-

Posts

1,293 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Glen McGuire

-

-

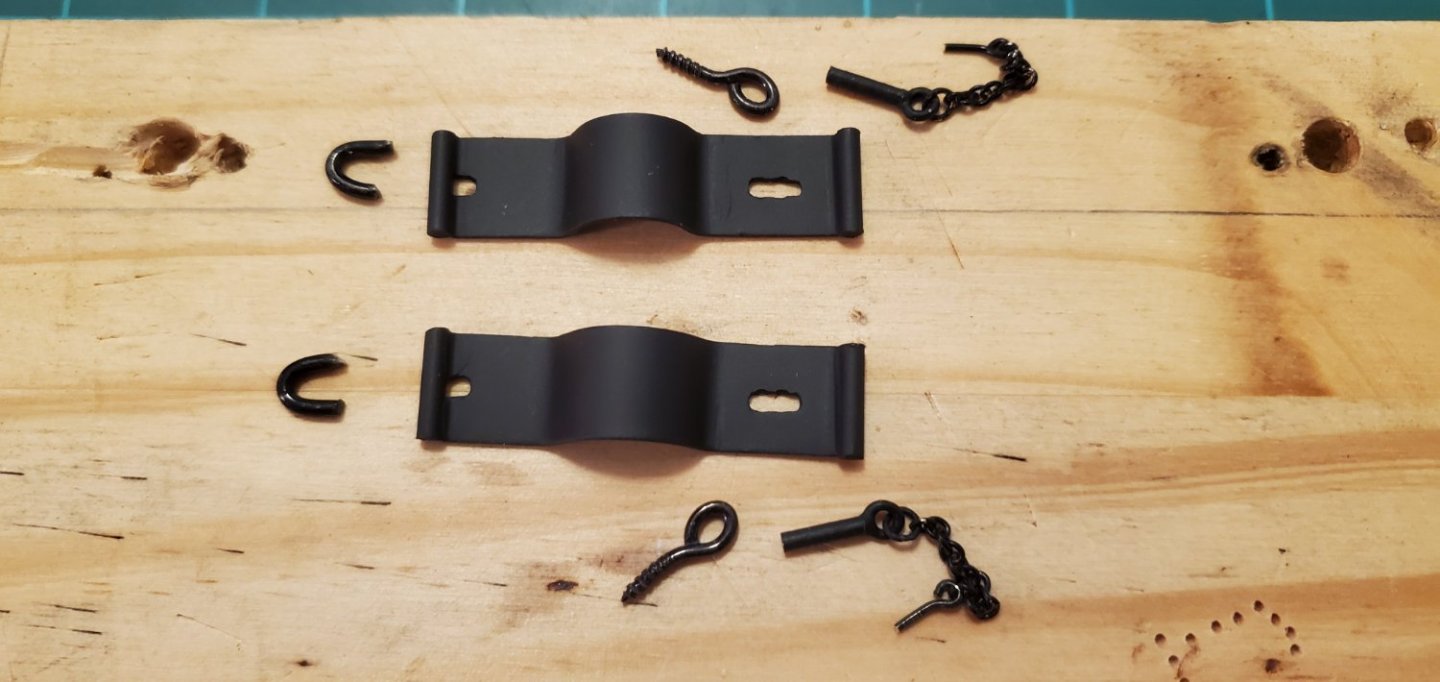

Finished making the last pieces of carriage hardware. For the breeching ringbolt I took a piece of copper wire, wrapped it around a dowel rod and soldered the ends. For the capsquare key I took a small brass rod, bent it into a circle around a small nail, and soldered it to part of a small finishing nail.

The 2nd pic shows all the completed capsquare hardware.

- gjdale, Keith Black, Ian_Grant and 4 others

-

7

7

-

@Deperdussin1910 Thanks for the comment. I do find the list very interesting. When Chappelle said the Independence was the first ship of the line commissioned by the US Navy, I assumed it was the first US ship of the line. But maybe he was alluding to the fact that the Dept of the Navy did not officially exist until 1794 and the Independence was the first one commissioned after that. The history is always fascinating.

- mtaylor and Keith Black

-

2

2

-

41 minutes ago, Landlubber Mike said:

Did you try it on the end grain of the carriage sides? The change seems very subtle, and not so drastic as with redheart. Looks nice to me.

Thanks, Mike. Yes, I did put a touch on the end grain of the carriage sides. It was going to be a hair light without it and a hair dark with it. It was not going to be perfect either way, so I went with the slight darkening.

-

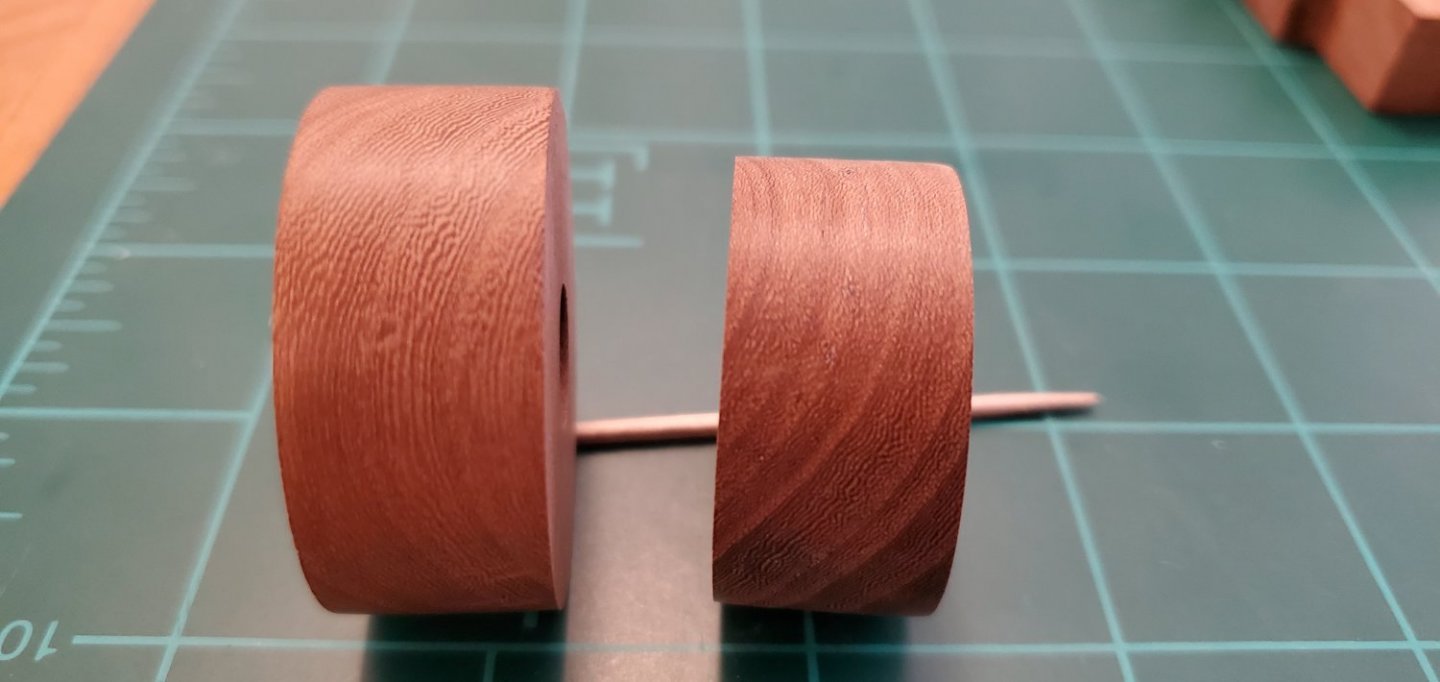

File this under "Questions I should have asked before doing something." The end grain is really exposed with the wheels and as soon as I applied the tung oil, I noticed it was darker that the long grain. So I buffed it quickly. Of course since I did it on 1 wheel I had to do it on all 4. It ended up being a touch darker but I can live with it. Lesson learned - I tested on the long grain but didn't think to test on the end grain.

Thanks for your insight. I like the way you tested and laid out all the different shades of stain in your Pegasus build. In hindsight, I think varnish might have been the way to go, but I will definitely test all sides from now on!

- mtaylor, GrandpaPhil, Keith Black and 3 others

-

6

6

-

6 hours ago, Joe100 said:

See, I’m not the only one who uses railroad rail to hold things when I’m glueing.

OMG Joe! I've got 4 pieces of rail of various sizes lying around (along with a few tie-plates) and it's unbelievable how many things I use them for. Next to duct tape, they are about the handiest thing in my garage!

2 hours ago, gjdale said:Still trying to catch up with other “priorities” before I start my own SIB.

Hey Grant, understood! As I mentioned in the first post, I was trying to avoid my own list of "other priorities" when I began this project! Still very much looking forward to when you are able to start your Amati Hannah.

1 hour ago, Landlubber Mike said:That wood you are using is beautiful. In earlier pictures it was like a golden brown, now it seems to have almost taken on a color like swiss pear. I bet when you get a finish on it it will really pop.

Thanks, Mike. I actually added a light coat of tung oil to the wood before this last set of pictures. It darkened it just a shade and gave it what I think is a richer tone. To my eye, the color is a bit darker than the picture so I'm not sure I'm not sure if I want to do anything more that would change it too much.

How do you finish wood with this type of natural color? I've got minimal experience with wood-working like this so any advice is much appreciated. I actually looked for some Kunos oil that @gjdale mentions in his Capstan project but could not find any around here.

-

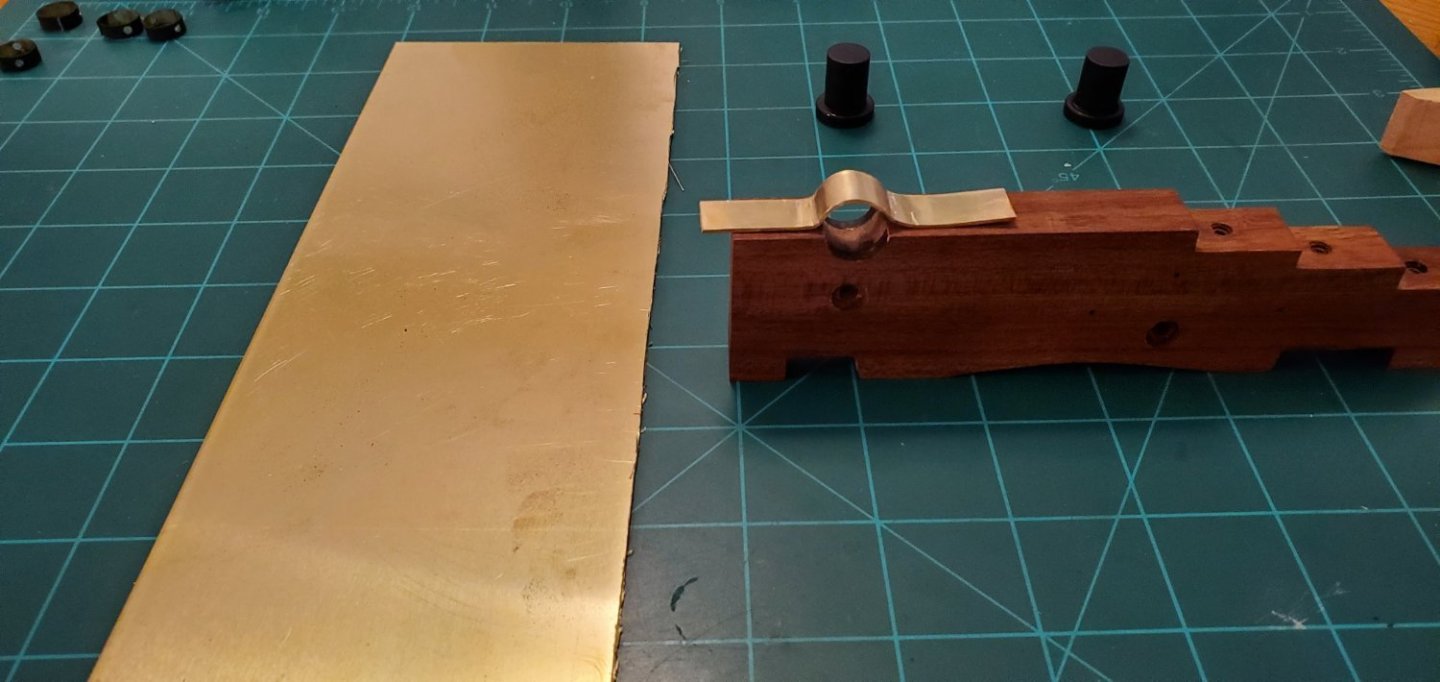

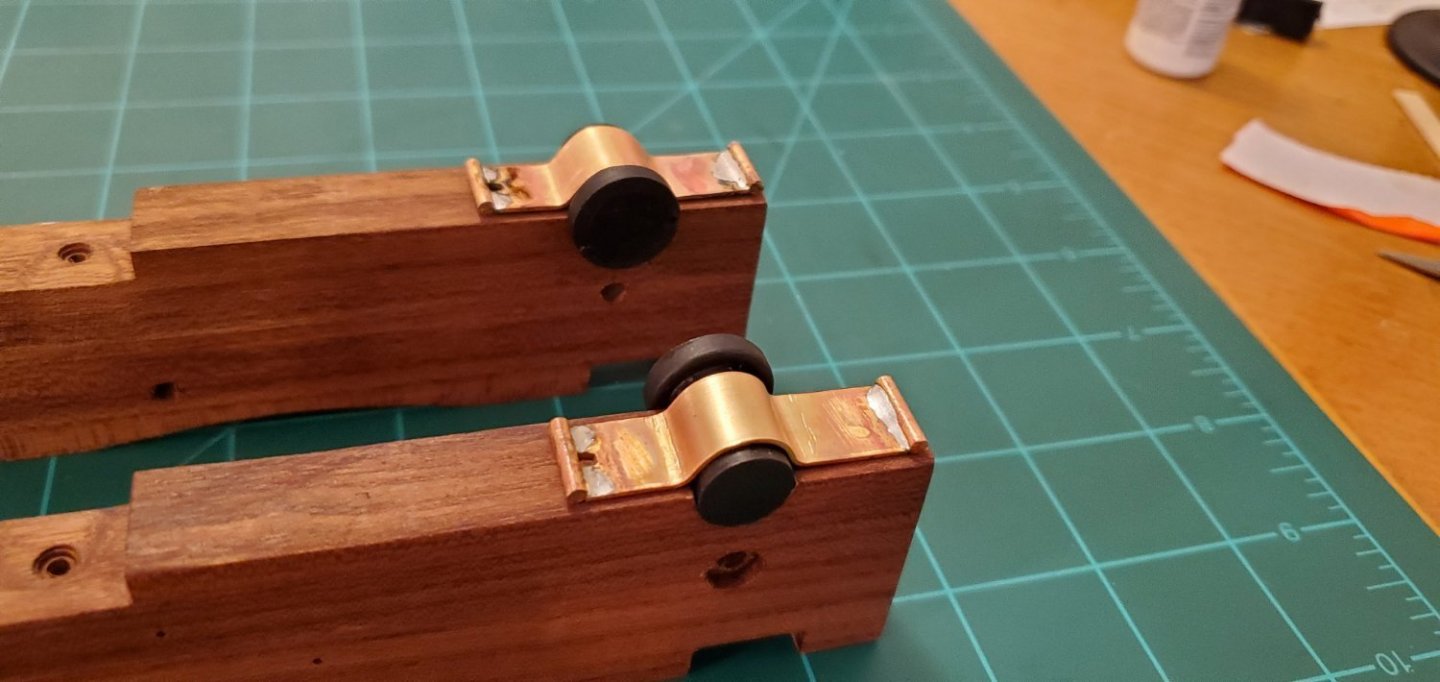

After that minor detour, it’s now time for the capsquares. After playing around with several different materials I finally decided brass was the easiest to work with. I bought a 1mm thick brass sheet from Hobby Lobby, cut 8cm x 1mm strips, and bent them into shape (1st pic). Piece of cake!

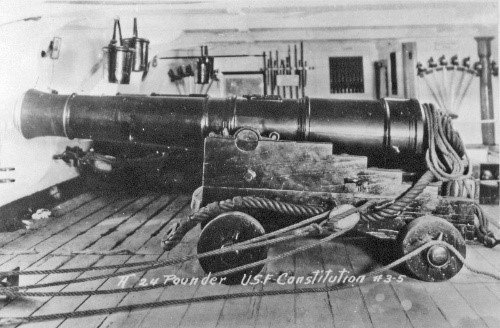

Uh, not so fast. I looked at the carriage picture again and once again spotted something I’d overlooked. The ends of the capsquares are rolled up (2nd pic). Ugh! The only thing I could figure out to do was solder a brass rod to each end. So that’s what I ended up doing. The last pic shows how they look before cleanup. I think they’ll be ok after some filing and painting.

- AJohnson, Keith Black, BANYAN and 7 others

-

10

10

-

Every time I look at pictures of the real carriage it seems like I see something new. This time I noticed that it looks like there’s a thin sleeve bearing in the trunion groove on the top edge of the brackets. So I took some copper tape left over from the Alabama and used it for the bearing. It will be painted black later.

- gjdale, Keith Black, mtaylor and 2 others

-

5

5

-

It's making my neck sore turning my head to study those pictures, but it's well worth it!

Really beautiful work on that whole bowsprit assembly, Rob.

Really beautiful work on that whole bowsprit assembly, Rob.

-

-

Welcome aboard! Your username reminds me of a really poor joke I heard the other day: Two robbers were robbing a liquor store when one robber grabs a bottle and asks the other robber "is this whiskey?" The other says "yeah but not as whiskey as wobbing a bank". Sorry! 😁

- Dave_E, ccoyle, Keith Black and 1 other

-

4

4

-

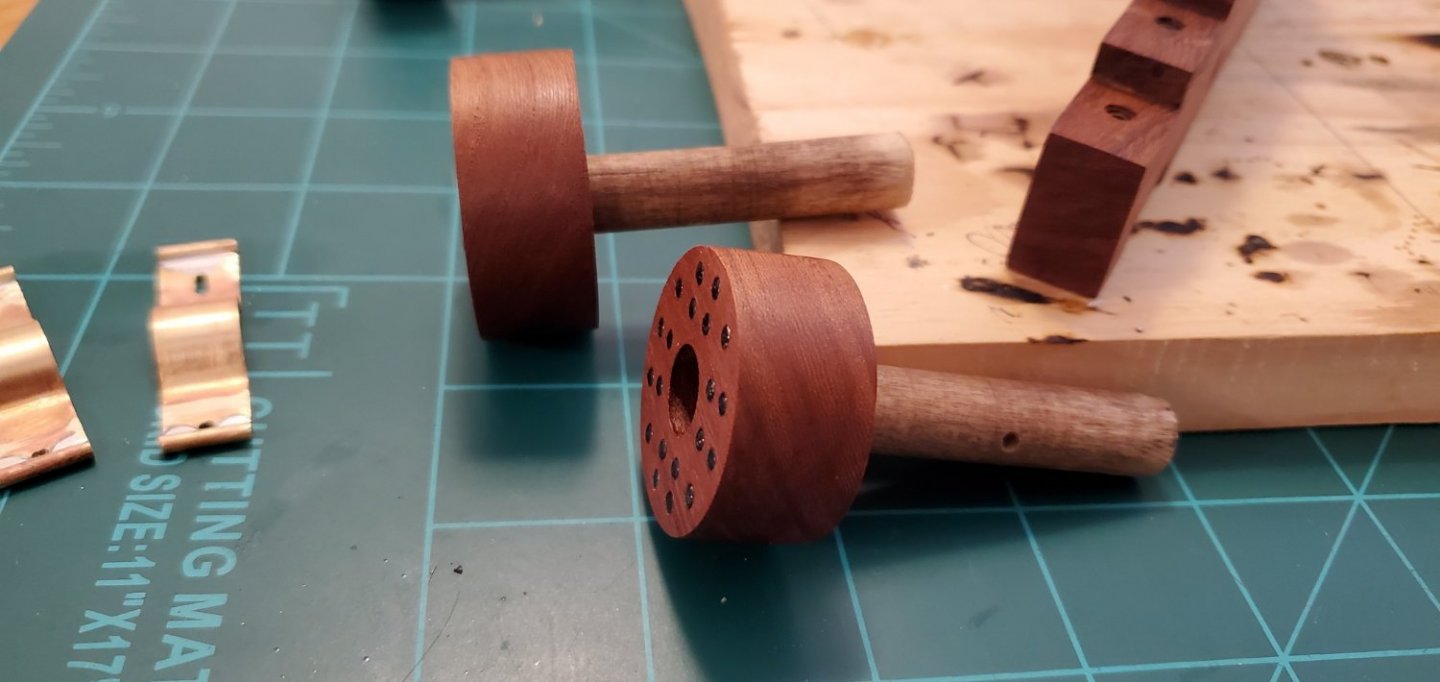

The axles have a collar and linch pin on each side that keeps the wheels (trucks) in place. For the collars, I took some brass brads, folded them around the axle, then drilled holes for the linch pins. For the linch pins, I’m using finishing nails since their head is similar in shape to what I see in the real pictures.

For the trunions, my toolbox sacrificed a 6” long 3/8” socket extension. Unfortunately for it, it was the perfect diameter that I needed. The grommets on the end (which will rest against the bottle) are hard rubber dampeners from my dirt bike handlebars. Nothing is off limits when you’re scrounging pieces and parts!

Next up, figuring out how to make the capsquares.

- mtaylor, Ian_Grant, Keith Black and 3 others

-

6

6

-

I am making slow progress on the carriage hardware – slow because it takes me forever to figure out what to use and what to do. I spend a ridiculous amount of time fiddling around with a whole bunch of different things trying to find something that works.

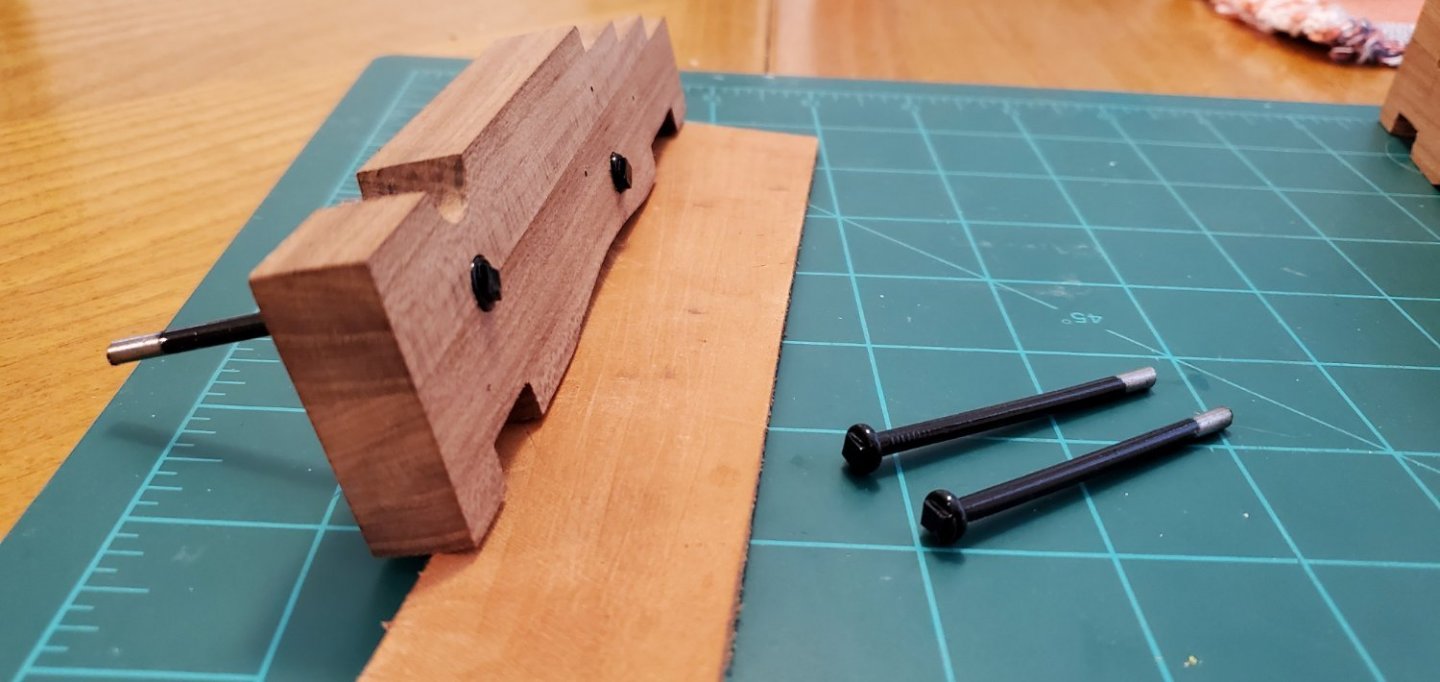

The carriage has 2 tie-bolts with square heads that run the width of the carriage and protrude through countersunk holes in the side brackets. The front tie-bolt goes thru the transom and the rear supports the stool bed. To make the tie-bolts, I took a 1mm thick metal strip, cut it into 4mm x 4mm squares and soldered them onto the head of a common nail.

There are 6 joint bolts that go thru the steps on top of the side brackets and 2 joint bolts that go thru the front bumper. I’m using some small nails with rounded heads for those. Mine are just for appearance as I am not pushing them all the way through.

-

Thank you, Pat! They help distract from all the flaws in my ship build! 😃

- mtaylor and Keith Black

-

2

2

-

21 minutes ago, Landlubber Mike said:

Hey Glen, I'm in for another great ride if you'll have me.

Hey Mike, I'm thankful to have you checking in on me. You always offer great ideas and insight which help make my builds better. For instance, I remember in your Charles Morgan log that you were using different woods for their natural color rather than staining or painting. I really liked that idea and it's one reason I wanted to go natural with the wood for this carriage.

8 minutes ago, Keith Black said:Glen, super carriage, it looks really nice.

Thank you, Keith!

-

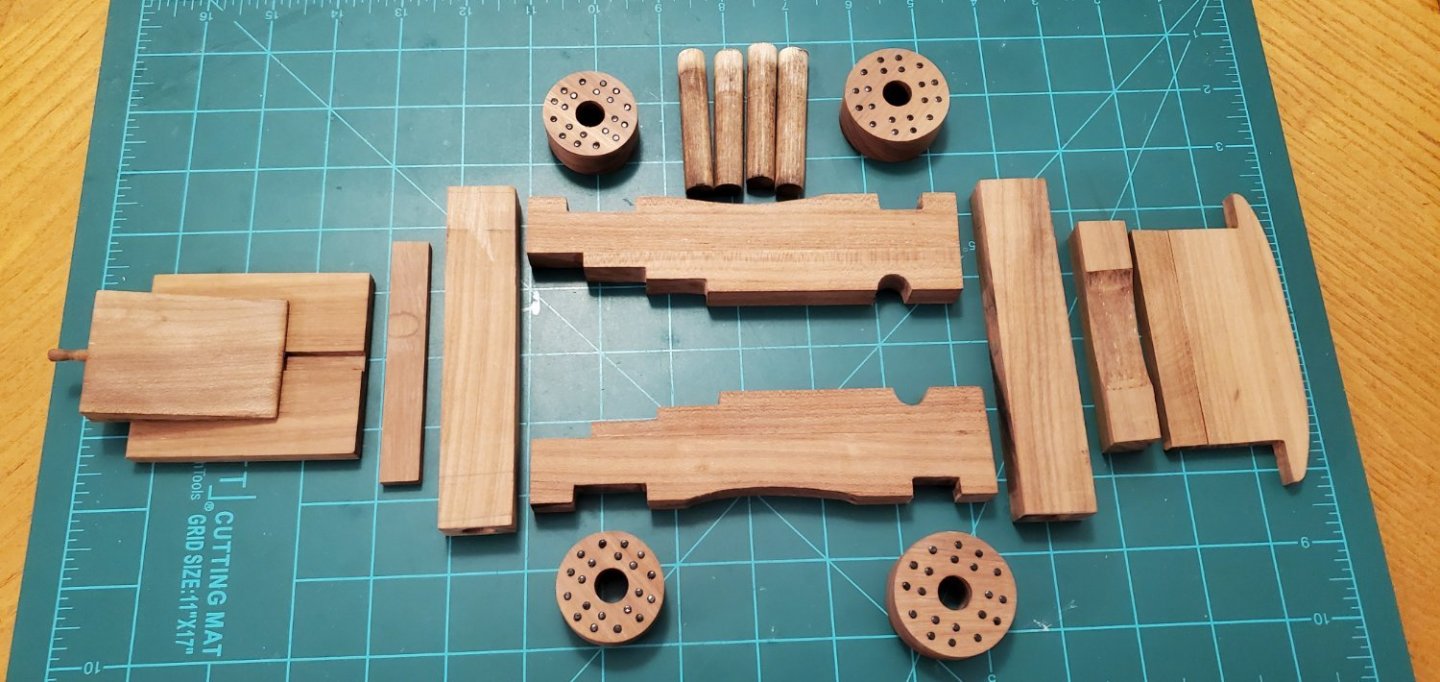

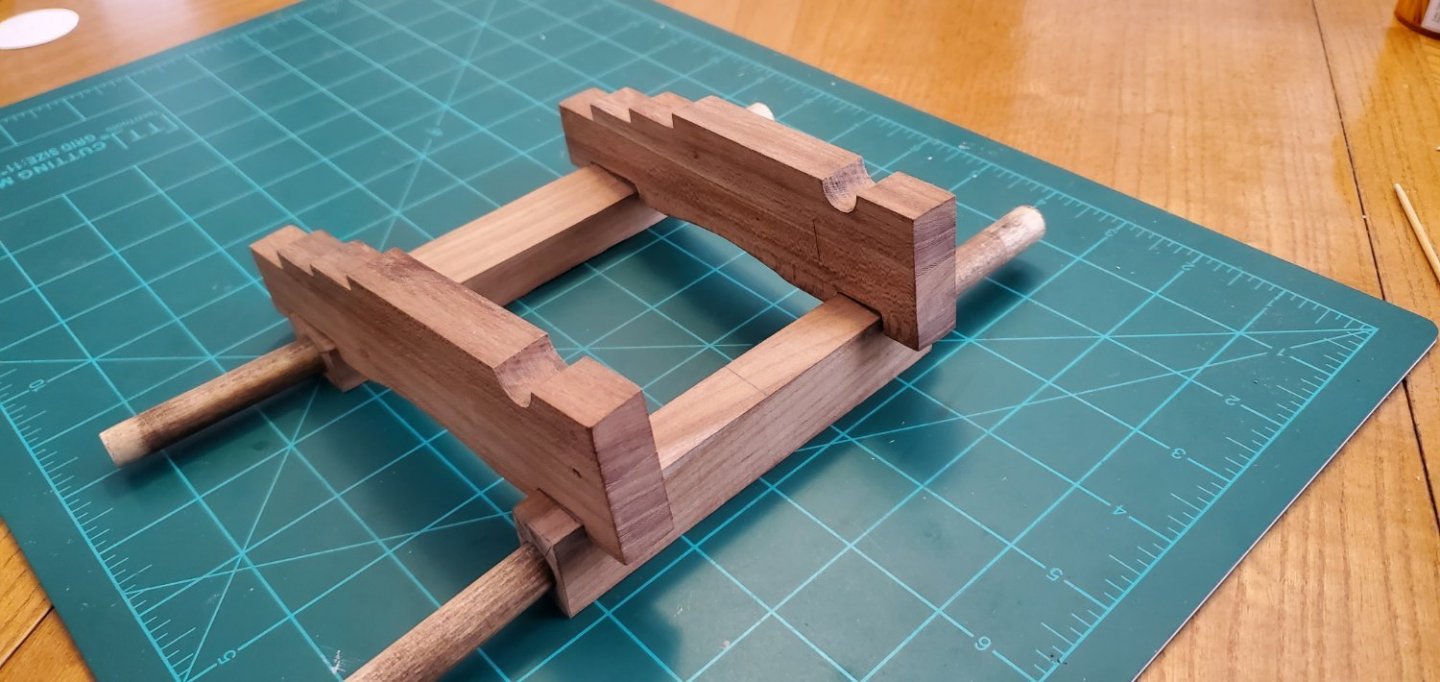

I finished all the woodworking for the carriage. This was definitely harder than I originally thought it would be! Just looking at carriage pictures, it seemed like a simple build. But when I got into the details, there was quite a bit more to it. I could probably say the same thing about my ship modeling in general!

One thing I learned for sure is that if I’m going to do much more of this type of wood work, I’ve got to invest in some better tools. It took a looooong time to file, sand, file, sand, file, sand all these pieces to size. Regardless, this was fun!

The last couple of pics are a dry fit just to get an idea if this thing is going to have a good look or not. There’s still some hardware to build/add (trunions, linch pins, cap squares, breach rings, etc), which is my next step. I’ll wait till the very end to add the rigging.

-

22 hours ago, Joe100 said:

Glen is back at it again!

It was either house chores or another ship project. No brainer!!

-

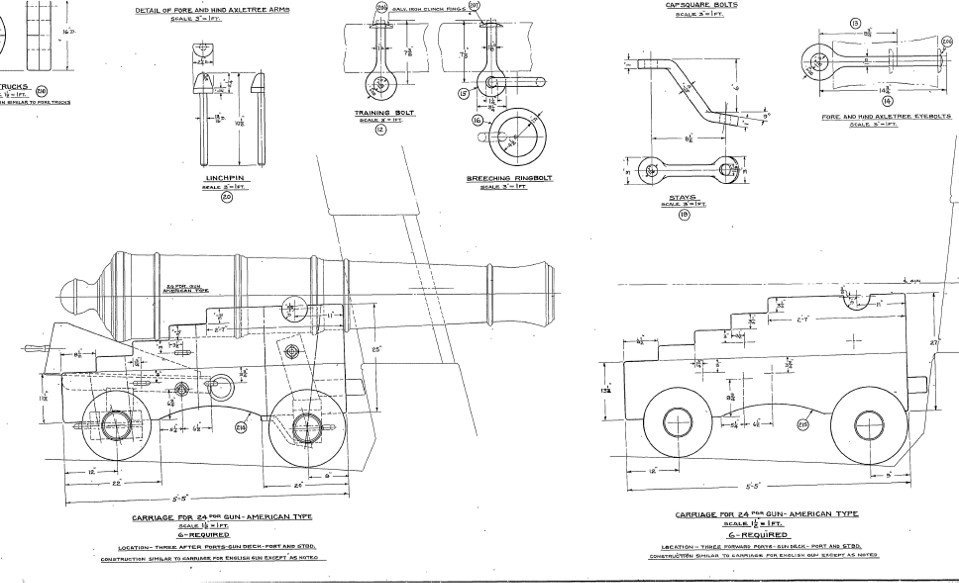

Below are the side brackets, the fore and hind axletrees, and axles. The axles will be cut to their final length later. For the side brackets, I made them with 4 “steps” instead of 5 like the plans show (and pretty much every other carriage I’ve seen). I need a lower profile for the brackets. The normal profile would hide too much of the bottle and potentially obscure the front half of the ship. The fore axletree will sit vertically in the final assembly and the hind will lay flat.

-

Rum buttered popcorn??? Dang you, Keith. Now I've got to go shopping tonight.

- Keith Black and mtaylor

-

2

2

-

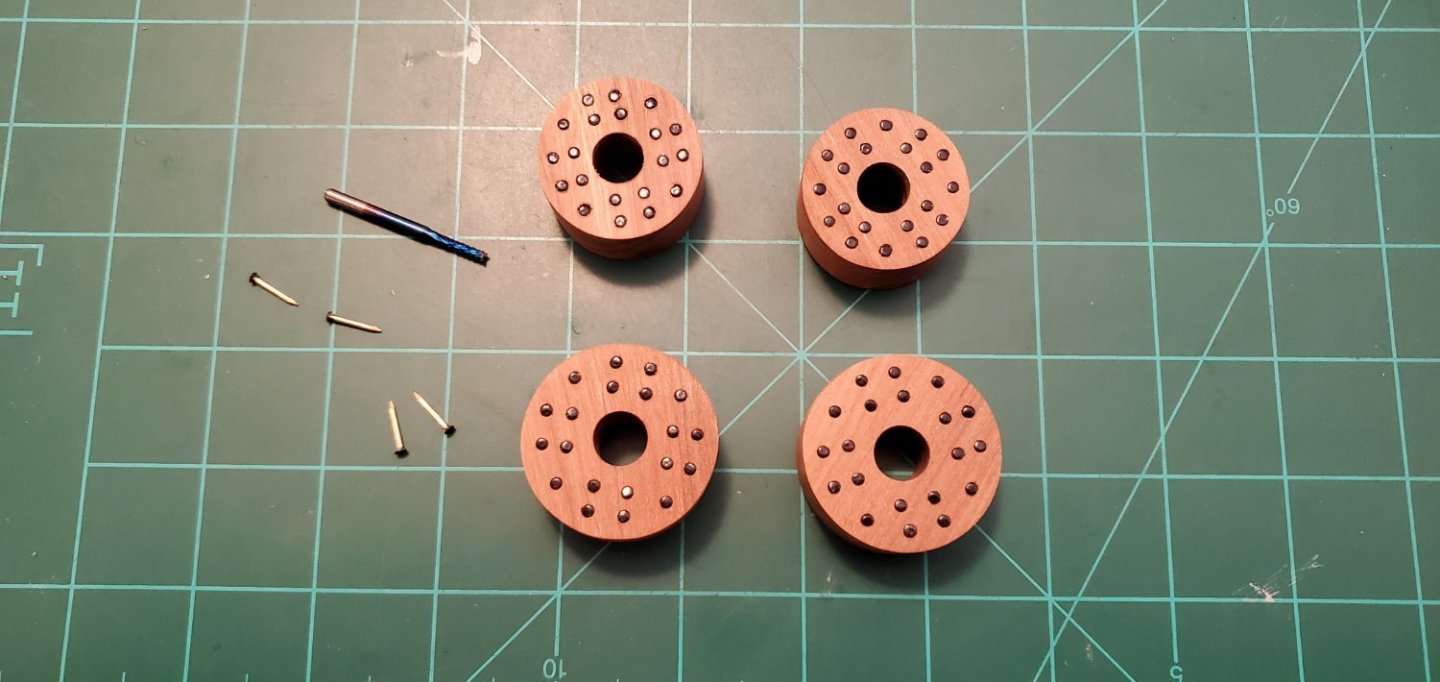

For the “lug nuts” on the wheels, I used brass nails that are 3/8” long with a 3/32” diameter head, which I ground down to a flatter surface. They are supposed to sit flush in the wheel, but I do not have a flat base counter-sinker. So I used an end mill router bit to countersink each of the 80 holes.

- GrandpaPhil, mtaylor, Keith Black and 5 others

-

8

8

-

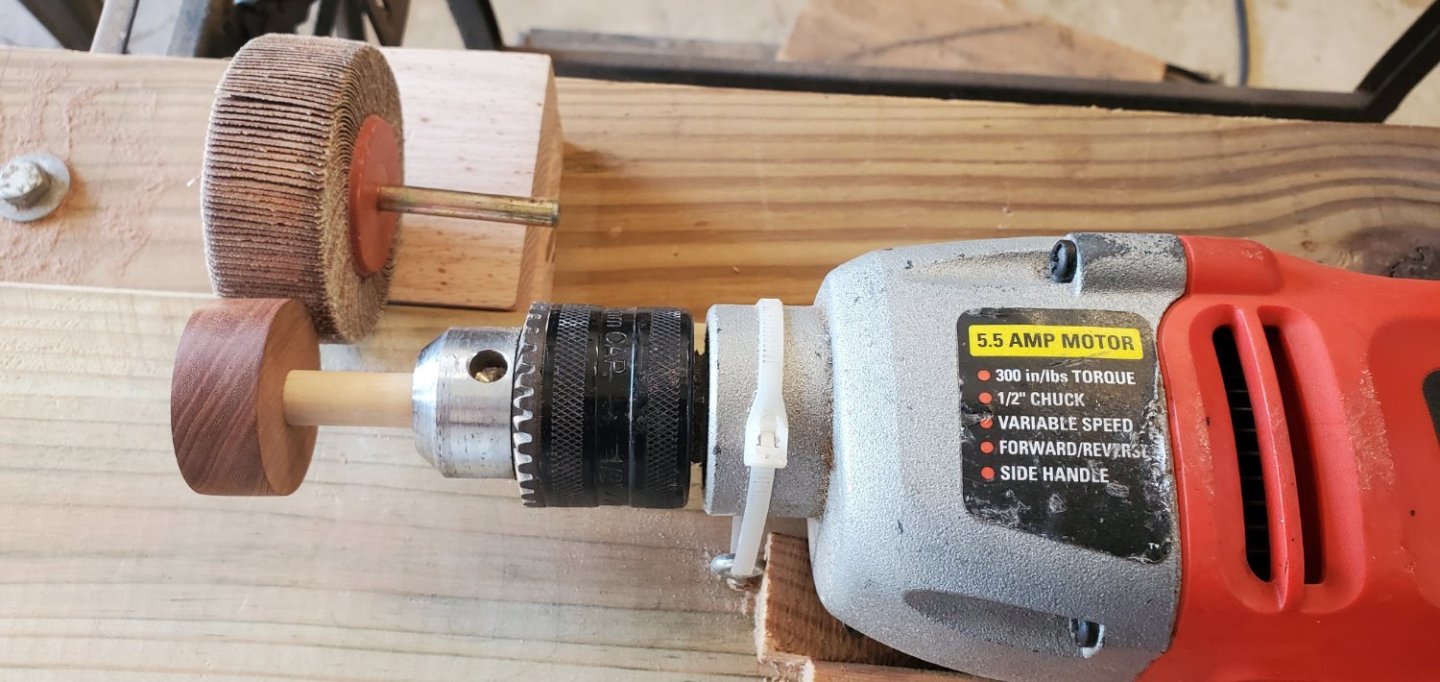

The wheels were a particular challenge for me. I do not have any hole saws that were the sizes I needed, so I cut the wood into rough circles and hand sanded them into a final rounded shape. Then I used a flap sanding bit with my drill lathe to give them their final finish. I just love the end grain of the wood, which shows really well when looking up close at the wheels.

- Keith Black, Ian_Grant, GrandpaPhil and 5 others

-

8

8

-

The only thing more meager than my woodworking skills is my array of woodworking tools which consist of a 10” table saw, a bench sander, and a band saw. When I was following @gjdale's capstan project, I almost quit looking at his posts because I was so jealous of all the tools in his workshop (as well as his high level of skill). But I’ll do the best I can here with this carriage.

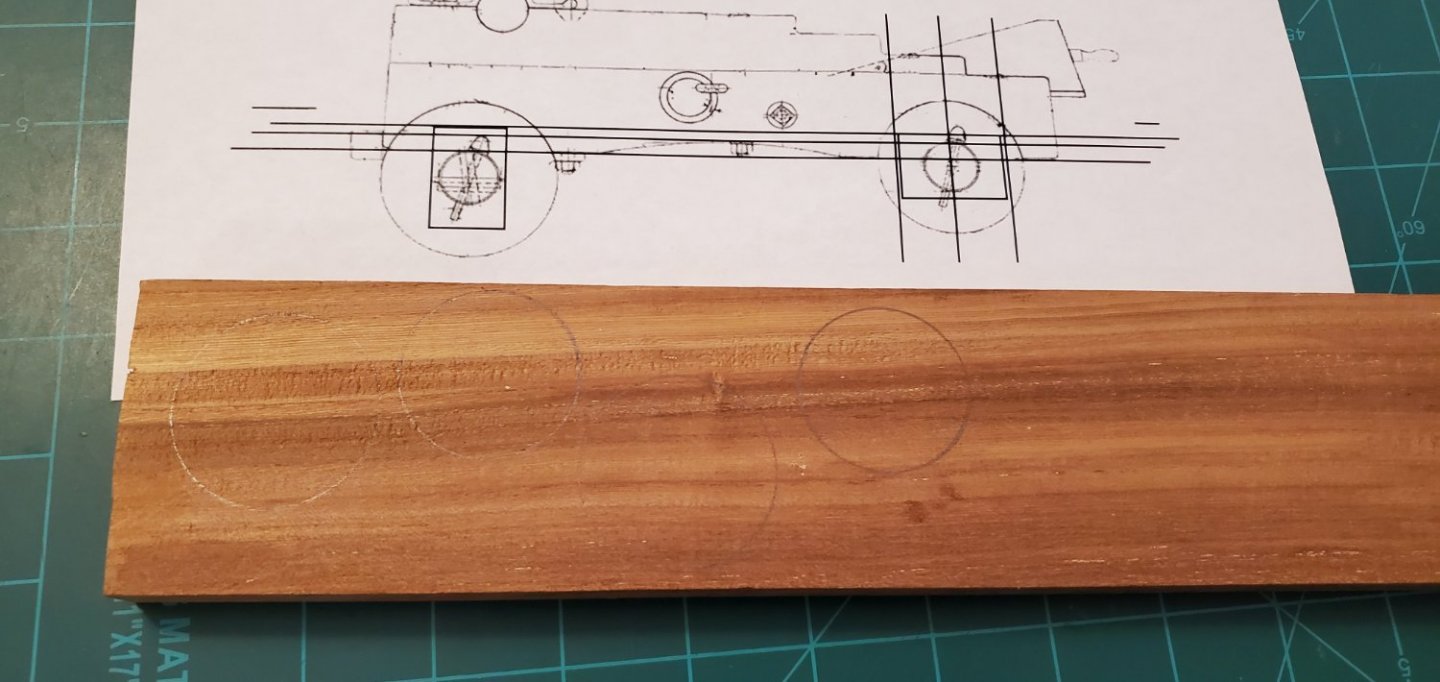

The wood I’m using is the heartwood from a large english elm tree that came from the south lawn of the Texas capital. It is really hard, dense wood and has a beautiful natural color and grain. Unfortunately, it tends to scorch if the cutting or sanding is not done carefully.

I started with a couple of slats that are about 14” long, 2 ½” wide, and 5/8” deep and cut them into the basic shapes for the sides and axletrees.

- Keith Black, CiscoH, gjdale and 2 others

-

5

5

-

-

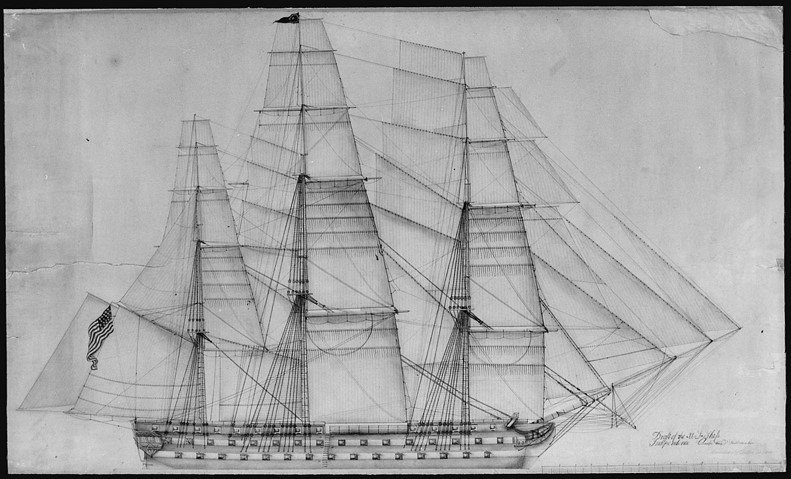

In the meantime, I’m going to start by trying to build the cannon carriage for the display first. With so little info available on the 1814 Independence, I’m going to assume that it had cannons and carriages similar to the USS Constitution since both were launched in sort of the same time period. I found carriage plans on the USS Constitution Museum website for a 24 lb “American-Type” cannon so I’ll try to make my display carriage similar to it.

There will certainly be some deviations required to accommodate the rum bottle vs a cannon barrel. Plus, one thing I know I’ll change for sure is the color. Pictures from the website show the restored Constitution carriages painted a reddish color. However, old black and white pictures make the carriage appear unpainted. I like the look of natural wood much better than painted wood so I’m going au naturale. Here we go!

-

According to Chapelle, no plans exist for the original Independence. I could not find any model kits nor could I find any builds on MSW. And the only picture of the 1814 version I could find was a sketch of the sail plan (see below). I’ll continue to research the ship and if anyone out there knows where I can find more info please comment.

- GrandpaPhil, Keith Black, mtaylor and 1 other

-

4

4

.thumb.jpg.79528104ecb6e4a19c849ff689fce75e.jpg)

USF Independence 1814 by Glen McGuire – FINISHED - 1/500 - 1/500

in - Build logs for subjects built 1801 - 1850

Posted

The carriage is now complete with the exception of the rigging. I’ll “tackle” that after finishing the ship. 🙄

The first pic shows all the pieces and parts of the carriage before assembly.