Rick310

NRG Member-

Posts

833 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rick310

-

George, congratulations on your new job! Good luck!! Had to laugh when I saw the picture, as I have been on board her! The Mather! Lived outside of Cleveland for 36 years, in Mentor, lake county, before moving to Maine full time in December, 2019! My daughter and her husband still live there. Would love to meet you next time we are in town! Rick

-

Keith, another fun build!! She looks great!! Rick

- 457 replies

-

- sternwheeler

- Hard Coal Navy

-

(and 1 more)

Tagged with:

-

Totally agree Rob. Jared, we all make aesthetic decisions based on what we know and what we think looks good/ correct. I will choose to mount the booms in their irons, the traditional way to display them. Not right or wrong, just personal preference. The model looks great!!! Rick

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

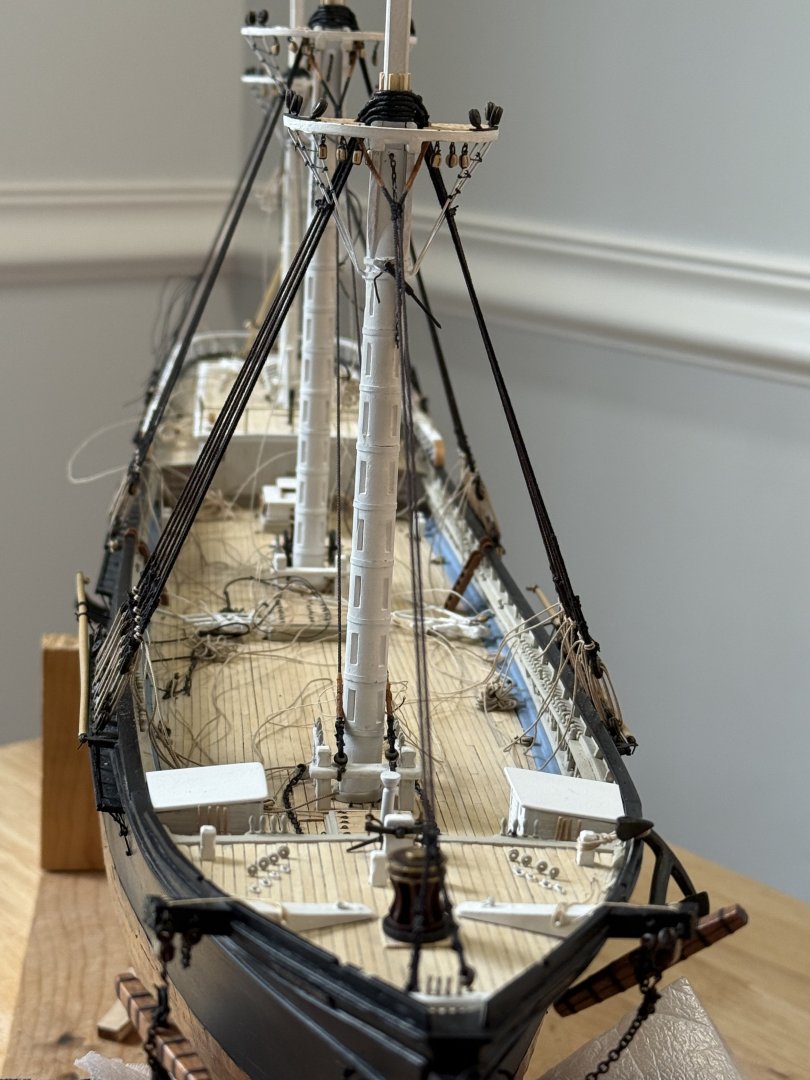

Nice job on the bell and binnacle, look’s really good! your Flying Cloud is coming along nicely!! Check the lengths of your chai plates, in the picture they look a bit long. Rick

- 200 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Rob, thanks for your kind words and encouragement! To answer your question, no, I bend to complete the entire model, all masts, yards and rigging. Rick

- 360 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks Jared, you’re doing a great job on your model also! Rick

- 360 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks George and Snug Harbor Johnny! The arch on the stern is pretty crude, but I didn’t have a better idea. No way I could carve it out of wood and no good design for a decal . Rick

- 360 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Finished the fore mast shrouds, with serving. parcelling and leather as per the main mast . Took 2 attempts to get the fore stay right. First attempt, I didn’t account for the line stretching, which caused the 2 legs to be misaligned in regards to the serving and leathering. Second attempt came out really well until I noticed that the legs were crossed. This necessitated cutting all 6 seizings which of course damaged the serving , which then had to be repaired. Self inflicted wounds are much too common! Next, placed all the shroud fairleads as per EdT. using 3/32 deadeyes with a groove filed to fit onto the shroud. Finally, placed and rigged both Spencer booms. I included the inhaul/outhauls as I have never seen a model with them on. I tied these together with bowlines as they would have been tied to the head of the sail.

- 360 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Jared, I read that the stuns’l booms were tied off to the chain slings to get them out of the way when the sails were furled, just as Rob suggested. At sea, sails would not be furled, but they would be reefed. What then? Can’t imagine man handling those booms at sea so the sails could be reefed. Rick

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Congratulations!! Model looks great!! Well done!! Rick

- 144 replies

-

- Harriet Lane

- Model Shipways

-

(and 1 more)

Tagged with:

-

Beautiful!! I would be completely lost building the Flying Fish if not for EdT’s fabulous books on building the Young America! Thanks again Ed!! Rick

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Jared, just got home after being away for 12 days and the shrouds are still taut, although I will need to tighten the mizzen shrouds a bit at some point. Passing the line through the dilute white glue solution and stretching them as they dry, seems to have worked well, as I had a dehumidifier running the whole time I was gone. Rick

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Jared, for what it’s worth, I’ve been dragging my line through a dilute solution of white glue and then hanging it with weights to stretch while drying, both running and standing rigging. Don’t have enough running rigging to tell yet, but hopefully the shrouds on the mizzen and main masts will stay relatively tight. Been gone for last 10 days, so I will check when I get home tomorrow. I anticipate having to adjust the lanyards, but hopefully not too much. One issue is the change in humidity, high humidity, lines swell and tighten up, dry humidity and line go slack, as I understand it. The solution of white glue is supposed to protect the lines from moisture. Running the lines through wax is supposed to do the same thing. Rick

- 431 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.