-

Posts

2,516 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Rustyj

-

-

Hi Greg. It would be an honor to clean up after you!

Hi Michael and Grant, It just struck me as funny when Antony was talking about “clean build”

and I knew I had all that cleaning to do. So it was fun to share with you all.

Oh yeah when I first started building it was on a small table in the corner of the living room.

You know I kept that a whole lot cleaner with the Admiral right there.

-

OK you may have thought it was tongue in check when I said I had to clean the

shop before I continued.

You see I am the type who likes to spend as much time

as possible working and I just jump from one step to the next. If what is on my

desk isn’t needed for the next portion of the build I just push it aside and onward

I go. Well seeing that there was no workspace left for me to start cutting the

red heart for the inboard planking it was time to clean.

So I just spent the last 3 hours cleaning and now it's be full steam ahead this weekend!

- Trussben, fnkershner, gjdale and 5 others

-

8

8

-

Thank you Daniel. The build may be clean but I sure have got to clean up the shop before I can

do anything else. I’ve been a little lazy when it comes to putting things away!

As far as sealing the wood goes if I have finished a section and no more gluing will be done I apply

a coat of MinWax Wipe on Polyurethane satin finish. This seals the wood and helps protect it.

Also with so many nooks and crannies it would be really hard to apply later.

-

Hi Antony, I just got caught up with your log and you are doing some

outstanding work. Very well done and the look is so clean. I love it.

-

Hi Chris, Of course they fit! It’s just a testament to the great care and patience

you have put into building her. Very nicely done.

-

Hi Bob, I always enjoy your updates and that’s a very nice planking job. It is a shame

you are going at it alone but then your log will be a great reference for all who will

build her once the “issues” are corrected.

-

-

-

Thanks Augie, Yes the holly, like all the wood from Hobby Mill, is really nice and fun to work with.

Thanks Chuck much appreciated.

Hi Bob, Thanks and your Essex is coming along very nicely too!

I have completed planking half of the gun deck. One plank had to be notched to fit around the hatch.

It doesn’t adhere to planking procedures and it is a little too thin but close enough. There won’t be

any rot issues anyways. At least I hope not!

The hatch has not beeen glued in place yet as I have to sand and scrape the deck, treenail and seal it.

- Pete38, dnputnam, fnkershner and 12 others

-

15

15

-

Hi Ryland,

I see that you’re slow and steady pace is picking up some speed! Don’t worry about

how long you are taking just keep up the excellent work.

-

Thanks Greg. Not much, maybe 1/64”. I always over bend them hoping to

compensate for the spring back.

Thanks grant. It’s always fun for me to mix in different woods.

I’ve milled all the holly needed for the decking and have started laying them.

Again I am using black paper to simulate the caulking. Hopefully later tonight

I well get to the area around the hatch completed.

-

Hi Elmer, Thank you and welcome aboard.

Thank you Dave.

Hi Floyd, Thank you but I’ve seen your work and you are being too modest.

Hi Bob, Thanks and not to worry. I’m planking just one side so we will be

able to see some of the framing.

Thank you Michael.

I've started planking and will have some pictures tomorrow.

-

Thanks Antony. Yes wandering through the mind can be quite something at times.

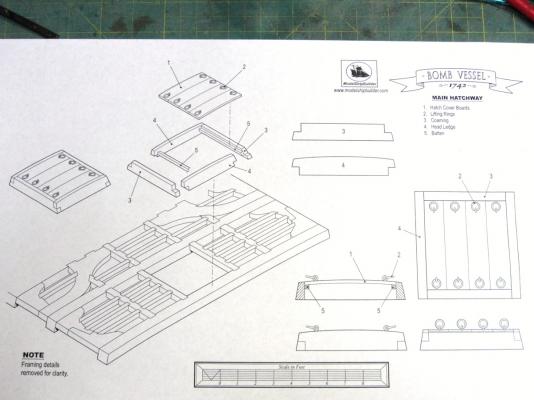

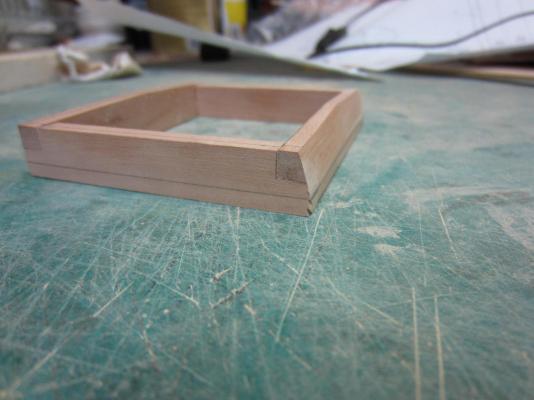

I’ve now started on the main hatch cover. The first thing I did was cut the hatch cover

boards, boxwood, to length, soak them and then bend them over a scrap piece of wood

to get the correct curve. I let them dry like that for 24 hours.

The coaming and head ledge, swiss pear, were then cut out and assembled. The boards

installed and the hatch set temporarily in place. I marked its location for installation

later. I also still need to install the lifting rings.

I didn’t want to permanently attach it until I had the decking done. It’s easier for me to

sand and finish the decking if it’s removable. Also in the last two pictures you can see

the waterways have been placed and they too are made from swiss pear.

Thanks for stopping by!

-

Thanks Ben and Grant.

Hi Mike, It is fun and a bit scary. The plans are great but there are no instructions

so it’s just flip through the pages of plans and hope my interpretation is correct.

-

Thanks Joe, It is my intention to go but I have to keep life in line. Last year she interfered big time.

-

Thanks Anthony!

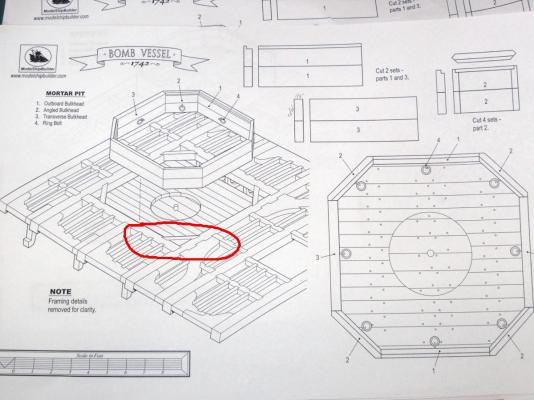

Here is the promised update.

Success! I was able to keep the side pieces in place and then attach thecorner pieces, the correct term is angled bulkhead, but I like corner better.

The biggest problem after getting the length right was using enough glue

to hold the sides together but not gluing the sides to the beams.

Once the glue had set marked the placement of the angled carlings I carefully

removed the assembly. I the placed the angled carlings sanded it down and

then permanently glued the pit assembly in place.

The deck was sanded smooth and I applied wipe on poly to the side (starboard)

that will not be planked.

- fatih79, dnputnam, captainbob and 11 others

-

14

14

-

Thank you all for stopping by.

Hi Grant, I had a good night in the shop and it’s looking good so far.

Hopefully tomorrow I’ll have more pictures.

Jan, Welcome aboard.

How did I miss this log?

I understand what you are saying. With so many builds it’s hard to catch them all.

I constantly find new ones too!

Hi Ben,

Looks like it will work from here

That’s similar to a saying we had while building my brother in laws house. We’d put something up and he’d ask

“how’s it look? And invariably someone would shout out “Looks good from here” or “Can’t see it from my house”.

Drove him nuts the entire time. If it wasn’t for the free labor he’d have booted us on day one!

-

Thank you all for stopping in and the likes.

Thanks Bob, you never know what kind of oops or such that could pop

up and ruin the day.

I have competed the framing of the gun deck. Pretty straight forward and

at this size it turned out to be a lot easier to do.

Next in the mortar pit the walls need to be built. There are angles involved

and I didn’t trust myself to build it off the model and keep the correct

dimensions. Also there are four cross braces between the beams that

need to be put in.

So to help me keep it square and position the cross bracing correctly I clamped

the side walls in place and then started fitting the angles. This way once

completed I can mark the cross bracing, remove the walls, install the bracing

and then return the wall to it's correct location.

Here is just the top piece of the wall confirming the angle and length are correct.

Time will tell if this will work or not.

- fatih79, SailorGreg, puckotred and 11 others

-

14

14

-

-

-

Thank you all for all the likes, visits and comments. They are very much appreciated.

Thanks Ben, I’ve been asked a couple of times if working at the larger scale is a good thing or bad.

Well when it comes to ledges, carlings and knees it seems to be easier. Although there is a lot more

wood that needs to be removed I find my errors are smaller and less frequent at this larger scale.

Time will tell if this still holds true.

Hi Jim, Thank you and it’s good to hear from you.

Thanks Jack, from what I’ve seen so far on they are very solid and I don’t know about the Erebus

and Terror but it makes sense to me.

Hi Kevin, thanks and I’m sure you can handle this cross section once you are ready. All you need is

a LOT of patience and a willingness to throw away parts that didn’t work and do them over.

Plus it’s a good excuse for more tools!

Thanks Grant. That one fit right off the scroll saw. Not all of them were that close. A little

adjustment here and there and in they go.

Thank you very much Christian. Your work has always inspired me.

Hi Augie. Thank you. Yours and everyone else’s support and interest makes my day!

Well I’m off work until next Monday. Thanksgiving day is shot but the rest of the time

has a whole lot of shop time scheduled in. By Sunday night the Admiral may have

forgotten who that troll is in the basement.

Happy Thanksgiving to all here stateside and best wishes to the rest of you. Be safe!

-

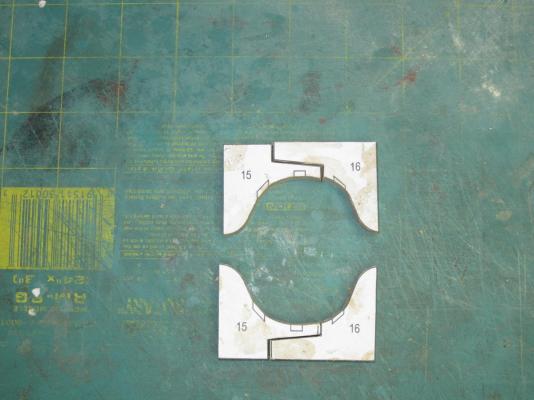

Thank you Antony. Your continued support is very appreciated.

As I work my way around installing the ledges and carlings there are also

assorted knees, hanging knees and double knees.

All of the deck framing pieces are being cut from Cherry.

Here you see one set of double knees rough cut out.

Here is a hanging knee rough cut and then set in place to test the fit prior to the finish sanding.

Everything seems to be going well, so far, now hopefully I just didn't jinx myself!

- AntonyUK, Wishmaster, popash42 and 14 others

-

17

17

-

Hi Greg,

Oh that is soooooo nice. I can appreciate your not wanting to cover those timbers.

That is some fine workmanship.

- druxey, avsjerome2003 and dnputnam

-

3

3

-

Very nice Antony. I admire your abiltity to build the deck off the model. Great workmanship.

Bomb Vessel Granado by Rustyj - FINISHED - 1:24 - cross-section

in - Build logs for subjects built 1501 - 1750

Posted

Hi Daniel, We were posting at the same time. Yeah I’ve envied all those spotless,

Yeah I’ve envied all those spotless,

well organized shops for years. But then once I walked into one of those they would

never be the same again!

I agree the aroma of the shop is something else but I also find that we are the

only ones who truly appreciate it.