-

Posts

1,837 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Glen McGuire

-

-

28 minutes ago, Knocklouder said:

Is it in yet!!! Frist Mate wants to know lol

Yes! I just finished posting the video that your First Mate requested.

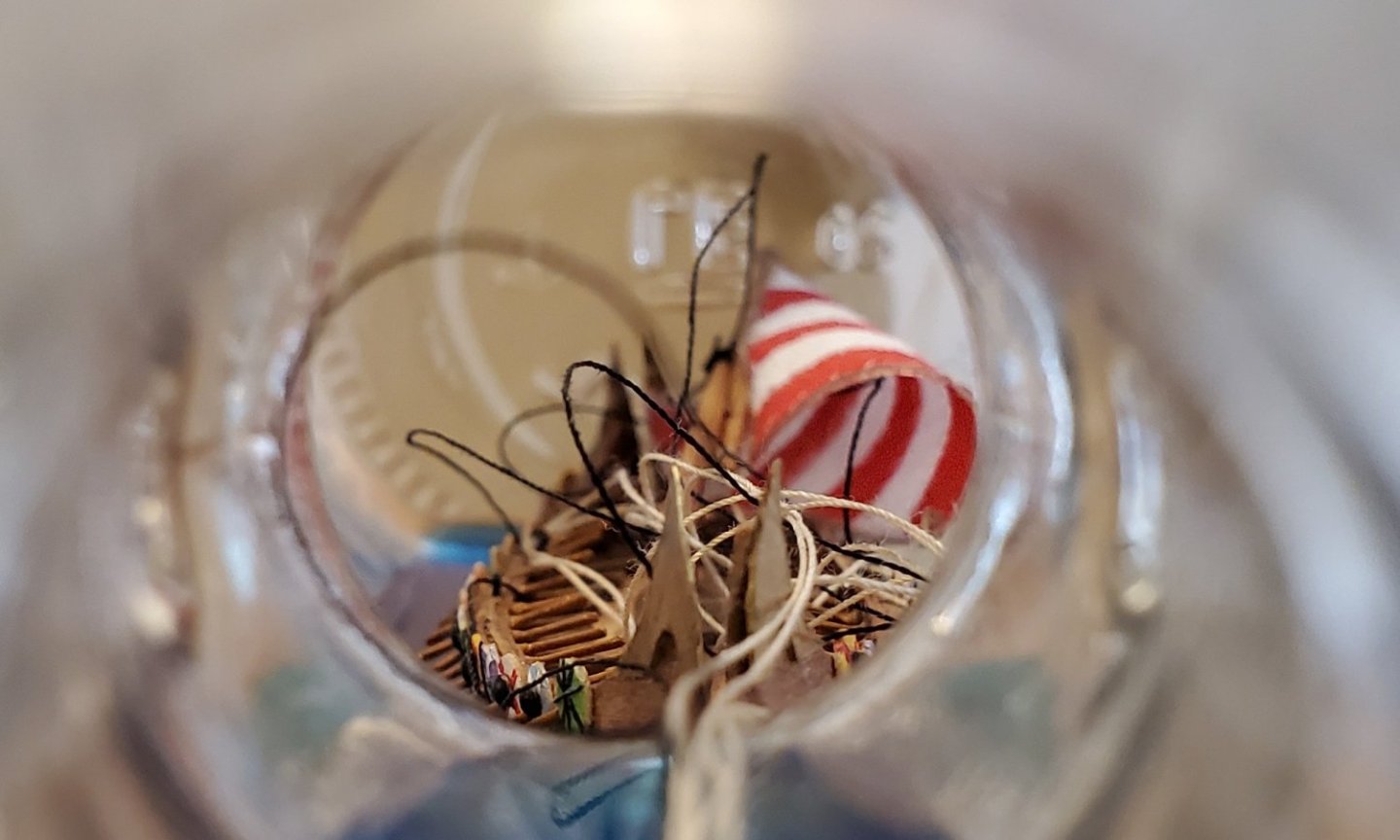

Apparently I am unable to build anything with greater than a zero margin for error. The insertion process went pretty well, but it took a while. The oars and tips of the stem post were scraping along the neck of the bottle as I pushed each half of the hull inside. I ended up bending a few of the oars but they can be straightened without too much difficulty.

I got the hull pieces in pretty quickly. The time consuming part was getting the rigging threads out of the way (while making sure they did not slip into any of the small epoxy blobs) and then lining the hull pieces up and pressing them together. The whole process took about 10 minutes but felt like an hour! Long video link below.

https://www.youtube.com/watch?v=mqDFXTSlX2s&t=116s- Knocklouder, O.B.one, DonBMichigan and 13 others

-

8

8

-

8

8

-

14 hours ago, BANYAN said:

Sorry, couldn't help myself.

Y'all are way beyond hope! 🤣🤣🤣

- Keith Black, mtaylor, Knocklouder and 1 other

-

4

4

-

-

-

-

1 hour ago, Javelin said:

but do you recall any heating of the epoxy inside the bottle? Did it turn the bottle (at least at the bottom) warm?

Hey Javelin, unfortunately I don't know if it heats the bottle up or not. After I pour the resin in, I do not touch anything for fear that I'll slosh resin up the sides of the bottle where I don't want it.

I like your idea of doing a test run on the process. Let me know what your results are.

- mtaylor and Keith Black

-

2

2

-

1 hour ago, gjdale said:

After your last couple though, this one should be a walk in the park!

Don't jinx me like that, Grant!! You know I have a knack for making simple things unusually difficult!

- FriedClams, mtaylor, Keith Black and 1 other

-

1

1

-

3

3

-

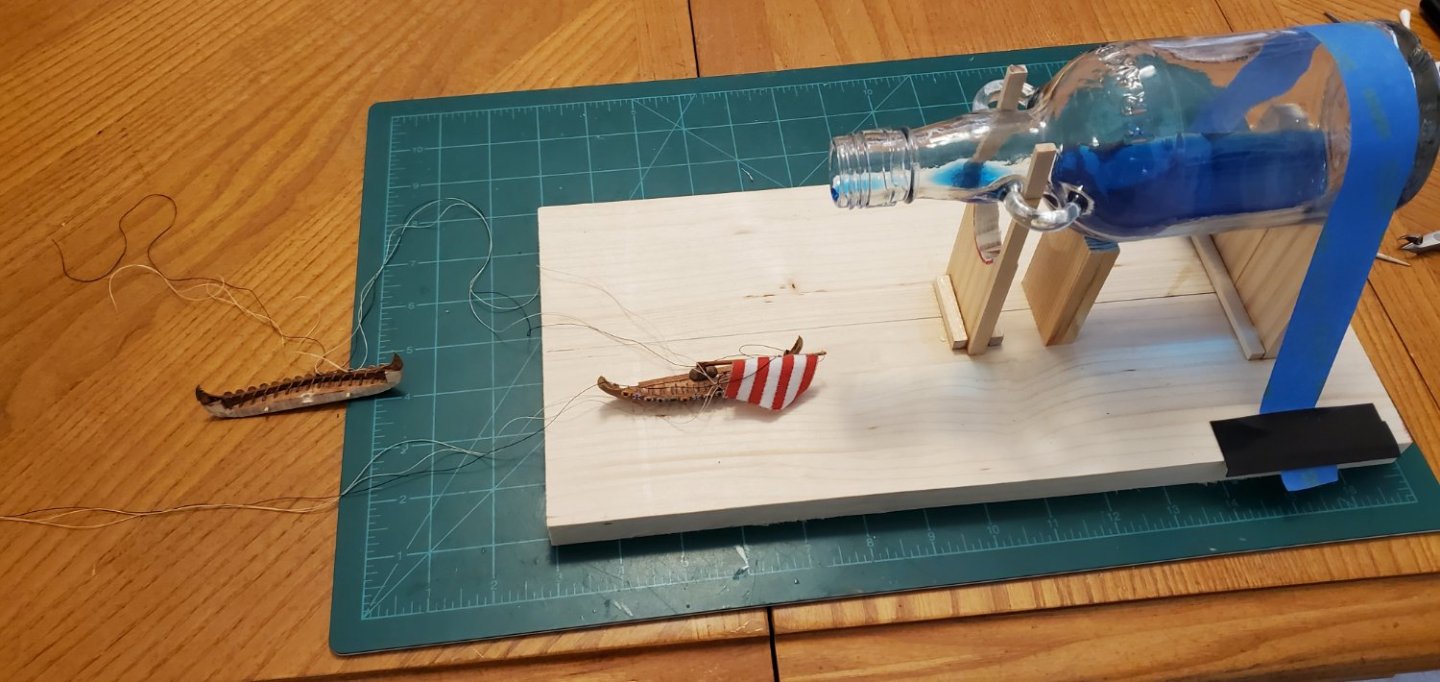

The rigging is complete. With only 1 sail, there are not too many lines. However, the split hull and separate insertion will make things quite interesting.

I’m using black thread for the stays and shrouds. The Oseberg has a fore stay and back stay. The back stay is tied at the top of the mast and to an eye pin at the base of the stern post. The fore stay is also knotted at the top of the mast but runs thru an eye pin up front and will act as the pull thread to raise the mast.

There’s 1 shroud on each side. The port side shroud is tied to the top of the mast and to an eye pin on the bulwark. For the starboard side, the shroud is tied at the top of the mast but runs thru the eye pin and all the way out of the bottle.

I’m using tan thread for the braces and clew lines. They are affixed similar to the shrouds with the port side tied securely to the mast and eye pin on both ends, while the starboard side is tied off at the mast but the other end runs thru the bulwark eye pin and out the bottle.

All of the starboard side rigging runs thru the eye pins and out the bottle because the starboard half of the hull will be inserted after the port half is already in the bottle. Rather than trying to thread those lines thru the eye pins inside the bottle, they are threaded outside. As I push the starboard side of the hull into the bottle, the lines will run thru the eye pins. Once both halves are inside and joined together, I will pull the lines tight, glue them to the eye pins, and cut off the excess.

That is the plan, anyway. Next post will either be the thrill of victory or the agony of defeat!

- Louie da fly, FriedClams, Ian_Grant and 9 others

-

8

8

-

4

4

-

On 2/1/2023 at 4:51 PM, Ian_Grant said:

Phenomenal work at that tiny scale, Glen! That shot of the whole ship is amazing!

Thanks, Ian. Just getting back and catching up on all the action I missed on MSW the past week. We lost power on Tuesday during the great Austin ice storm and just got it restored yesterday. Never seen this much tree damage my entire life. We have mostly live oaks around here which still have all their leaves. So they accumulate a lot of ice (and weight).

- Keith Black, mtaylor, FriedClams and 1 other

-

4

4

-

On 2/4/2023 at 1:19 AM, gjdale said:

I dropped it on the carpet twice and was lucky to find it again both times!

LOL! Welcome to my world, Grant!!

Great update and superb work (again).

- Egilman, Keith Black, Canute and 5 others

-

8

8

-

29 minutes ago, FriedClams said:

What a fun and creative project this is. Looking forward to future updates.

Hey Gary! I am honored to have you checking in on my work. I have been thru your shadowbox logs multiple times and am in awe of your miniaturization work. Absolutely phenomenal.

-

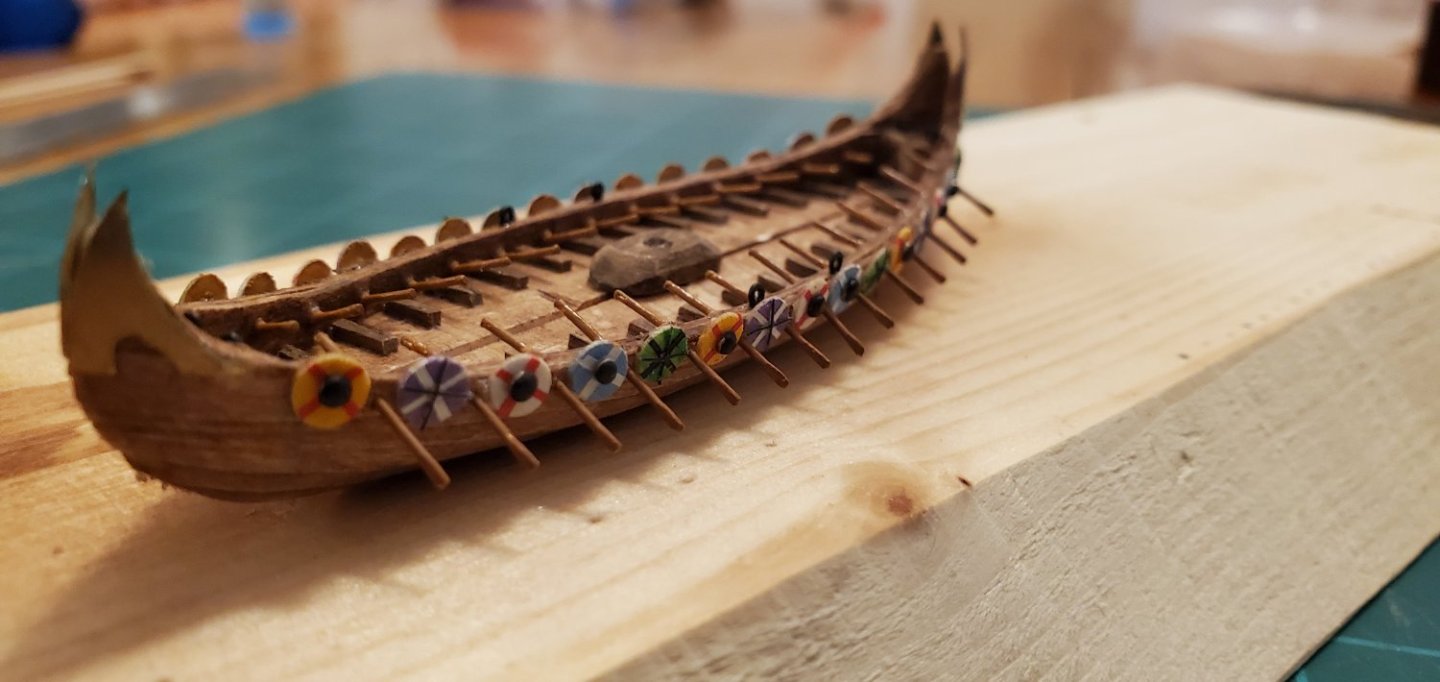

The resin finished curing, so I was able to figure out how much the oars could extend from the hull and still fit inside the bottle. I got all 30 oars installed and gave it a test. The tips of the widest oars just slightly scrape the inside neck of the bottle. Perfect!!

While working on the mast, I realized that my original plan of stepping it into the hull while inside the bottle would be extremely difficult if I wanted to rig shrouds, stays, and braces. So I went back to a hinged mast which I will affix to one half of the hull before insertion. I've still got some thinkin' and figurin' to do on the rigging plan because of the split hull. Not exactly sure how I'll pull that off yet.

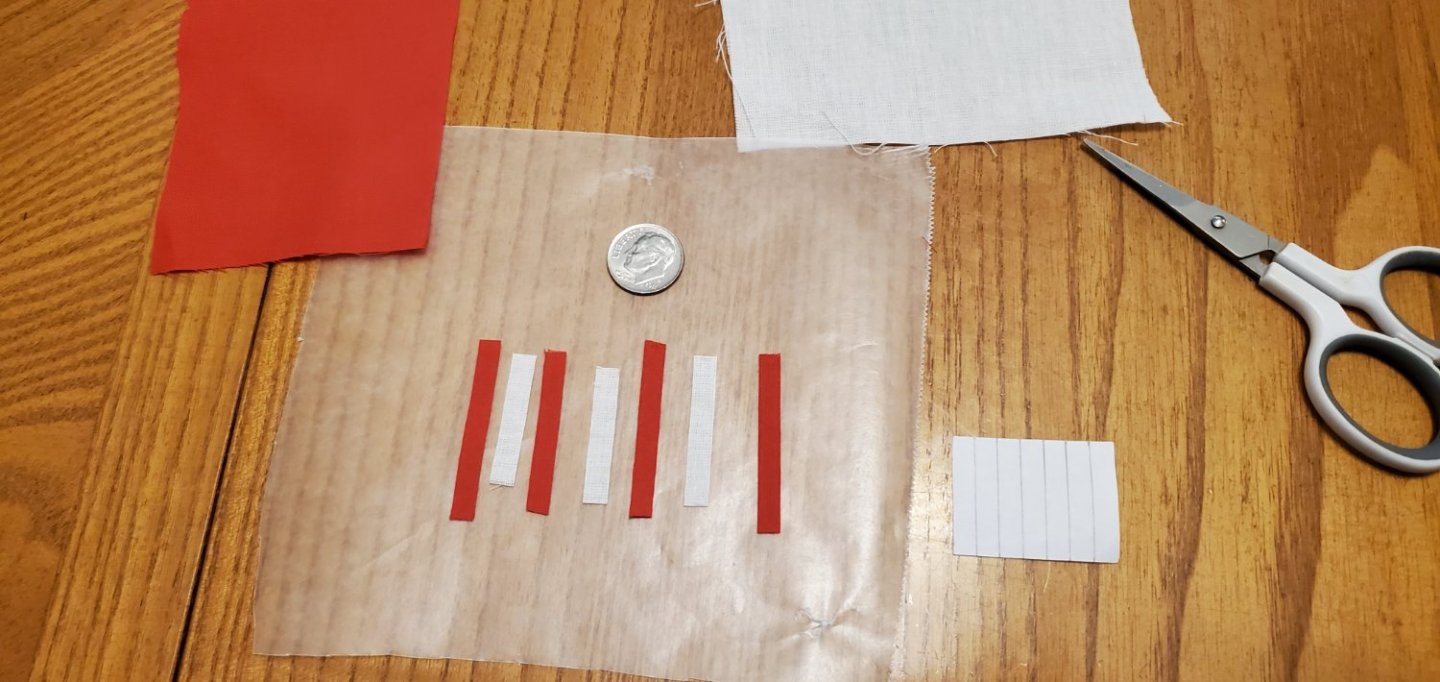

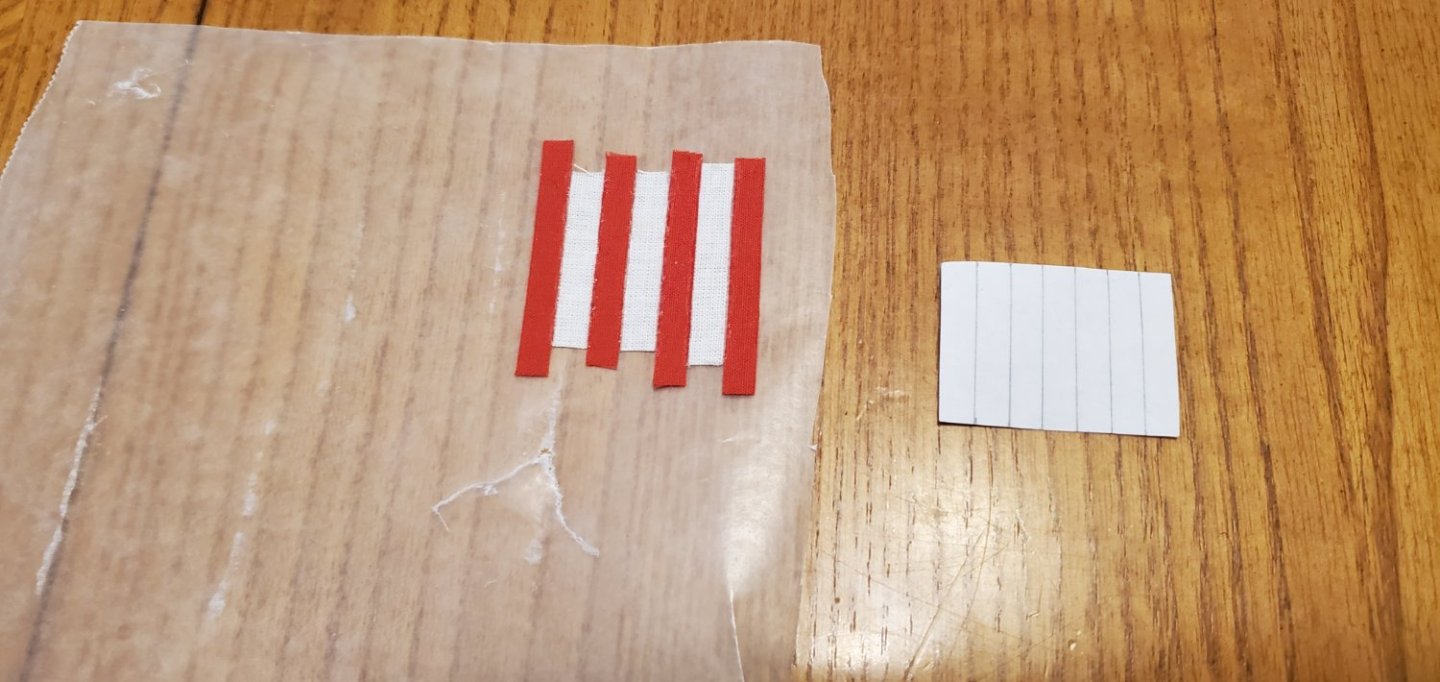

For the sail, I wanted to display another iconic look of many Viking ships - the Mr. Peppermint jacket sail with red and white stripes. I cut strips from red shirt fabric and slightly off-white muslin and glued them edge to edge with fabric glue. I was not sure how sturdy the edge to edge connection would be so I decided to add a hand sewn, modified zig-zag stitch to make them a bit more secure. I glued a bolt rope around the edges and also added a stitch to help secure it as well.

-

55 minutes ago, Knocklouder said:

Sorry Robert did not mean to Hijack your thread.

I'm glad you posted on Robert's thread. I would have never seen his work if you had not.

Robert - really cool project you've got going here. I had no idea that there were metal model kits like this (and only $25 - wow!). Very nice work so far!

- Knocklouder, mtaylor, Canute and 1 other

-

4

4

-

-

-

I was quite ready to do some easy stuff after those dang shields, so I hit the oars and rowing benches. The oars are made from .5mm brass rods. I cut 30 of them into 5/8” lengths and smashed the ends down with some pliers for the paddles. Then I painted them a shade of brown. I drilled holes for the oars in the hull between each shield at a downward angle so the oars will point towards the water. I won’t install the oars into the hull until I get my water in the bottle and see how much room I have to work with (i.e. how far to let them stick out towards the water).

Next up were the rowing benches. I took a 1mm x 1mm walnut strip, cut it into 3/16” long pieces, beveled one edge to match the curving angle of the gunwale, and glued into place. I also added the mast step. It is glued to one half of the hull and overlaps the other.

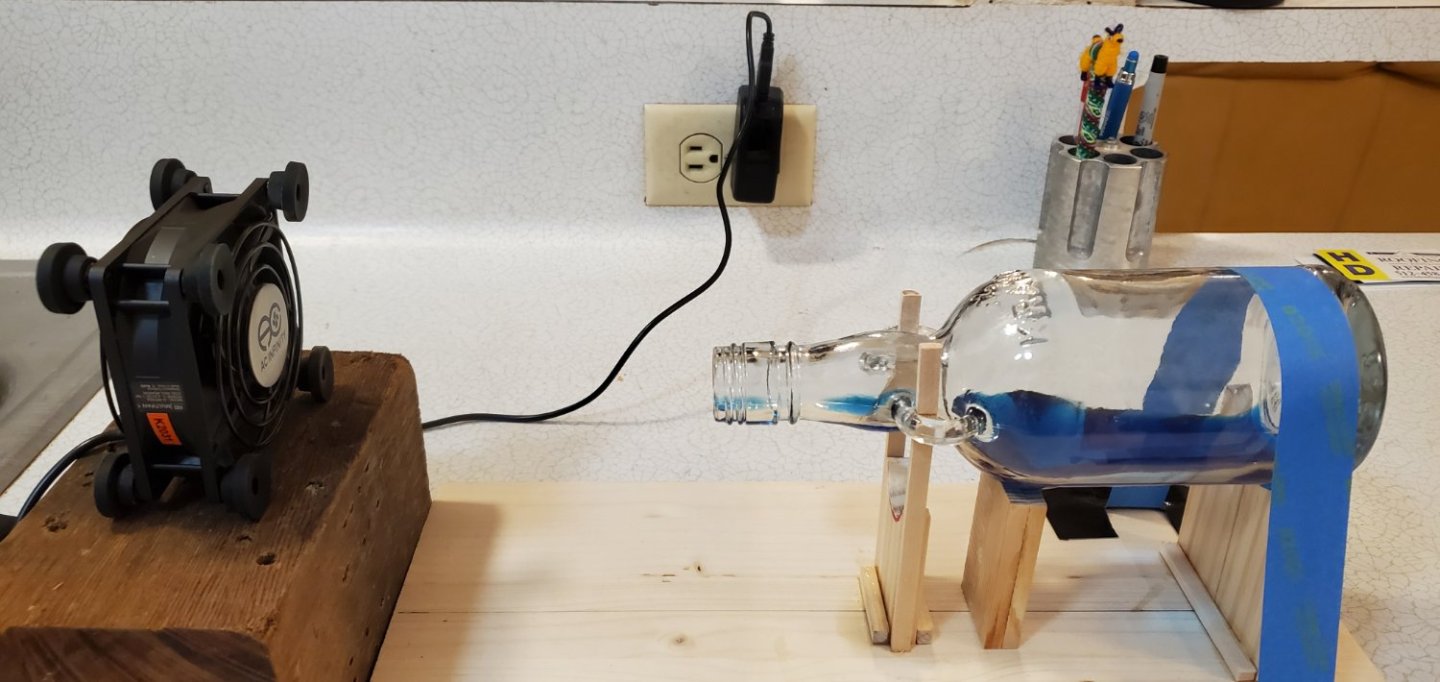

Finally, I added epoxy resin water to the bottle. It looks like I got sloppy and drizzled resin in the neck of the bottle. For once, however, that was on purpose. Since the bottle will be tilted a bit towards the Kraken’s mouth (as if he’s trying to drink the ship out of the bottle) I thought it would look better to have a little water in the neck.

It will take a couple of days for the resin to dry, so now I will begin work on the mast, yard, and sail.

-

Congratulations on a great project, Bob! And really nice work on making those repairs inside the bottle, which is not the easiest thing to do!

What a fantastic keepsake for your niece!

- Knocklouder, Ryland Craze and mtaylor

-

2

2

-

1

1

-

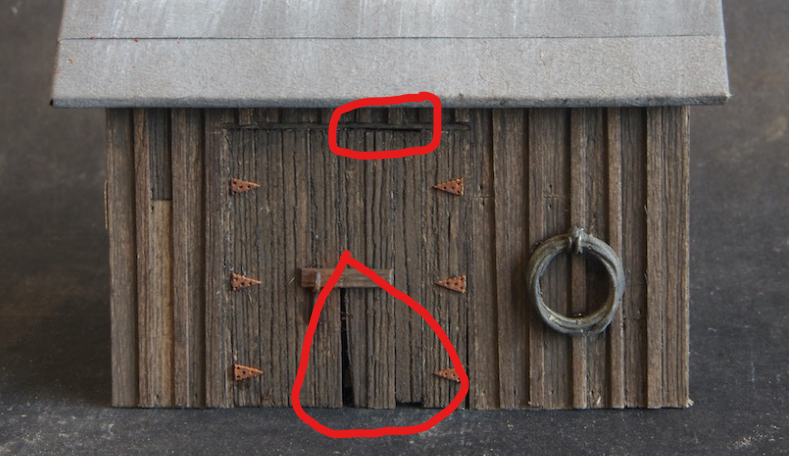

That small building looks fantastic, Grant. The split in the board and the uneven ends on the double doors are very nice touches. Were those spelled out in the instructions or did you do some artistic kit bashing?

- Old Collingwood, Jack12477, Papa and 10 others

-

13

13

-

-

Very nice work, @modeller_masa!! Looks like you figured out a rigging plan that will work. It also looks like you have 3 pull threads, which is interesting. I only had 2 when I did mine. Here's what my Hannah rigging looked like.

- Landlubber Mike, mtaylor, modeller_masa and 1 other

-

3

3

-

1

1

-

-

4 hours ago, Louie da fly said:

Amazingly, you seem to have positioned the punch exactly right to have the pattern centred properly - not an easy thing to do at all

You are right again, Steven. I quickly realized the difficulty you describe after doing a few practice punches. So I took a hi-tech approach and used a sharpie to mark to mark the tip of the punch at 0, 90, 180, and 270 degrees to line up with my crosses. Once I did that it was a breeze!

- Louie da fly, Keith Black, Ian_Grant and 1 other

-

3

3

-

1

1

-

34 minutes ago, Keith Black said:

Glen McGuire, Agent of Shield

Rapidly Ageing Agent of Shield is more like it after this ordeal!

- gjdale, Keith Black, mtaylor and 1 other

-

4

4

-

Looks great - especially the sewing job on the sails! Your first mate deserves a promotion!

Regarding the water, please avoid my Hannah build log for ideas. You do NOT want to try what I tried. Epic fail.

My preference now is epoxy resin for the water's base with a touch of acrylic paint dabbed on top (after the epoxy dries) for texture. If you look at page 5 of my build log for the Independence (link in my signature below) you can see some pictures of what I do with the resin and acrylic paint.

The resin also works well for just a thin layer of water. See my build log for Zheng He's Treasure Fleet for an example. My bottle for that build had 3 bulbs and the resin was a different thickness in each, and super thin between 2 of the bulbs.

- mtaylor, Knocklouder and Landlubber Mike

-

2

2

-

1

1

The Shipyard at Foss' Landing (Diorama) by gjdale (Grant) - FINISHED - SierraWest - Scale 1:87 (HO)

in Non-ship/categorised builds

Posted

Words to live by!