-

Posts

1,567 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Vladimir_Wairoa

-

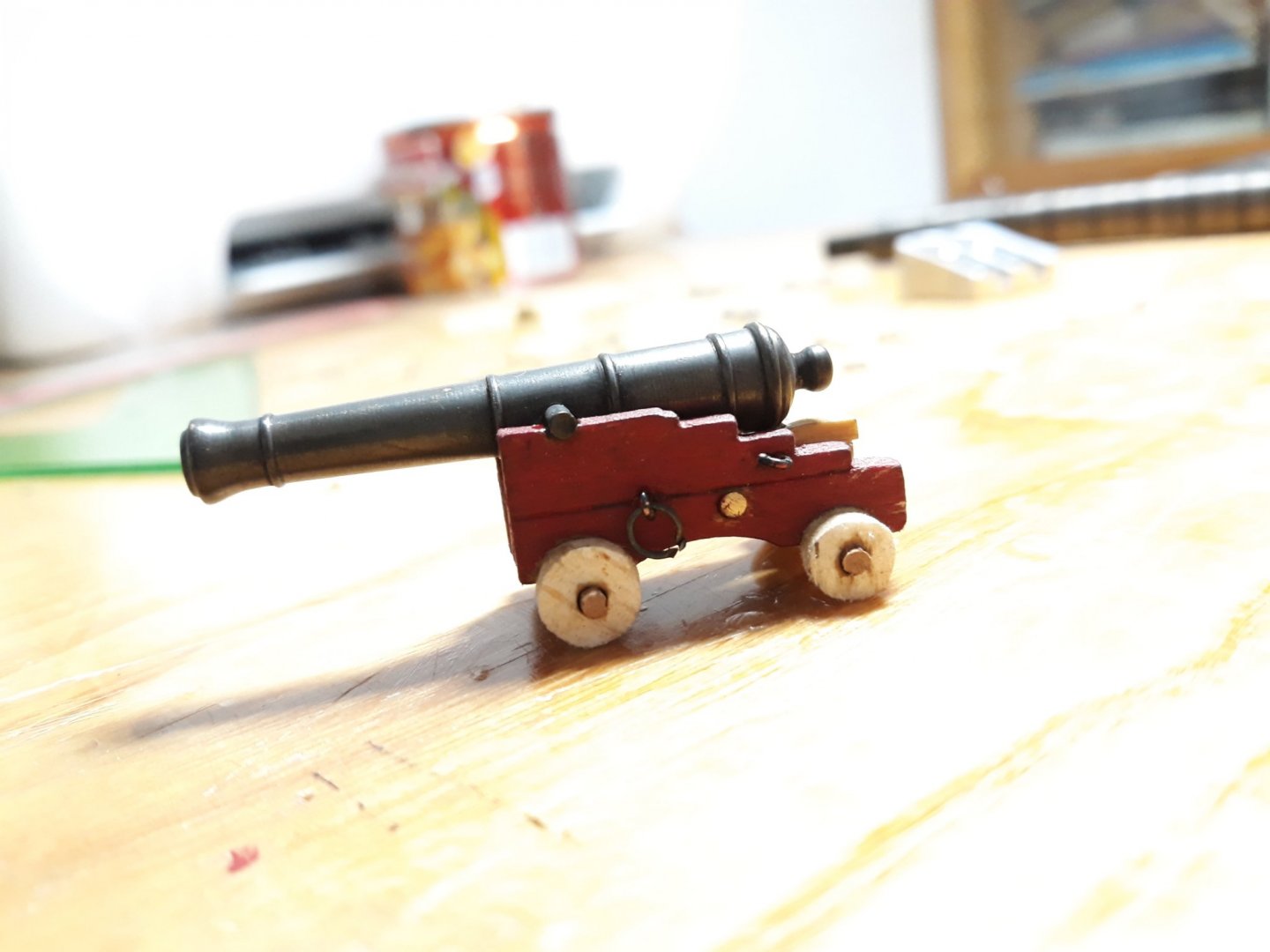

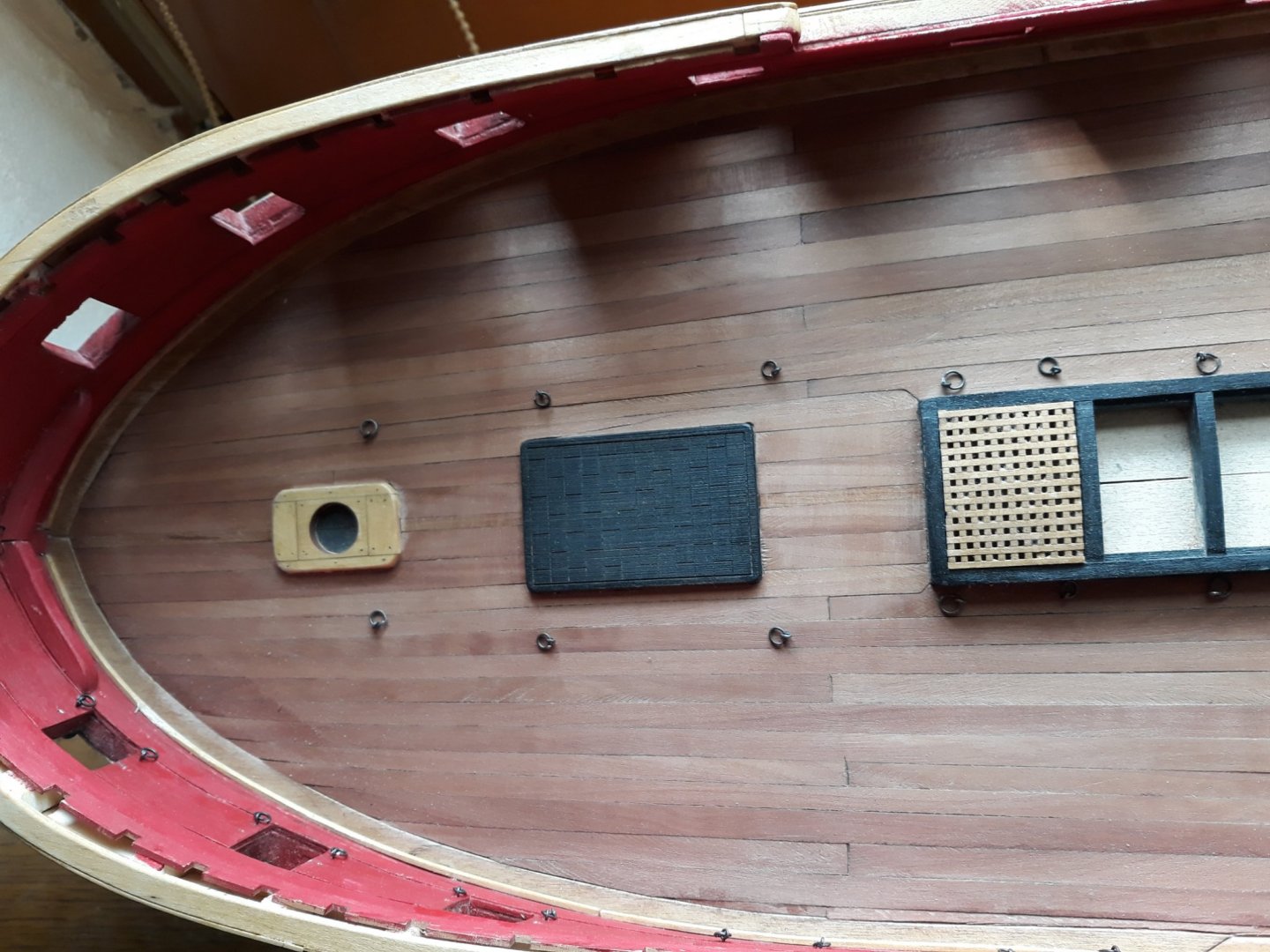

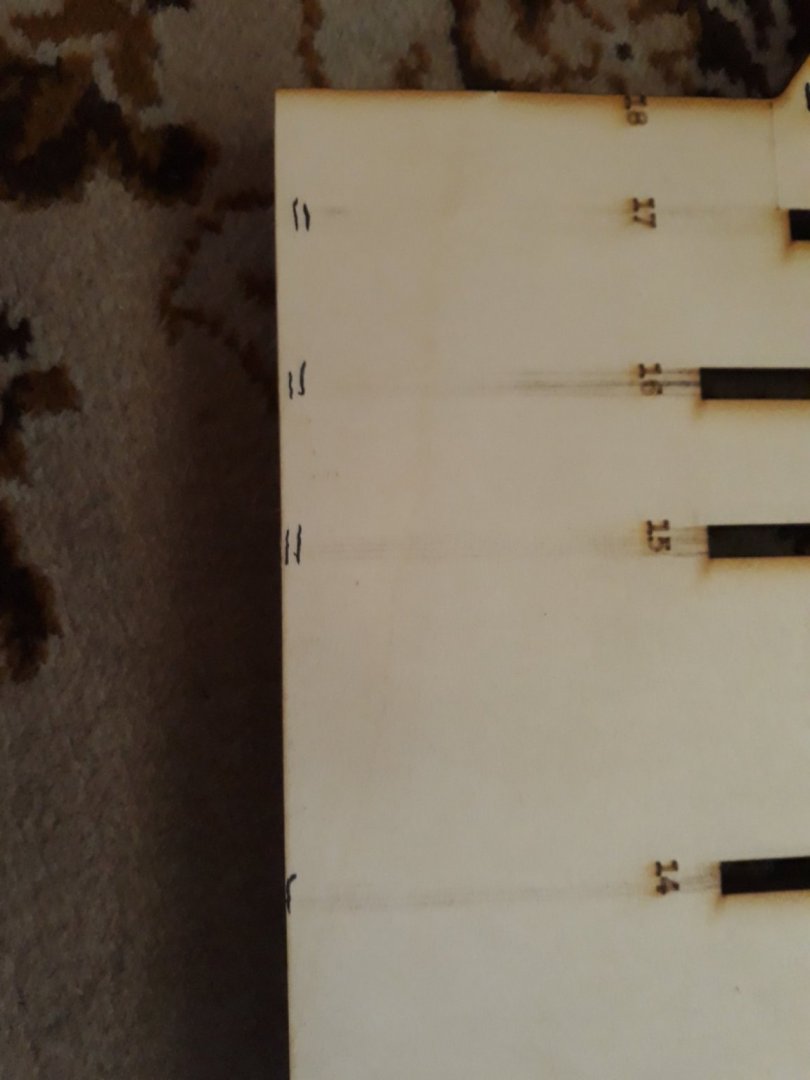

Deck sanded finally. m moving along with things over pear deck....from now on i plan going with natural installations in hull color/ basically french polish over sanded wood. Capstan and columns as well. Maybe no red at all. Best thing i ever did was byuing black wire. I always sgruggled most with blackening wires. It takes time. Still i have to install various things, ladders, etc... Any comments appreciated. V.

-

yay, I think than Chuck plans those peculiar curvy instalments around catheads leading towards figurehead to complete what was started in chapter 6 seems will be in chapter 8. Amazing.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Rich, it looks i will really start in september. Time is scarce commodity these days and time is money as well. I will have no time till than. But I will enjoyably watch Robs progress. Speaking off I had little time to play with her. Rob. please run some strip thru planksheer in abaft to adjust smooth line of the planksheer. 2 or three bulkheads need to be raised i think. look at photo pls.. looks like 3 bulkheads need to be adjusted slightly . dont glue those before adjusting. rest should play handsomely. and slight offtopic, i did little 7 inch tmberframing, and with the fine smell of beautiful pine and oak, one can close eyes and be easily transformed right to the boston shipyard of bygone era, chiseling out those timbers. been quite a whole different experience than miniature modelmaking. more closer to actual ship building though....by the way i got book building of american clipper ship..so I can educate myself more. cant put it down...:) all good V. th line of the planksheer. 2 or three bulkheads need to be raised i think. look at photo pls.. looks like 3 bulkheads need to be adjusted slightly . dont glue those before adjusting. rest should play handsomely. and slight offtopic, i did little 7 inch tmberframing, and with the fine smell of beautiful p th line of the planksheer. 2 or three bulkheads need to be raised i think. look at photo pls.. looks like 3 bulkheads need to be adjusted slightly . dont glue those before adjusting. rest should play handsomely. and slight offtopic, i did little 7 inch tmberframing, and with the fine smell of beautiful p

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Hasnt yet but stay calm Rob :)), . it depends on many factors as frequencies of flights and we are country like quarter of texas it might have arrived just there is overload at custom entry due pandemic ets ...i sent it within trqcking number so it surely sped it up ....

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Rich wow . arrived? great ! that was quick for todays standard ! . Im glad it came. ! cant wait to reach Rob and see him building. V.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Thanks Rich. I take this to consideration & assume carving angling designing and instaling & measuring knightheads will be one of the most important tasks/ challenge to get right considering overall aspect of look. it will certainly take time. V.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

@Rob, fyi trackable parcel was sent to Rich so he will resend your half within states. officially should be 6-9 days but im sure it will be longer nowadays ...we will see. Hoping for the speeď V.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Oh Mike astounding.i love kind of dry color of it very much matching carving statues. this is modeling porn level:)

- 607 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Im having blast watching whats materialising on deck and Chucks speedy progress. Looks like we are going forward standing aft. deck is getting lovely busy. im anticipating the final black rail most. but ill zave to wait tillend i guess:))). from the start :). thank you.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Rob, Richard, too much of good things i see - i didnt have time to study your posts will check it over weekend though, just FYI both sets have been cut and already on the way to me! meaning next week im sending them to you guys. apology for taking it longer he apologized for being very busy. V.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Thanks Rob for nice post. is been no doubt godsend to me the fact i was welcomed here and my passions for clippers by your gratious generosity friendship and help . and others. its remark of 21 century technology might and human brain evolution and genetic advantage to cooperate which gives us advantage apart of other living species. my apology for not following my own topic lately as im out of time atm. hopefully soon ill be free...

-

George, thanks i follow your fish closely so i try to observe specific caveats of model shipways design as we made it upon their design. i use commertially available cutting service. they usually need only draw in pdf. im not sure what laser they have. but ill ask becasue later down the road ill beed to cut miniarures with very thin cut.

-

Absolutely superb Rob, beautiful. Its quite something.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Lovely Richard, her decks are capter itself especially roof overhangs ...bit that will be dream of mine somewhere around next year. i think i will want to have stanchions laser cut and file rounded after. and draw them exact as original prior to that. V.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

you are a Craftsman Rob, delicate stanchions at such scale , I watch with pleasure. youre giving us great ideas what to make in advance.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

very nice Gorge. watching with anticipation.

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

I didnt move on Rob. I scouted for planks to gather for hull.actually im thinking of wideness of planks, observing model shipways flying fish i will widen palnks according to ratio margin. so i elan to set on ( metric here 4 or 5 mm wide and 1.5 mm thick european basswood as it prvoee ne the best material cutwise and bending wise so i can taper down to 2 mm at the bow..... i like it enormously. and its fairly cheap . ( by the way Lime as it is called in my country is national tree of country so it has very long carving tradition as its perfect for sculpting and violin work. ) I will have to get it sawn to my liking. if i count it should be smaller based on original Planks dimensions 6" - 2 mm is pretty much unusable by modeling standards in case i want to taper and bend towards bow and aftwards as well. i dont have window to dive into it properly and focus on her at the moment or anytime soon. i made a promis to myself that i will start with the autmun rains so 4 months till than but when there is a window i will work small bits. sanding bulkheads... and i want to put wooden blocks as suports for bulkheads as those are not so near to withstand sanding...so these are my actual doings...

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Great job Rob Im amused watching ehat sou do in that scale folks. 1:72 warms the mind a little.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.