-

Posts

1,811 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DocBlake

-

I finished up the build board. I had some beautiful curly bird'seye maple so I cut off a piece and framed it with some rounded over 1/2" X 1/2" east Indian rosewood. It turned out pretty nice!

- 128 replies

-

- mordaunt

- battle station

-

(and 1 more)

Tagged with:

-

Thanks, guys! Michael: I think it's because I have a short attention span and get easily bored!

- 128 replies

-

- mordaunt

- battle station

-

(and 1 more)

Tagged with:

-

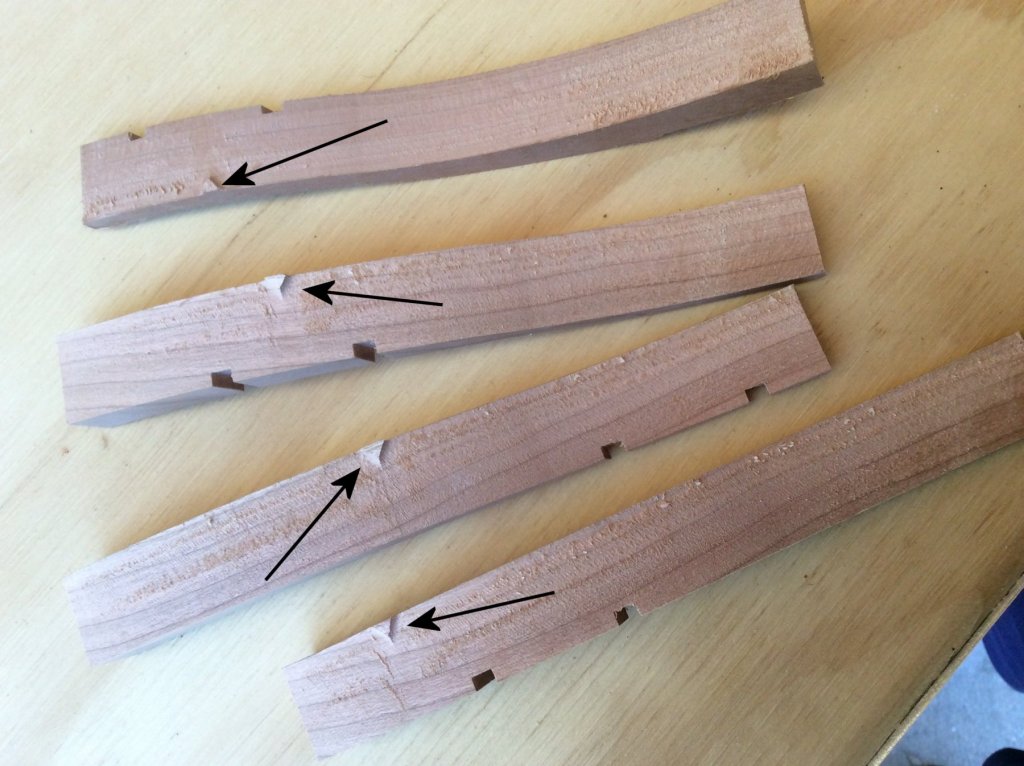

Most of the framing including the hull and deck framing is made of cherry. It's too bad that so much of it will be covered up, but it isn't expensive and it was just easier to cut the parts all at the same time from a limited number of billets, seen or not! The hull framing is 3/4" thick, actually 3/4" WIDE on the model. After CNC cutting, you can see that each piece is held in the 3/4" billet by 2 tiny triangular tabs (arrows). Very easy to remove and clean up the frames. I worked on those while the build board was drying (I glued a rosewood border around a beautiful piece of curly bird's eye maple I had). I also scribed scarfs in the two end frames as well as simulated bolts. I then gave these two a wipe of boiled linseed oil to even out the color.

- 128 replies

-

- mordaunt

- battle station

-

(and 1 more)

Tagged with:

-

After a lot of prep work getting the plans into a form CNC and laser could utilize, a prototype was built of basswood and poplar. The point here wasn't to have a perfect model, but rather to proof the plans and our dimensions and make sure the pieces all fit! We will obviously clean up the laser char on the finished models. The hull frames were CNC cut from 3/4" stock. The treenails are surface etched, but deep enough to allow finish sanding and still be visible. We plan to leave the laser char in between planks to simulate tar.

- 128 replies

-

- mordaunt

- battle station

-

(and 1 more)

Tagged with:

-

This will be my build log for a 17th century Royal Navy Battle Station. The station is loosely modeled after a 4th rate ship of the line, HMS Mordaunt, launched in 1681. It is based on the excellent plans drawn by Jeff Staudt, and the model kit itself is one of three produced in collaboration with two modeling friends. I'll be adding background information and details on research and development of the kits is as the build proceeds. Here is a reprint of the message I posted when I received my kit:

- 128 replies

-

- mordaunt

- battle station

-

(and 1 more)

Tagged with:

-

I’m glad you got your plans. I’m frankly surprised by AL’s rapid response. That’s not the reputation the generaly have, at least from my experience. Glad it worked out well. Yes, post a log!

-

Excellent work, Elijah! That is about the best approximation of a weathered wooden boat I have seen! Fantastic job. Your metal work and guns look great, too. BTW: It was nice meeting you at Manitowoc in May. Hopefully I'll see you there next year.

- 228 replies

-

- gunboat

- model shipways

-

(and 1 more)

Tagged with:

-

Ken and Lou: Another option for the transom: An aftermarket fix for the horrible stamped metal transom and quarter badges that come with the kit! I spend a fair amount of time rebuilding these areas, and while I'm happy with the results, this would have made the job far easier. Only $10.00! The transom piece is reversible so you don't have to use the name "Independence". Available at http://traintroll.com./ Quarter badge windows included! Well worth it if you plan to build this model!

- 122 replies

-

- independence

- privateer

-

(and 1 more)

Tagged with:

-

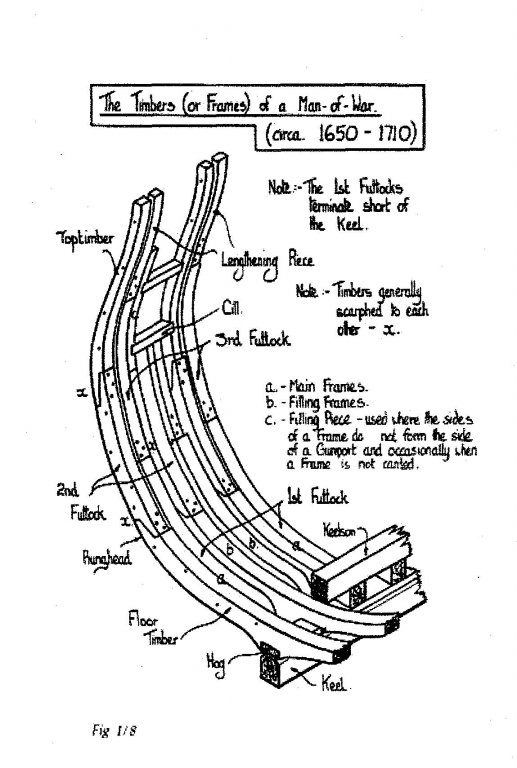

In looking through my copy of Goodwin's book "The Construction and Fitting of the English Man of War ,1650-1850" , I found that late 17th century British ships had a scarf in the framing at the weather deck level and bolts holding the futtocks together. I plan to replicate that for a build I'm starting. My question is how big would the bolt head have been? Goodwin doesn't say, and I couldn't find an answer in Steel's book either. The image is from Goodwin's book.

-

Requesting feedback for future MSW Group Projects

DocBlake replied to Chuck's topic in Group Projects on Model Ship World

I'm in! I was involved in a 1:24 scale long boat project a few years back. It was a group build. The project got scrapped when the CAD guy drawing the plans died unexpectedly. Hopefully we'll have none of that with this build! -

Requesting feedback for future MSW Group Projects

DocBlake replied to Chuck's topic in Group Projects on Model Ship World

I’ve a lot of things underway but I’m interested: especially if templates are provided. I’d opt for scratch built! -

- 75 replies

-

- constitution

- mamoli

-

(and 2 more)

Tagged with:

-

The carronades for the upper deck are cast metal, and are the same design as currently in use on the real ship. These were introduced during the 1927 refit of the Constitution and are not original to the ship. I opted to rebuild them in the style used for the British 36 pound carronade dubbed "the Smasher". I plan a minimalist approach (no rigging or fittings) because of the small scale. The wood is better than cast metal, anyway. I also completed the woldings on the stub mast.

- 75 replies

-

- constitution

- mamoli

-

(and 2 more)

Tagged with:

-

Requesting feedback for future MSW Group Projects

DocBlake replied to Chuck's topic in Group Projects on Model Ship World

A great project would be a stern section including a great cabin, magazine, light room and filling room in a larger scale, say 1:32 -

Thanks, Ken! The fashion pieces caused a lot of heartburn! They form a compound angle so carving them from a single piece of wood would be difficult. Sculpey wouldn't look right, so here's what I did. I installed the taffrail and simply made the fashion piece in 3 pieces, each one onforming to one of the planks between the wales and running back to the taffrail and the counter. Turned out OK. Here's a photo and I link to how I did the windows.

-

Clare's build was the inspiration for my Independence kit-bash. It's a good resource. Planking pictures, Ken?

- 122 replies

-

- independence

- privateer

-

(and 1 more)

Tagged with:

-

I think the upper hull planking turned out great! Nice job!

- 164 replies

-

- first build

- model shipways

-

(and 2 more)

Tagged with:

-

Great job David! The little boat turned out nicely.

- 59 replies

-

- prince de neufchatel

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.