-

Posts

174 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Voyageur

-

I found this canoe at a second hand store a while back. Even before I thought of building ship models. I had it on my shelf all this time and decided that I could do something with it. Definitely inspired by @Osmosis and his beautiful Peterboro, recently completed. I always thought that this canoe is out of scale; 20.25” long and a beam of about 3.25”. I has no tumblehome, no keel, no thwarts and a large rocker. But I think I can do something with it. I initially thought I would somehow cut it down to 16” to make it more proportional to a typical canoe but decided against that. I've sanded all the paint off of it. As you can see the planking was very well done. Interesting on how the builder crossed the planks at the bottom instead of meeting in the center. I don’t know if that is a usual way of planking a canoe. I’ve never seen that before. I removed the fore and aft decks and then the gunwales. I want to clean up the inside but I don’t know how. Any advice is appreciated! I plan on stemming the whole thing and compressing the beam by about 1/4” - 1/3”. It’ll be a long skinny canoe but I think that will take away the flare profile to make straight sides or maybe a little tumblehome. I would like to build up the bow and stern to change from a touring profile to a more traditional profile. I think that will help in making it look more proportional. At least to my eye. I’m going to plank over the existing planks. Add a keel and stems. Add nice decks and gunwales. Add seats and thwarts and finally make a nice pair of paddles.

- 69 replies

-

- canoe

- restoration

-

(and 1 more)

Tagged with:

-

You bet! You inspired me to do this. I was perfectly happy looking at it on the shelf but your Peterborough looked so sweet that I just had to do something. I spending some time thinking about how to approach it before starting the log. Maybe tonight. I’d like some input from my friends here as I don’t think I have all the answers to accomplish what I want. Thanks for your interest!

-

You are doing a great job on this. Looks fantastic so far!

- 204 replies

-

- marine model company

- charles w morgan

-

(and 1 more)

Tagged with:

-

priming hull

Voyageur replied to helge's topic in Painting, finishing and weathering products and techniques

That is great info. I will be sure to return to this thread for reference. Do you also shellac over the paint, as a sealer or protector? -

priming hull

Voyageur replied to helge's topic in Painting, finishing and weathering products and techniques

Bob, this is great information. Is it common to shellac all wood of a ship model? I can’t say that I ever recall seeing someone applying shellac to masts or spars, etc... I would think all the same reasons for shellacking the hull would also apply to the rest of the wood. -

Looks great! And I’m a voyageur and I know my canoes! 😉

- 84 replies

-

- peterboro canoe

- Finished

-

(and 1 more)

Tagged with:

-

Model Shipway’s Katy of Norfolk. Hope to start next week.

- 42 replies

-

I agree. I think I’ll make more small craft in the future. I appreciate your comments!

- 42 replies

-

A solid Hull is on my list to do next so I am following along with interest. Looking great so far!

- 57 replies

-

- finished

- yankee hero

-

(and 1 more)

Tagged with:

-

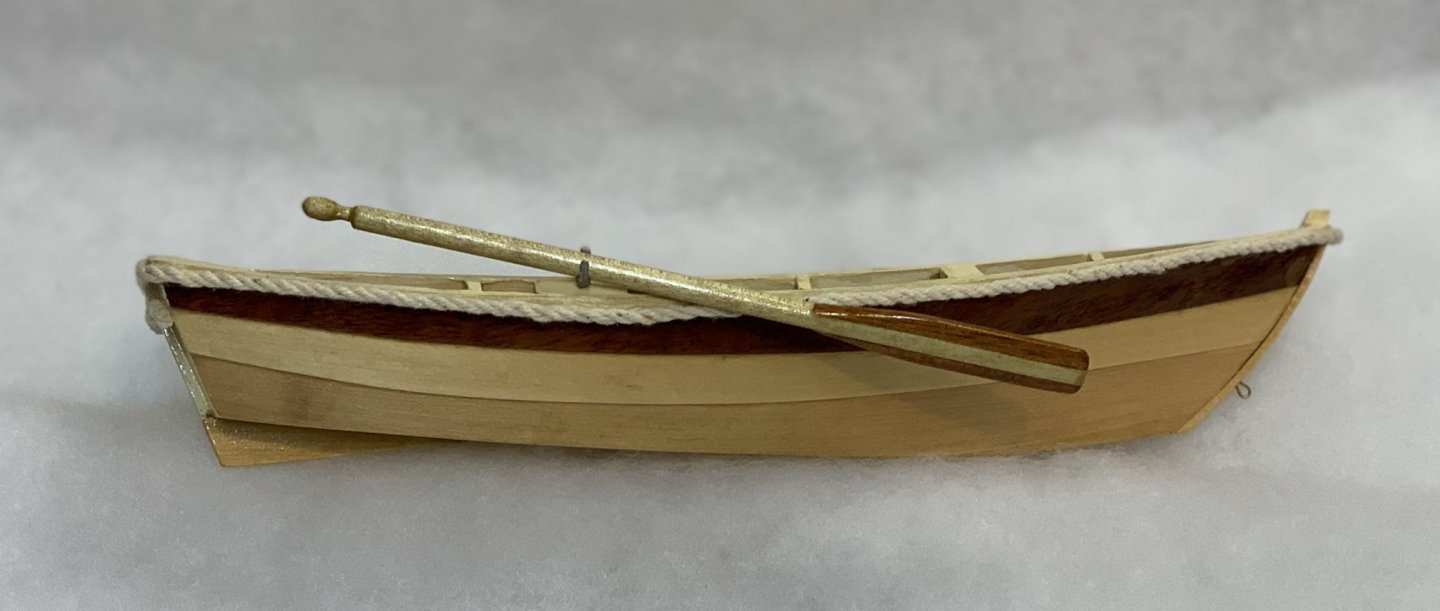

Well, here is my finished dinghy. Not perfect but I think she’s seaworthy. Thanks for your likes and comments! on to my next project...

- 42 replies

-

Thanks Bob. Yes they are! I discovered them through a post somewhere on this forum. Mine aren't magnetic. My arms screw in from the bottom through the rubber foot. I was expecting magnetic but got this and I'm OK with it. I wrote a glowing review on Amazon.

- 42 replies

-

Your Virginia 1819 looks amazing. I’m sure this will be equally magnificent. I’ll watch with great interest.

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

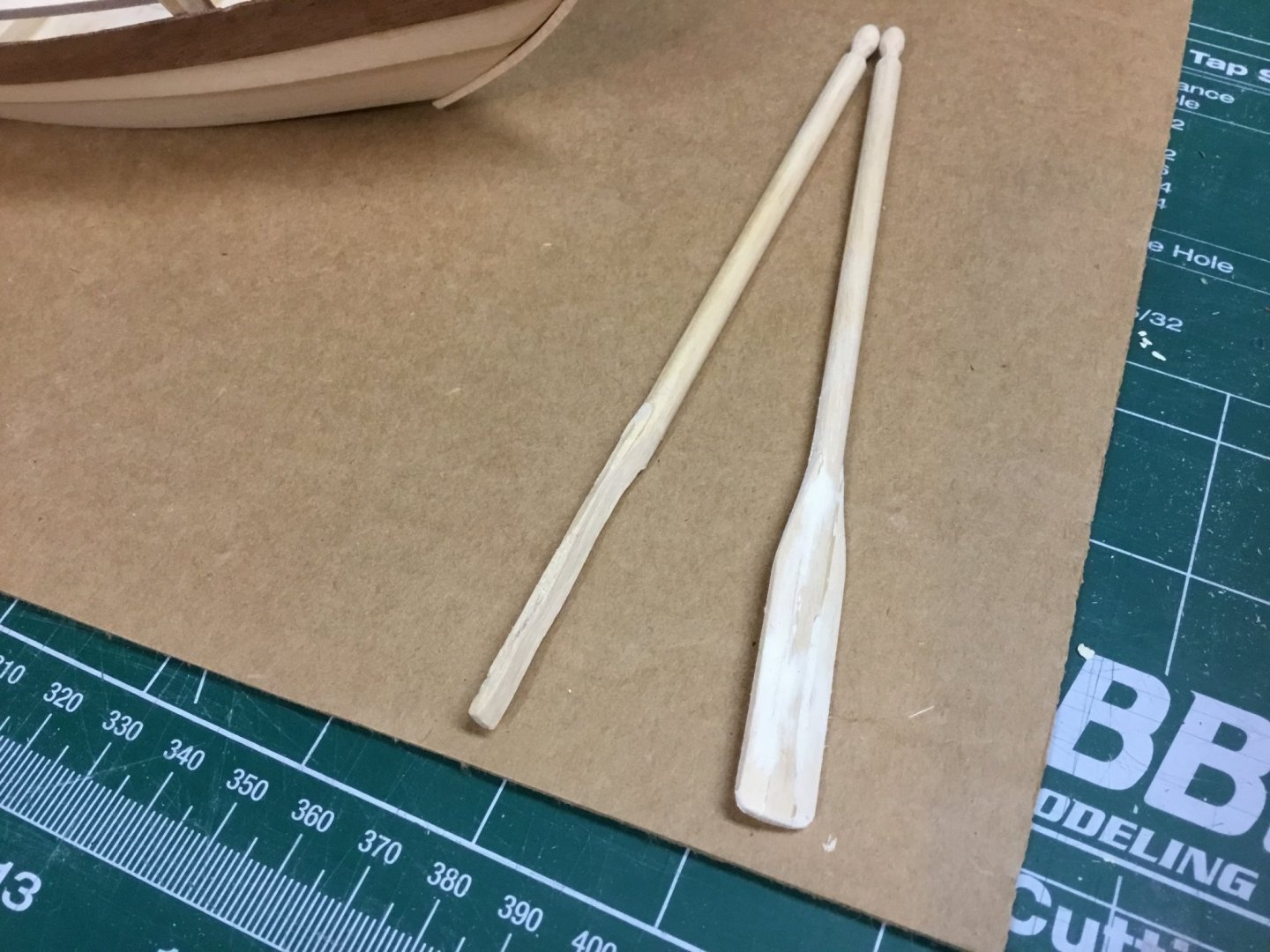

For the oars, I rounded out the interior side of the mahogany pieces so they fit flush with the 1/8” dowel. The fit was perfect and sanded down with no need for filler in the gap that would have been there if left flat. I don’t have a mill so it was freehand.

- 42 replies

-

Thank you all for your likes and much welcome and appreciated comments. Oars are done. I think they came out well. I didn’t like the way the natural wood looked on the interior so I painted the interior of the boat, the inwales, transom and guard. I am pleased with the results. sanded, applied poly, sanded again and applied a second coat of polyurethane. Maybe one or two more sanding and polyurethane coats.

- 42 replies

-

This was a master class for me and I’m sure to reference this build many times. It’s what I aspire to as a model builder. Thank you for the detailed descriptions.

- 335 replies

-

- alert

- vanguard models

-

(and 1 more)

Tagged with:

-

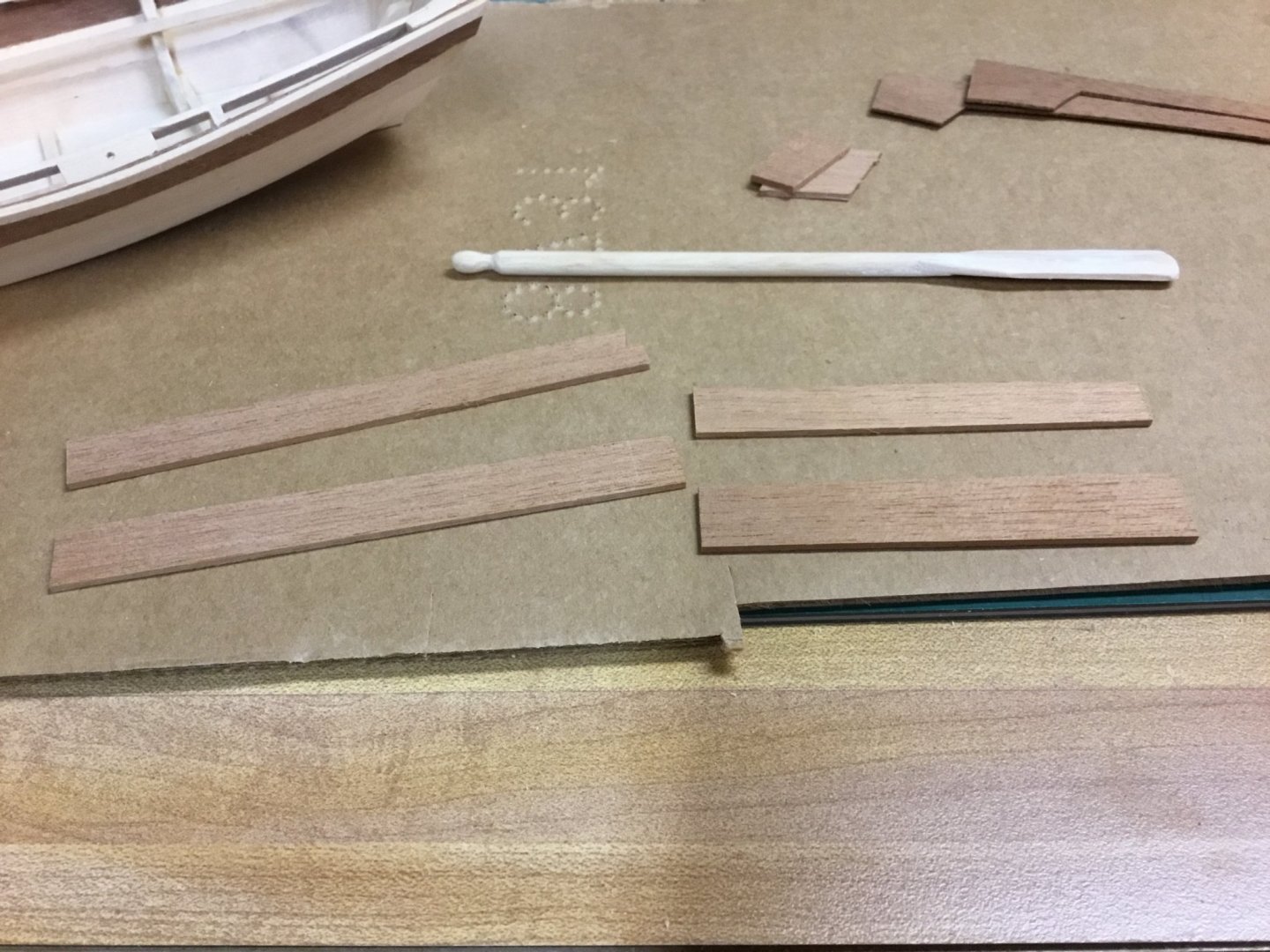

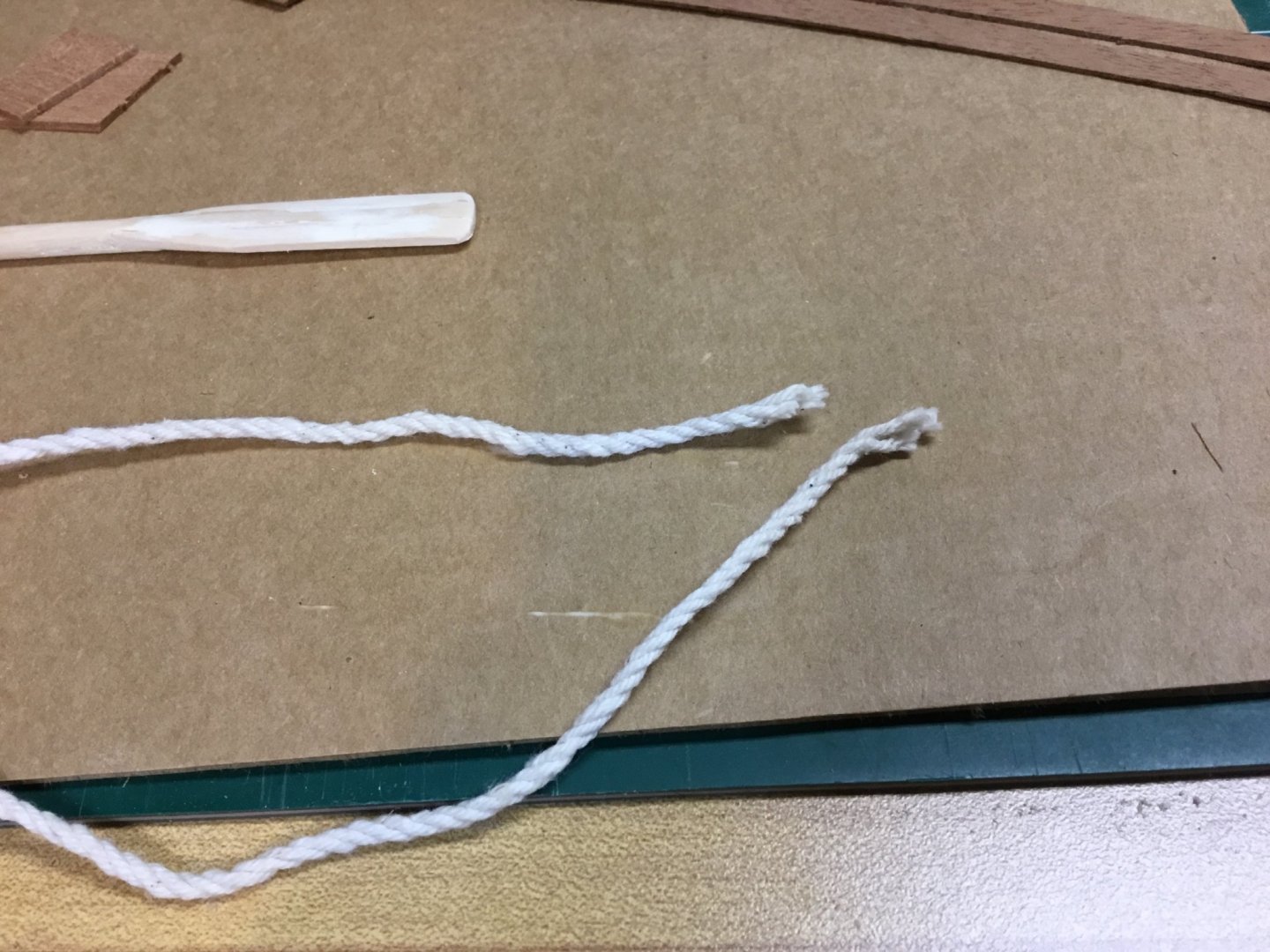

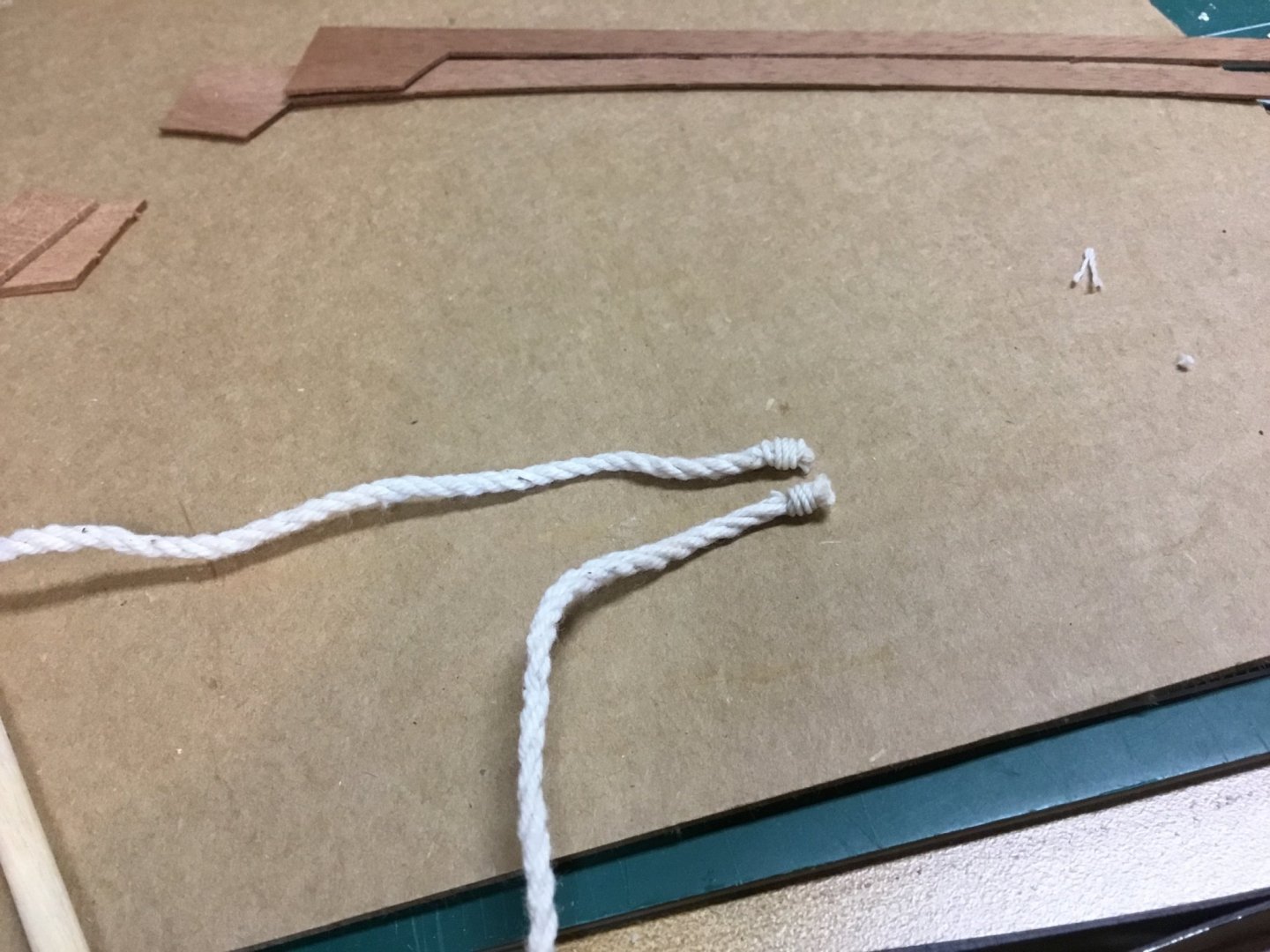

I screwed up the oars. One of them I really got aggressive on the sanding with the Drexel and botched it pretty bad. The other was OK but I didn’t like having to use wood filler. So I decided to go with plan B. I am gluing up a couple scrap 1/16th mahogany and I’ll make the blades out of that. They are clamped up in my vise overnight. While that was setting, I looked at the rope provided and thought those ends should be whipped.

- 42 replies

-

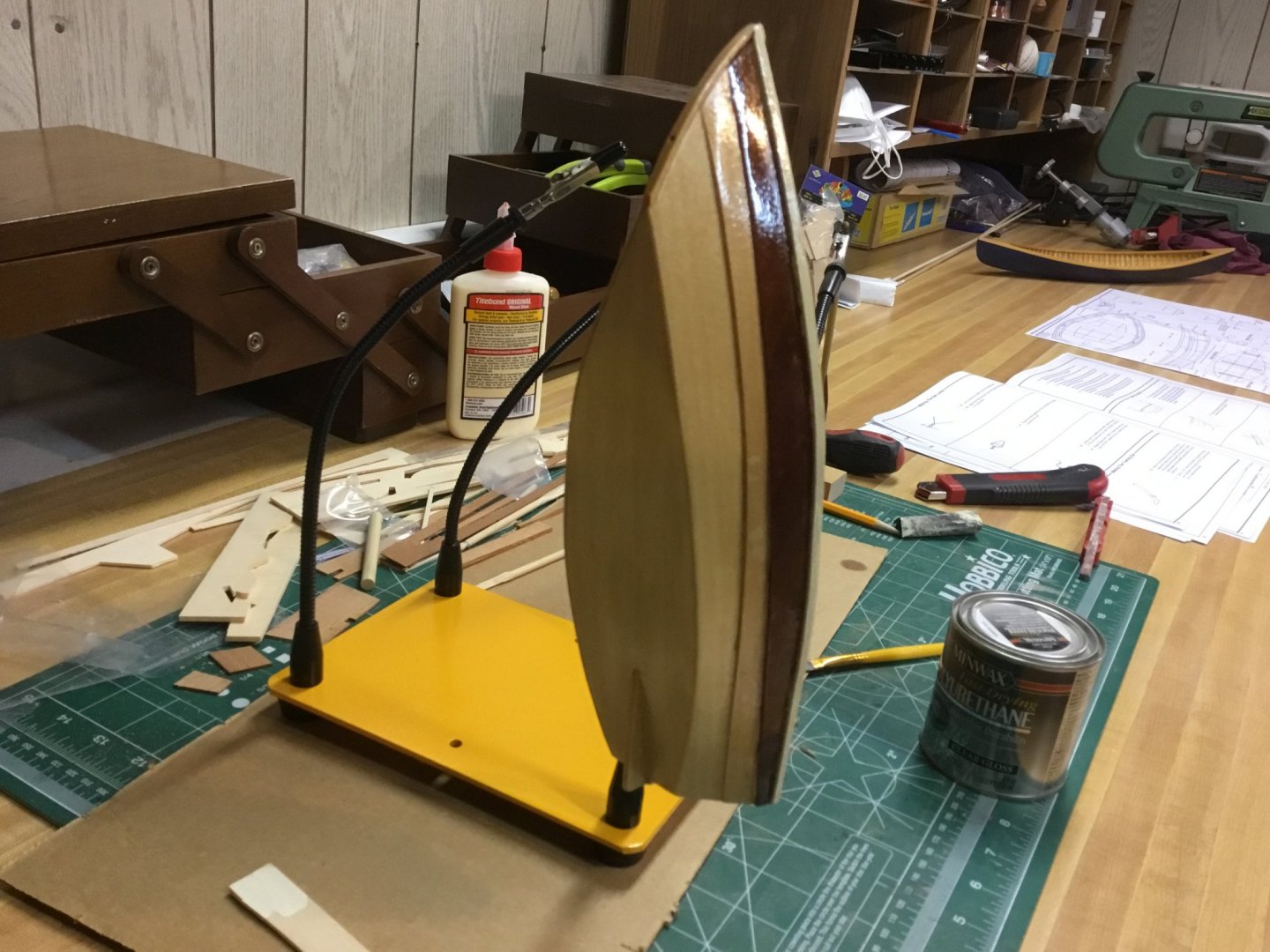

I’ve been making progress on this the past couple of days. Breast hook and knees are done. Inwales and guards are also done. I feel pretty good about how they came out.

- 42 replies

-

Good info! I was thinking the CA was old and beyond it’s shelf life, if there is such a thing. I’ll pull it out and get some accelerator. We’ll se how that goes.

- 42 replies

-

- 42 replies

-

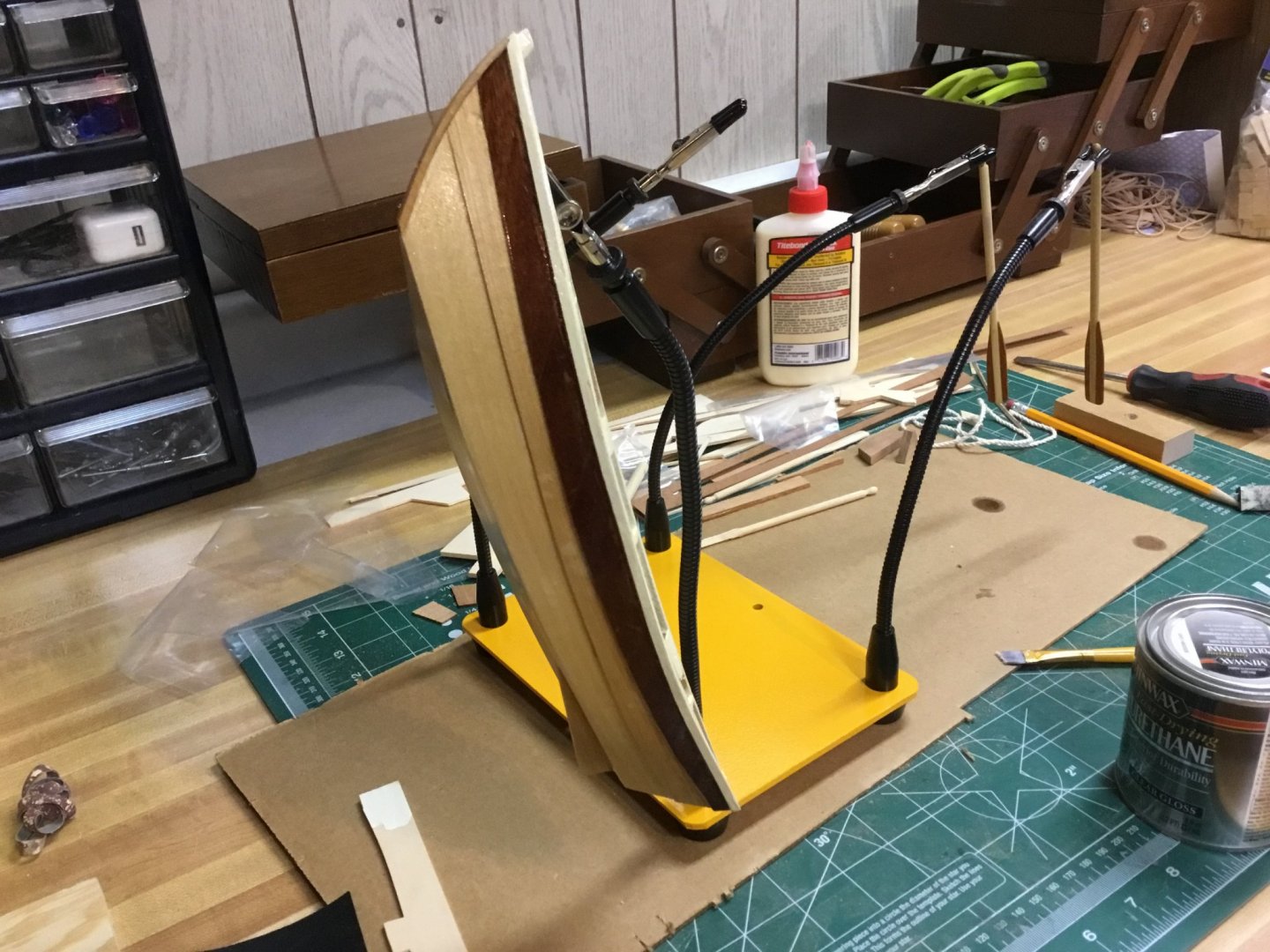

Disaster strikes! While bending the second top mahogany plank, I pulled a little too hard and snapped the piece. not having another pice of mahogany and I really didn’t want to. Order a piece and wait around for it, I attempted a repair of this piece. I tried CA glue first. It would not set. At all. I only succeeded in creating shiny spots on the wood. I then used titebond very lightly. I put a couple clamps on it and let it sit for an hour. I found the joint to be good and tight and straight. I then took my Drexel with a nylon brush wheel and was able to remove the excess titebond and even some of the CA shininess. A little gentle sanding using 320 grit on top of the titebond bottle as my base to help maintain the curve and have a little “give” as I sanded. I am very pleased with the results and will use the piece. You’d never even know it was snapped in two. I got the other side glued up and the oars started.

- 42 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.