-

Posts

1,650 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SJSoane

-

MIchael, Nice clamps! You are a genius, as usual, in thinking about and making tools. I still use the fence setting gauge I made based on your ideas. What is the dimple in the top of the fixed jaw for? Was it part of the machining process? druxy may have put you onto a business opportunity. I just saw that they sell for $24.95 for 2 on MicroMark... Mark

-

Mike, I picked up one of those benders you are showing a number of years ago, and didn't have much luck with it. But I didn't really know what I was doing back then. I soaked the planks, then tried bending around the aluminum former. They mostly burned or broke. You have inspired me to try it again, if I can find it in the bottom of my stored-away-because I never thought I would use them again-tool box. So are you sliding the aluminum head back and forth along the whole length of the desired curved section, before finally hooking it and bending it? Mark

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

Hi druxey, As I look forward to finally planking the 4" strakes around the gun ports, I am looking at your adjustments at the port heads and cills. Was there a rule about the angle at which the easing up or down came into the port corner? It looks more like a function of length than angle... And thanks, Mark, I'll look into the Micromark catalog. I have had those brass clamps for years, and this is the first time I ever used them. They are very well made, a joy to use! I did file off the flairs at the ends, which are meant to keep the sliding jaw from sliding off altogether. But sliding them off allows me to insert the bare bar from outboard, and then sliding up the jaw from inboard. Otherwise, can't make them fit through the ports! Mark

-

A quick update this morning. I realized that I was making life too complicated, using those screw-on planking clamps. They are fiddly, getting the right spacer behind them to create even clamping pressure on the face of the black strake. And they are soft metal, and began bending when I tightened things up. So I turned instead to some small brass clamps I bought years ago and never used. They go right through the ports and give nice, even clamping pressure. I don't remember where I got those, should probably get some more if I can remember. I may be able to use these for much of the planking, since everything is within reach of a port, one way or another. Mark

-

Hi Mike, The wood blocks are great for working on the edges, because they don't allow any rounding over of the edge. But sanding the surfaces where there are multiple planks to level would probably benefit from cork. I have some old flat sanding blocks I might be able to re-purpose and see how this works. Thanks for the idea! Mark

-

Hi Mike, I look forward to hearing more about your plank bending experiments. My efforts with a soldering iron bender were entirely failures! Mark

- 969 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

While waiting for glue to dry on the black strake on the port side, I thought a little more about working more efficiently as I embark on a lot of planking at this point. I have found the curved sanding blocks to be essential for obtaining smoothly faired edges for planks. And the radius reduces as I go higher on the ship's side, so I need multiple radius blocks. I finally filled out a few missing radiuses and then organized the group so I can find a desired radius easily. The little crescent on the side indicates concave or convex, not so clear at the larger radius sizes. I have accidentally started sanding with the wrong one on occasion, so now these are clearly indicated. These are made, by the way, by drawing the desired curve on the wood with an old, almost antique, set of drafting curves (although the curve can also be drawn by other usual drafting methods). I then bandsaw down the curve, and put sandpaper on one side. This is used to level the other side, and then the sandpaper is switched to the finished block and used to level down the mating block. Sliding well along relative to each other ensures a perfectly radiused arc. I was also taking a long time to rough in the planks with files, and I realized that I was often using too fine a file even though I have coarser files in my collection. It was too hard to sort through the files drawer to find the next one in the sequence. So I organized them in a little box at the desk from coarse to fine. Now I can move very quickly along, not searching for the next finest file. I also rediscovered one of the first tools I ever bought many years ago, a hand clamp with leather pads, and a wedge to tighten (see previous photo in background). My fingertips were being sanded down by holding the planks in my fingers against the curved sanding blocks. This hand clamp will firmly hold even the narrowest plank, and it sure saves on the fingers. It is also easier to see the angle at which I am sanding, when I need to bevel. All for now. The glue is dry. Mark

-

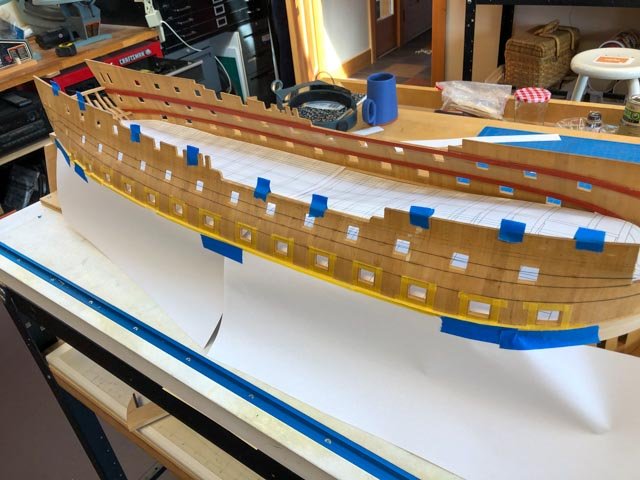

Snow just fell for the first time, one of the earliest times on record. News reports are predicting an "historic storm" in Northwest Montana. Which means, more time in the shop! I just completed the black strake on the starboard side. Because the sheer line rises faster than the gundeck and therefore the ports, the black strake eventually crossed right through gunports, leaving only short pieces between ports. My gunport stop jigs worked well here. Wedged into adjacent ports, this gave me the angle to sand on the Byrnes disk sander at both ends, and then I just sanded lightly at one end until the plank slid exactly into place. The aftmost plank had a bit of a twist, so needed bedding down with a larger clamp across the stern. The difference in thicknesses between the main wale and the black strake has left a gratifyingly consistent sliver of light, showing that they are parallel and not wavy relative to each other. Hopefully, the 4" plank on top of the black strake will form an equally even sliver of light. Now if only I don't have to snowplow for too long tomorrow morning, I will start on the port side. By the way, I received an important insight into animal behavior today. The ship's cat sleeps all day, except for the exact moments when I apply glue to something and need to work quickly without interruption to apply clamps. These are the exact moments when the cat wakes up and demands food. How do they know?🙂 Best wishes, Mark

-

A few more hours in the shop sneaked in. Installing the black strake is going better than I expected. Careful preparation with a sanding thicknesser on the wales has so far ensured that the highlight of light at the top of the wale is pretty even along the face of the black strake. That was my biggest concern, a wavy edge between the two. So far, so good.... Mark

-

Greg, I understand old Hollywood actresses always had their photos taken with a softening filter, to ease away the imperfections. You would never see the imperfections in real life, but in artificially close up photos, the imperfections showed. I wonder if ultra close up photos of the old Admiralty models would show greater imperfections than we see with the naked eye. If so, I think the model ship building community should use softening filters for all of our ultra close up photos. Fair is fair...😀 Mark

-

Hi druxey, Thanks, this confirms my thought that the widening of a wale up or down would be thinned to the adjacent planking, to maintain the smooth run of the wale edge. This becomes especially interesting in the Bellona, because both wales are significantly cut into by ports, given the greater sheer in the wales relative to the sheer of the decks. The wales and ports are interacting quite a bit. Nice view of your project, by the way! Mark

-

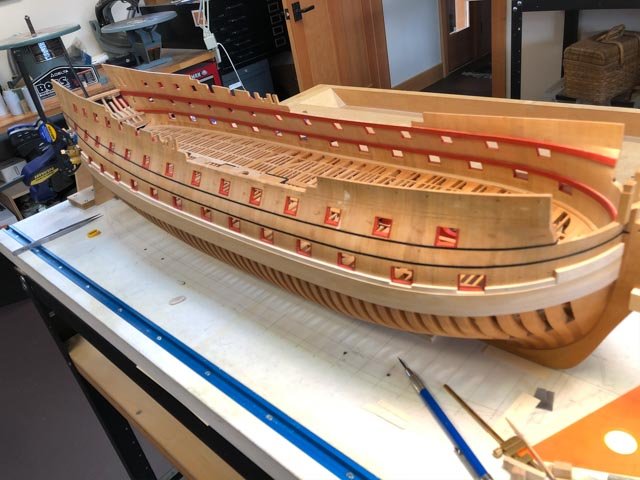

Thanks, druxey, Marc and Vane. I think this is probably more common that I would have thought, to live for the process more than the finished product! And also, projects that last decades... In between numerous summer visitors, I have slowly been working on the black strake above the main wale. A few points of possible interest in the photo below: 1. I finally settled on the black artist tape for locating the run of planking. I kept dislodging the string when messing with measuring the plank widths, and fitting the pieces. The tape allowed me to draw a firm and continuous pencil line on the hull, which enables me to move the tape back to the right position when it dislodges. On my solid hull, the tape pulls smoothly for developing a fair line and gives me an accurate line at any point on the hull; for plank on bulkheads, or an accurately framed model with spaces between the frames, I imagine the string will work equally effectively in marking at intervals on the frame. Each to his or her own, I imagine. 2. See the little wedge of planking under the first porthole. In principle, the wale below should have raised up to the edge of the port to avoid this skinny wedge. But after looking at numerous Admiralty framed models, I have seen not a single example of the wales--main or channel-- raised up or down to portholes to avoid this problem. I can only imagine that the wale did raise up or down, but it was thinned down to the adjacent planking at these points so as not to interrupt the flow of the wales. The end result visually is a thin wedge above or below ports. That is my story and I am sticking to it! 3. The offset of just 1 ½" in thickness between the main wale and the black strake means that there is a very fine reveal between the two. The slightest variation in thickness for either, or an inadequately clamped glue job, will show as a wavy, varying width in the reveal. To help ensure absolutely even clamping, I turned to some planking clamps I bought from Micro-Mark many years ago. They screw into the hull, and closely spaced they really pull the black strake evenly to the hull. The hole will obviously be covered up by later planking higher up. I did have to modify them, with a card pad on the clamping side, and a thicknesser above the screw to ensure that clamp grabbed evenly all the way across the plank. 4. I may have to make up a special sanding block to sand both the main wale and the black strake at the same time, ensuring a constant reveal between the two. We will see how close it is before I resort to this. Best wishes, Mark

-

Thanks, Greg, that makes sense. So you chose to start with stock larger than the diameter of the round portion so that you could trim down exactly to the diameter, rather than trying to cut the round part to the exact dimension of the square portion. Mark

-

Greg, Sweet tiller! How, exactly, did you hold it when you trimmed it in the Byrnes tablesaw? Before or after it was bent? Mark

-

Hi Vane and Marc, Thanks so much for your kind comments. I looked up in my log book, and reminded myself that I decided to build an Admiralty model while I was visiting the Maritime Museum in London in 1988, choosing the Bellona because I like the look of mid 18th century ships the best, and I was able to obtain Lavery's book on the Bellona. I spent the next 10 years--off and on--redrawing the ship from ¼" to 3/16" with the limited resources I had at the time, and began construction June 5, 1998. And since that time, I have been able to work on it off and on, sometimes putting it away for months or a year at a time. So I started drawing 31 years ago, and constructing 21 years ago, with gaps in between. I am not sure if I am unusual in this regard, but I would have to acknowledge at this point that I am only going to build one ship in my lifetime (other than a wood kit of a schooner I built when I was 16). I think I am about 2/3rds done, and at my current rate of progress I am likely going to need another 10-15 years. This project obviously became much more than just building a model of the Bellona. I decided early on that I wanted to craft my model as well as the Admiralty models I saw in London, even though I had no particular skill in this when I started. So building the model also involved learning through doing, and thinking hard about how to accomplish something at a higher level of skill than I had at any given time. This meant it went very, very slowly as I built jigs or practiced skills while tackling a new aspect of the build. And throwing away a lot of efforts that didn't meet my standard. Also, when I started, I had access to very little information about how these ships were constructed. So throughout the years, as more information became available--particularly thanks to this website--I have had to go back and rework things already made, or redraw things not yet made, to accomplish a model as close to the original Admiralty models as possible. At the risk of sounding like a cliché, this project really has become more about the journey than the end. I enjoy the learning and puzzle-solving as much as the construction, and working away in the shop is almost like a meditation period--a focus on a familiar yet always challenging project. I can't quite imagine what life would be like without the Bellona to work on. I will have to hold off gluing on the last part until the very end! Mark

-

As we start to approach the end of summer, lots of things get in the way of working on the ship. I am almost looking forward to winter.... I did manage to stain all of the port sides and cills. I had to remove the string showing the run of the planking to do so, and just for fun, tried showing the run of planking with artist's 1/16" tape, as shown in Chuck's planking tutorial. It seems to work well either way, with some advantages and disadvantages on my solid hull. The string required gluing on, leaving little lumps at the glue spots, and it is harder initially to pull it into a fair line; but it is easier to push and pull it into place for a fair line before the glue sets. The artist's tape is easier to pull into an almost fair line, but harder to move for adjustments because the adhesive sticks immediately. I had to run a scalpel along the tape in places to release the adhesive, pull into a fairer line, and then press down. My hull frame is starting to look a little ratty after all of these years of banging around, and I look forward to covering this up with some nice clean planking! Mark

-

I finally got things organized enough to stain the port sides and cills. This stain at the edges and top will be overlapped by planking, so it was not essential to keep a neat edge. But I thought that I might be staring at this for some time to come, since I am so slow in construction, and so I decided it would help my morale if it looked neat at this point. I therefore masked the edges with Tamiyo tape, leaving a little beyond the 3" that will be revealed by the planks. I also blocked out with paper, just in case I got messy. And then I used my normal red stain, wiping on with a cloth. Messing around with this dislodged my thread planking lines, making this look all ahoo. I need to clean this up before FINALLY beginning planking... Mark

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.