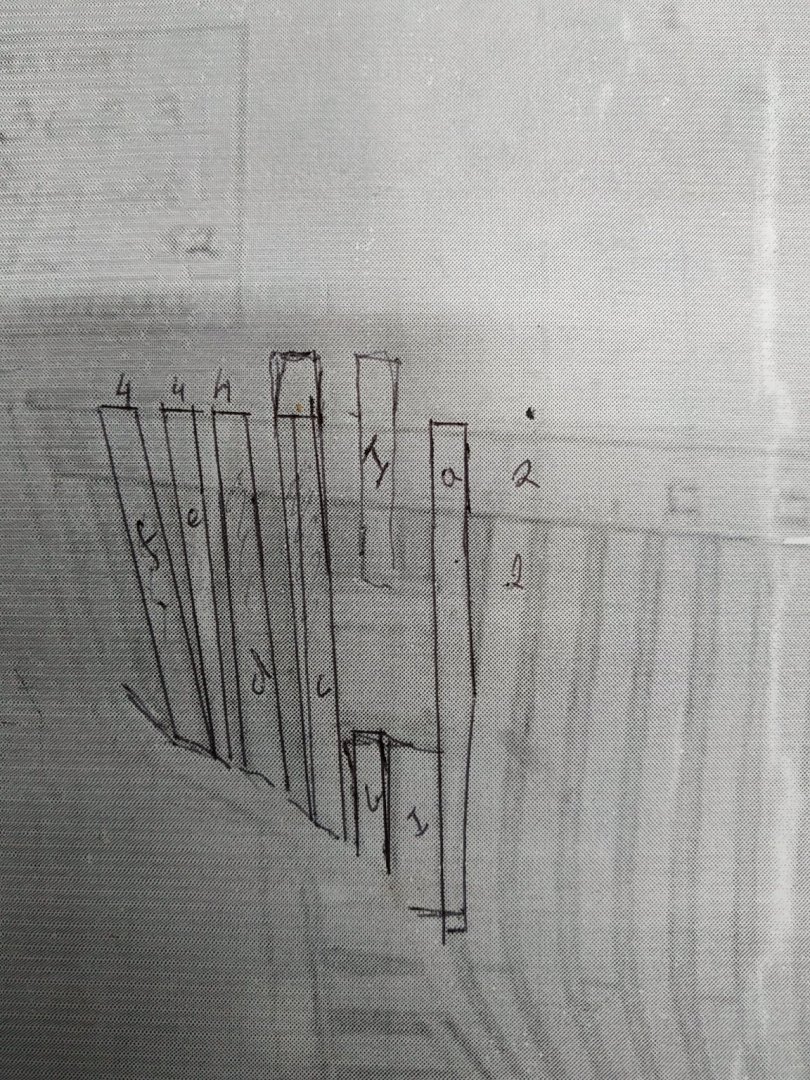

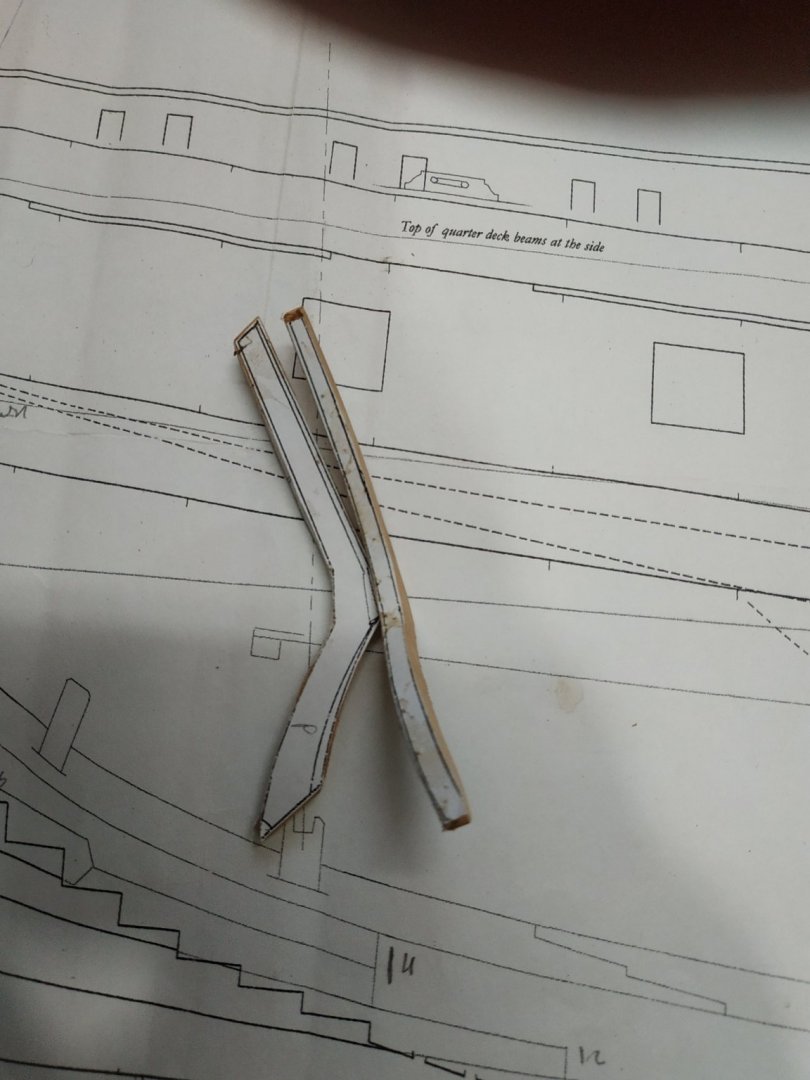

Need help/advice Now making the the square frames as suggested -reducing size pats/futtocks-10",9.5" and 9". I tapered the transition points and ended with timber tops too thin or wave profile. Should the transition points -chock or scarf- be left as step? What have I forgotten or not understood?- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

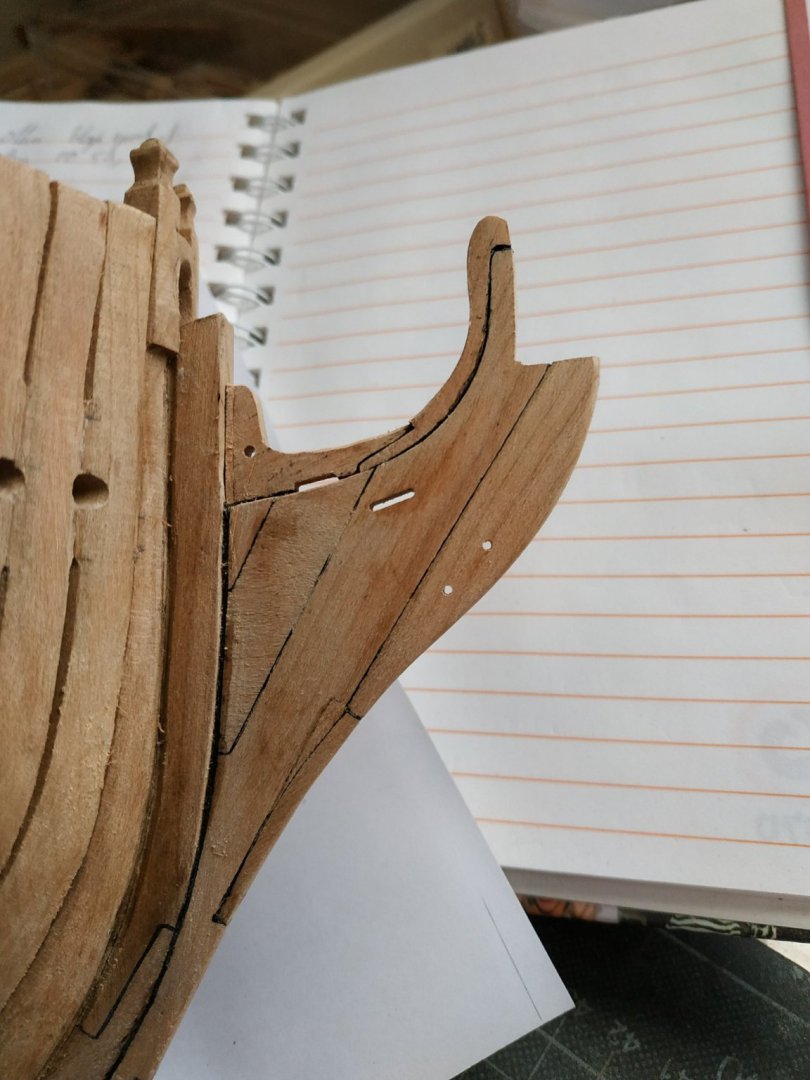

Knee of the Head (my dyslexic son referred to the ”elbow in his leg“ instead of knee) The good news is that we finished chapter 2 (TFFM)!!! This is a set of seemingly simple pieces that make up the foremost part of the ship The gripe was easy- I had already made it when I made the stem -not yet fitted but fortunately found in a “safe”box of bits.The blank is 5.3mm Need to remove from the building slip to fit these parts, which is worrying as the keel is very vulnerable. I supported it with a large piece of sponge. This, and other parts abutting the stem, have “felt”-black paper- filling the joint. The next pieces, chock, cutwater,lacing piece and bobstay piece are cut out from 5.3mm blanks.Here I cut on the pattern line, and the pieces fit well. Note the TFFM comment on the line of upper curve of lacing piece-a faint line under upper cheek,where it joins the extension piece. The pieces at various angles to the grain and joined by “black” glue (PVA+charcoal) - the contrast looks better this way. Dry fit to the curve of the stem, with adjustments as necessary- a few light touches with the spindle sander was effective. Bobstay holes and gammoning slot as shown, with milling piece #56 The combined piece needs tapering -from 5.3 to 2.12 mm at top of bobstay piece- the top of lacing pieces only to 3.18mm.That is from below, above and aft, forward . As before, I did this by cutting a pattern of this taper and sticking this to the fore curve. Tapering by alternate sanding on stati sanding board. A small imperfection in the wood was noted on the bobstay piece but I expected that this would be removed with the taper. Instead it grew like some cancerous iceberg.No camouflaging this. (Of course the piece with the extra work-holes and slot) Remove and, of course, the cutwater was damaged, and this also had to be remade. Another lesson I must remember- don’t waste time on suspect material. When satisfied with taper, glue felt for joint to stem. More mistakes- didn’t allow for thickness of felt and didn’t notice thoat snug fit caused the the gripe to lift away. Reset and the felt removed , some sanding to allow for felt in joint.And reattached. Glue reinforced with wooden trunnels from aft aspect of stem. These are limited because the thin drill bits are short. Augmented adhesion with rubber band and S@@$%T- all slipped off, taking gripe with it. Again clean all up (paper and glue is messy) and try again- this time with copper wire trunnels from front and back- and finger pressure. Ensure alignment with string midline from top of building slip supports for and aft. ? How to improve bond when using the intervening paper- wood is not being glued directly to wood. While setting, made the last 2 upper pieces- standard and extension pieces. These are thinner , 3.71 tapering to 3.18 (matching top of lacingpiece). Added the hole (larger, use #52) and the aft gammoning slit. Fitted them separately, but perhaps would have been easier to glue together before final shaping. Used coloured glue for joint-not sure if this was ok join to stem, but sick of using the black paper. Difficult to clean up-was frightened of breaking it off.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

I fully agree. Each time I look I see mistakes and inadequate finishing. I keep thinking whether its too late to start again or start another when the hull is finished.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

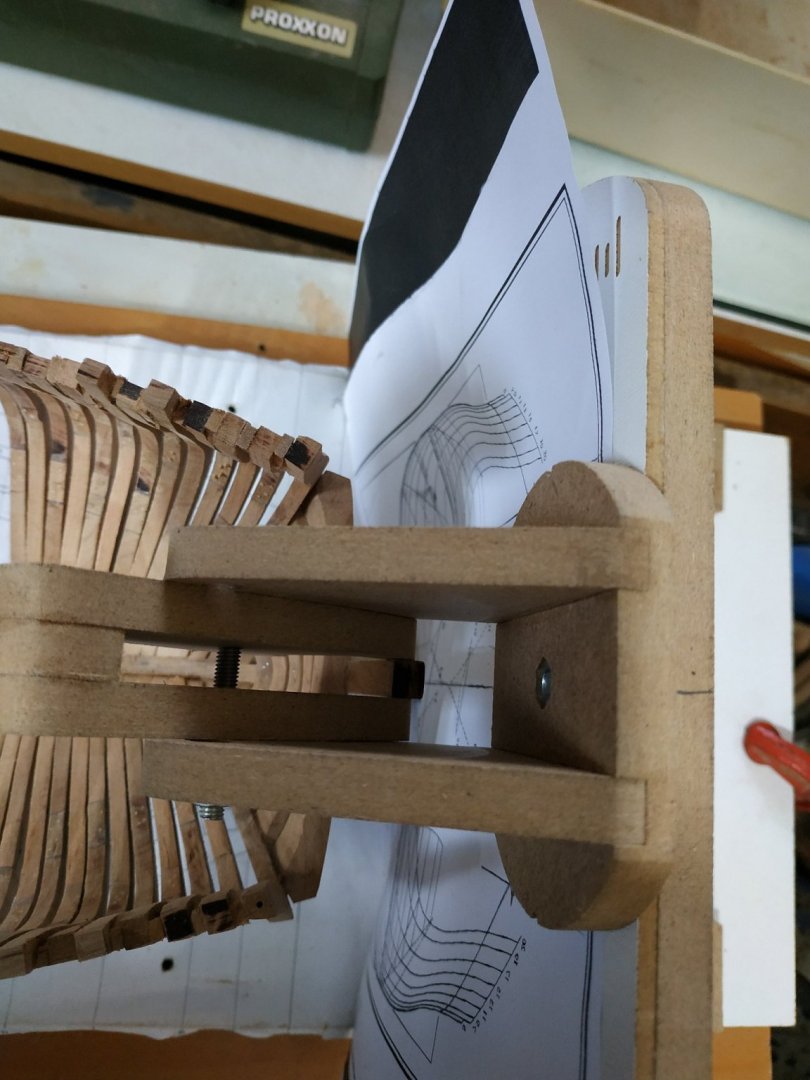

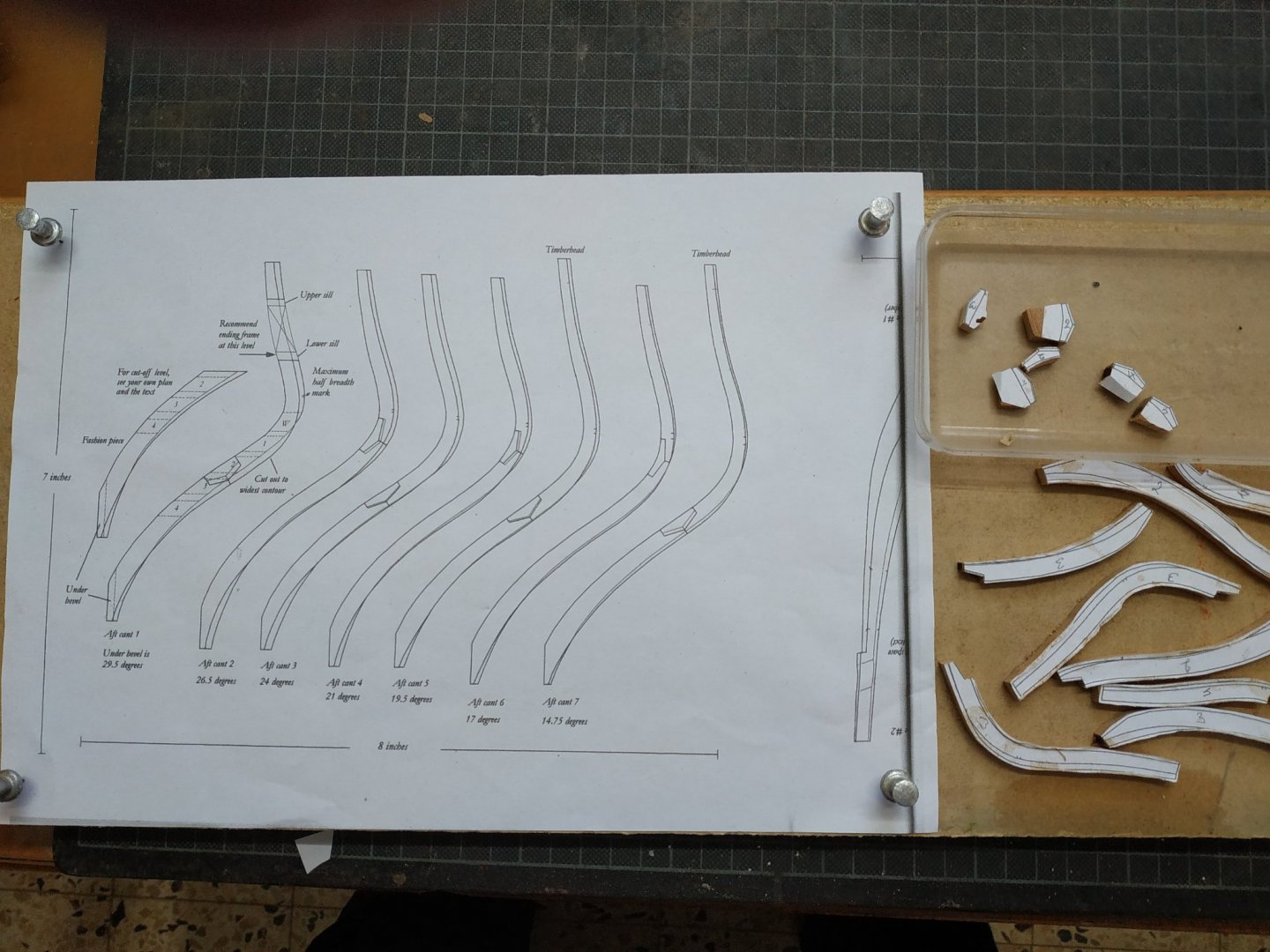

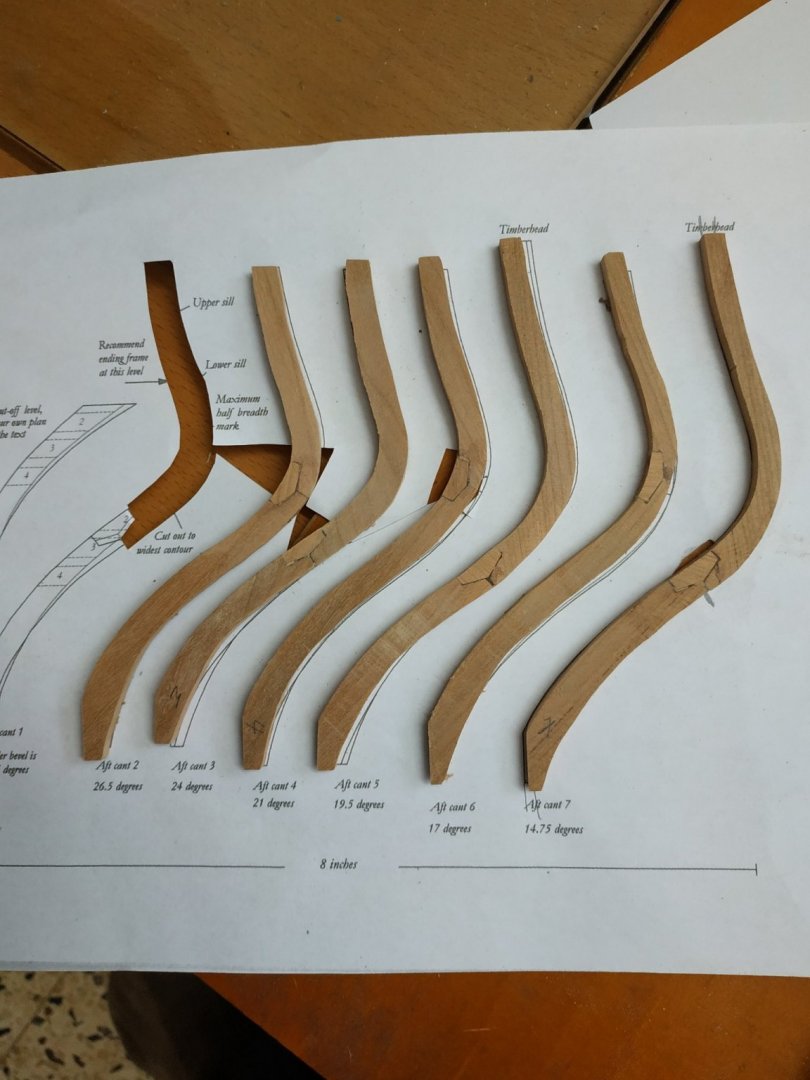

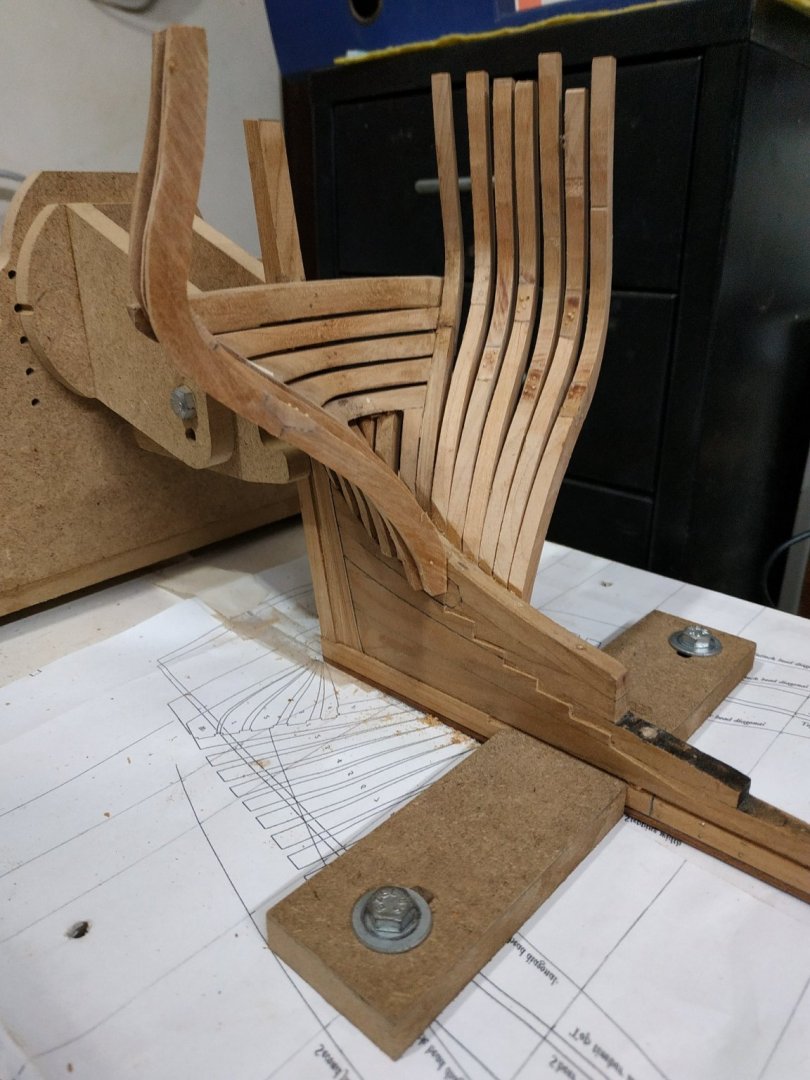

Finishing side framing and Fairing same: Just 2 short paragraphs and little explanation for what turned out to be a long and frustrating stage. This stage includes the forming of the stern lights (window). Position, angle and size from the framing plan. The upper part of 1st aft cant needs to be cut off at the appropriate height (cutting a part off the hull is always traumatic for me). An extra “limb” attached to the fore side forms the fore side of the window-the other (aft) side is one of the “fillers” that sit on the counter frame. The upper cant frames learn forward-this slopes back and 2nd cant frame at an angle therefore cut as a blunt-ended wedge.I decided not to glue in place yet so that I could build the window on the plan before fitting. This,like the other fillers, follow the line of the aft cants but as no patterns are available, I used wide blanks (15mm) and for the most, kept them the same thickness of the other cants. The aft side of the window sits on the counter frame, parallel to and at a distance shown on the framing plan. The angle of the sills is also shown. The position of the sills marked with on the side frames- Not clear from the plan the thickness of sills, so I guessed at 3mm lower and 2.5mm upper. The TFFM shows a “v” shaped mortise for lower with a variant for upper joints. I thought I’d be clever and use a “V” milling bit to a depth of 1.5 and widen the V with the chisel but with my defective thumb I found this impossible. So I cheated and used a square ended bit with a width of sills. Forgive me. The other fillers caused me more difficulty than anticipated. Balanced on the thin counter frame they needed the small fillers at the top to be held in place while drying. Keeping alignment was anticipated thus the excessive width of the blanks. There is also some variety of thickness-again referencing the framing plan. Angling correctly the “feet” was fiddly and lack of patience on my part (fatal for a modeller) caused frequent dislodging of bits. Also an overly tight wedge between two tops, caused one of the counter frames to part from the wing transom. This necessitated unsticking the adherent bits, realign the counter frame as before, and start again. The PVA glue has a fast grip, but be left overnight for good adherence. Fairing: Because of the extra wide fillers, window frames and sills, lots to take off. So I used the hand band sander for these. The rest of the sanding was time and effort and I’m sure any modeller is familiar with this. Just to emphasise the need to support the work -by hand and clamped beams. I again left the lower external fairing until keel more stable. These stages have taken me more time and frustration than anything so far. Perhaps the designation ”filler” suggested something simple and I didn’t give the attention and respect needed I’ll try not to repeat this mistake.(Modelling is like life-nothing is as simple as it seems)- 475 replies

-

I beg to differ. I have a proxxon mill and it is in constant use , even before I started POF/scratch. After some short learning curve, it gives quick, accurate and reproducible results. Its limits are the need for variety of bits and experience of user. These can be overcome with more experience, inventiveness and some money. The aforesaid does not detract from the other tools mentioned. Start young and get your money's worth.

-

Beautiful. You are an inspiration (and help to make my poor effort possible) Have a great holiday

- 1,132 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

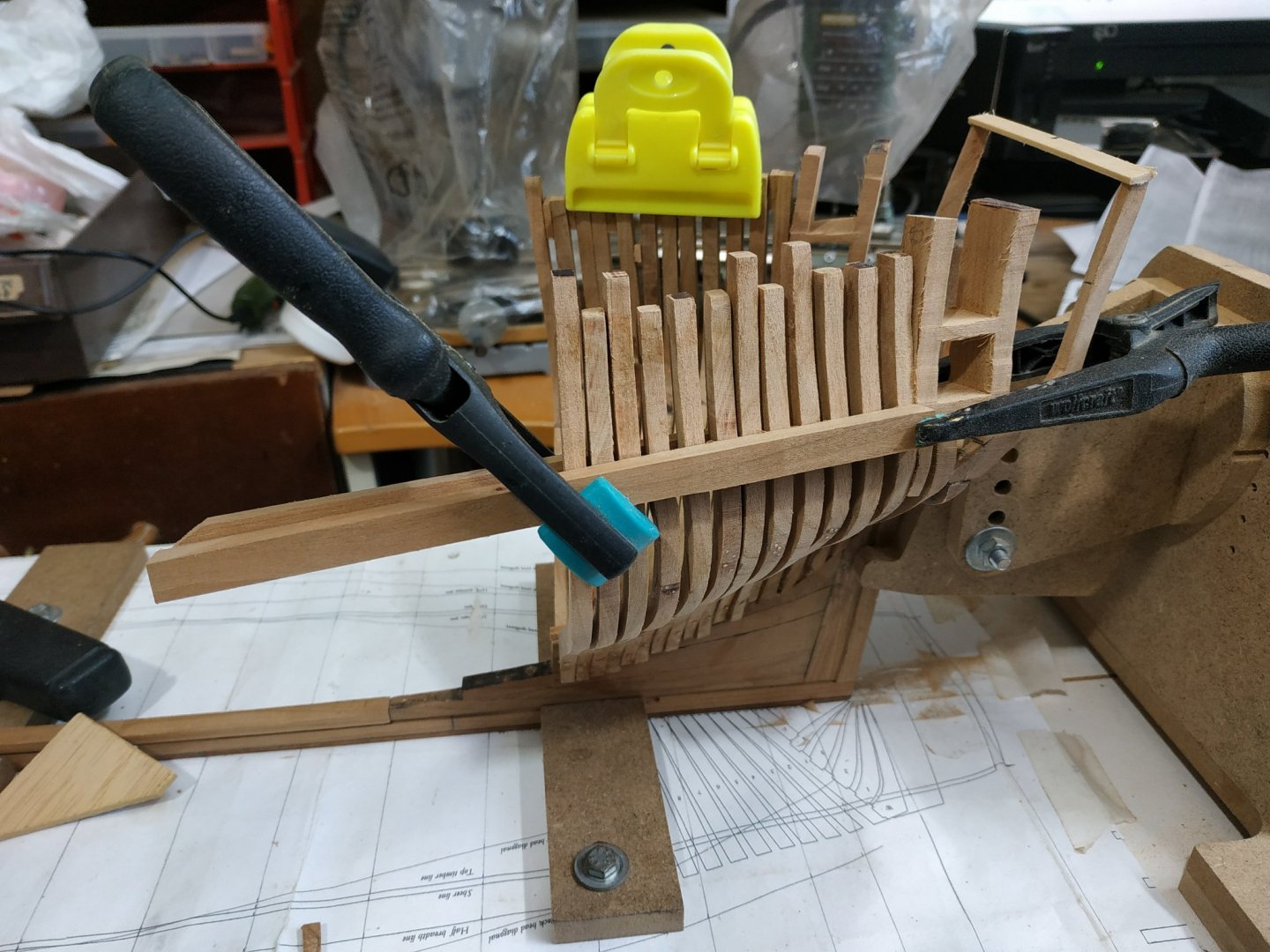

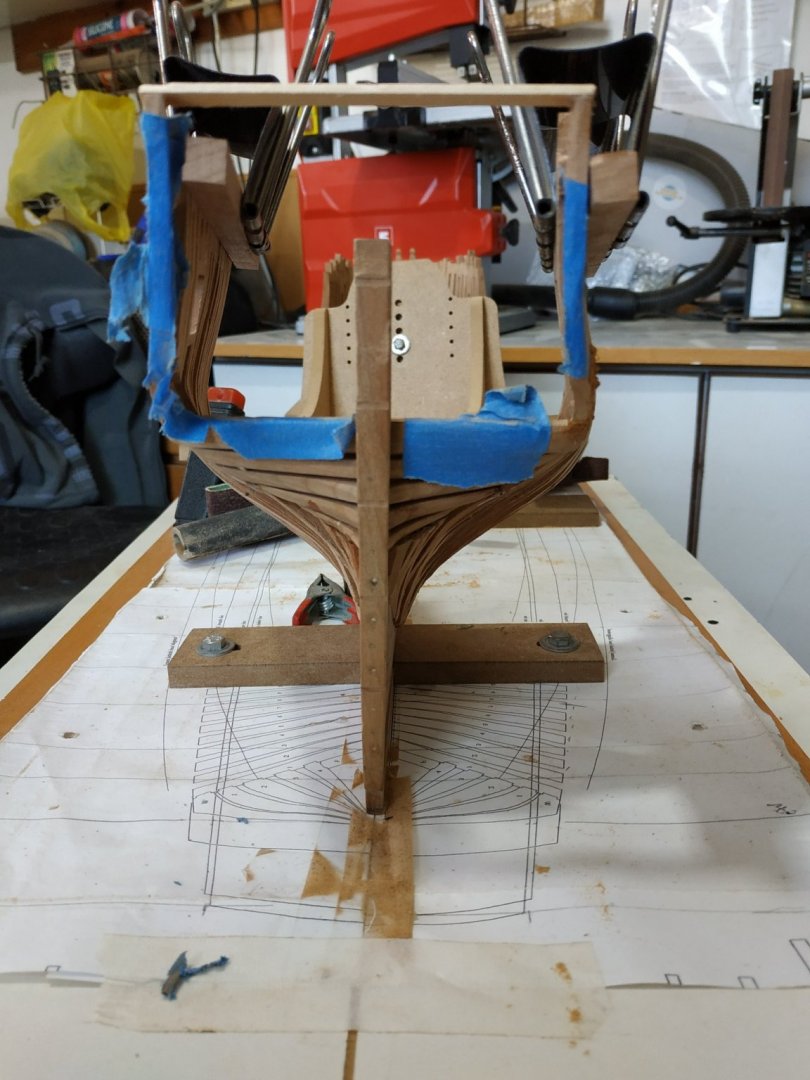

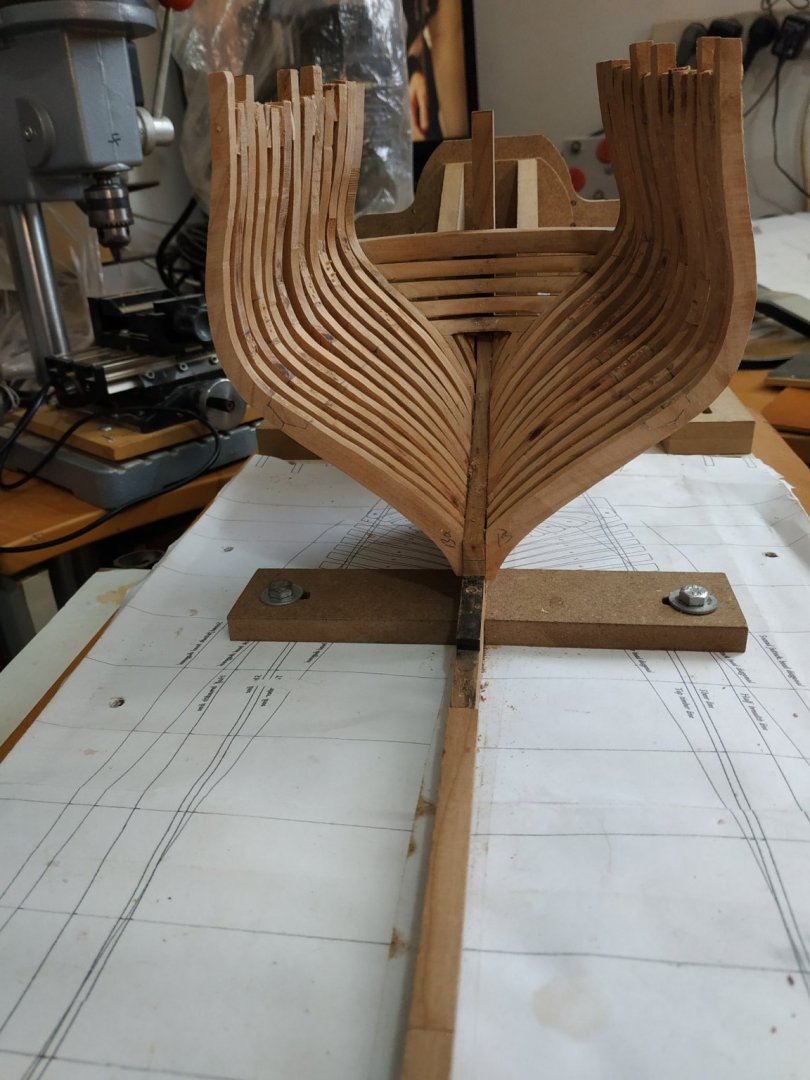

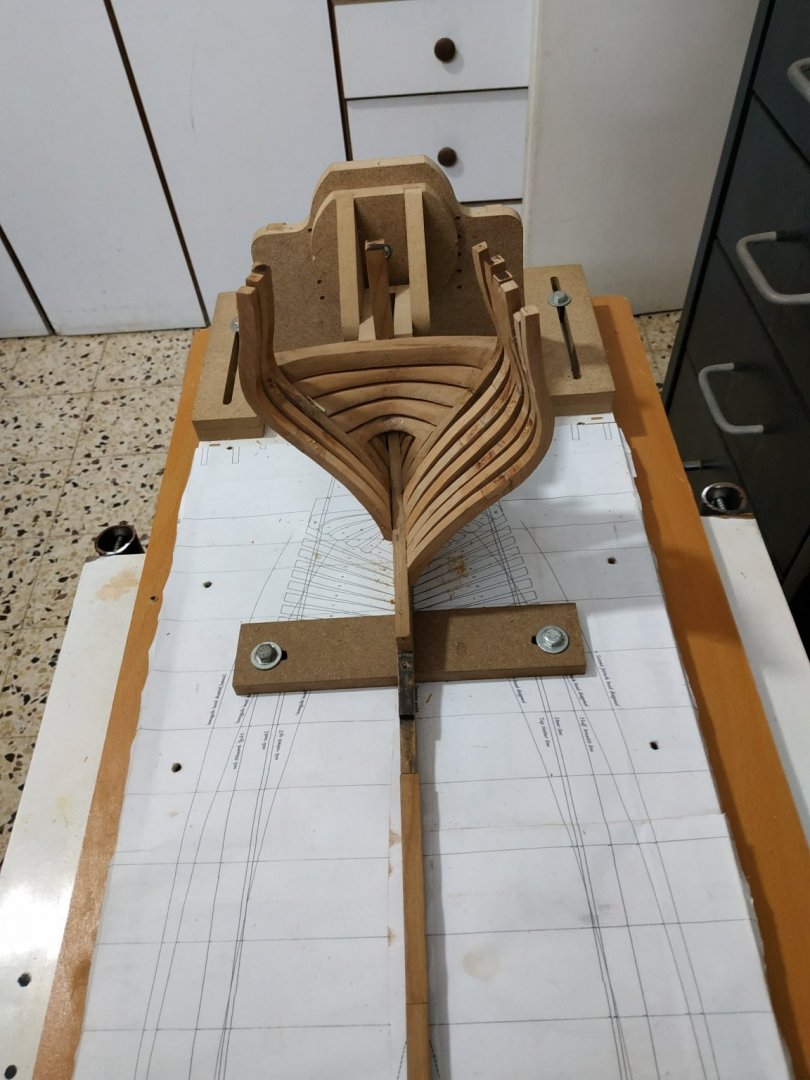

Framing the stem/side Counters (TFFM mentions a 9th port- at present this would be an unnecessary complication and I’m still on chapter 2.) The practicum gives a detailed explanation which encourages reading to the end. I don’t really understand, so I turn to Kevin’s video-he says something similar, so we go ahead and make the pieces. Before attempting to make the piece, a jig of some sort needs to be made to align and support the aft end, at the correct height, and angle so the pieces are separated by the correct distance. Additionally, the stem needs support to maintain the vertical 90deg position. The hobby building slip has a vertical plan holder. By adding the stem clamp to this (with the body plan underneath)it supports the stem, the new side counter while controlling its position and angle. Instructed to draw line parallel and 3.34cm aft of AP line on the breadth plan. This intersects with the end of the timberline and is aft position of the pieces and the mark for the vertical plan holder. On the body plan, vertical lines, 3.9 cm either side of the midline are drawn and the point this intersects with the height of timberline, is marked.(A simple drawing on the page makes this very simple). Fortunately the book gives a (correct 1/48)scale image because I spent a half an hour searching the plans.Note this is for the starboard side - it took me a while to be sure of this. Photocopies for templates, 7.95mm blanks, and using the sanders, made the pieces in 2 stages ie dimensions. The timber line is marked on the pieces and the inner aspect aligned to the mark on the plan (again the drawing in TFFM is self explanatory) The “foot” needs some refining to accommodate angle of #1 cant and slope of wing transom. This is (if only temporary)a fragile joint so I used 5min epoxy while the plan holder supports the end and vertical plane is maintained. An additional measure is used- 9.22 cm between the 2 upper knuckles-this is checked while glue is still semi-flexible. Finally, if sure OK, a spall or beam is temporarily stuck to the tops for additional stability. PS accumulating lots of photocopies of part plans/templates. Filing them in separate plastic envelopes in a file makes for order.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

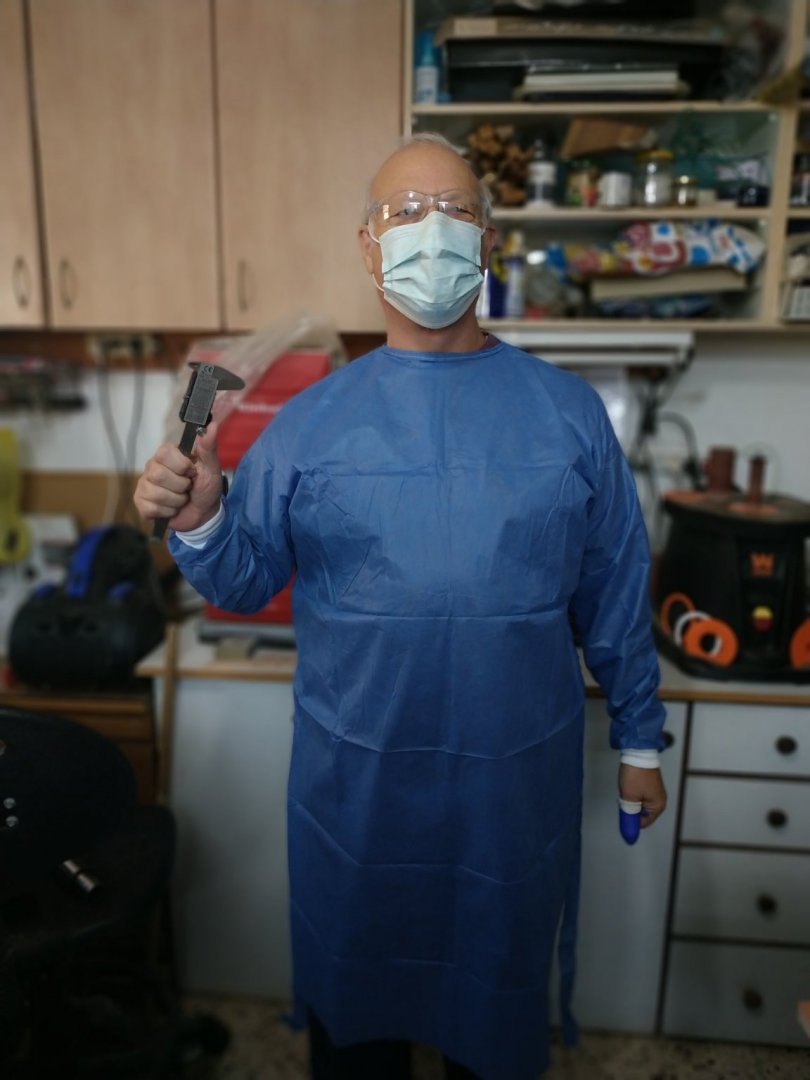

Aft cants #2-13 cont. Finishing making of the aft cants. More adept and less removals and repositioning . ( ? is this called RECANTING-ha! ha!) Regular except for #10 which as a “shift” similar to the #11 fore cant. Note the shift is directed amidships in both cases. Also note #12 has a scarf joint instead of chock. Also note that when trying to minimise wood waste, I layed out some templates across grain- not very clever but doesn;t appear noticeable as yet.Will replace if required when seen after initial fairing. You may have noticed the horror picture of me wearing my schoolboy apron. It left my upper jumper unprotected therefor still half covered in sawdust. The new picture is more practical and to misquote Gabriel Garcia Marquez- “Woodworking in the age of Corona” (ppe 2020) Keep well and safe everyone.- 475 replies

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

Just catching up today. really good ideas and will try them even though I've seen the post after initial placing of my cants- 475 replies

-

Electric sword or reciprocating saw

stuglo replied to stuglo's topic in Modeling tools and Workshop Equipment

Have several but the thin ones are "bendy". Saw one used by Kenny on video and had fantasy -

does anyone know of an alternative to the microlux brand? I simply do not want to buy their special transformer which they say is essential. https://www.micromark.com/Micro-Make-MicroLux-Sword-Saw

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

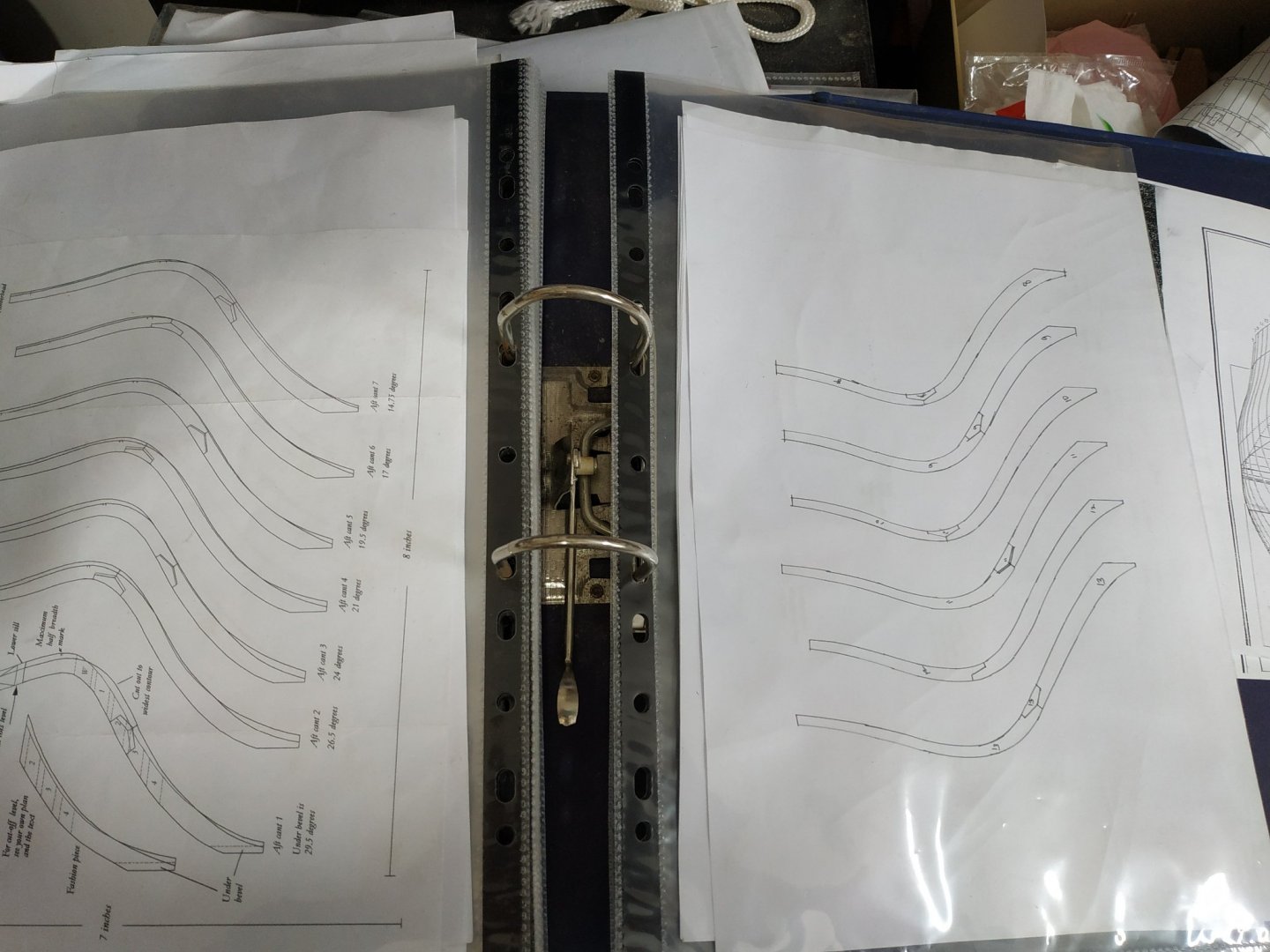

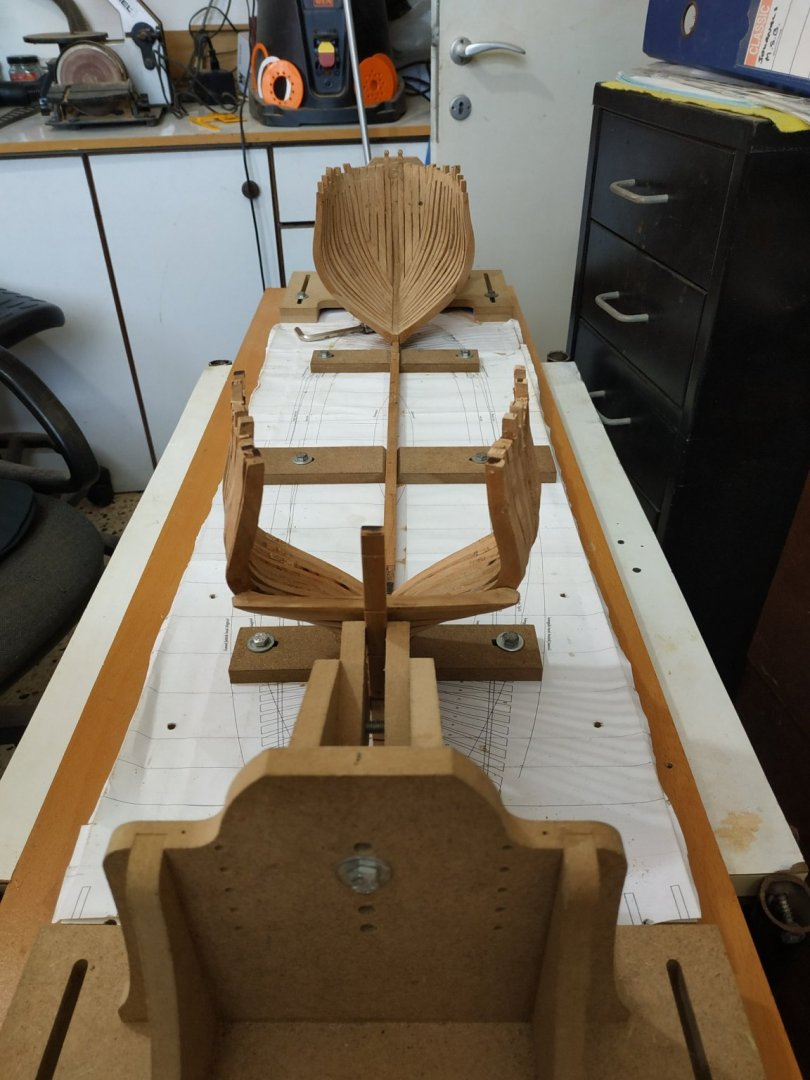

Back to building cants-this time the aft sets. Similar principles i.e. 4.77mm wide. This time I want to try some new ways. My experience with the chisel was not too successful. Now with a defective digit (injured thumb) I would think nearer to impossible. Nevertheless, I’ll try the chocks using cut out plans, jig saw and 5in disc sander. Cutting out the timber plan separately with the chock section cut on the lines. The upper and lower timbers attached by rubber glue to another complete copy of plans. The narrowing lips of the 2 pieces have a drop of PVA and the the pieces are stable to fit the chock. A chisel blade is used to create the slight angle if the plan requires it. The is made slightly oversize, the slope of side if required and the final fit are made by removing the thinnest of slivers to size required. Although initially against it, I tried using the 5min epoxy and it seems to work well, but it is pretty irreversible and leaves a slight stain.I don’t think it will be too noticeable when finished. I also decided to make and fit one side at a time. I also have left of the fairing bevels as I found that a close adherence to them when making the fore cants, created some problems with alignment. After a try out with the 2ns and 3rd cants, it seems as if the upper timber of both 1st cants are incorrectly placed. I had broken the starboard one, twice already so made a new one. The port side was separated and adjusted-the tips of the wing transom protrude but I checked it with a plan cut out and it is ok. This may have a function which I’ve forgotten- I will have to wait and see. Greg mentions this is like a chess game in terms of planning ahead, but I did not expect such an innovative opponent ! PS In my first year of secondary school (age 11) we had a weekly woodwork lesson. Our parents had to buy an appropriate work apron. My dear mother kept mine for the next 40 years and returned it to me so I can now use it for its intended purpose.- 475 replies

-

I only break the ones I have least of!!

-

Sorry that I have posted this in bits

-

Also some Utube videos:

-

https://en.wikipedia.org/wiki/Ma'agan_Michael_Ship

-

Last friday, a small group of us had the privilege of visiting and receiving a first hand explanation on a replica of a 2500 year old boat. The technical details show these were not primitive but rather advanced designers and craftsman. For me personally, it closed a circle as I saw the original under preservation treatment more than 25 years ago, along with my friend and mentor who built the first model of this most important find.

-

Swan-Class Sloop by Stuglo - FINISHED - 1:48

stuglo replied to stuglo's topic in - Build logs for subjects built 1751 - 1800

Excellent advice gratefully received. The "pencil" lines are obvious in retrospect but I hadn't thought of it. Genius is simplicity and innovation-you have both. Please continue keeping a watchful eye and continued input.- 475 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.5fee1de1e1f312723ebe6a69a60a2695.jpg)