Wahka_est

Members-

Posts

521 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Wahka_est

-

Hi I would like to add hobbymill.eu to supplier list also. Located in Estonia, EU. Sponsorship also announced today. Https://www.hobbymill.eu

-

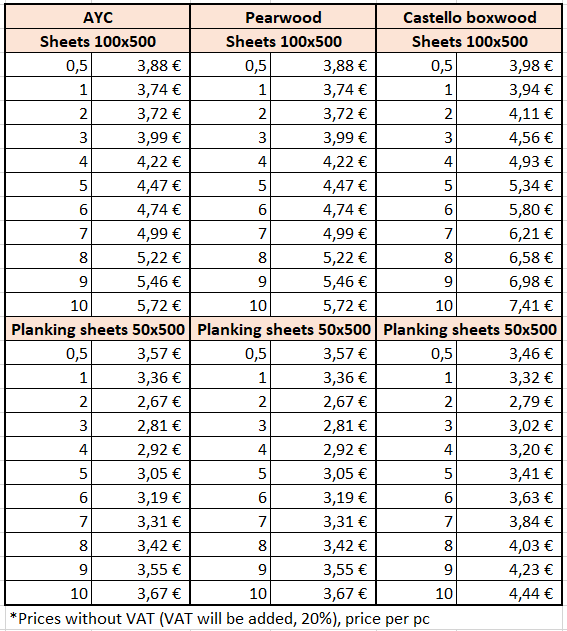

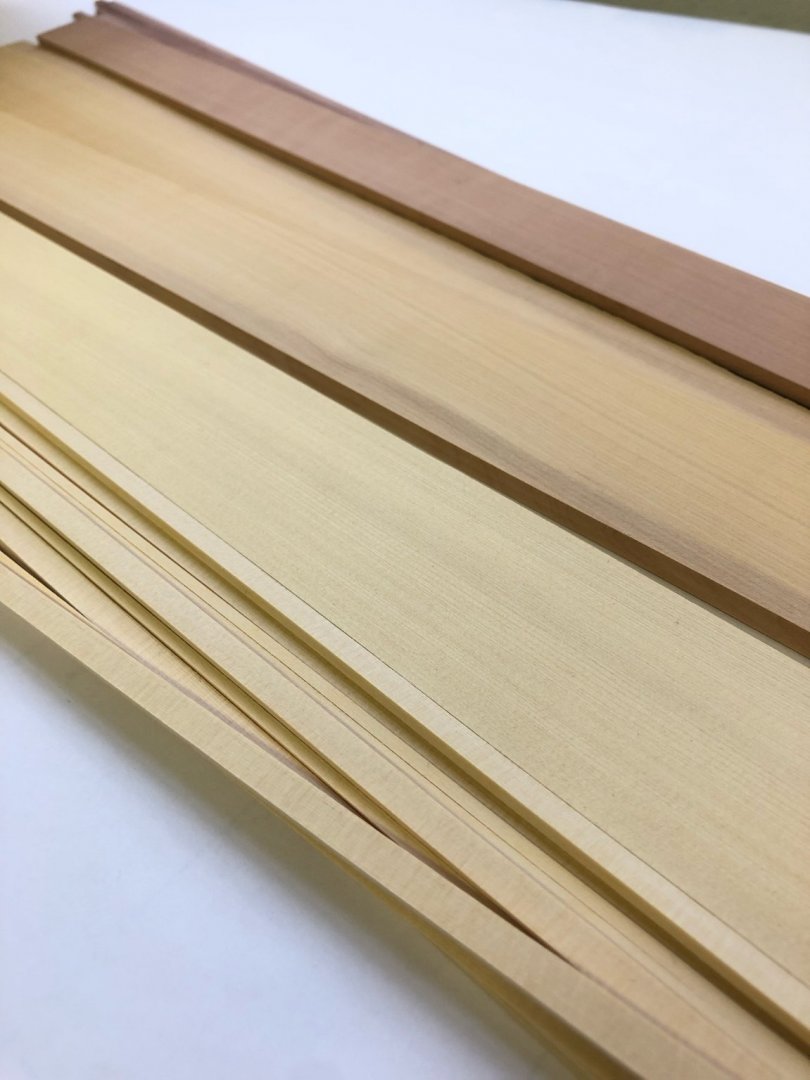

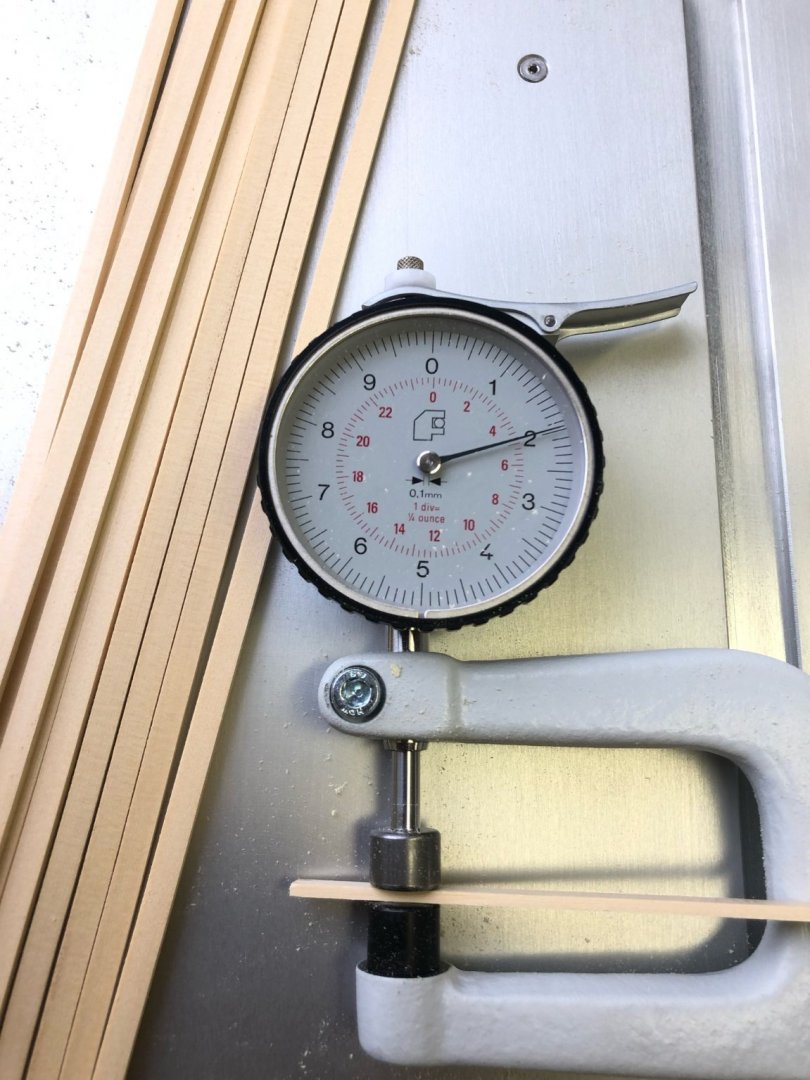

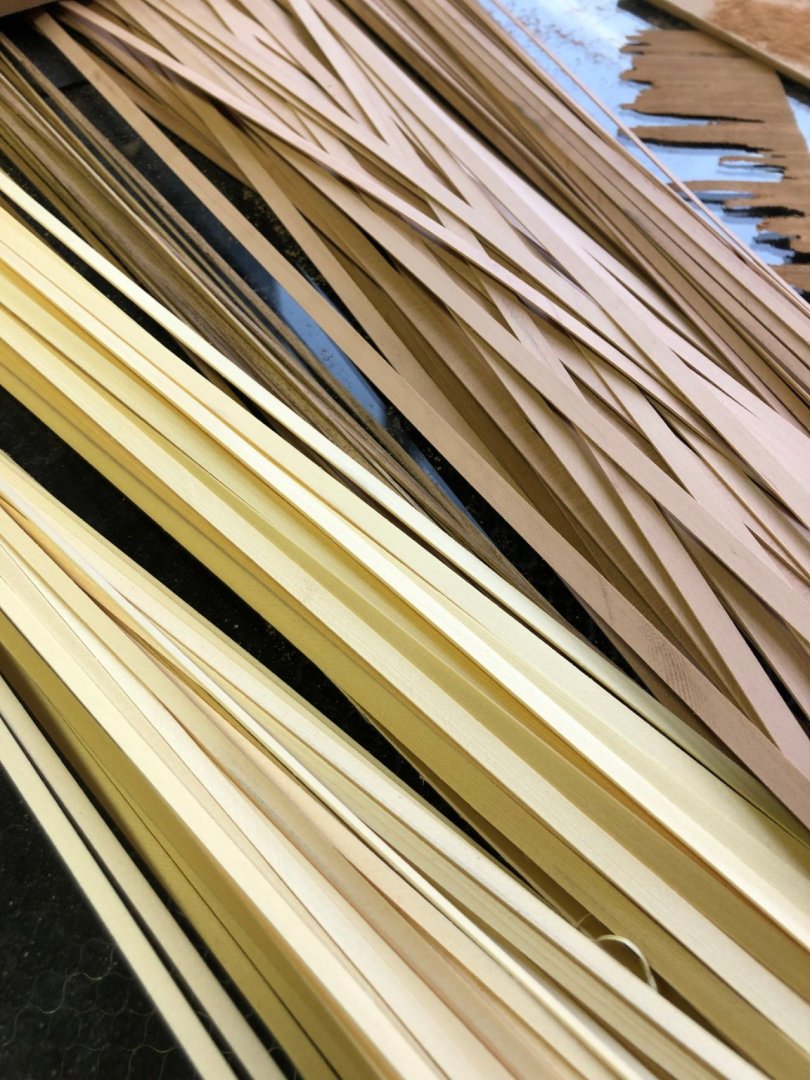

HTTPS://WWW.HOBBYMILL.EU proud new sponsor of MSW Please note following: Hobbymill.EU has no direct contact with Hobbymill operated by Jeff. After choosing the name i accidentally chose the same without knowing about its well known history (that wasnt the intention to step into Jeffs shoes) I have contacted Jeff and asked for his permission (thank you Chuck for pointing out the possible problem) to use the name. Jeff gave me his blessing to use the name, even gave tips and offered advice - superb guy. Thank you Jeff! Im sure he will also confirm that at some point in the topic. ------------------------------------------------------------------------------------------------------------------------------------------ It all begun as i wanted to orders sheets and strips of AYC in EU but no one could offer it, so i had no other option to solve the issue and offer solution to fellow members. 😊 Precision milled exotic woods for ship modellers and hobbyist in EU and other. Located in Tallinn, Estonia. Our range includes: - - Alaska yellow cedar - - Swiss steamed pear - - Castello boxwood - - American hard maple - - American Black Cherry - - Beech - - Madacascar Ebony - - Teak In near future to come: - - Stabilized hornbeam (black, blue, yellow) - - Holly? - Our product includes: - - Sheets 100x500 (+/-3mm) - - Planking sheets 50x500 (+/-3mm) o I hereby thank Chucks for guidelines posted here at MSW, specially regarding AYC cutting - - Wooden strips 500mm (+/-3mm) - - Wood-turning pieces o Cut according to request - - Laserable sheets (AYC, Cherry, maple) depending on the wood from 100...200 x 300...500 with standard thickness 5mm - - Laser-cutting service max size 350x600 and wood thickness 5mm - Woodpackages: - Syren Ship Model Company HMS Winchelsea wood package (in agreement Chuck Passaro). - Syren Ship Model Company Revenue Cutter Cheerful (coming soon) Probably you will need sizes not listed on web-shop, then please contact me here or by hobbymill.eu@gmail.com for pricing. For achieving maximum result we use JET woodworking machines together with Byrnes Model Machines. Our website is constantly updating with new products. Contact me if there's a question if we can provide something or not . All MSW members who will present order directly in email or here at MSW will get 5% discount on final row. Payments can be done with wire transfer of Paypal. For deliveries we use couriers (DPD, UPS etc) and postal service. United States (mainland): 1-2 kg - 28 EUR 2-5 kg - 40 EUR 5-10kg - 65 EUR Canada: 1-2 kg - 28 EUR 2-5 kg - 45 EUR 5-10kg - 70 EUR United Kingdom: 1-2 kg - 22 EUR 2-5 kg - 30 EUR 5-10kg - 35 EUR Australia: 1-2kg ~ 26 EUR 2-5kg ~ 51 EUR 5-10kg ~ 80 EUR EU: 15-35 EUR depending on the size and destination of the order. Lead time for until shipping is 2-7 days. Prices can be found at https://www.hobbymill.eu Sry for not having the best photos , working on that. -------------------- Vahur Vannik www.Hobbymill.eu

-

Thank you. Needs quite a lot of sanding. Im still missing wales as i glued pieces to wrong height so i had to take them away and kit does not have extra strips. I should get that done in few weeks also. Funny is that in real life it looks better than photos. On pictures you see flaws that you dont see in real life W

-

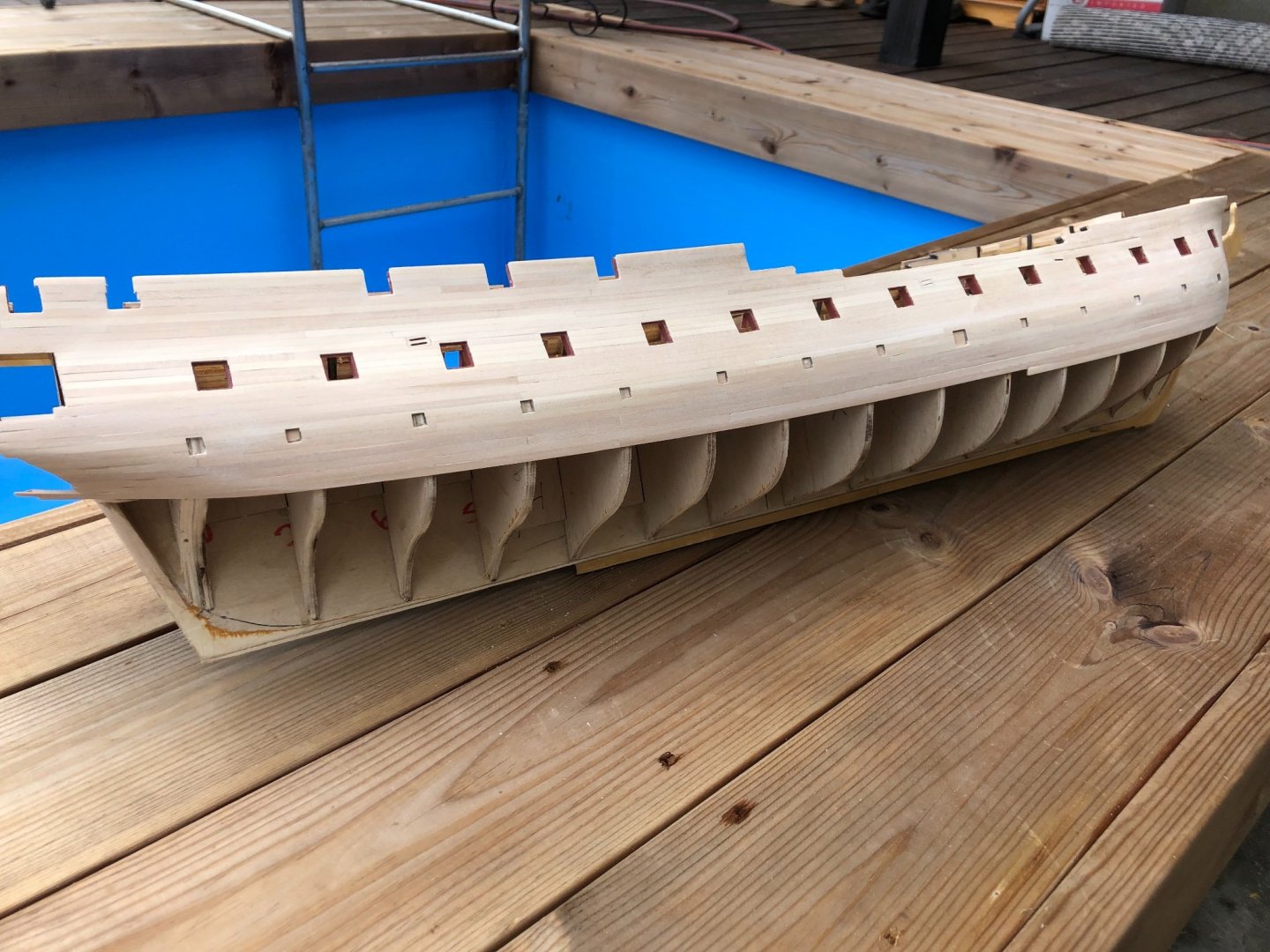

Nice progress. I finally chose plank length 12,5cm +\- depending on the location and tried to follow Chucks scheme. Above the wales its ok to follow the drawing but below it get interesting as i didnt understand clearly the scheme that was supplied but eventually i got it to work. You are right-it takes time….a lot of time. And as it does not have 2nd planking you really cant make many mistakes. Only the ones that sanding would solve. Lovely progress, hope to hear from you soon. W

-

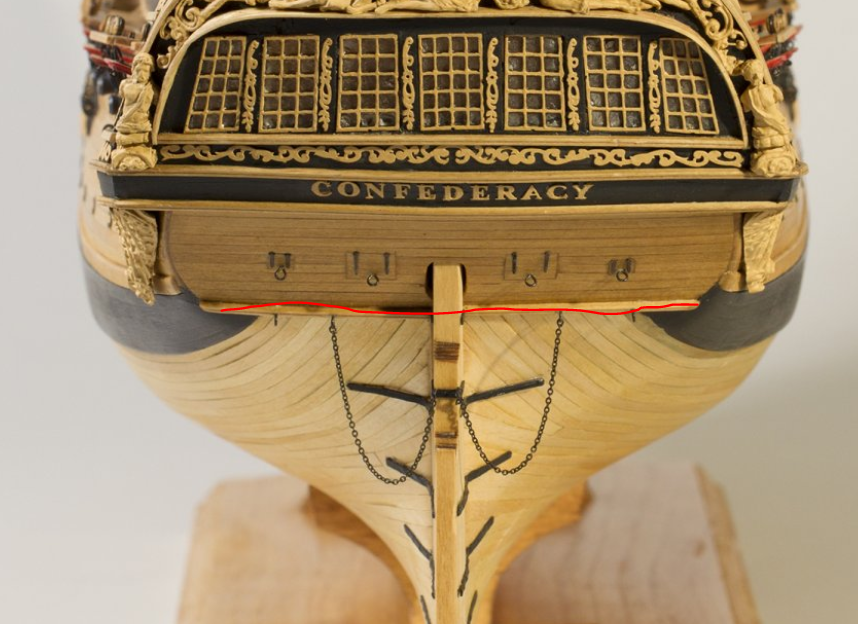

You are doing a good job! Keep it up. This build is quite difficult-i wish there would be more photos of the prototype build but i guess for development some stuff you just have to sort out yourself Do you have info what size is the wood strip between lower counter and hull planks? I cant find that info in the manual-its seems that some info is missing.

-

Superb job Chris! Regarding lasers check Trotec. They have new affordable line coming out in few months(if not allready). I think its called Q400 or similar. All awesome features as normal superb Trotec but assembled in China to take costs down etc. To be noted i have no connections to Trotec or their sales. If you are interested you can pm and i can send you info that they provided me few months ago.

-

Hi Not sure what sizes you are looking but you maybe wanto to check this topic here: Vahur

-

Really nice job! Cant imagine 500hours and 2 months…. Hope to see you soon with next build! Check also Models Shipways kits by Model-Expo, they have really good discounts time to time. W

-

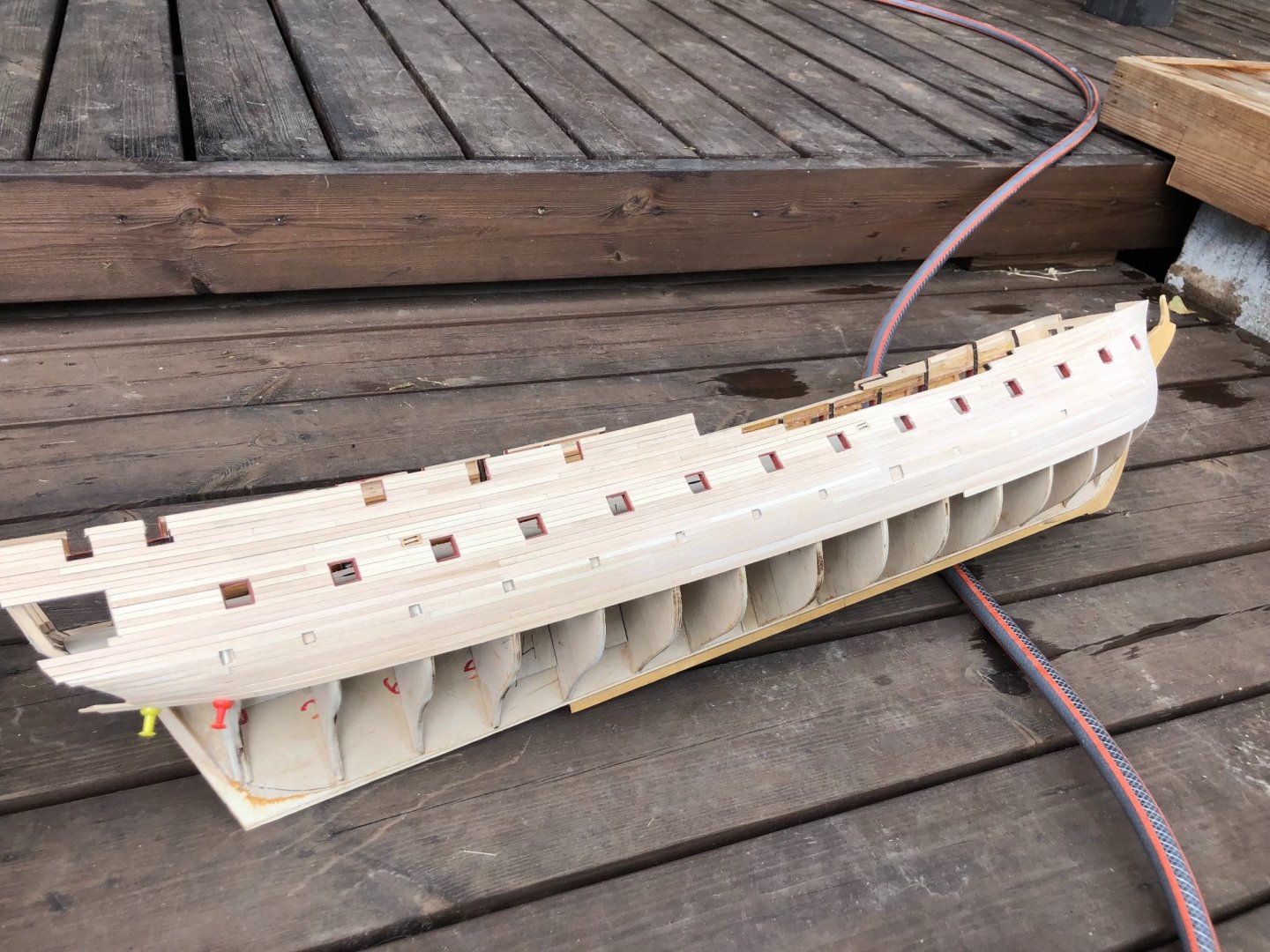

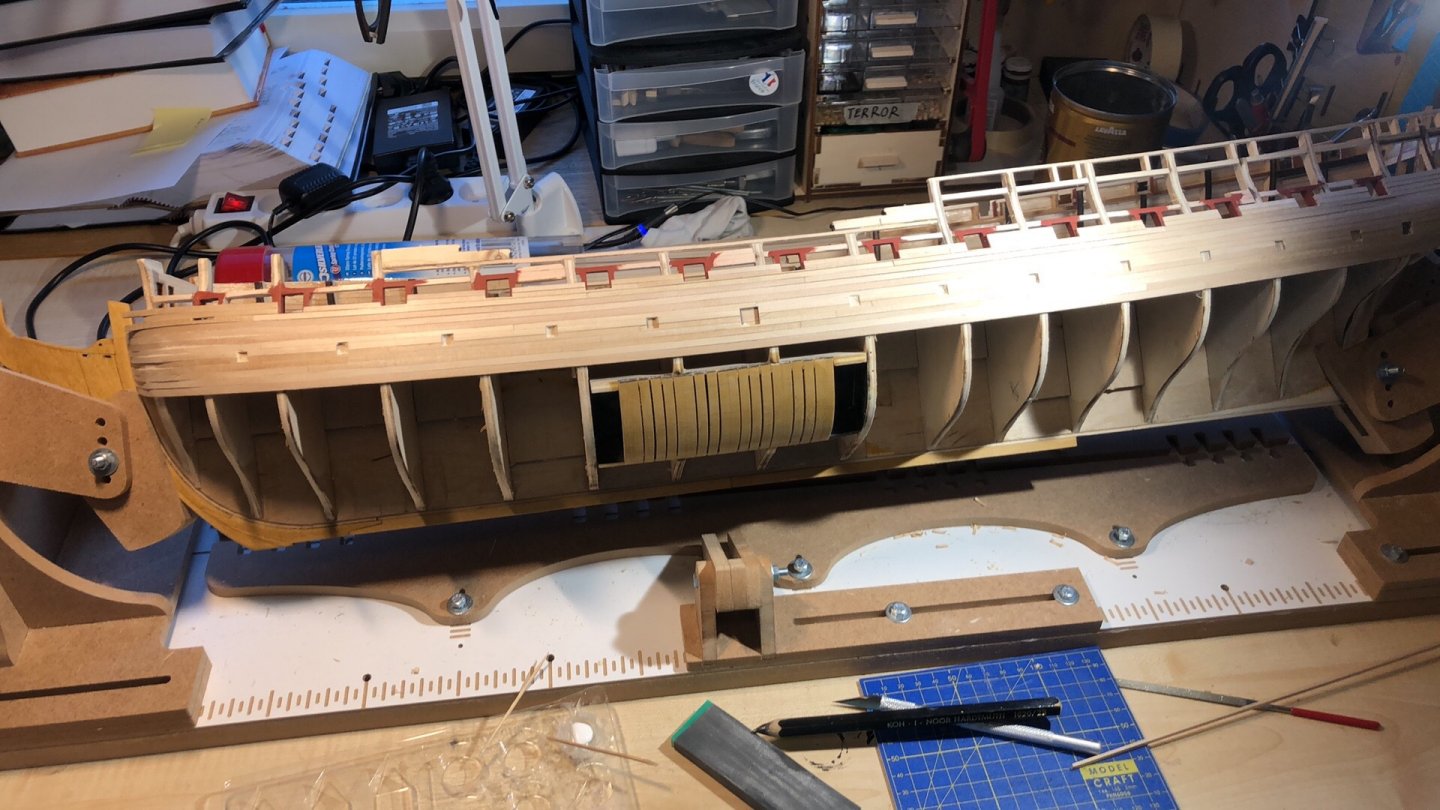

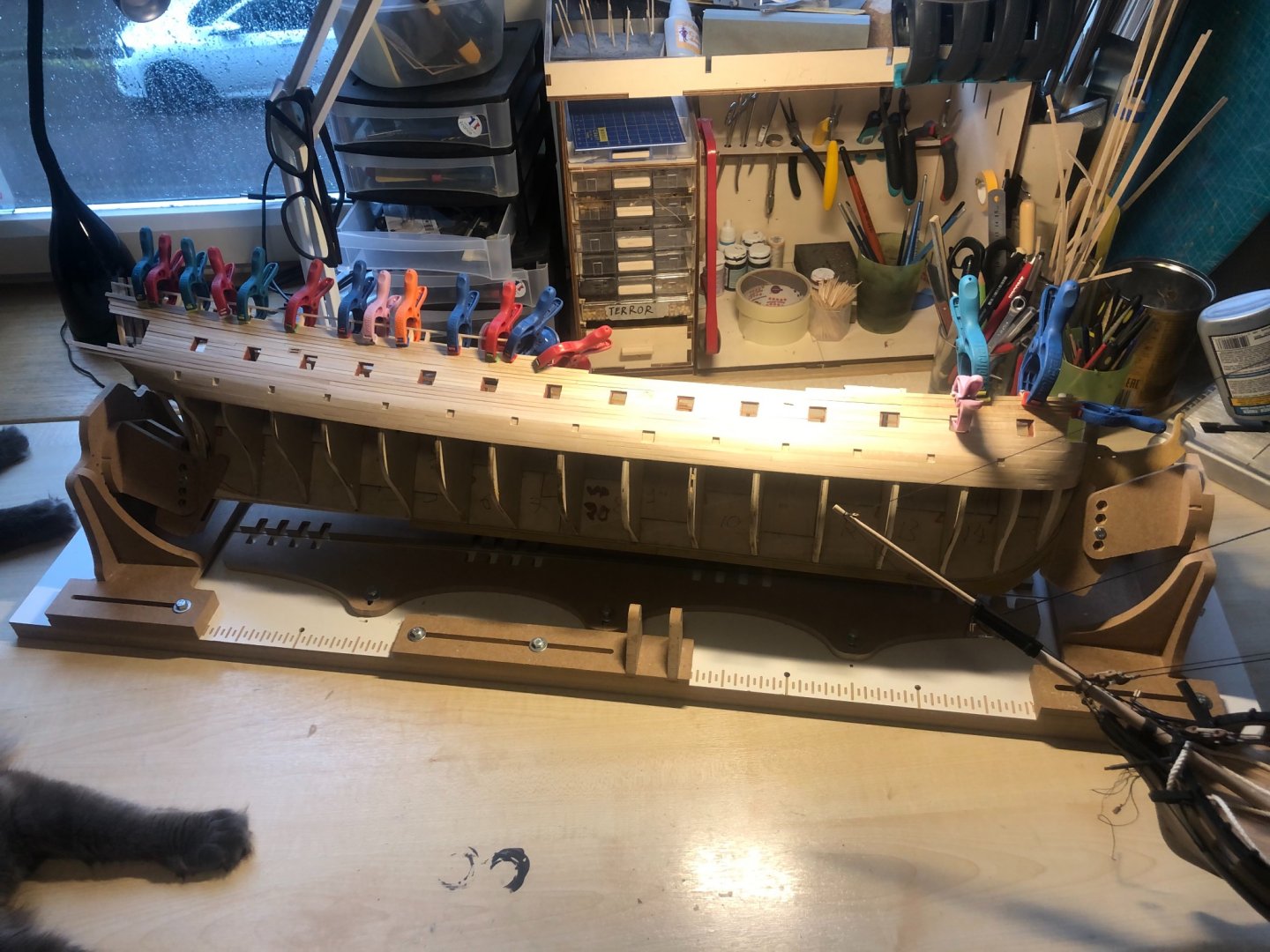

Small update. Planking ongoing. Takes time as every piece is 12,5cm long. Made a mistake with wales position one side and had to take them off with alcohol. Dont have any spare ones so i have to wait until mu Byrnes saw will arrive to make some. Kind of messed up in stern area i think, maybe i will replace some planks with stealers. I looks rough for now but it will look nice when sanded. Have small Proxxon delta sander that will make miracles . For next build i will follow planking guides posted here with dividing widths and starting to tapper each plank etc. As bending wise im good as Chucks tips are superb.

-

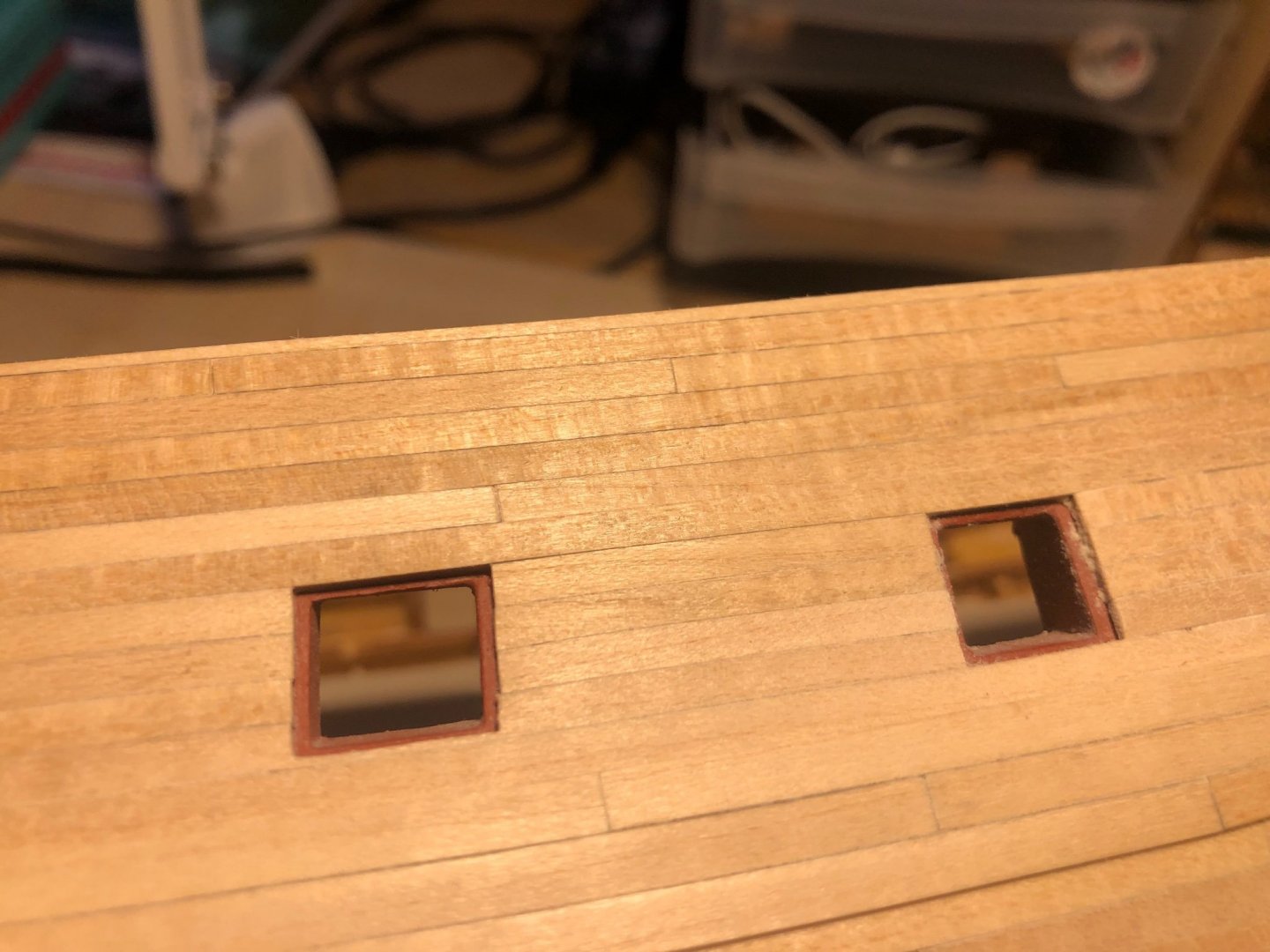

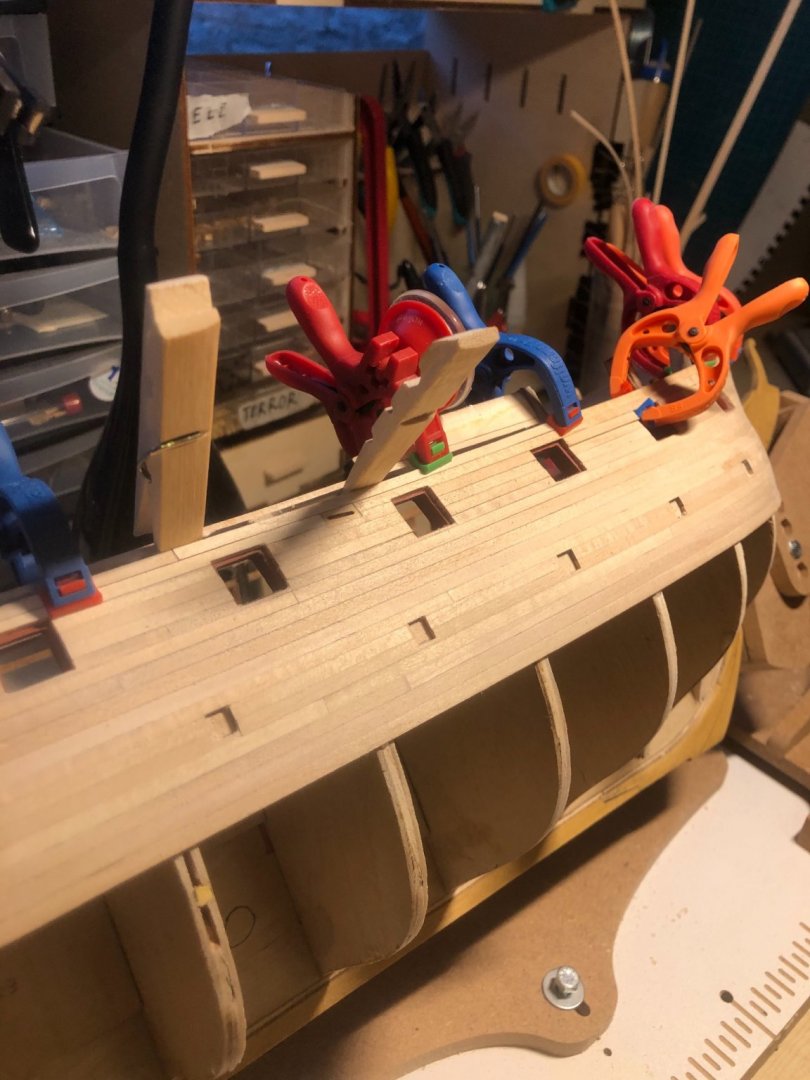

So decided to show some progress. Its still planking of upper wales. Only one layer of planking is a great challenge but it also teaches you a lot. Outcome requires nice sanding but im sure it will be good in the end. Plan is to finish all planing and then start with wales etc. Surprising is that ME planks arent the same thickness, not to mention the width that i have to take into accout. Edges of gunports are something i wasnt happy about but with chisel set from Mikhail i could make them much better. Will finish all those after planking. Upper wales planking might be done next week. Boarders have opened a bit so now its possible to go on business trips again. And yes one thing i did is that after planking i noticed its quite soft surface on planing and planks move ,so i added layer of glue inside to make it steady enough. I like the result and will definitely help with sanding.

-

Superb job. I dont understand how have you finished them so fast.... Im still in middle.. My admiral also talks about sails.....

-

Home, bench top laser cutters.

Wahka_est replied to Bill Hudson's topic in Modeling tools and Workshop Equipment

I just add that there are machines like k40 that are cheap(200-300usd) but have long learning curve. If you have time and like to tweak machines then for start it should be enough. But you you want machine to work as you plug it in and shorter learning curve then they are more expensive. -

Home, bench top laser cutters.

Wahka_est replied to Bill Hudson's topic in Modeling tools and Workshop Equipment

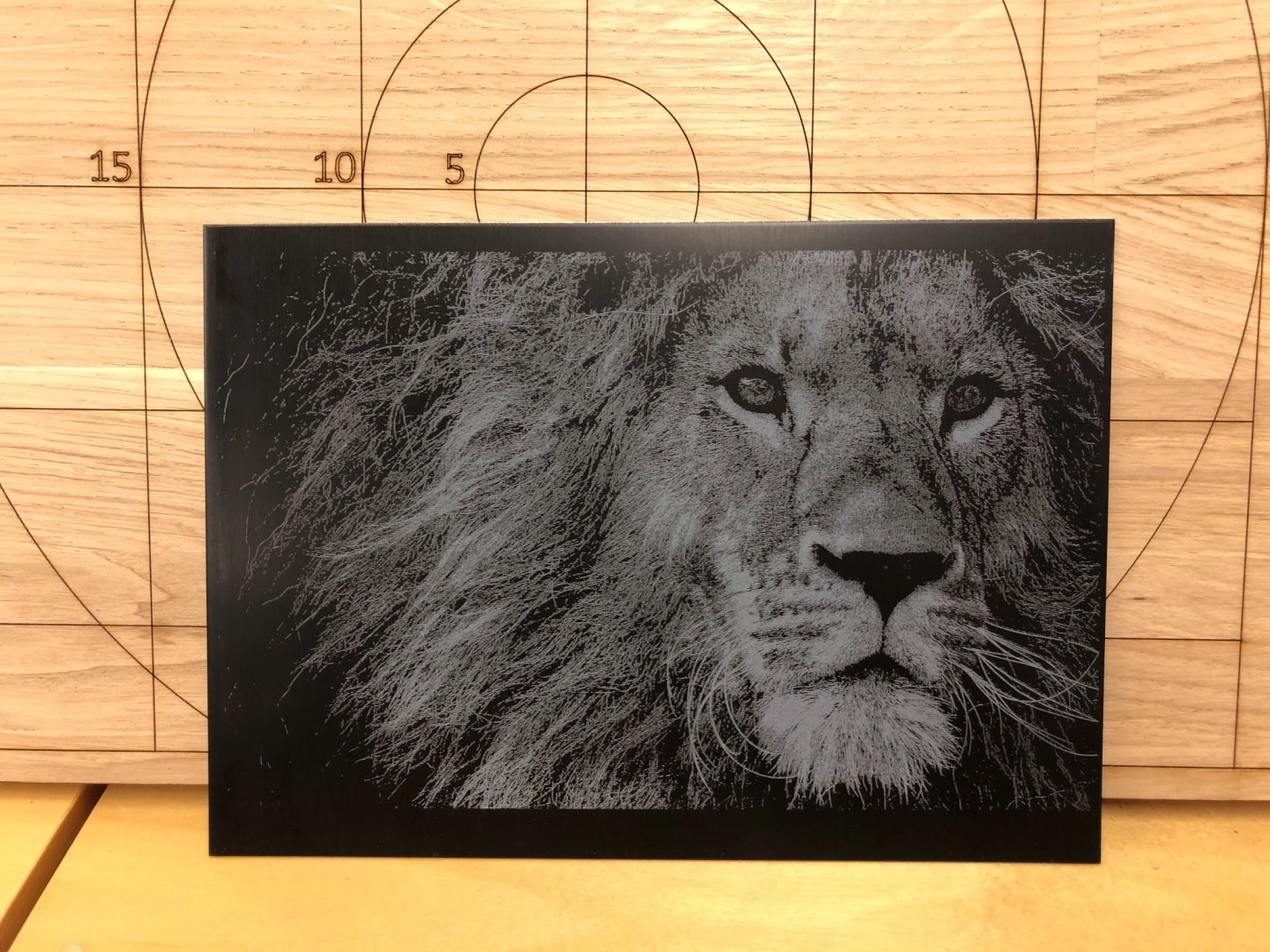

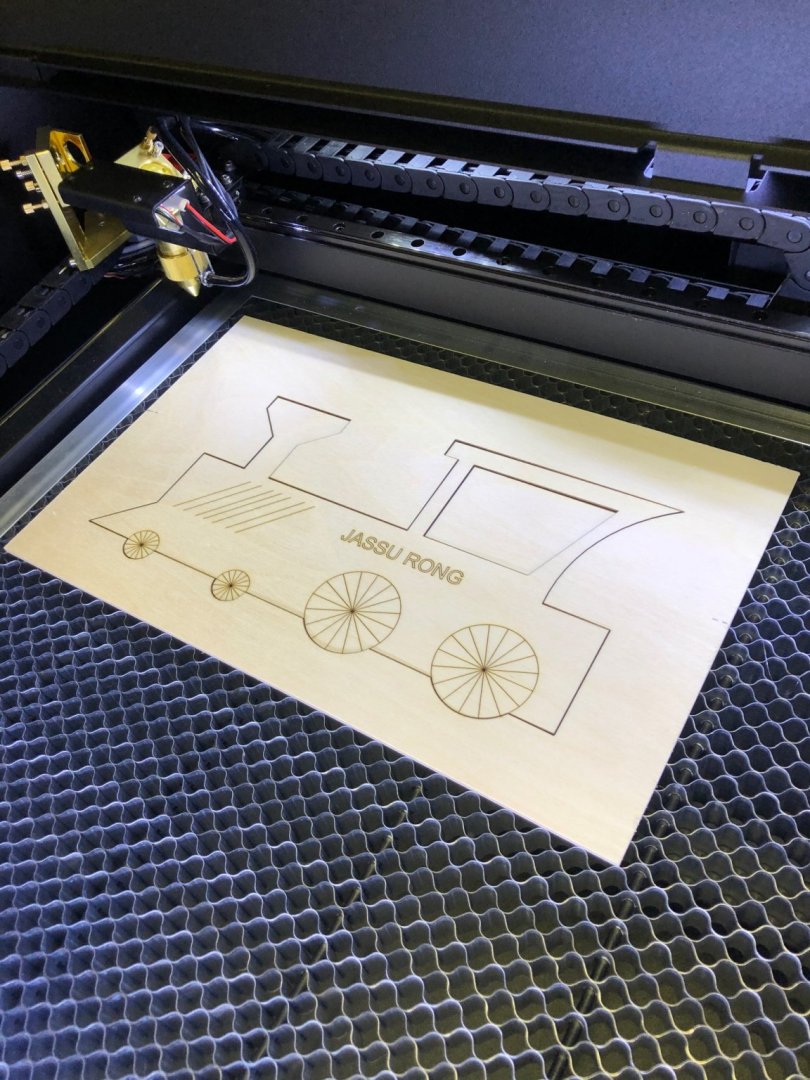

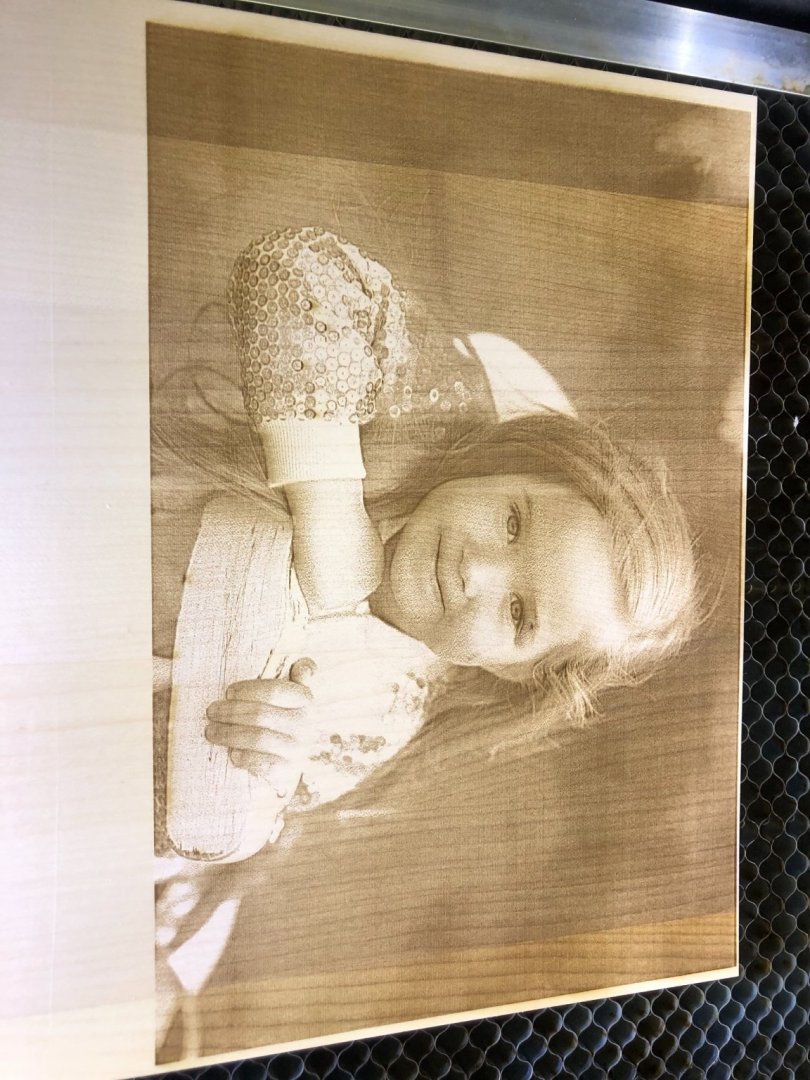

I have flux beambox pro 50w. Can cut up to 6mm ply with one pass. We bought it to have small side business that isnt ongoing yet. i use autocad daily so design isnt issue for me. Like with all machine there is learning period-power and different woods. Havent used it for ship building yet but all other stuff yes-cars, trains for my sun. Engraving bottles etc. If you have more question you can pm me. Some samples i have done.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.