stuglo

Members-

Posts

707 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by stuglo

-

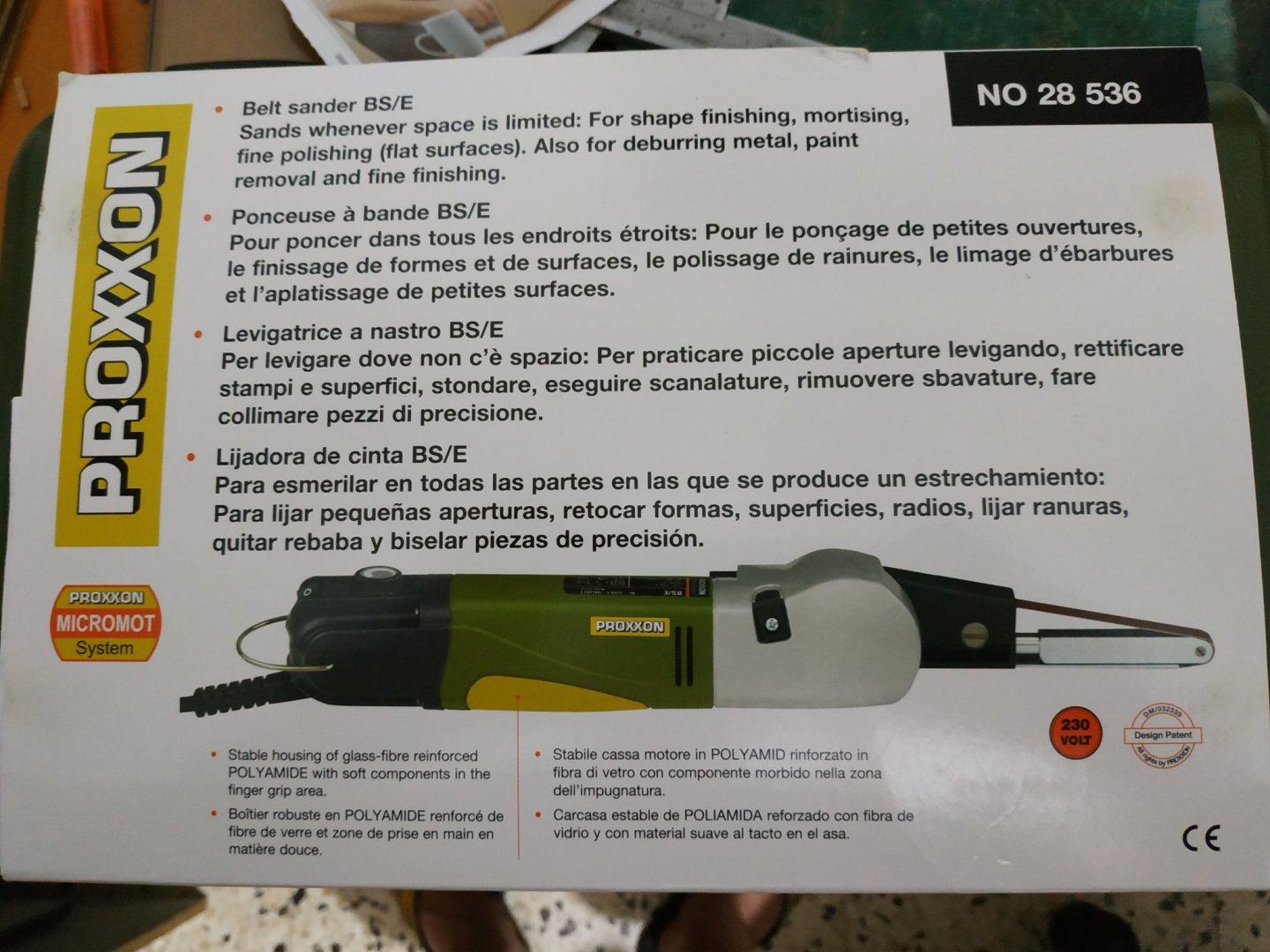

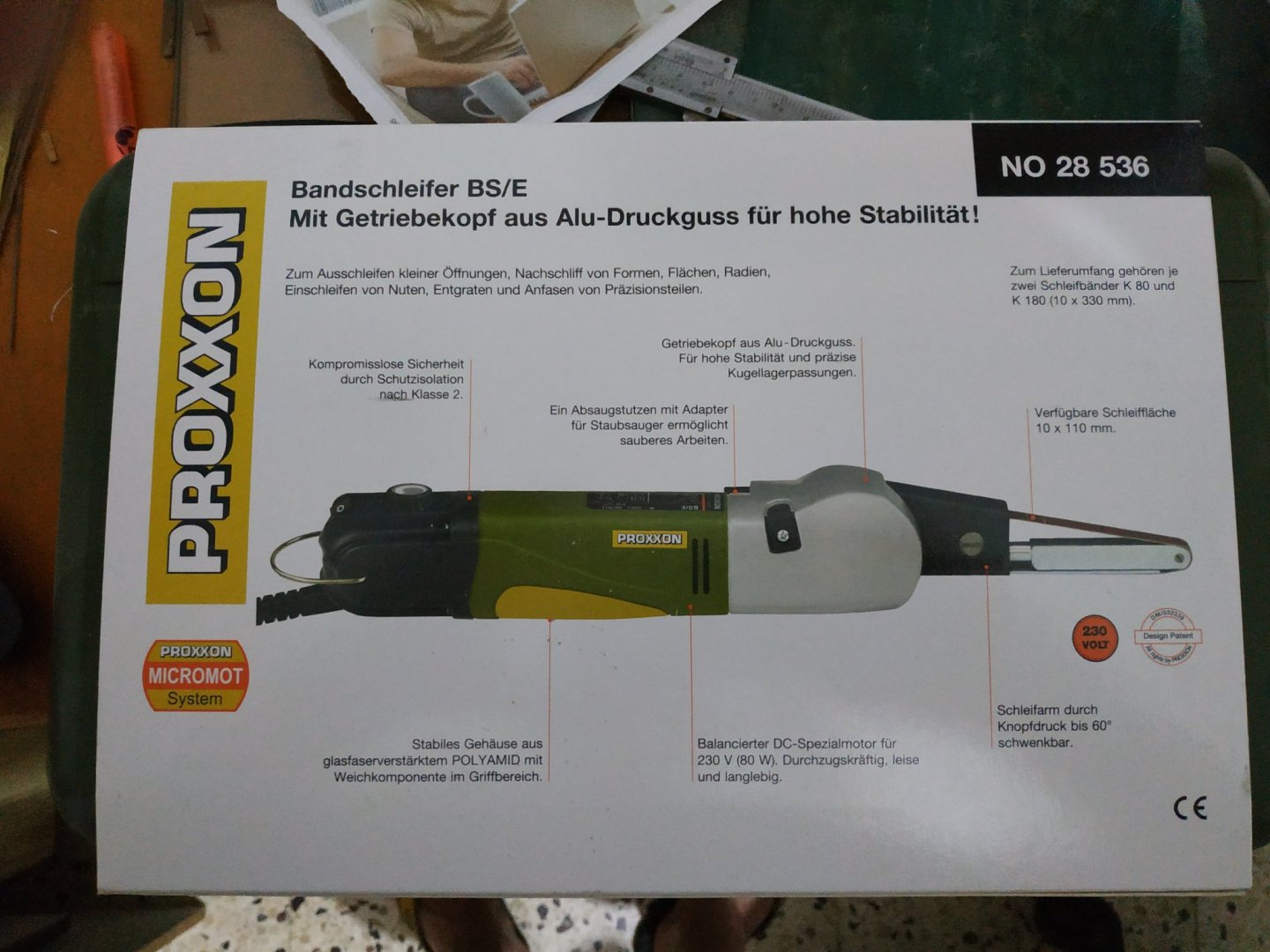

I have bought quite a few power tools in recent years , most already mentioned, but I would suggest the my belt sander is used almost daily. When used c arefully, it saves a huge amount of time

-

I use chloroform brushed on. (so far remained conscious ) I never tried thickening it, but I found with the syringe, it was difficult to control the pressure and therefore avoiding squirting (both glass and single use).capillary action didn't work for me. I use 3mm plexi even with cases of over 1 metre. Glass looks better but is very heavy. I also had a nasty accident once (not related to modeling) so I cringe whenever I handle it. PS very original, great execution and I might copy your base design

- 168 replies

-

They look artificial and do not represent the real thing. The ports can be lined if not painted. Check out some virtual tours on u-tube or better still visit the ship ! Generally speaking I like the wood look and to see my work. I paint badly but certain models, look better painted eg Diane and Agamemnon, others such as Woppen, only the upper stern and side decoration. Like much with this hobby, its very personal.

-

This was my first build and still one of my favorites, in the days before internet. The wood was good, the plans needed understanding and the Longridge book a necessity. Apart from a Dremel drill, work by hand tools. But then I counted years not months of work. Be prepared for undoing mistakes, which is easier if things are glued later or use PVA which can be "undone". Minor points- I'm glad that I did not paint the hull and regret using the metal port frames. Have fun, share and ask when in doubt.

-

Single planking on bulkheads is in my opinion , much more difficult. The ability to form smooth and accurate lines demand a substantial base-frames or close bulwarks, or a much thicker plank. Also a second layer of planking gives a second chance to improve without undoing and being short of wood. I applaud those who produce good results from the single planking ships- my efforts require (?excessive) filling and paint to disguise my underachievement.

-

HMS Warrior 1781 by John Rose

stuglo replied to John Rose's topic in - Build logs for subjects built 1751 - 1800

inspirational -

ancre La Jacinthe 1823 by guraus - Scale 1:48

stuglo replied to guraus's topic in - Build logs for subjects built 1801 - 1850

beautiful - a true professional -

Brig Eagle 1814 by ChadB

stuglo replied to ChadB's topic in - Build logs for subjects built 1801 - 1850

amazingly good. -

I'm building the Panart bow section and definitely had to move the ports- this and other patterns I have used are usually only guides. Try a small center hole and see - remember also height of sills relate to the cannon/deck height which may not be the same as allowed for by the pattern.

-

Mini Table Saw recommendations

stuglo replied to captainscott's topic in Modeling tools and Workshop Equipment

I use https://www.axminster.co.uk/ for blades and other things. Good for delivery in UK and also to Israel. Good price and service. -

Its cheap to photocopy everything several times- I use my simple home printer

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

Mini Table Saw recommendations

stuglo replied to captainscott's topic in Modeling tools and Workshop Equipment

I've had a proxxon K230 for 6 years including 2 scratch built models. I've had to buy several types of blade and certainly agree that for "heavy"work, tungsten are worthwhile. If and when this breaks, I would like the Byrnes but with shipping it is VERY expensive. The lack of accuracy of the proxxon can be compensated by finishing by sanding as can the lack of tilt facility -

Have you used this method of shaping/ marking frames before. I found that when I cut out the paper pattern as you have done, they tended to distort when glued to the wood. I therefore stuck them "whole" then cut them together with the wood. I hope to start my Rattlesnake in a couple of months, so I want to share your experience

- 50 replies

-

- rattlesnake

- brig

-

(and 1 more)

Tagged with:

-

I also discovered the log only after seeing the gallery pictures. Reading from the beginning was worthwhile and increases the appreciation of the quality of work. Many helpful tips. How did you make those mast hoops and miniature hinges on the doors?

- 231 replies

-

- model shipways

- armed virginia sloop

-

(and 1 more)

Tagged with:

-

superb

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.