-

Posts

1,811 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DocBlake

-

Sharpie by Jim T - Scale 1:16 - SMALL

DocBlake replied to Jim T's topic in - Build logs for subjects built 1851 - 1900

Thanks, Jim! -

Sharpie by Jim T - Scale 1:16 - SMALL

DocBlake replied to Jim T's topic in - Build logs for subjects built 1851 - 1900

Jim: Very nice work! Did you have any problem fitting the chines? I may have made the notches a little too deep so I'll have to shim them, or increase the chine height slightly. -

Ken: Are you planning on rigging her? I'm considering stub masts and sprit for mine.

- 122 replies

-

- independence

- privateer

-

(and 1 more)

Tagged with:

-

Good job! These cannons in larger scale are fun!

- 125 replies

-

- 9 pound naval cannon

- 3d cannon barrel

-

(and 1 more)

Tagged with:

-

Great job! I think you've found your niche, Ken. You can do carvings for me anytime.

- 122 replies

-

- independence

- privateer

-

(and 1 more)

Tagged with:

-

Great job so far, Bob! I can't wait to see the masting and rigging!

- 359 replies

-

- prince de neufchatel

- model shipways

-

(and 1 more)

Tagged with:

-

Great job on the headworks, Ken! I struggled with the temptation to over-do the decorations on this small ship that began life as a merchantman, but in the end, opted to include the headworks, quarter badge windows and a more elaborate stern. Couldn't help myself!

- 122 replies

-

- independence

- privateer

-

(and 1 more)

Tagged with:

-

Swan class 3D model in progress

DocBlake replied to dvm27's topic in CAD and 3D Modelling/Drafting Plans with Software

Fantastic....- 141 replies

-

- pof swan series

- swan

-

(and 1 more)

Tagged with:

-

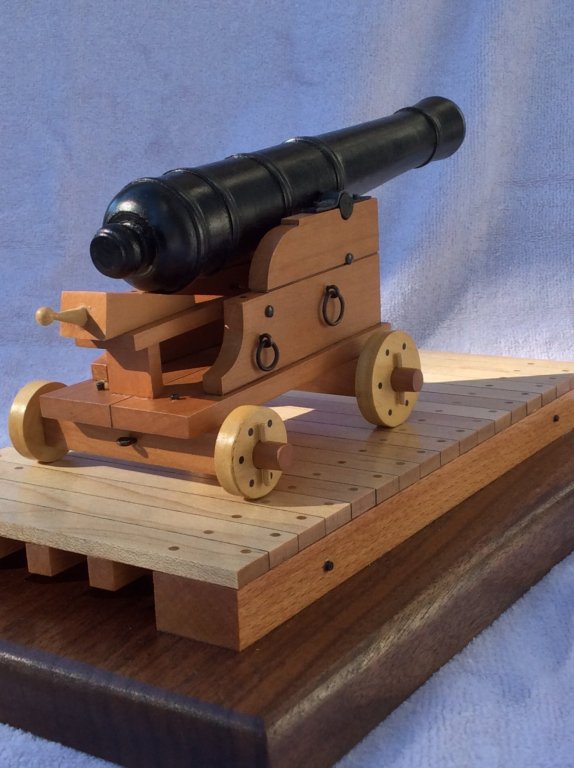

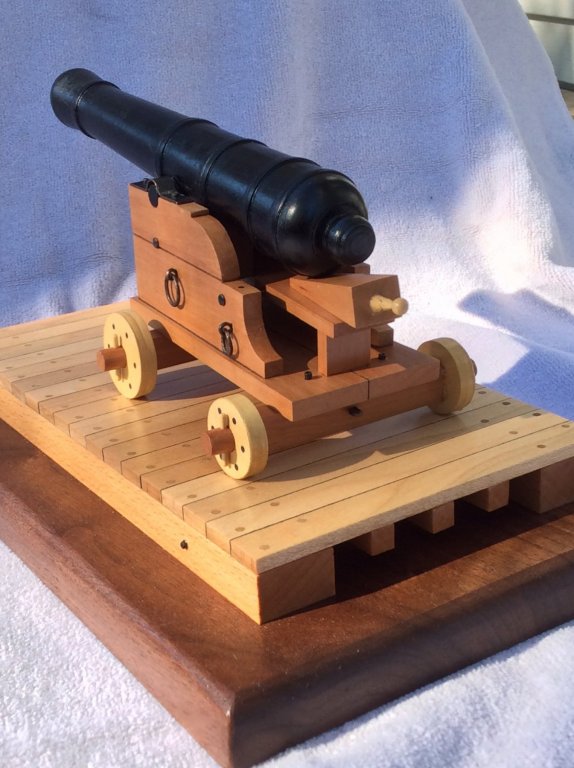

I finished the base. It is really a stylized section of decking to mount the gun on. There are black bolts in the deck beams sides that are not historically accurate - just there for visual interest. The carlings aren't visible but you can see the ends of the ledges. Once I attach the metalwork to the cannon, and mount the cannon on the deck piece I'm done!

-

I opted to finish the cannon with satin wipe on poly. In deciding how to present the final model, I knew I wanted a little more than just a slab of wood, but I wasn't prepared to build a whole battle station section at 1/12 scale! I opted for a section of decking. I found a walnut cutoff in the shop and rounded the edges. I then glued 2 long parallel pieces of beech (1" X 5/8"0 to represent the deck beams. Then I added the two short cross pieces representing the carlings. The deck will be planked with 1/2" X 3/16" maple. Once the deck is planked, I'll add the ledges between the deck beams.

-

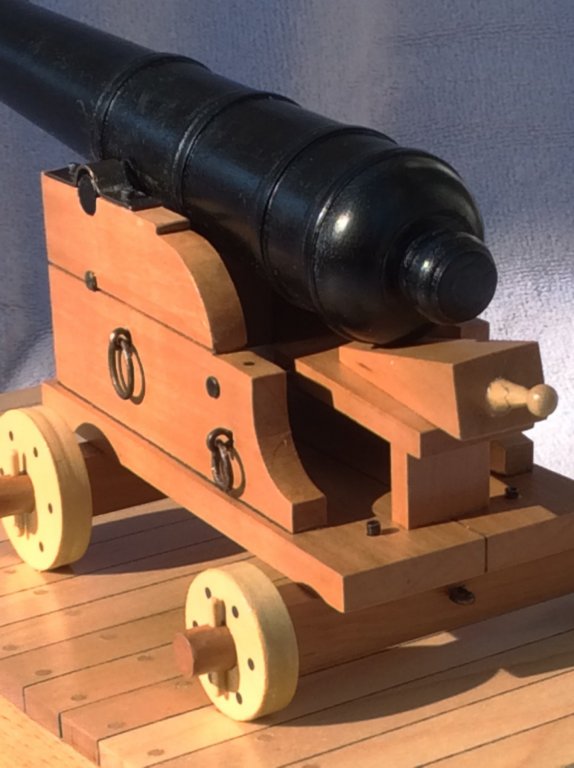

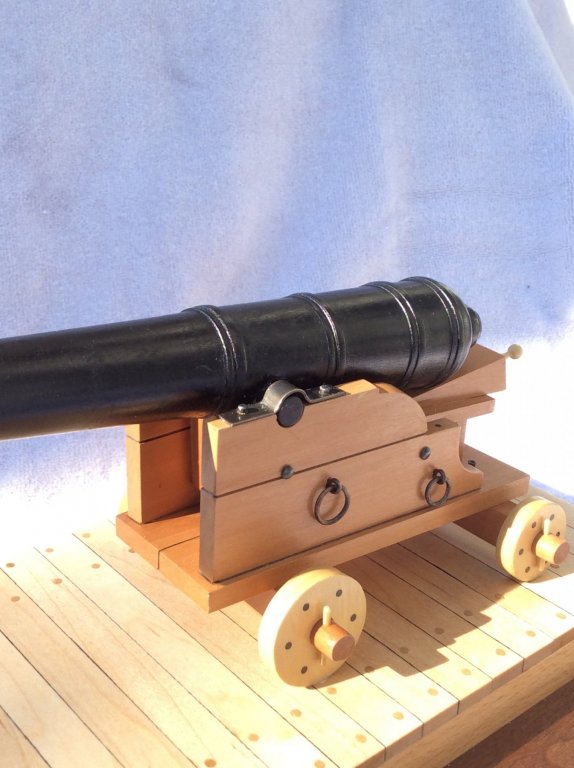

So I used the lathe and fine sandpaper to smooth the canon. The final polishing is done with handfuls of wood shavings pressed against the turning barrel to use "wood to polish wood". The technique works really well. I then had to decide how to blacken my maple cannon. Three choices: Paint, stain or dye. In the end, I chose Solar-Lux Jet Black wood dye made by Behlen. It's alcohol based, dries quickly, penetrates into the wood fibers, doesn't raise the grain and won't obscure the detail on the reinforcing rings and the cascabel. It turned out well. Obviously I'll need to protect the dyed cannon. When we blacken brass cannons chemically, the resulting gun has a bit of a sheen to it. The cannons were cast, so would have been flat black in color. The "sheen" doesn't look bad in my opinion, though. So what do you think? Flat/matte poly, or semi-gloss/satin poly for a little sheen?

-

Thanks for the likes, guys! I drilled the holes for the trunnion and bore. The trunnion hole was a little out of square so I had to use a rattail file to square up the hole and a glue a slightly larger diameter trunnion in place. I used wood filler to fill the irregularities in the trunnion hole. Dying is next

-

Looking great, Ken! The bell was the only thing I used, also!

- 122 replies

-

- independence

- privateer

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.