mark.bukovich

-

Posts

95 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by mark.bukovich

-

-

It has been a while since my last post. Progress has been slow with various other priorities in my life.

Since my last post, I have faired the mold, glued on the planks to the transom, and bent the garboard planks.

I do have a question for @*Hans*

Should the first planks be glued flush with the bottom of the keel? If not, is there a specific measurement on where the planks should be glued?

Hopefully these pictures will help explain my question:

This?

Or this?

-

Congratulations Melissa! It looks awesome! Definitely a model to be proud of

-

Thanks @*Hans*! Those are great images! This is a very cool little vessel.

I thought it would cool to build the model with an open door to the cabin where some things might be visible with the right lighting. I suppose the contents of the cabin could be different for each owner and each voyage. I wonder if passengers would sleep in hammocks or cots or maybe just rolls on the floor.

Considering the scale, it might be more trouble than it's worth.

- GrandpaPhil and Knocklouder

-

2

2

-

On 2/4/2023 at 2:35 PM, *Hans* said:

Oh sure! Thank you for this nice start. If you have any questions you can always contact me via this forum, pm, our website kolderstok.com or via email 🙂

Hans

Kolderstok

Thanks @*Hans*!

By the way, do you know of any images or resources that could help me understand how the forward cabin would have been fitted out?

I wonder if these Speel-Jaghts were more often used as daysailers or camp-cruisers (to use modern English terminology)

-

Speel-Jaght- Kolderstok

Welcome to my build log for the Speel-Jaght, a 1:50 kit by Kolderstok.

I am still working on my Melonseed project, but there are often waiting periods and breaks when it is nice to have another project to work on. I bought the Speel-Jaght kit from Kolderstok last year, and every time I see it on my shelf, I get excited. I finally caved-in to the excitement and started it!

Here is the box shipped all the way from the Netherlands to the US:

A little bit of damage to the box, but the internal contents were just fine. The contents include a manifest which confirms that all necessary components are in the box (in other words, someone actually audited the kit before shipping it. I think that says a lot about Kolderstok's quality control 👍

This kit uses an interesting construction method for the hull. In this kit, the false keel and bulkheads are not permanent like in many other kits. For the Speel-Jaght, the hull is built around the form created by the false keel and bulkheads and then removed completely. According to the instructions, this resembles a common construction method used during the historical period in which the Speel-Jaght was built and sailed. I can say confidently that this is a common method for building full-sized traditional wooden boats.

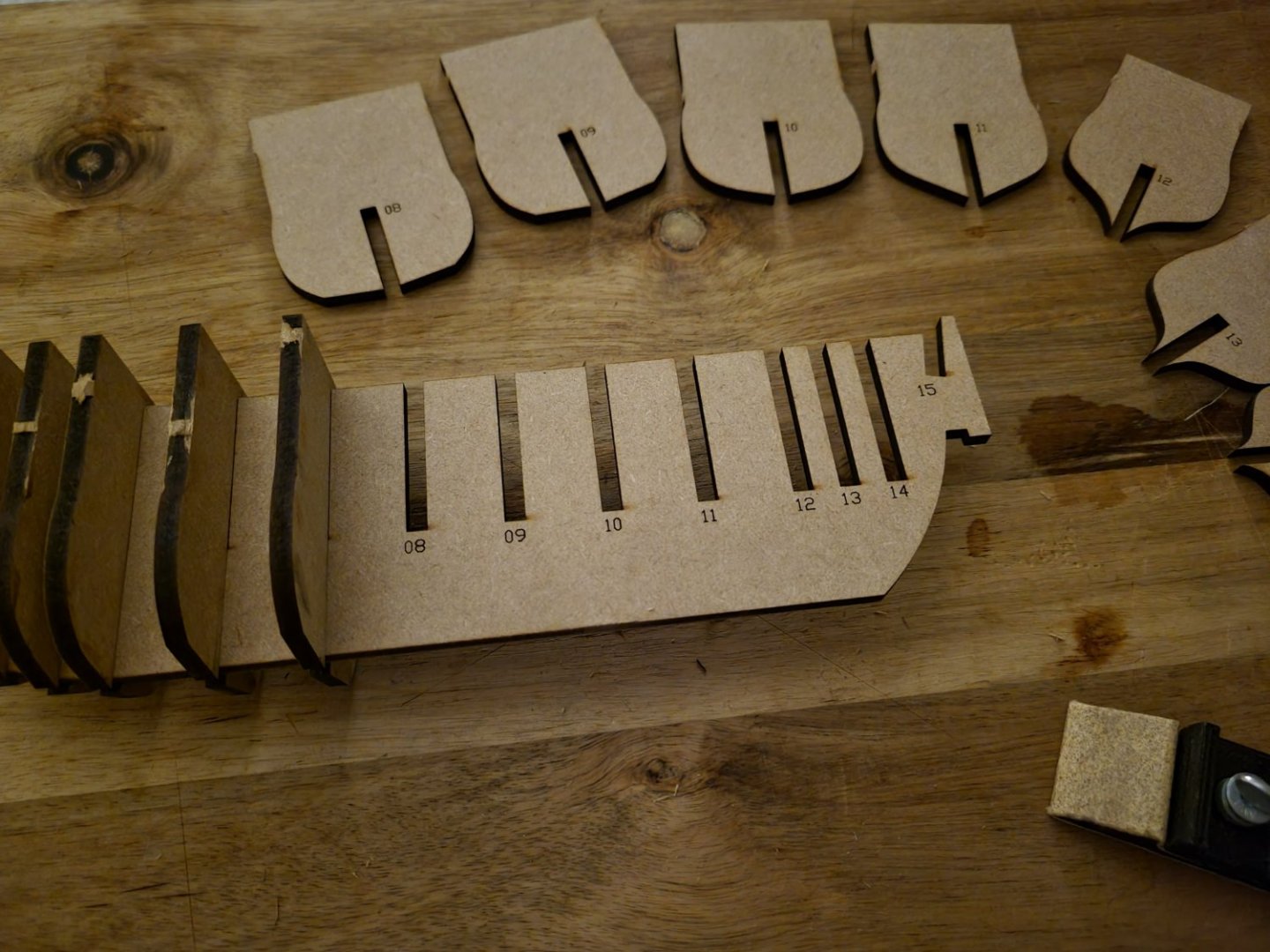

I cut the pieces out and assembled the form. I feel like Kolderstok did a very good job with tolerances and making it very easy to know how to assemble (notice the numbers on both the frame and false keel). I should also mention that the points where the pieces need to be cut out seem to be located where the potentially rough cut/break will not affect the final product 👍

@*Hans* (I thought you might be interested in this 😁 )

- chris watton, *Hans*, rcweir and 7 others

-

10

10

-

-

It has been a while since my last update. Things have been slow due to moving into a new house; however, there is still a decent amount to update.

Sails and Rigging:

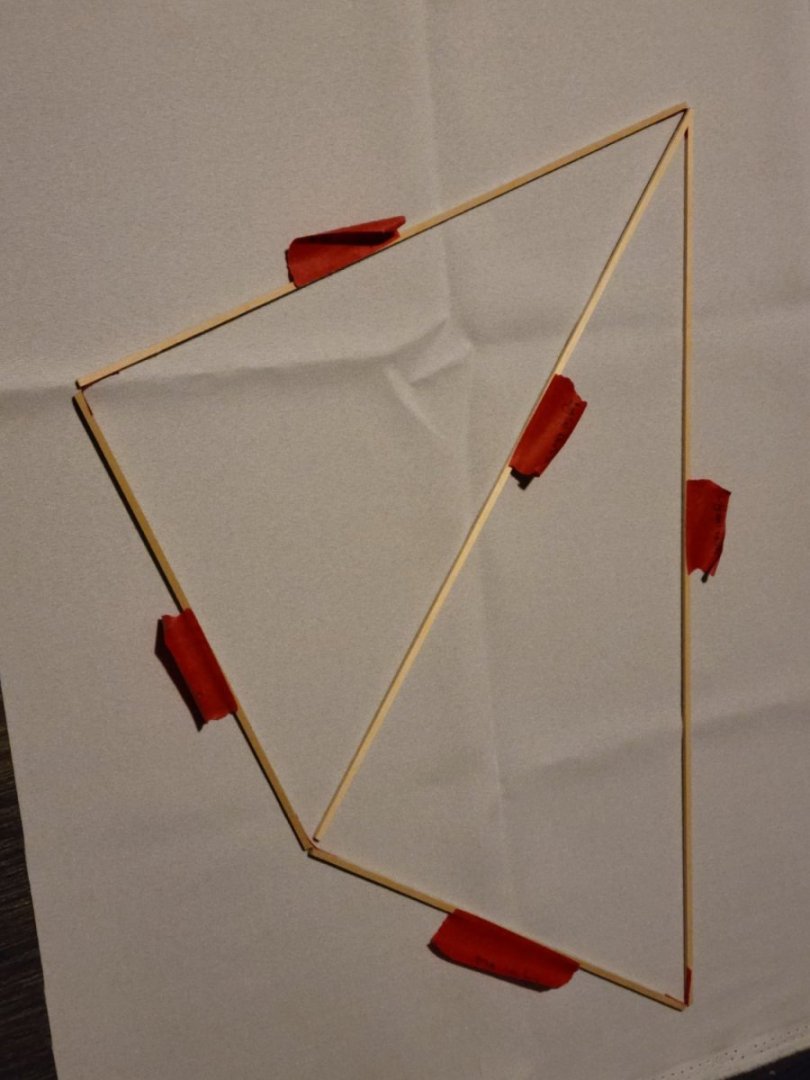

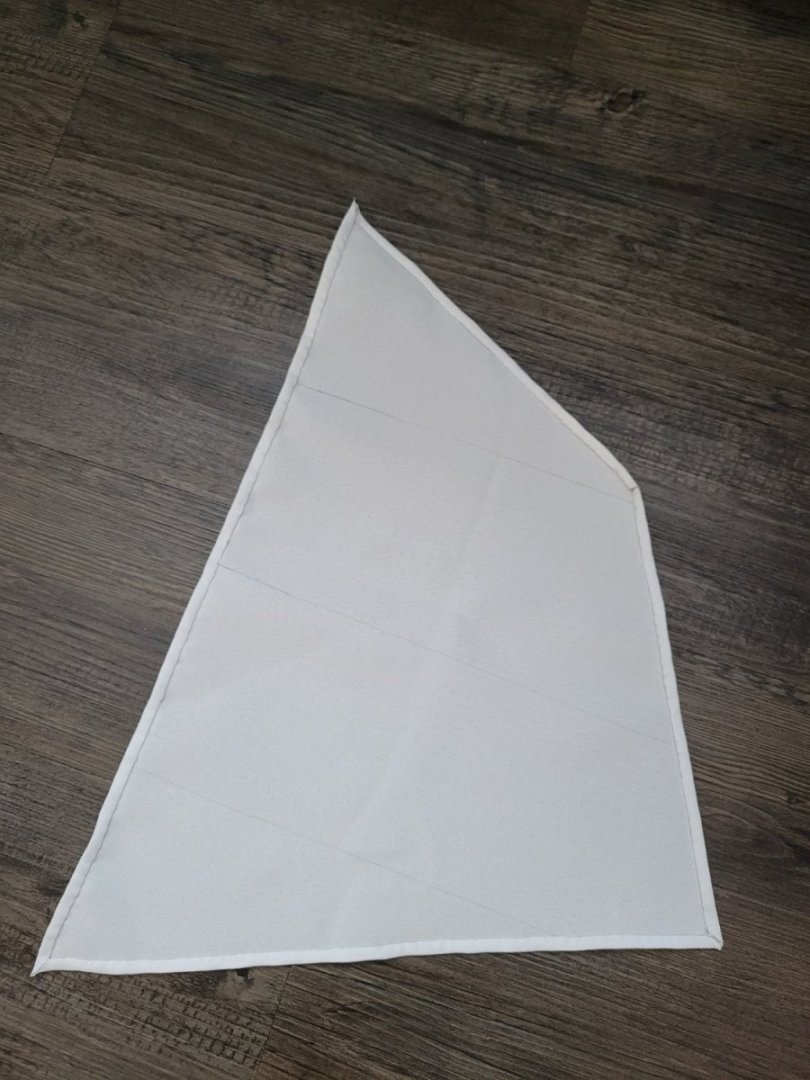

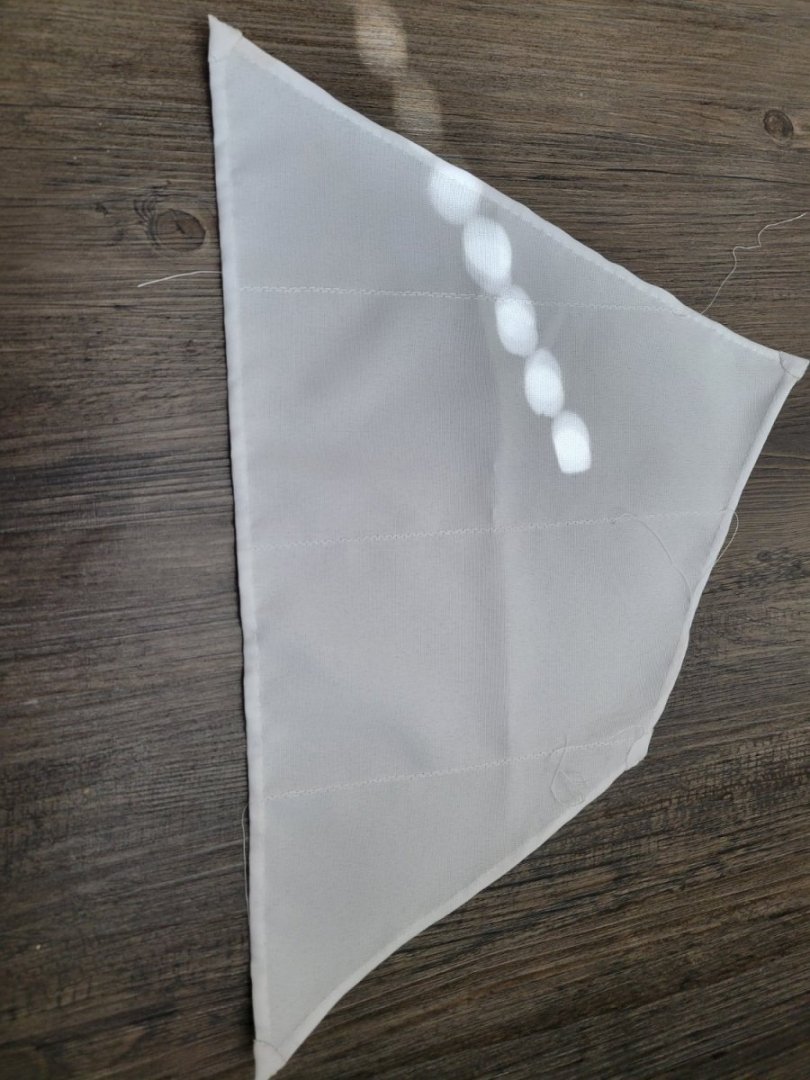

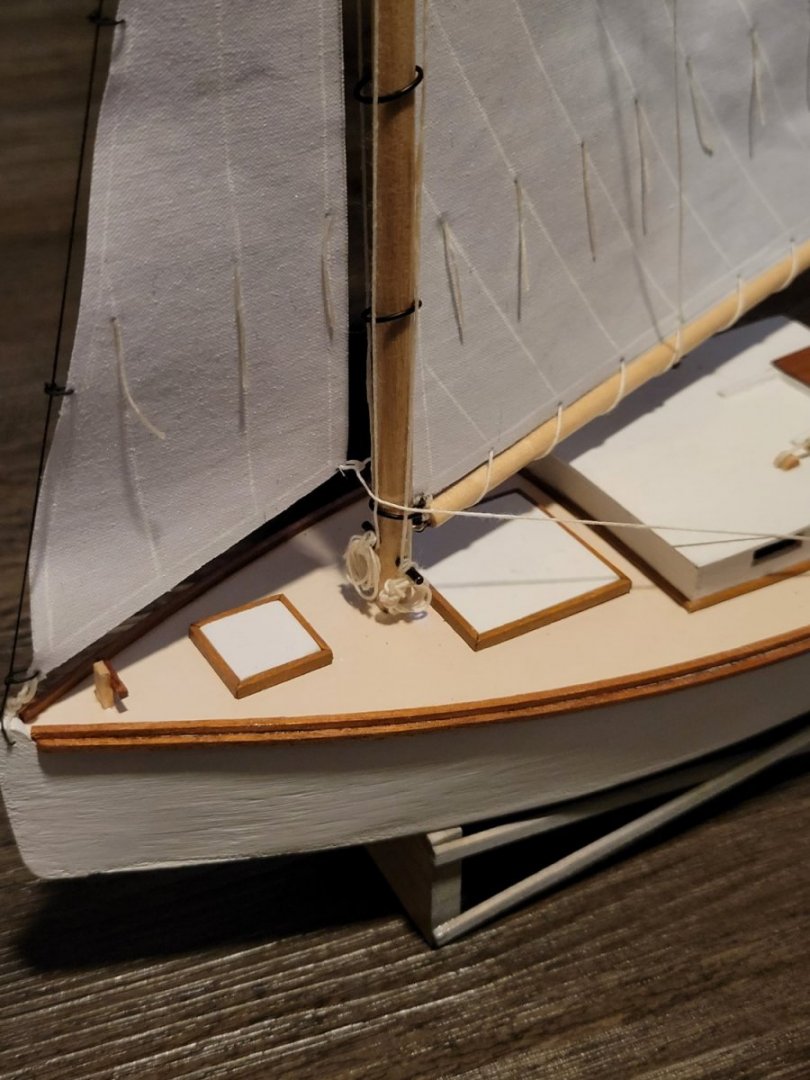

I used a light polyester fabric as my sail material, and used to battens cut-to-length to measure the correct sail shape:

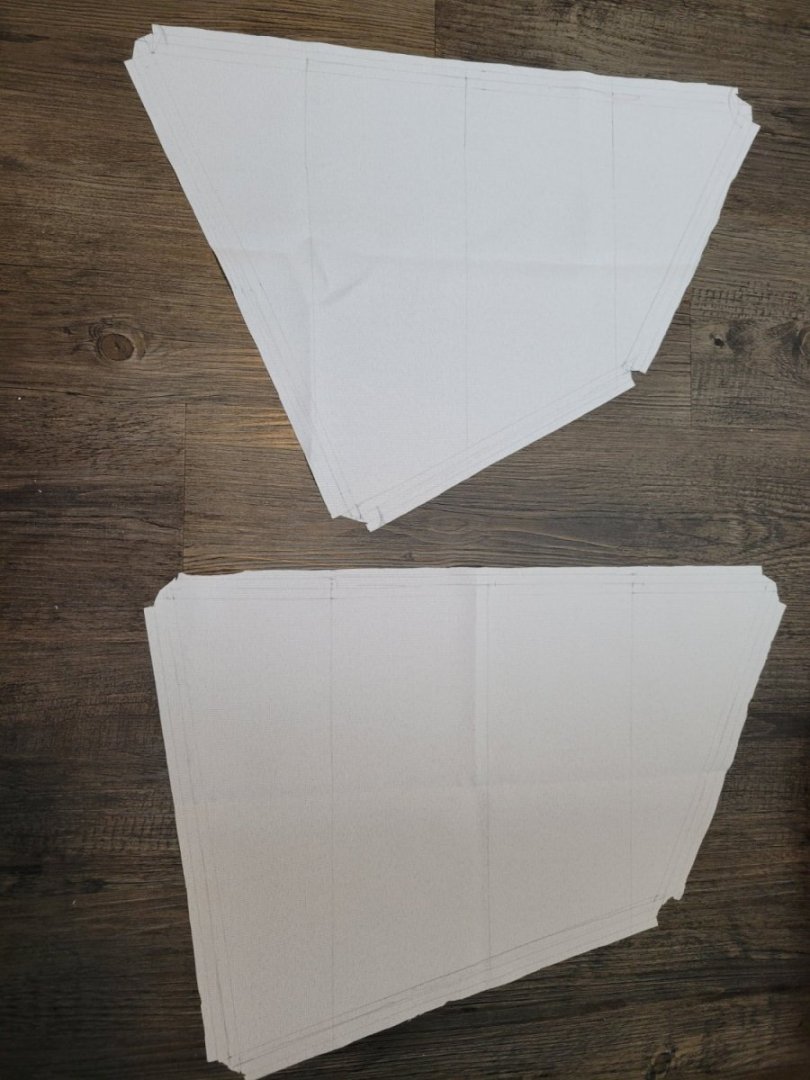

I cut it out oversized for hemming (I actually made two sails of different dimensions, but chose to use the standing lug):

Hemmed:

Added reinforcing fabric to the corners:

Added grommets:

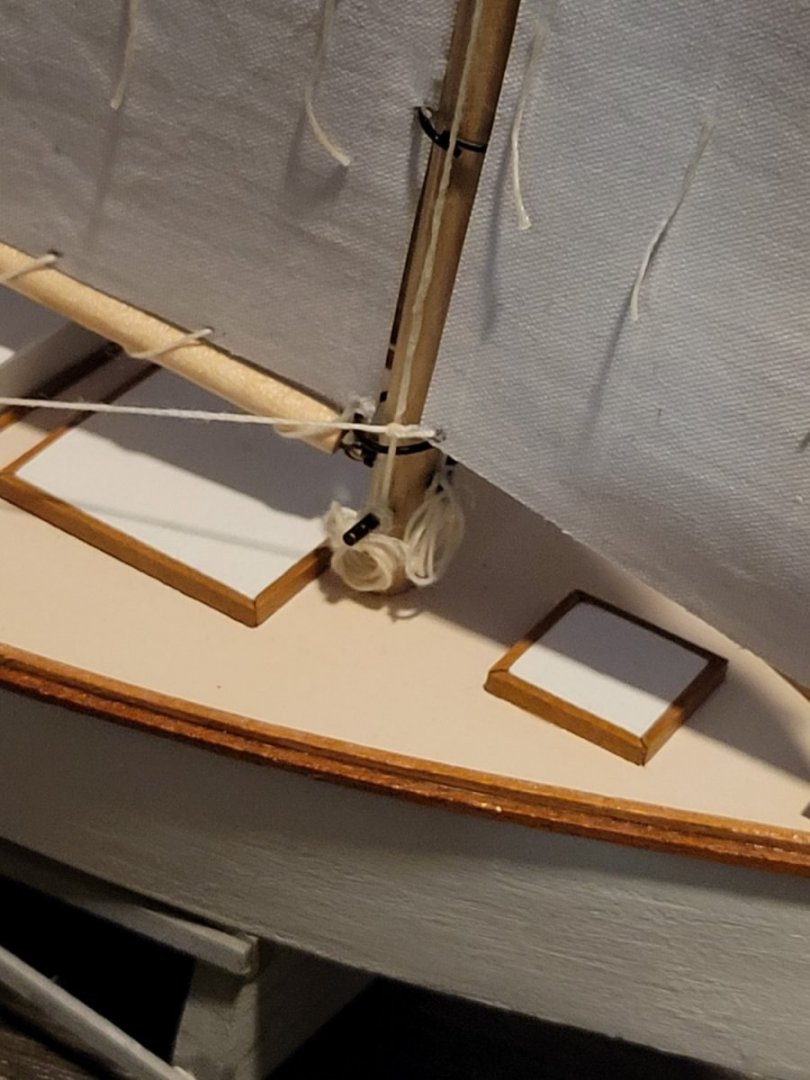

The sail is bent to the yard and boom, and temporarily hoisted. Later, there will a mainsheet, blocks, and cleats to complete the rigging:

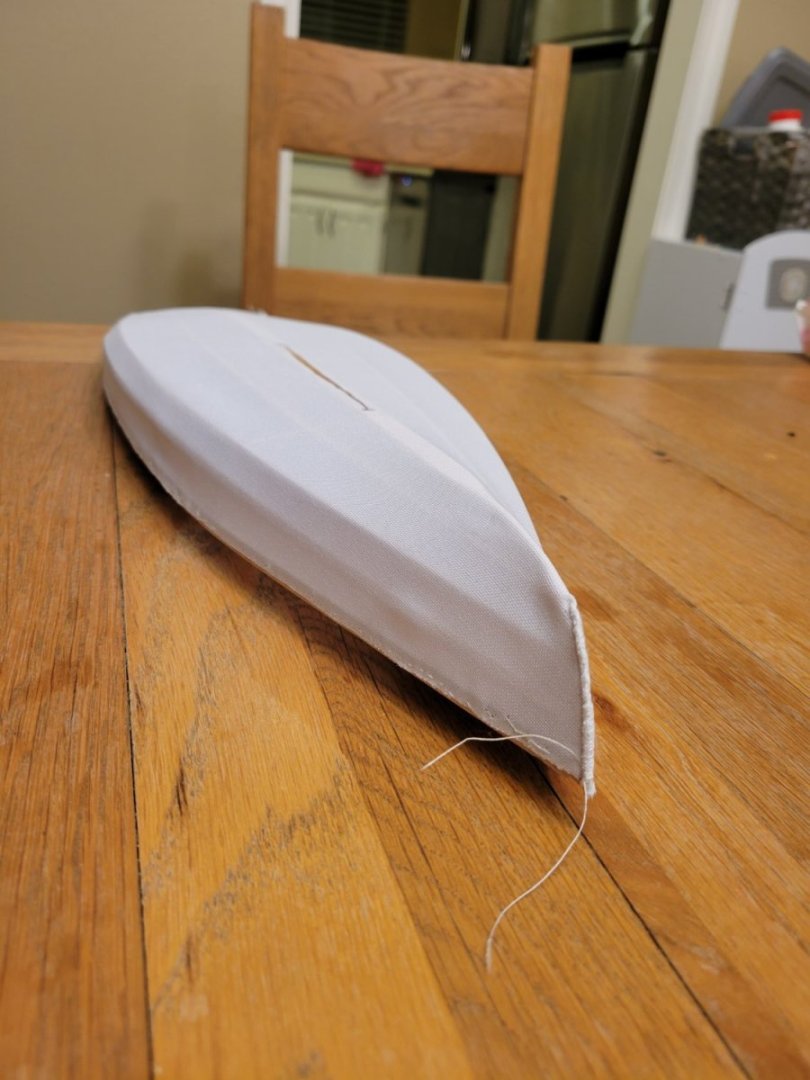

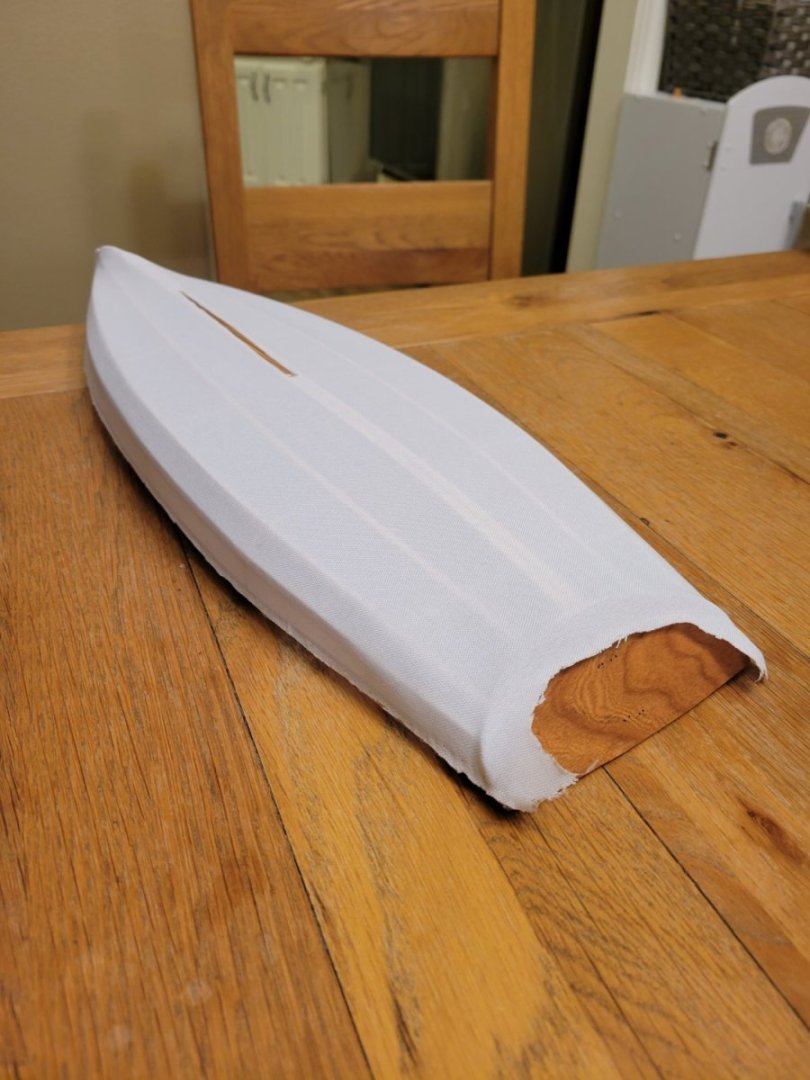

Sewing skin to the frame

I drilled many small holes in the gunwales to sew the fabric to the frame:

At the seats, I couldn't accurately thread the needle underneath the seat, so I drilled the holes at an angle like so:

There is still more work to be done, but the large part of the hull is skinned:

-

It's looking great, Melissa! The more I see of your build, the more I want to buy this kit

- Keith Black and *Hans*

-

2

2

-

-

I decided to finish the frame where it will be visible with Danish Oil. I really like the effect, and I think it will look beautiful once the boat is skinned and painted.

My next step is to skin the boat, but I need to decide how I want to attach the fabric to the gunwales. On the full-sized boat, I will use staples similar to how furniture is upholstered. However, to my knowledge, there is no staple suitable for this scale. The rub rails will cover up the interface between the fabric and gunwales, and I can see normal staples interfering with the fastening of the rub rails. I will probably use some kind of glue, but I need to decide which kind of glue.

Since last post, there are some significant progress on the frame:

Centerboard finished with Danish Oil and light coat of flat clear-coat

Centerboard attached using a m0.8 bolt and nut.

Centerboard cap attached

Before-and-after applying Danish Oil. I feel like the pictures don't do justice to the Danish Oil. It looks more balanced in-person.

Floorboards attached (cut from a 1/32" sheet of cherry)

On the full-sized boat, these will be properly lashed, but at this scale, the knots are too thick and will press into the boat's skin. For the model I just did a simple overhand "knot" and used CA glue to secure it.

-

Update

Centerboard case, mast step, and kingplank have all been added.

Right now I'm thinking about whether I want to stain the basswood that will be visible in the finished product or leave it its natural color. I'm planning to paint the hull a light-blue and the deck white or cream (or something of that nature).

If I do stain the Basswood, I want to do so before skinning the boat.

- Paul Le Wol, KeithAug, GrandpaPhil and 5 others

-

8

8

-

On 6/16/2022 at 12:45 PM, GrandpaPhil said:

Congratulations! Well done!

Thanks! It was a great experience

-

8 hours ago, gsdpic said:

Nice! I missed your log until now but will follow along with interest. Some time back I was paging through Chapelle's American Small Sailing Craft, looking for something to catch my eye as a potential first scratch build, and the melonseed skiff was one option that I liked and did some research on, though I did not find the Gentry custom boats site. For me the project is still somewhere off in the future but I will be interested to see yours. It looks like you are off to a great start.

Thanks!

I think this is a bit different from a typical scratch build in that it has a detailed build guide. It also introduces some unique challenges. For example, the frames are pretty difficult to cut out precisely at miniature because of the notches you have to accurately cut out (especially frame 1). Also the skinning will be an interesting departure from the typical solid hull or plank-on-bulkhead.

If you do wind up building Dave's Light Melonseed as a model, and you are not doing so as practice for the full-size thing, I would recommend creating a "false keel" to hold the frames vertical and plum while you are attaching the chine logs like you would see on any typical model. Dave's method will work great for a full-size boat, but at miniature, I found it too easy to accidentally nudge the frames out of position.

6 hours ago, KeithAug said:Mark - A nice little craft, it will be interesting to see it develop.

How do you keep the wood dust out of your keyboard?

Good question 😆

Actually, when I'm sanding something, I almost always hold it under my desk over the trash can.

-

Update

Transom and knees are attached, seats attached, and mast and spars are shaped. I am currently working on the centerboard case and will upload pictures of that soon.

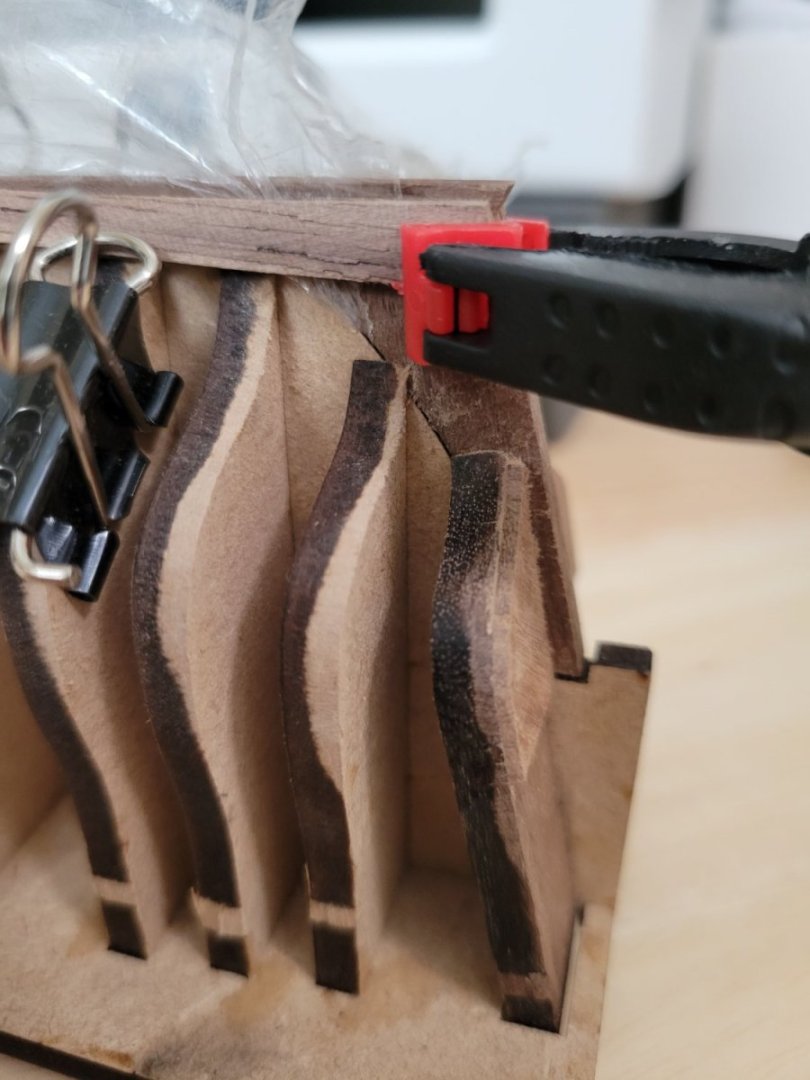

The transom has a significant angle, and it was challenging to keep it secured while the glue dried. In a full size boat, you can use screws, but this is too small for that. I mostly used pins from the inside, but I found a nifty use for binder clips to secure the transom to the keel.

I laminated the transom from basswood and cherry. Since it will be visible from the stern, I wanted wood prettier than basswood visible.

Mast and spars:

Mast and spars are laminated, shaped, and sanded. I will varnish them after finalizing my plans for the rigging and drilling necessary holes. They have a rounded-rectangle cross-section.

I found the mini plane from Lee Valley Tools to be very helpful in shaping the spars and other aspects of the project.

(Pardon the messy desktop)

-

Great to see your progress! it's shaping up to be a lovely little ship

- Melissa T. and Keith Black

-

2

2

-

Congratulations Dan! As others have said, she looks great!

I have to say also that it was a great build log with plenty of helpful detail. Seeing the experience makes me want to try this kit at some point in the future.

It seems that while the curves make this boat quite pretty, they also make her more challenging to build.

-

- Harvey Golden, mtaylor, gsdpic and 4 others

-

7

7

-

2 hours ago, DanB said:

Jib sail — twice

Moving a long slowly. Working on my rigging skills 😀

The kit comes with a full size sail plan. I meticulously copied the locations for the holes for in the sail for the hanks that hold the jib sail to the fore stay. I did not take a close look at the brass loops that are supplied with the kit for the hanks. If I had , I would have figured out that the holes needed to be closer to the edge of the sail. I will probably need to keep learning this lesson: read the instructions, look at the plans, and the materials, and the ship!

There is an option to use rope hanks to attach the jib sail and the plan even has a nice diagram to show how to do it, but I used up all the beige 0.4mm line. I went to the local hardware store, bought some 28 gauge black annealed steel wire. I wrapped it around a small screw driver and used the same technique that was used for the mast hoops to make slightly larger loops that the ones supplied for the hanks for the jib sail. That seemed to work well ,but then I noted that fore stay did not seem tight enough. I took the whole thing apart today and rigged it again

The down haul form the front of the jib sail is supposed to belay at a cleat on the bow sprit. I think my splice loop on the sail was too big and the line was not close enough to to the block it goes though and not long enough to belay at the cleat. I will do that that again — after a break.

I am going to spend some time looking at videos and diagrams of how lines are supposed to be attached to a Sampson post and watching videos to relearn how to make a cleat hitch.

It's looking good, Dan.

I encountered a similar problem when I was working on the rigging for my Chesapeake Bay Flattie. The instructions said to cut a line of a certain length, and it turned out too short on the actual model. I should have checked the length on the model first. These were the halyards, and I didn't realize they were too short until I ran them through the blocks. Since they were already tied, I decided to splice more line to them instead of redoing it.

-

6 hours ago, Melissa T. said:

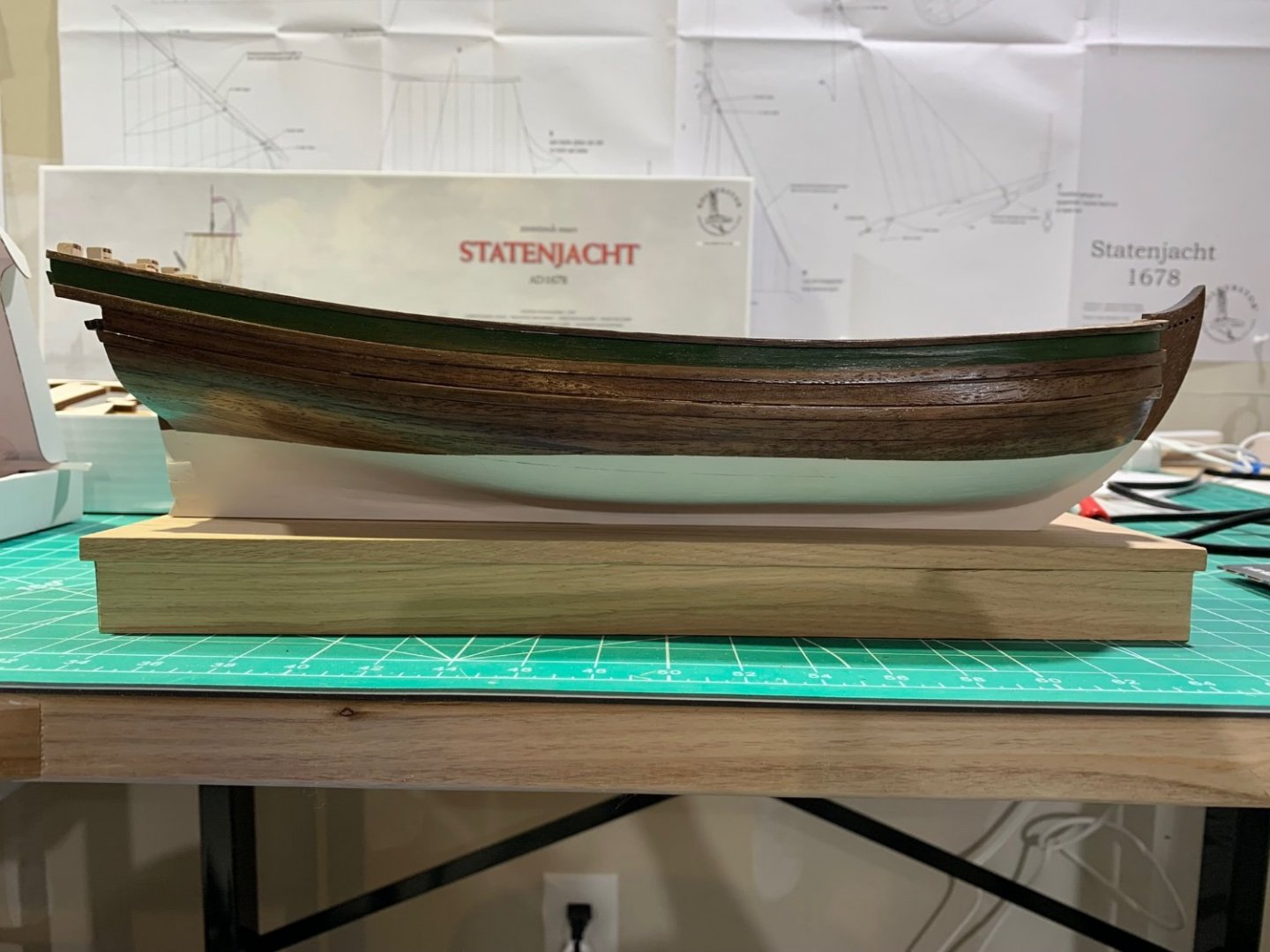

I’ll be off on a brief trip out to Oregon through next week, so I thought I’d post a quick update before I leave. I’ve finished the upper hull and the keel - it’s been fun to see these scraps of wood gradually take on the contours of a ship! When I get back, I’ll finish the deck planking and the inside of the upper hull. The latter will be painted bright red. One of the things I love about this kit, and a reason I chose it, is for all the bright colors.

She is looking like a lovely little ship!

On 5/16/2022 at 6:12 AM, rtibbs2018 said:Melissa,

If you have not visited the modelbouwforum I encourage you to do so. The following link will take you to Pietsan's superb build log of the Statenjacht.

The site is in Dutch however, windows does translate to English. You will find many Dutch ships built by Piet on this site.

https://www.modelbouwforum.nl/threads/statenjacht-uit-1678.263783/

Thanks for that link! I purchased a Speel-Jaght and definitely have the Statenjacht as a highly desired follow-up. That thread and forum look to be a great resource.

- mtaylor and Keith Black

-

2

2

-

- ccoyle, Bildad, Paul Le Wol and 6 others

-

9

9

-

Update:

Strongback is ready, mast and spars are laminated, and all "plywood" parts are cut out. Everything is temporarily collected together for a group photo:

I used a jewelers saw (Knew Concepts jewelers saw) with a jewelers blade to cut the shapes out of mostly 1/16th inch basswood sheet material. A few pieces are Cherry. This was my first time using a jewelers saw, so all this cutting, especially with the details has been very instructive.

Everything is pretty rough right now and needs to be trimmed and sanded, but I'm overall happy with the jewelers saw. I was able to get much more detailed than I expected. There were a couple of interesting things to consider when using the saw. For example, cutting across the grain was an entirely different experience than cutting parallel to the grain.

Cross-grain, the saw ripped through the material incredibly fast even with a very fine-tooth blade (I used #3/0). It was very easy to cut too much material in one stroke. I found that, in this situation, using very short, relaxed strokes with virtually no pressure against the material gave me the most control.

Additionally, the saw has a 5" throat (I believe that is the correct term?), and the material I was cutting from was 2 feet long. It was fun to plan the cutting to try and preserve as much scrap material for future use as possible while also accounting for the 5" limit of the saw.

Next Steps:

-Refine the cut-out shapes with files and sandpaper.

-Positioning of frames and chine logs for fairing.

-Shape and sand the mast and spars. These will remain mostly rectangular, but will be tapered in some cases and the edges rounded.

- ccoyle, Roger Pellett, grsjax and 8 others

-

11

11

-

Nice! I love the Swampscott Dory, and even better, the idea of helping others into the hobby

-

Looks great!

I'm curious... after all the painting and gluing and such, is the centerboard still functional?

-

I'm almost done!

Below are some little things I've worked on. Stay tuned for the finished product!

I wasn't really satisfied with the cleats that came with the kit, so I ordered some pewter cleats from Model Expo and polished them to what I think is a nice result. Polished on the left, original rough cleat on the right

I used scrap from snipped "cotter pins" to make an additional eye bolt and also a brass thimble, both to be used in a the centerboard block and tackle.

The kit says to cut a block in half and glue it to the cabin roof for the centerboard sheet to run over. The blocks that came with the kit are basically rectangles and I didn't like that idea, so instead, I cut off a bit of dowel, put a groove in it, and cut it in half to achieve what I think is a better result.

I had fun staying the line, but realized afterwards that it is likely way too much line for a centerboard sheet 😅

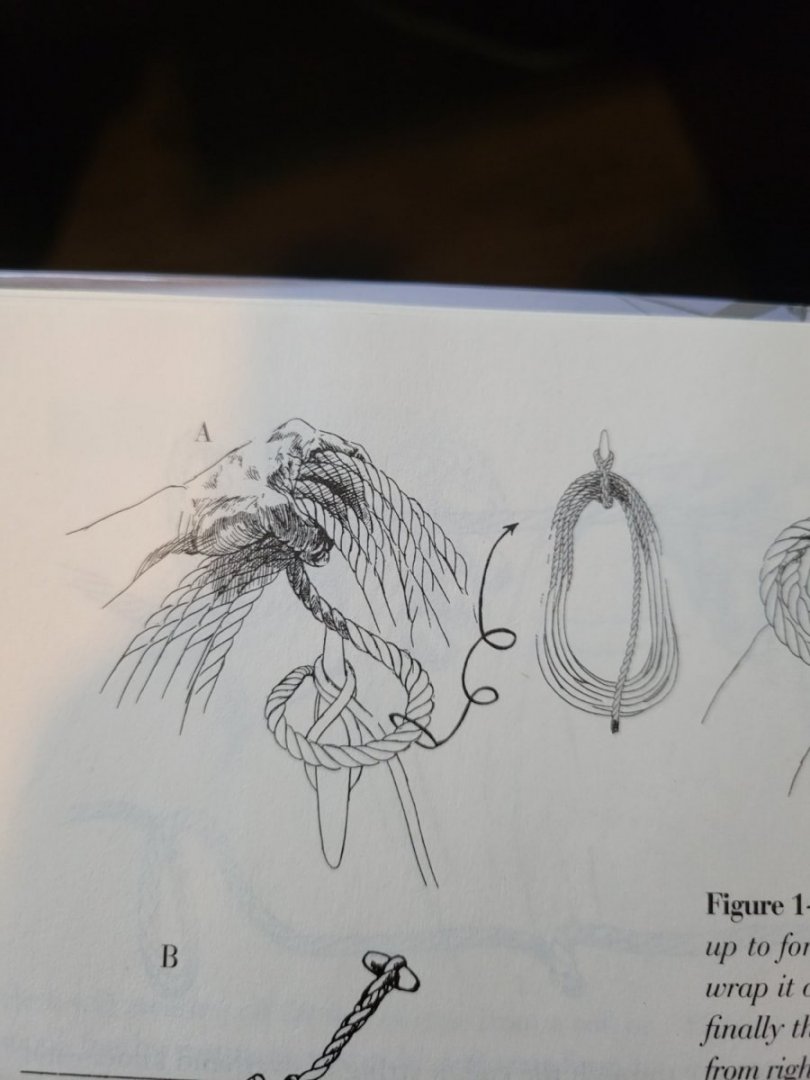

I found a decent way to sort of replicate this image from Brion Toss's "The Complete Rigger's Apprentice"

Hold a bight with some self clamping tweezers.

Coil the line around the tweezers

Slide the coil down the tweezers, over the bight, and completely off.

Give the bight a twist and hook it onto the cleat.

Again, probably completely unnecessary for a centerboard sheet, but it was fun

Light Melonseed by mark.bukovich - 1:8 - SMALL - from design by Dave Gentry

in - Build logs for subjects built 1901 - Present Day

Posted

It has been a while since I updated this. Progress has been slow but significant.

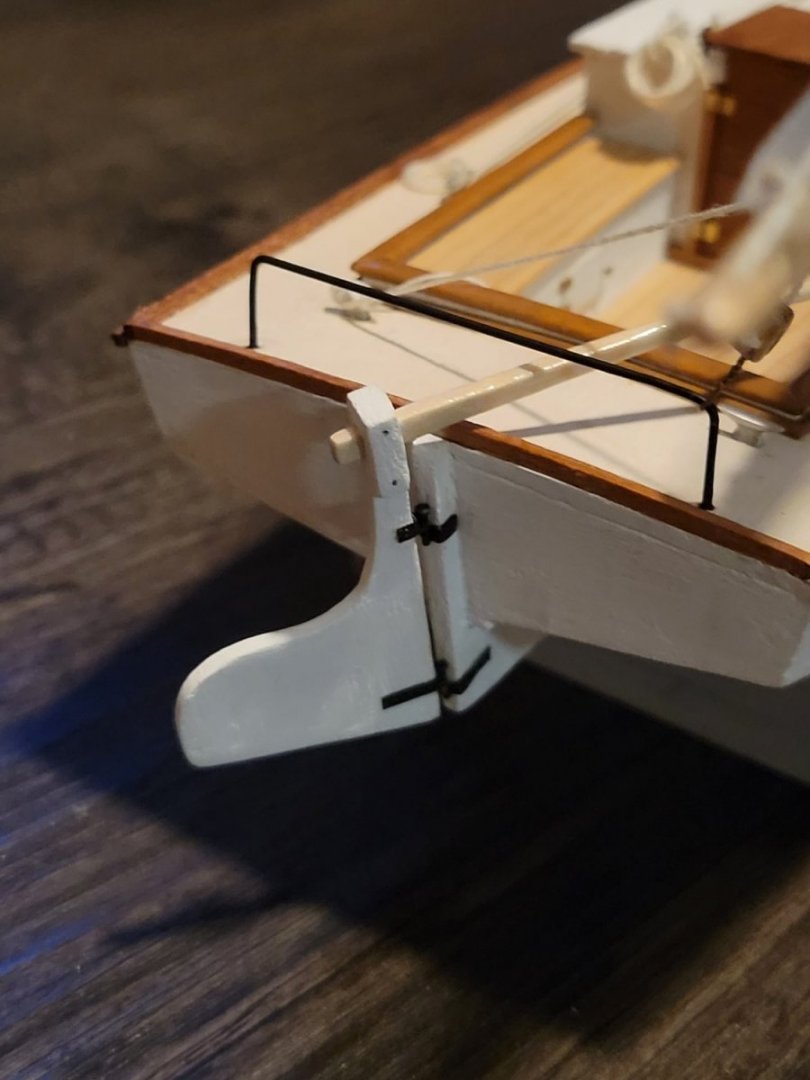

I fabricated the gudgeons (still need to finish the pintles).

I used a stainless steel sheet and cut out appropriately sized rectangles using a coping saw.

I then bent the pieces of steel sheet around the rod I will use for the pintles and then bent the "flaps" outward until flat. I then drilled holes in a pattern similar to the boat hardware I will use on the full-sized boat.

I then used a dremel to round the corners and edges, and then hand-polished the result. Below you can see the gudgeons fastened to the finished transom (transom finished with acrylic clear coat and polished).

I'm aiming to make them look like the Racelite Pintles and Gudgeons I will put on the full-sized boat:

I have also begun to skin the deck. I started by cutting out a piece of fabric a bit bigger than the necessary size, and then pinned it to the gunwales.

Starting from the middle, I sewed the fabric tightly to the existing hull fabric slightly past the seats.

I cut the fabric in the cockpit, trimmed it, and sewed it to the deckbeams and frames.

I then sewed the fabric all the way back and to the transom.

For the centerboard opening and the mast partner, I cut out the necessary fabric and then glued it to the king plank with epoxy.

As you can see, I'm almost done skinning the deck. Afterwards, I will trim the fabric, do some careful heat shrinking, and then paint the deck and hull.