-

Posts

1,566 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Vladimir_Wairoa

-

plank 1 guide established. Today I attached temporary square plank to serve as a guide for forst plank. It follows sheerline / waterway, i simply attached by tiny wire stuck thru plank. Line ends iest where hood moldibg follows. I updated knightheads extensively and first bulkhead so the planks meet rabbetline smoothly , and i pushed upper half of knightheads slightly back. Tomorrow I plan makijg temporary bowsprit to hold knightheads firm in place and finish portside plank guide. Awaiting planks by end of this week i cant wait laying first planks. Fingers crossed folks. Big thank for whatever observation you may have.Vlad

-

just a headup. Seems im almost done with preparations, although there is some window or maybe cargo opening at the side of ship , i will have to make a coamings for it prior planking i guess. Will have to determine where it exactly is. but anyway, We got some unberable sunshine lately thus i know 38 celsius is somwhow funmy for US citizens, i almost fainted what Rich wrote how hot it was there. My god. So i will sneak into my cool workshop and already irdered first batch of planks. I plan to lay first swction of non tapered one probably 10 pieces , 5 mm wide 1.5 mm thick, and from there i plan lining up a plan how to continue. Im aprentice on Chuck winchelsea here so hopefully i learned a bit or two there lets fun begin . Looks like she will be in state of the famous launch state photography untill this christmas, :))

-

Thanks for interesting points Roger, I feel too that painted will hopefully bring her charm she deserves. well im not that good as some lines are atill not perfect looking at photogrphs but we all agree that as much as preparation si tiresome and boring its probably most important thing for planking and planking is important as hell . skpeaking of, this is still my first build of american clipper so it is double exciting for me. Im eyeing build of Other folks here who are cureently building model shipways flying fish, which is very helpful to me as It is even more helpful than looking at plan. I also think that planking will not go to that perfection that i would like to keep it natural wood i assume some filler will be necessary so i firmly decided on painting . to some point i think unpainted would also look very blossoming if done extremely right and using fine woods. V.

-

You all have great remarks very to the point Rob. I see you as a master of smaller scales and yes I feel i will have to go thru more obstacles following exact plan parhs but still, i have time. i would not going to plank probably until I had a bender as it will be impossible not to destroy stem and rabbet line with 2 mm planks. I have to check planks first how they fit both to the rabbet and around knightheads. seeing Richs remark I plan to fit in false bowsprit when planking so knightheads are supported and wont break. i atart liking idea i am quite following exact ship building which is educationa land enlightening at some point as well. happy continuation with yours

-

Rob you are artisan! i like ornamenatation very much and molding is spot on, at this scale it is so so difficult to achieve what youve done its fantastic ! V.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

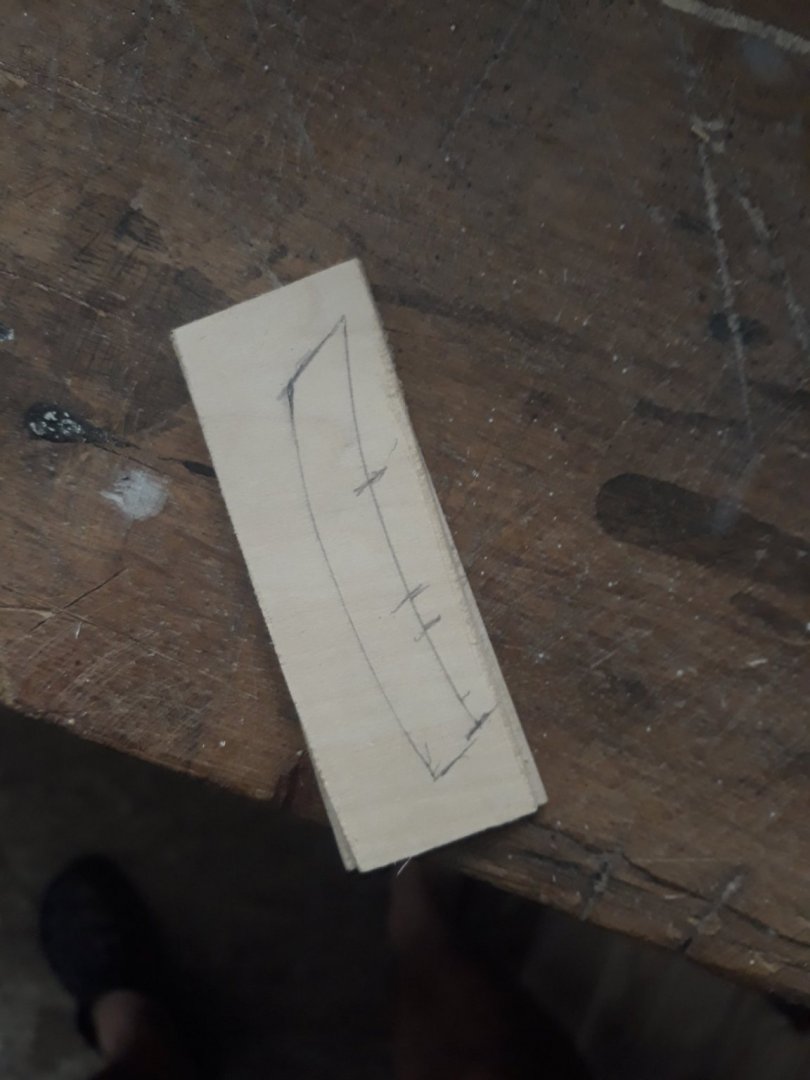

Thanks Rich for looking in and caring for this build. I exactly understand what you mean and jus worjing on it knighheads are slighly pushed backwards so curve is the same just little bit offset of main curve. Here is the preparatiin how i out took drawing to the wood... it not yet fastened should it be even more back what you think guys? . I made it little longer so ut can be cut shorter a also sanded/modeled complete stern deb profile for planks as stern is delicate matter i wanted planks to follow curves as much ad possible.

-

you did spectacular job on stem planking Rob. straight line. I am about to attach knightsheads no process witll be different fingers crossed. V.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

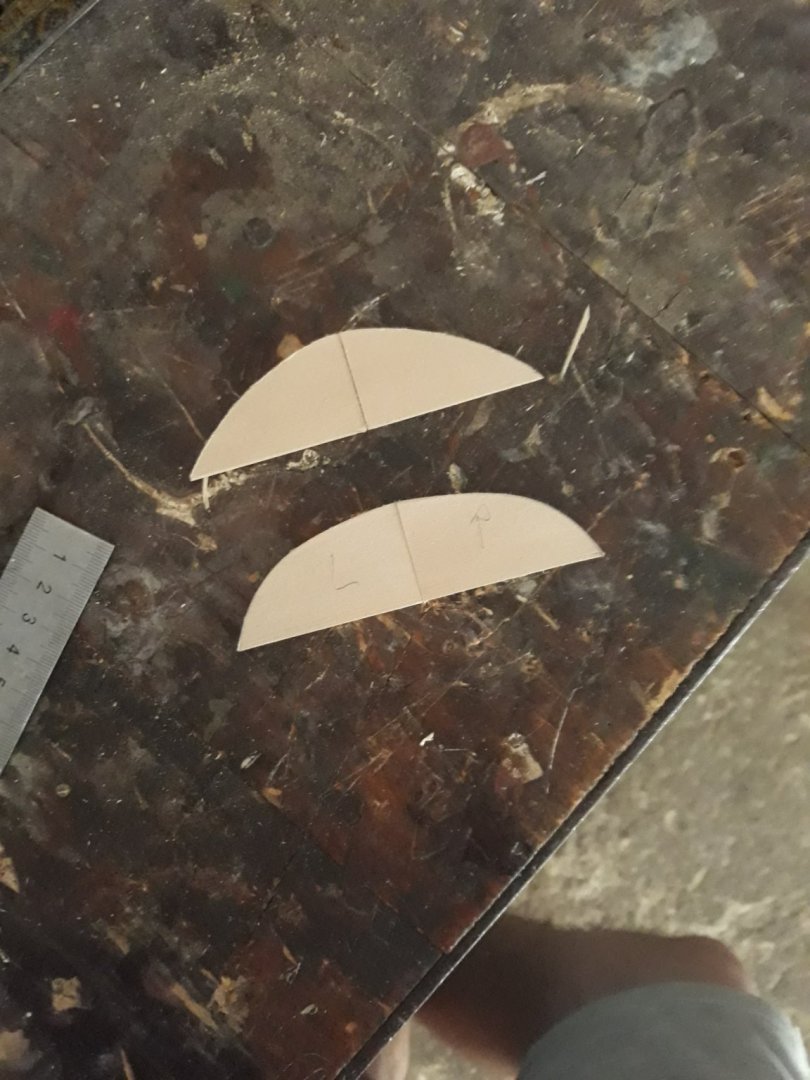

Issues. Issues. Well, im going to paint her. Definite. Finally moved somewhere. There was myriad of issues with bulkheads i would finally not recommend this unprofessional set of bulkheads to novice to deal with so much corrections. So many sanding to set waterway properly. Bumps ups and downs etc. Still yet I cant imagine shaping this beautiful vessel i without grand help of this laser cut set. Anyway lately i had bad day nothing went ok but today i moved on brilliantly. I dont have trained eye but i used help of photography as well. There is no point to continue if those most important design lines like waterway / as base for sheer are not of great smooth natural curvature. There are still minor bumps but i am pretty satisfied . I even continued and made bottom of stern - semieliptical with help of my bible- crothers book. So finally waterway and sheer aftwards are set - next time i will move to bow part and continue with keel. Most difficult work done, yay still some bulkheads to be faired ..i took some pics to show the result of the lines i did my best to form and sand natural curvature of waterway both horizontal curvature and vertical deck following pattern....no bending there. I cut it off basswood and sanded off. Cant speak how much i value baswood for structural building. I dont know of better wood for it. Stiff yet Beautiful to cut sand and shape.its made of two planks glued up high together... I feel sorry for Rob he had to go thru this pain as well but looking to his outcome he dealt with it naturally and he has great eye for it for sure. Im still new to american clipper / my first/. Feel free to put any comment advice remark etc...thanks for looking. Vlad. Ps. At this point im slightly derailing from model shipways plan design as i wont install sheerline overstretching out hull , it will be fair with hull - its only mark for me to lead planks atm . I plan to glue sheerline afterwards flmadeo f different wood anyway...

-

Yes Rob, all good points there, thank you. but to tell the truth, im still not decided on finish and therefore on process. I saw nice brigantine today with all wooden finish that apealed to me not painted at all. I think you liked it as well. I have to think it over again and again. All i know I want to use boxwood for molda and sheers. Im not sure i want to go with coppering this time.... so even without paint it can go pretty if i palnk her with dark wood and light wood for contrast. there are basically two ways and aproaches for me. going with true colors or going with wooden contrasts.... Im ready to plank her properly if going with wood . well... i have to think. not decided yet. V.

-

I am happy for your recovery progress Rich. Nice to have you back here. V.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

She looks mighty Rob, i wish to see stern with all the rails high up so it will look full. looks you really know and controll your process. nice pics. V.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Guess what? I was thinking today about damn useless proper planking not speaking of tapering etc. what for - if all ends up painted black... still having time but i dont see another option than planks atm . instead of proper size i can use way thicker to speed it up...

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Wow thats interesting approach i may try ti mimic. I ll watch closely .

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Rob check my log its all there. yep i confirm around 10 bulkhead strangely i had to diminish it and no 4 as that one was slightly narrowed for smoother arrow ...but i had to add to it finally to go smoothly. its all even. next i will go making waterways, stern profile and knightheads and rabbet and keel - seems it all will be some important fun. ill inform along. lets hope i will guess stern curvature right. fingers crossed V.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Yes and with quite different approach . so far a bit hassle with evening bulkheads but once done should be straightforward. waterway and sheer would take me longer though. good luck. V.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

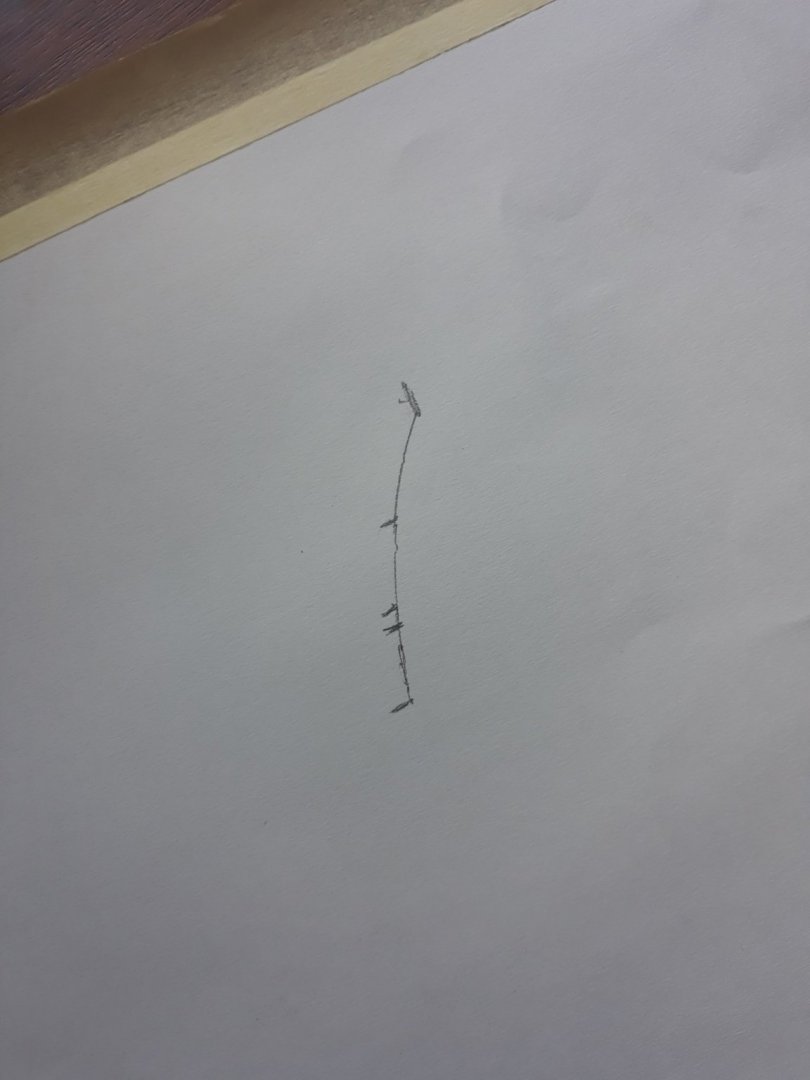

Issues. Dear clipper afficionados, I had fantastic time today working on glory surprised how much work ive done even it was not planned. I was surprised how many issues was with evening bulkheads. Much work - youre correct Rob. first, there is no advantage to have not many bulkheads because every attempt to fasten them misalign centerline. But there is no workaround i guess. Second. These bulkheads were offset from book so it was to be that there will be some issues. What i was suprised those were in middle ! . I was pleased how bow and stern played well. No issue there. But there was quite a lot i had to add or remove for at least 3 bulkheads . It was slow work as i had to align with plank over entire hull...but I enjoyed all the process, much easier to sand the poplar. Voila. She is sanded already ! And even im pretty satisfied. I want to build her to my best so there is no time to rush me...only planking will show sharpness of my eyes, and evennes but i intend to plank with thicker as usual so i can even her after planking to extent needed. There was issue with bulkhead no 4 as I expected as I derailed from Michael Mjelde and drew it less sharp on the too side so rail and topgalant profike from above is smoither longer arrow - different from his design. There had to be fillup in center of bulkhead however which i issued and corrected. You can see the pic. Bulkheads 10 and 11 were pain as well those seemed to me thicker than should be giving hull strange bump so i had to even thst bump. But considering last stern bulkhead curve is basicaly guess and also bulkhead i am really pleased watching Robs iteration and also eirh mine after alignments and sanding. Cant wait to plank her. Another thing was i made pattern for waterway , so i can cut it straight. It alsi shows if curve of bulkheads is smooth band elegant enough i can go further. I added some plywood on the deck fasterned it by two naips and run thin strake along bulkheads so i could draw pencip line to the plywood of that pattern of waterway will be cut basicaly. ...i think line is pleasingly even. Many pics to fillow. Thanks for any comment etc. This time i wleven didnt break bow upper forecastle bulkheads extensions. Strange. New lt i guess i will add keel, make knightheads ( that will be important fun and stern profile. Vlad.

-

Outstanding work Rob. I moved along with mine as well.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.4fde7fe8e22a833eaa87e063fedb3aec.jpg)