-

Posts

3,254 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by NenadM

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

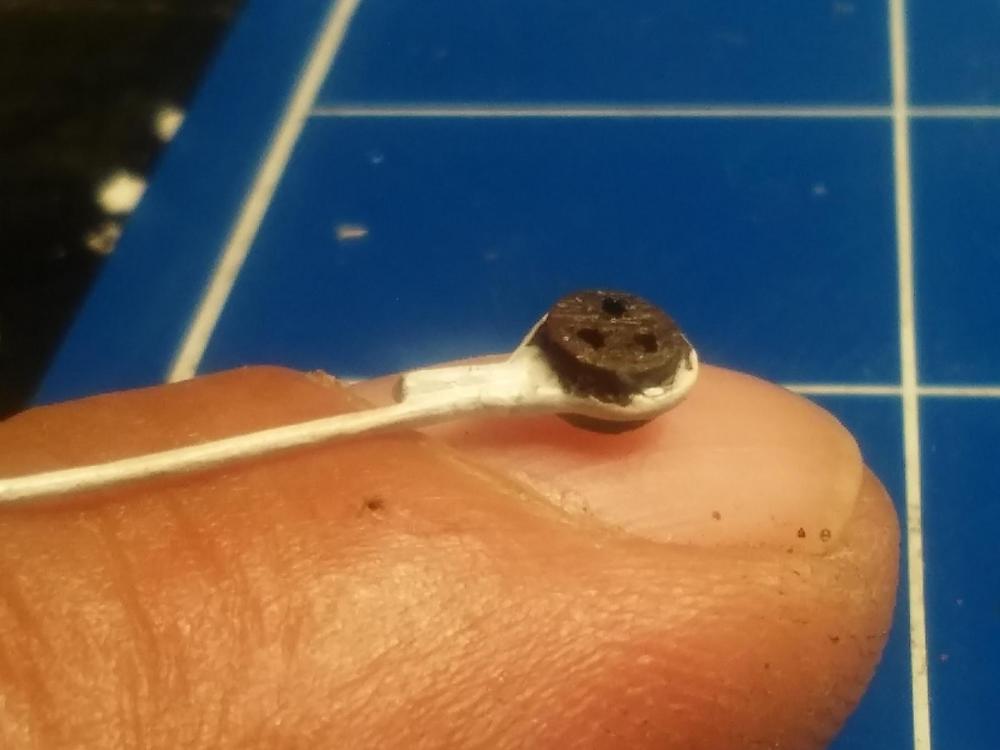

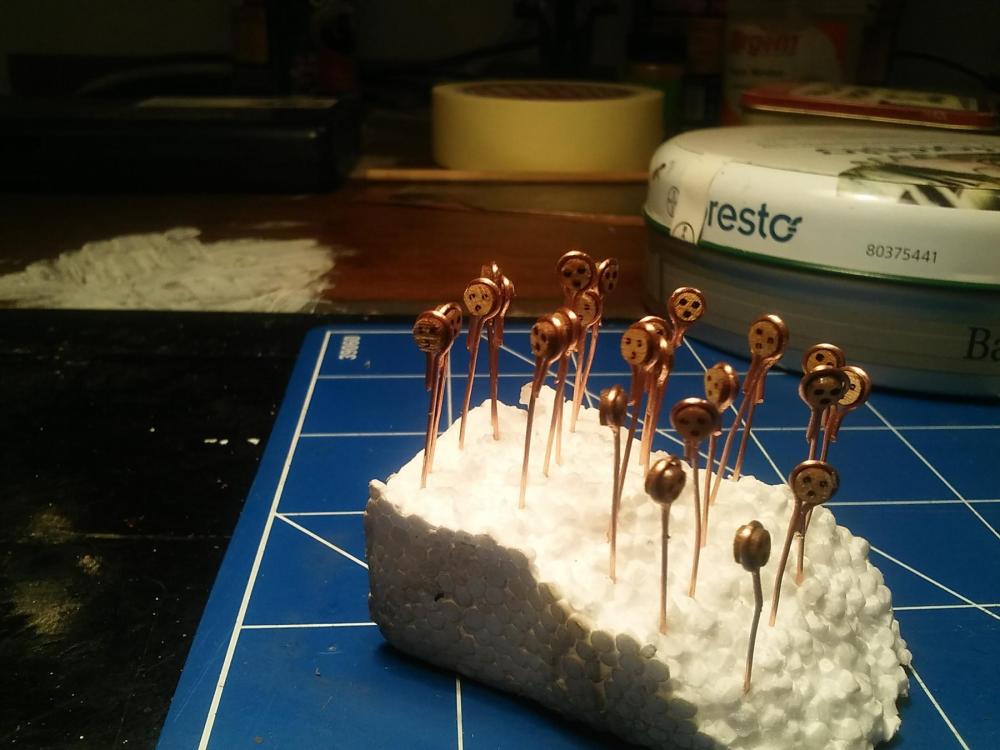

Thanks Omar for nice words Move forward to final look of dead eyes CA drop - done. Re-drilling holes - done. Coloring wood - done. Coloring wire - started. Follow nice fiting of holes and applying mat acrylic transparent warnish. It is raining whole day, and no work in homeyard can be done. After 2+3 hours of looking throught magnifier, my eyes dropped somewhere, which told me to stop.- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Mmmm ... smelt of coffee attracts me here to watch and learn

- 72 replies

-

- bootlegger

- speedboat

-

(and 1 more)

Tagged with:

-

I have no doubt in your work. It will be ok

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Thanks for your input, Denis. Did you know - you are not only stuborn builder on MSW! Alea iacta est !!! 3mm fit well, and I think this is a limit- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

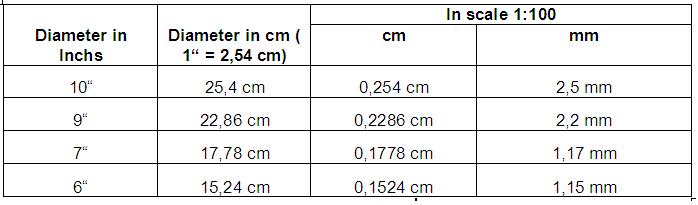

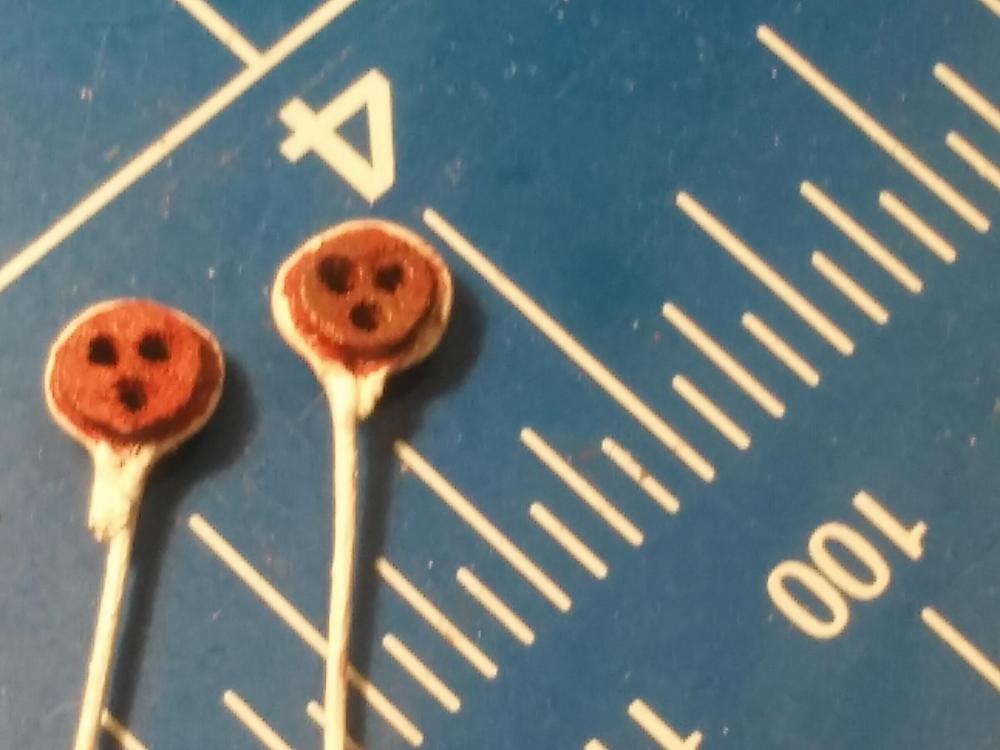

Thanks Carl for your input. Many options are around me right now. I`ll make some 3 mm dia dead-eyes tests with 0,5 mm Cu wire, and we`ll see how it will look. I was considering your solution, and, If I can, I`d rather keep 0,5 mm wire - it visually fits better with 0,5 mm Cu wire holder under rail, and it is, for sure, stronger than couple of twisted thinner Cu wires. With all ratlines on place, there will be constant force pulling them up, and I do not dare to make something which visually fits, but which is not strong enough and can crack at any time Anyhow, it is impossible to follow right proportion published by Campbell on his plans in scale 1:100 Mr. Campbell on his drawings shows dead-eyes with dia: 10", 9", 7" and 6". That means : And that means that even 3mm dia dead eye is too large. We agree that 3mm with three holes inside is really small devil- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Ok, some testing Much better, but ... When I was calculating width of dead eye, I forgot to count depth of wire. 0,5+0,5mm=1mm !!! Enormous 1mm on that place in this scale! And exactly this 1mm produced all 4mm dia dead eyes to be too much close to each other Tomorrow I'll consider the possibity to make ALL of dead eyes from 3mm laser cutt pieces, if I have enough of them- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

One step forward, two steps backward. Paying back time for my impatience comes again. Today I started with cleaning of white panels, it goes well, and happy, cleaned my working table to make comfortable place for delicate working ... And ... you can guess ... all my work with dead eyes goes to hell At next pictures you can see why Here is 3mm dead eye on position next to it`s own hole And here is 4 mm dead eye also on position next to it`s own hole Obviously, my idea to simulate real way they are connected under rail with wire and deck - simply - does not work, at least not in this way. Under rail construction is too wide, and demands hole to be expanded to 3mm, which is out of question. Holes are too close, and expanding all of them them easily can make rail, at least, ugly So, in this scale, having in mind my earlier mistake ( not equal width of bulwark under rail), I will waive this solution, and make something like this Why, dummy Nenad did not make some test before making this bunch of dead eyes? Blessing in disguise is that I have enough ( more than I need) new 4mm and 3 mm dead eyes already laser cut Let`s go again, third time !!!- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

From arm to leg - probably Unemployed .... ? Practice, helping her to install standing rigging OK, little digressing ... I am still far from rigging. Many details on main deck has to be done. First - cleaning white panels and mounting dead eyes which is next move. It will take a time. Then: lockers, 2 x WC, hatch - couple, pumps, winches and ... life boats - four of them ... and many little tiny things on main deck. After that - bowsprit, masts and spars with full equipment, and then, after couple of millenniums, standing rigging. Long way to run. But, I am not in hurry. Rather a bit impatient. God thing is that I expect my skills to grow until rope-work begins And thinking ... it seems usual to think forward when you are doing some kind of boring and monotonous job on your model, particularly if it repeats- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Let`s do some exercise with a pair of ropes, for beginning ... Nai Ni Chen ... She exactly knows what she`s doing- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Soldiers ready to march on their places Final painting and fine-tuning done. Rounded shackle have got second white acrylic layer ( white acrylic is semi-transparent, and second painting was necessary). After that, all of dead eyes have got thin layer of acrylic mat varnish ( two reasons: I use feature of acrylic to plasticize, for: 1. getting stronger connection between shackle and wood; 2. to use feature of acrylic to penetrate into wood and to make it harder. I wrote earlier that I make some kind of mistake choosing type of wood for laser cutting, and it really need to be a bit stronger.) At final, every hole in dead eyes was "re-drilled" with sharpen top of toothpick. Also I wrote earlier, laser drilled holes were not pierced through, and I had to correct all holes. Now, after painting and varnishing, I had to remove excess of paint and varnish from every hole from both sides. If I do not, rope can not pass through, and it can be huge problem when rigging time comes.- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Best Paint Brush?

NenadM replied to mikiek's topic in Painting, finishing and weathering products and techniques

I use quality no-name thin brushes of natural hair, and paint Acrylic in several, but thin layers, even large hull surfaces. Acrylic "eat" them fast, no matter how good you take care of brushes, and if you have to do precise work, change them from time to time -

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

You are quite right, my friend. when I saw MSW member`s Sudomekh 50% larger Ariel model, with details ... toilet in WC cabin ... I got ideas ... Thanks Patrick. Patience is not my main attribute ... rather opposite, but I am well trained animal ... I am rather an action man than "sit and think", often faster than it has to be ... and very very stubborn and persistent man ... but life puts me in line ... almost ... sometimes working with my clients I must have steel nerves, court hearings request calm person, fully concentrated, with ability of brain to work fast with multitasking ... hard business meetings with delicate theme also ... all looks like complicated chess party which often need patience, and learned me patience ...so, I think all is a matter of willpower and commintment ... and training Thank you Piet. I think you overstate a bit. Shackles are not exactly as I planned, but ... who cares, they aresmall, situated and almost hidden under rail, and they can be seen only when you lay your head on deck. Happy for me for this ... if there are outside dead-eyes, I could probably learn hard soldering earlier than I need- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.