Wahka_est

Members-

Posts

522 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Wahka_est

-

Hi, Just looked at your Victory build. Really nice! Also your suggestion is simple and work really well. have to try it when i get home. Usually when we have problems we intend to search for complicated solutions where in reality the solution might be just a simple knot, twist and knot.... Keep and eye on me, maybe you have other suggestions also Vahur

-

Im not alone with the frustriation and that a good feeling . Reagarding rigging i have started to "summarize" all blocks info etc on to one drawing and also adding info from your build pluss from books to get it at least working. Biggest issue i have is that there is little info about block and cleats on masts. Some info is complitely missing (cleats on masts for example). Vahur

-

To be honest the instructions are quite bad and info is all over the drawings. But not all info is there and therefore you have to use books etc to get it allmost right. This creates frustration but..... It reminds my old days as facade engineer when i didnt know anything and i jumped in water. This situations where you have to find stuff out yourself from books, forums articles will educate you the most. The rigging drawings are unclear to me so I have all the needed books to understand how it should be for example. At some point you start understanding how all that works and why its there. After that build im pretty sure I have gained much knowledge how sihps function and future builds are much more easier. To summarize: for me its hard specially the rigging part. Location of some parts are also unclear as they are not marked on drawings. But eventually i will get there. Regarding rigging knots I contacted well known designer who calmed me down and said basicly that on 1:64 scale you cant go nuts over all the knots. Also thats something i have read in the forum before. So I decided if after 5 tries i cant get it right then i will step a bit down on that particular knot and try to make it allmost the same. Will post when theres something to show. A yeah, i will redo that yard that is offset

-

My headaches trying to use Blenders guide for block rigging. Have been strugelling with block knots. Found great instructions on site but never got them to work. So decided to try with bigger dimenson to find out whats the problem. So somehow with thicker rooe it came out great. Made more and more examples all good. Then went back to original rigging and disaster again. Was so desparate-WHY IT DOES NOT WORK....? Then thought ok i have cord from my Terror build, lets try with that. Again, come out nicely. Started looking more into CC rooe and realized that it does not slide at all. I tried siezing with normal knots and again it was so tight. Summary: cant use CC rope for attatcking blocks to yards or eyelts as it does not slide at all. Maybe im just imcompitent but pile of used tread on table showed that i didnt give up easily. So now i have nirmal sewing tread that i used for Terror and got from my father. Outcome is there. Covered brushed with dillutated pva and soon i can try if it loosens or not.

-

Amazing work! You are my example with this build as Cruiser is my first build based only on drawings. Im at the stage where i need to start attatching blocks to yards and masts. Can you guide me how you attached them (knots). I have tried different ways from youtube and also from this site but i really never got the to work as it loosens up or does not look nice. Really would appriciate the help. Vahur

- 102 replies

-

- cruiser

- caldercraft

-

(and 1 more)

Tagged with:

-

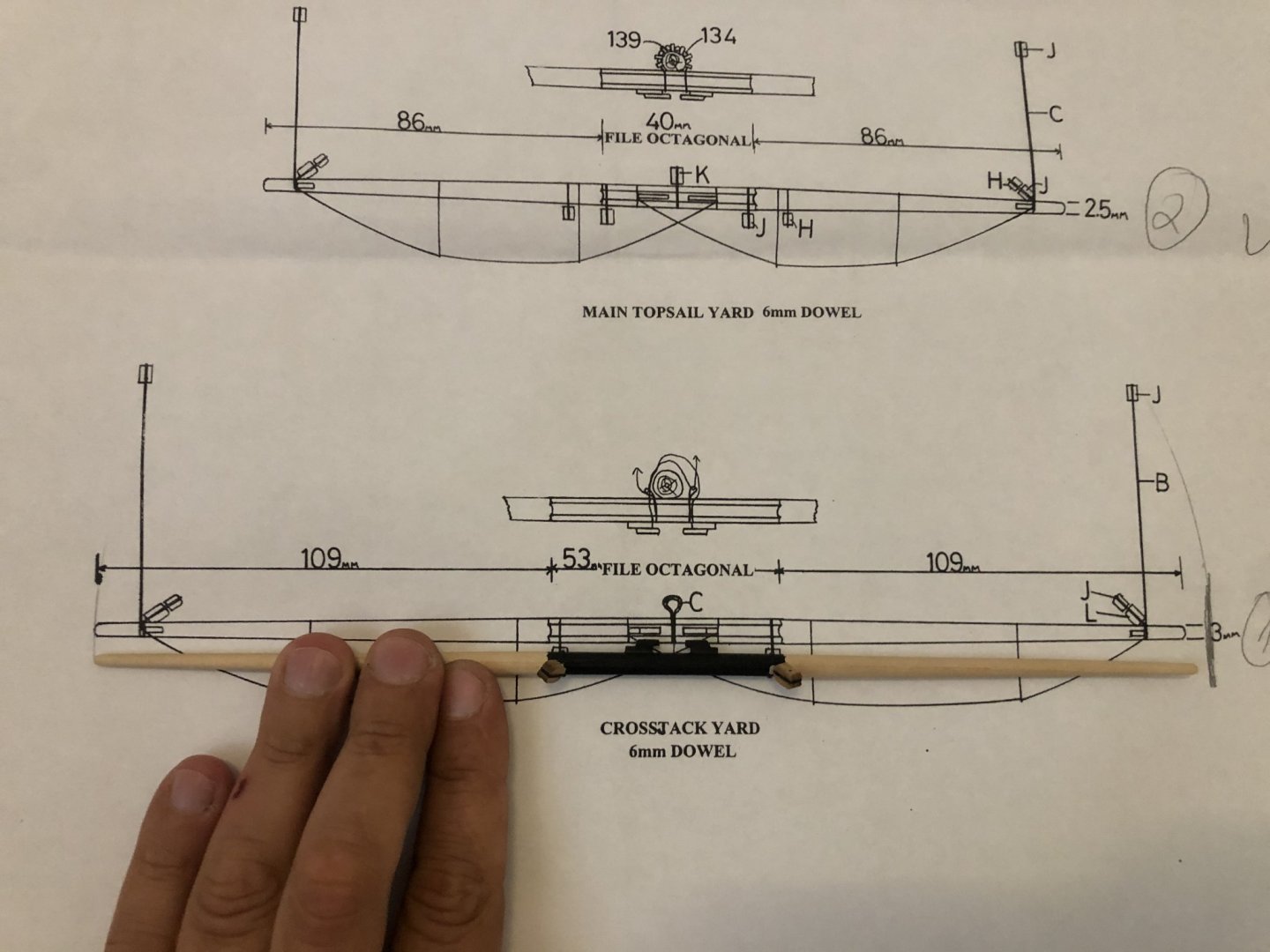

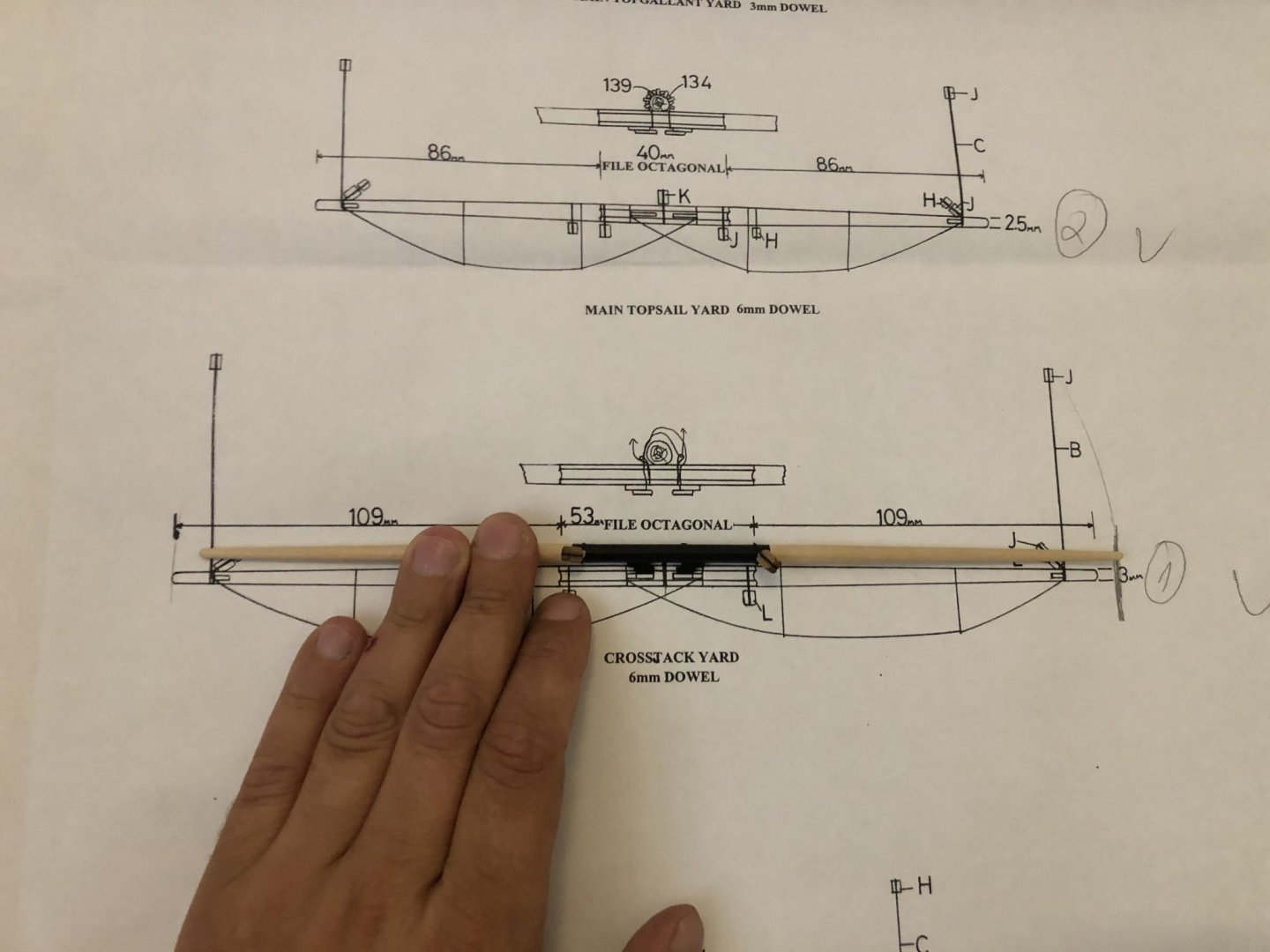

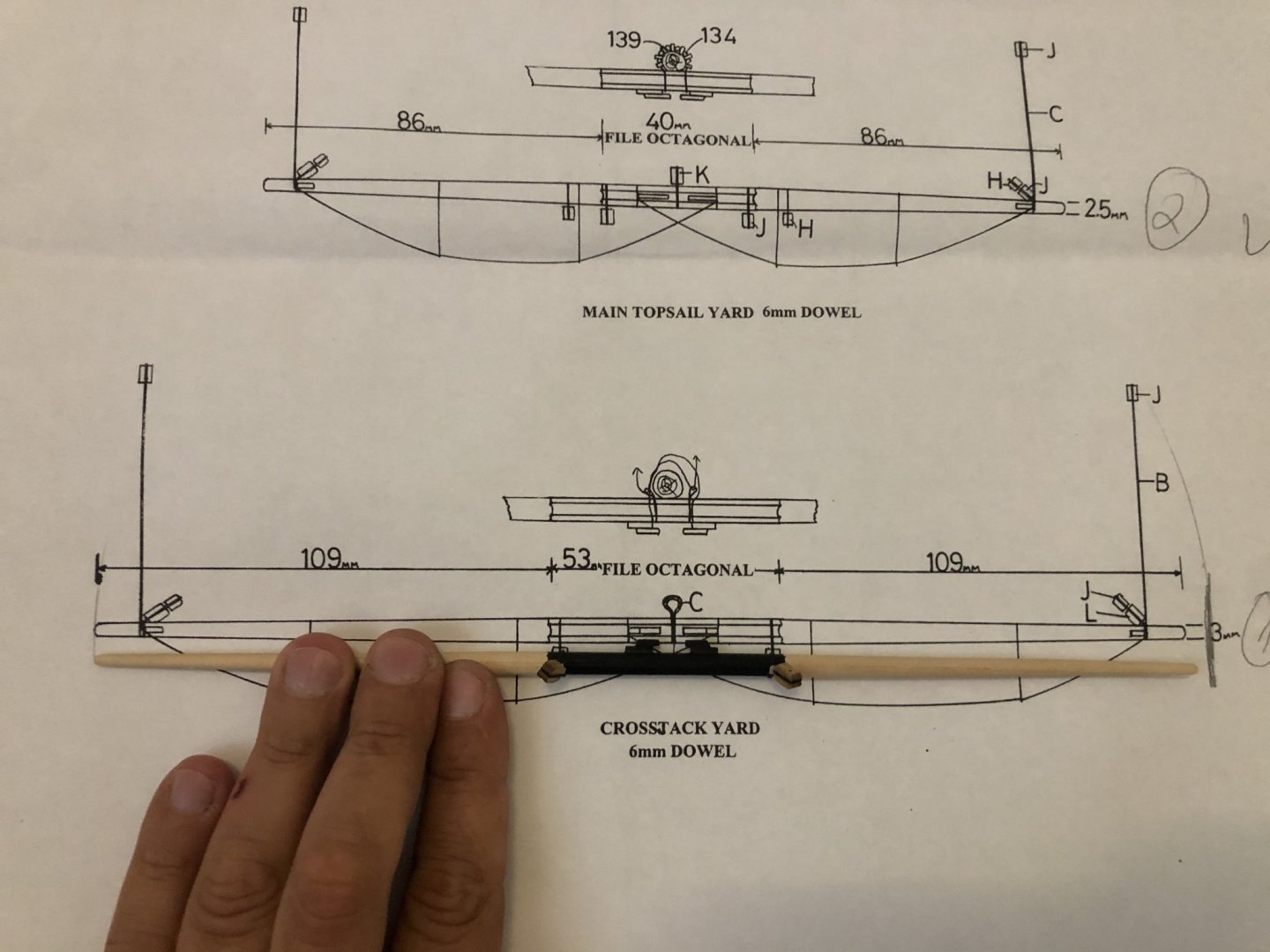

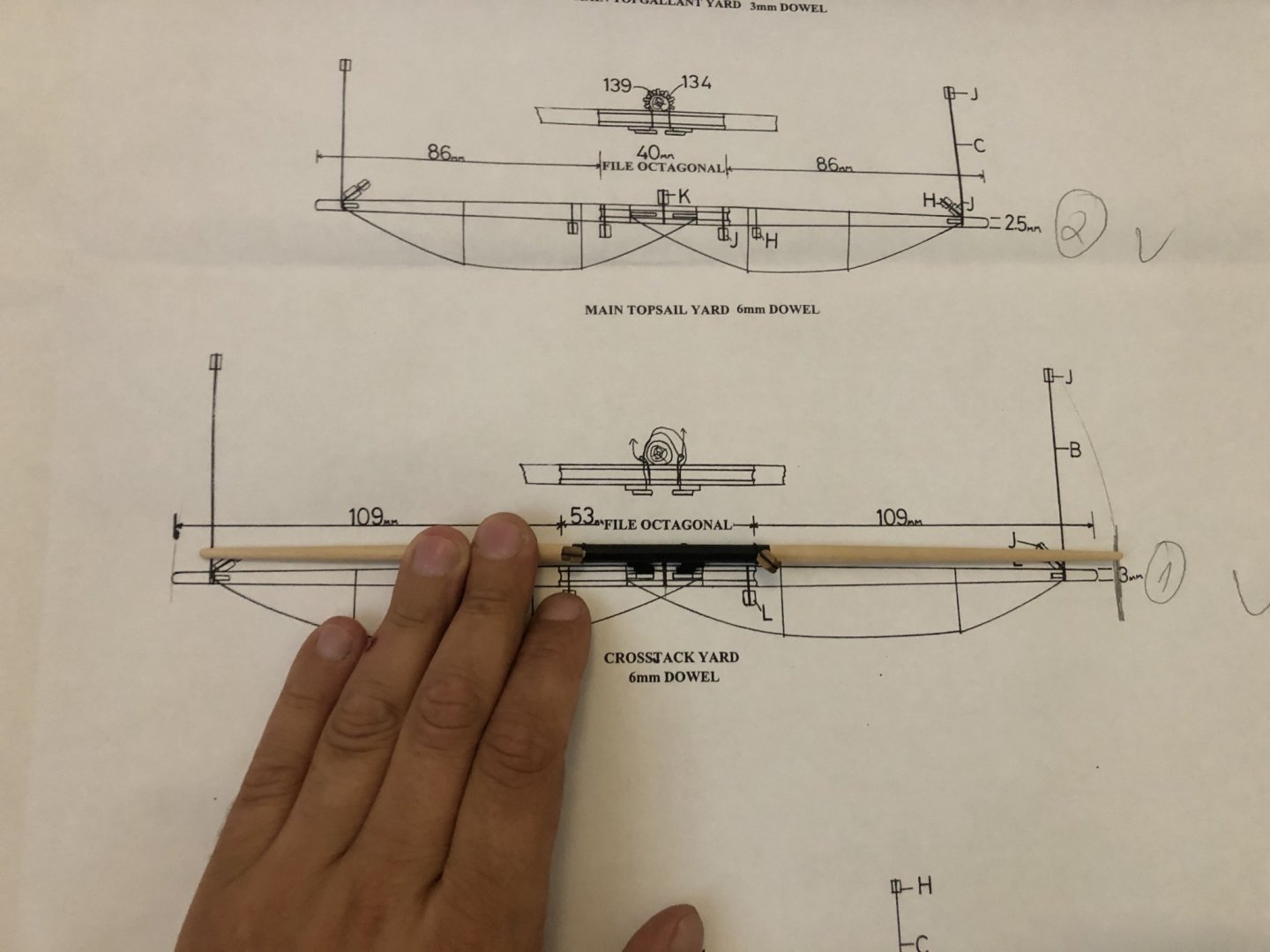

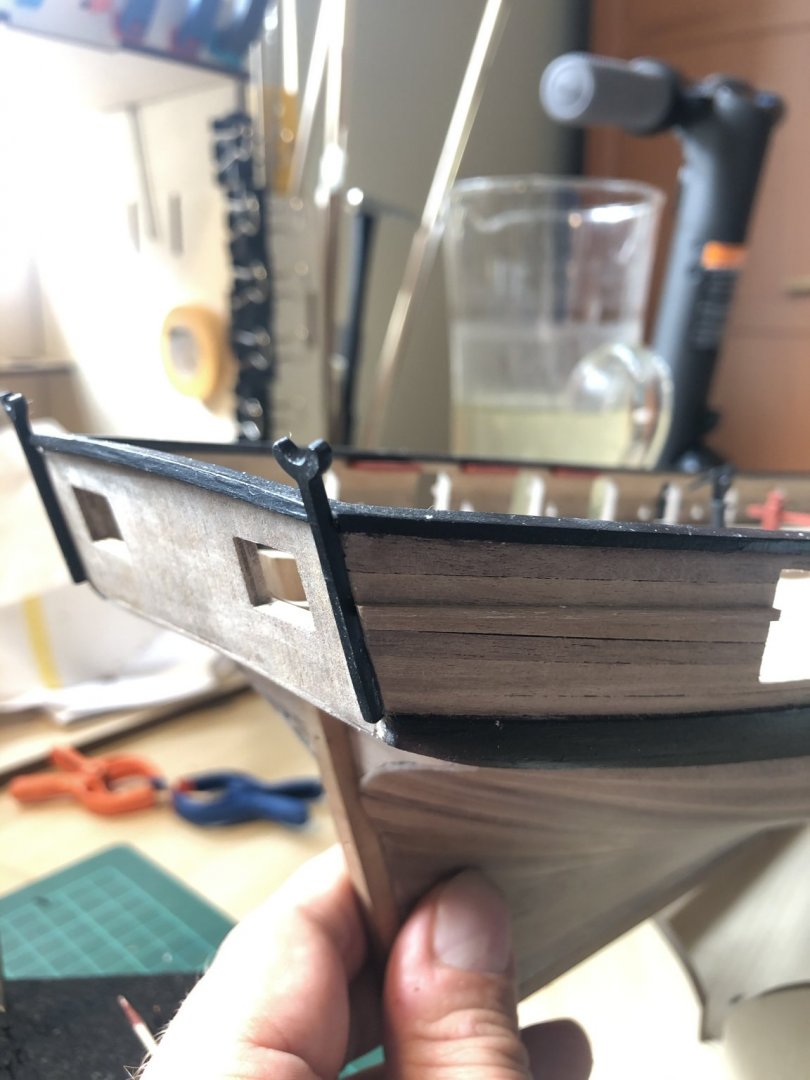

When making the spar i marked from drawings not mesaured. And then when i checked again it felt off. 2nd picture is spar rotated 180 degrees. So you can see its off. Guess i have to redo that spar.

-

Hi Maybe really stupid but here i go. Problem/question: shouldnt mast be in the center of yard/spar. CC drawings has it offset by about 5mm Logic say it should be in the middle.

-

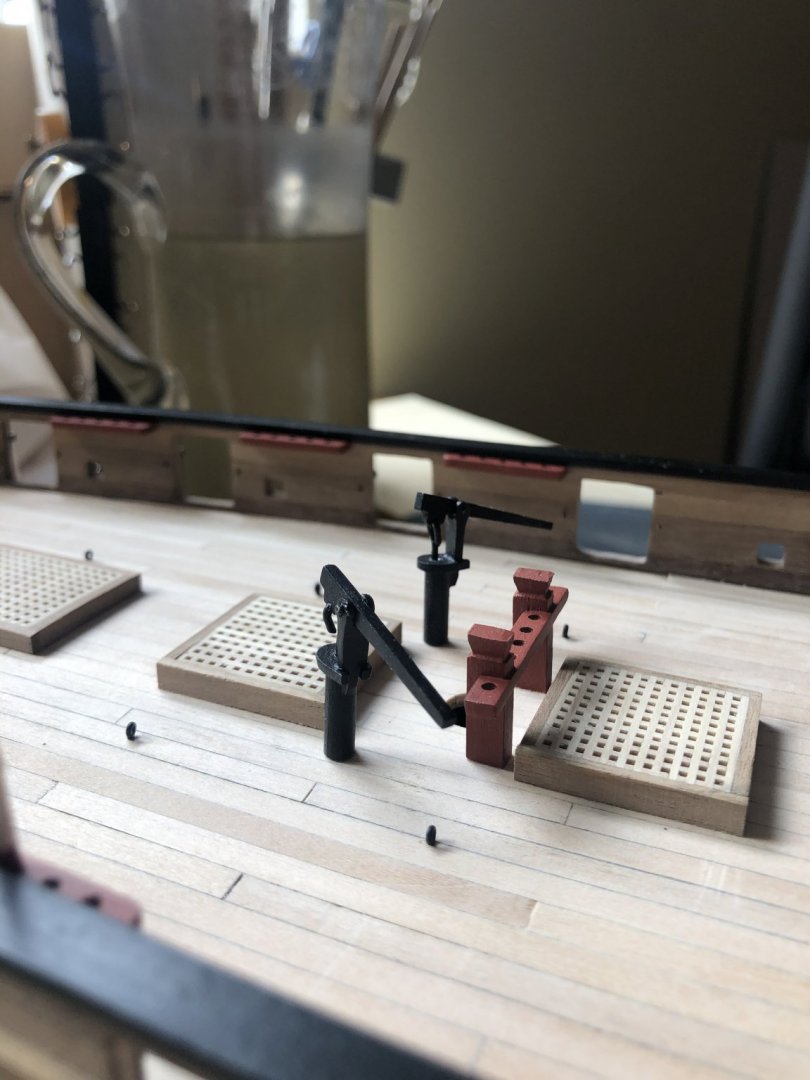

About progress. 2 of the olatformsnwjere deadeyes at the hull are, are now in place. Used brass wire to give it more strength-happy with result. All pin platfroms are in place also. Had to drill all new holes as pins didnt fit. Started with steel bands for masts. Apparently i have lot black paper provided by kit and bought new one. Painted it ironwork black before glueing with pva. Little progress on yards also. Learned that first you should make middle part hexagon and then sand the yard to correct shape. Outcome would have been better. Got rudder in place. Avoided it as i thought it would be nightmare-still hard but not nightmare. Irond bands still to be done. Building tip. Made sanding stivks from hard plastic and i used discsander sandpaper that has glue on backside. Really easy to change the paper and no glueing. Now have to make smaller ones and must find cheaper sandpaper soni dont have to use discsander ones Most deck fittings in place. Cabin missing and others will be added at later stage as i need room and sequence would be more correct. Seems that wood bar Made with cnc for rudder is 2cm too long... no part number on drawings but that was one of the last parts on sheets. So have to shorten that one. Admiral today after visiting harvour museum said that she would like me to build bigger ship next as she really liked the ones there as she definitely wants sails also. So have to look my storage what should suit her that i wouldnt have to build for years.....

-

Cant really focus on build cause of strange problem... So we took a cat, 3-4 minths ild. Hes little satan. Starting from 23:00 he thinks its fun to go all mad and atttack and run around. I have to keep him wuiet so my 2y son dosent wake up..... And here i am 1:33 am watching my vat and protecting the door that my son is sleeping behind so that the little satan would scratch it etc.... Only solution i see is to get dog also . Maybe then the satan will calm down a bit.

-

Nice work. Sanding will make it look better. If you plan to paint then it hides some mistakes.

-

Chris is correct about lineup of kits before big developments. Eventually is bussiness and there must be income for that development period. MSW has many members with different opinions what he should develop and im sure he takes that account if it matches with his goals. Lets not forget that there isnt anyone else besides Chuck who discusses what members would like do see in the future....correct me if im wrong. In other words im sure many will 100% support your decision on developments no matter what it is. Keep up the superb work and we cant wait to see your new develooments for upcoming years.

-

Hi Whats the best way to paint eyelets? Acrylic paints with brush tend to come off. I read that email paints should do the trick? Also tried spray paint Mantua one but that came off really easy. Brass black is something i cant get to work. So i would prefer painting. Is investment into spray paints now a thing maybe? Please share your experience.

-

Really nice. Do you plan to make rudder hole at stern later? Little easier if you leave there a hole. Just a suggestion.

-

Nice planking! Tapering for sure for next build, no filling of holes but again new thing to learn. Take you time on deck as thaths the part of ship you will look maybe the most. So quality there is important (like everywhere). Learned that the hard way on my first build.

-

For first sanding i have used small delta sander to get it more or less smooth. Try to dry fit keel at bow also before you start doing 2nd planing so it would fit nicely. Good progress.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.