-

Posts

1,655 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SJSoane

-

Thank you, Alan and Mike, for encouraging incremental posts on the wales construction. Here is the next phase. The sternmost planks of the wales were more challenging than I had expected, with the wicked twist to the stern counter. I haven't followed up on using a heat gun for bending, so had to wait overnight a few times for the steam bending to dry. I used artists' graphite paper to fit one plank to another. Squeeze the joint together with the paper in between, pull the paper through, and it shows highlights that need to be filed or sanded down. The last hi res photos shows how accurate this can be (thanks, Greg, for encouraging me into the occasional hi res photo). I also made long sanding sticks shaped to the curve of the wales (first photo), which help even up the lower edge ready for the next strake below. I can see that sanding the wale to the counter is going to be challenging, avoiding accidentally marring the finished counter surface. I will leave these a little proud and turn the hull upside down for final shaping when both full wales are in. I can't see clearly enough what is happening with filing when the hull is upright. I think I had better start on the port side before tackling the lower two strakes on the starboard side, just in case I start getting differential pull between the now constrained starboard side and the still unconstrained port side as the humidity changes. Mark

-

Hi Gary, As I look ahead a step on the Bellona, I noticed that Brian Lavery's book in the ship calls for two black strakes above the main wales, reducing, he notes, from 6 ¾" to 5 ½" with a step between them. But every other source I can find, including your Alfred build, shows just one black strake. Can you point me to a source for the size of the black strake as you researched it? Best wishes, Mark

-

Gary, Worth the wait. The Alfred is looking terrific! I swear by your batten idea for aligning major planking. It helps spot where lines are not quite sweet, and I don't know how I would have aligned the wales without this. Your photos show how well this is working for the Alfred. And the cheeks dramatically add to the character at the bow. I am sure they must have been pretty fussy to install, particularly the upper one with a scarph in the middle of a change in direction for the curve. Nicely done. Mark

-

Hi Alan, Looking nice! I remember just how slow it felt to be gluing on one frame after another, and the length of the hull looked so long in the unfinished part. The center frames were most tedious for me, because the shape was not changing much to make it interesting. And my frames were much less work than yours! It did seem to speed up towards the end, perhaps because one could sense that the end was near... Mark

-

Hi Greg, Yes, I removed the pads on the clamps to get maximum opening, and it just, just fit. My bigger clamp would have crunched the hull. That is an impressive twist! Michael was also talking about hot air guns, and I had hoped Santa might bring one at Christmas, but alas no. Which one are you using? So do you shape this over the hull while blowing hot air, or do you bend off the hull and periodically check for fit? Mark

-

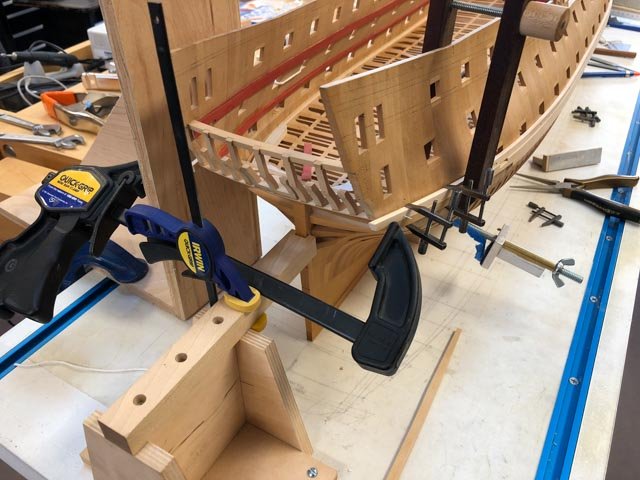

I apologize in advance if my incremental postings on installing the wales are getting too tedious. When I looked around for information on installing wales, there were many unanswered questions on some of these details. So in the spirit of helping others see some of the issues involved as I work through them, here is another unexpected one. The top plank at the stern takes a fair twist in the vertical direction, in addition to the curve in the horizontal direction. I intended to steam and clamp the top two planks, and then follow David Antscherl's advice in the Fully Framed Model to carve the lowest 2 strakes to fit the very wicked curve further down. Then I discovered the problem of how to clamp the upper planks, first for steaming, and then for gluing. Clamps from the top or bottom cannot reach the plank, and a clamp across the stern slips off due to the extreme curvature of the sides. So in the best traditions of Rube Goldberg, I clamped a right angle device to the table, which gave a surface parallel to the keel to clamp to on the left. I then had to place a small clamp on the device holding the sternpost, to keep the horizontal clamp from slipping away on the right. It is holding the piece in place after steaming; tomorrow I will find out if this will also work for gluing the piece on. I realized that this pulled the hull out of true on the table top, and it will have to be re-leveled before I start marking up for subsequent work on the hull. Mark

-

Hi John, Marc, yes, this model of the Bellona is absolutely captivating. I have studied photos of it for years, had a chance to examine it close up, and it still sings to me after all these years. The the lines of the ship, the exposed methods of construction, the assured craftsmanship of the model and its 250 year old patina, make this a timeless classic. As best I understand from the various Brian Lavery writings about this model, it was likely used as a demonstration or study for some proposed changes in the hull framing system. One side is framed in a conventional way, and the other side proposes a potentially stronger but more expensive way to run frames from keel to top with fewer interruptions. One side is partially planked, the other has no planking. druxey can probably give you a better understanding of the ribbands, the thin bands running longitudinally. They were removed as planking proceeded up the hull, and were initially used to align and fair the frames. Ed Tosti's books on the Naiad frigate illustrate how useful these were for keeping the hull together and aligned before the more permanent longitudinal structural pieces like wales, spirketting, deck clamps, planking, etc., finally locked everything together. It is interesting in the Bellona model that parts of planking are inserted between the ribbands, since these would not have been in the same place at the same time in the actual construction. I supppose they needed the ribbands to hold the model together, but wanted to suggest the actual lines of planking on one side while primarily concentrating on showing the framing system. I did not concern myself with ribbands on my model, because the stylized admiralty or dockyard framing system locks the frames together with no spaces between. This causes expansion and contraction problems with humidity changes, as I discussed earlier, but it does away with the need for ribbands. Best wishes, Mark

-

Hi Gary, Your idea of battens is brilliant. It helps see the curve better than any other idea I tried, it provides a solid surface to check the upper curve of the planks against while sanding them to a final shape, and a firm clamping surface for the final installation. I will definitely use this idea for the upper works. Hi res photos are uncomfortable; I admire Ed even more for posting these all the time. They show more than the eyes can see, and they reveal that one's craftsmanship is not as good as one thought. A little humbling. Maybe I can figured out a resolution for photos that exactly matches the level of detail that I can see without magnification... Looking forward to seeing your progress on the Alfred! Mark

-

Hi druxey, A few years ago in Denver, I put a humidifier in the shop and it didn't seem to make a huge difference. But I did manage to start rust on tools, so I quit. Moving to Montana certainly has helped with higher humidity. Maybe the Admiralty models did not have this problem because it is more reliably damp in London more of the time.🙂 My posted picture raises a new question that I have not yet faced on this project. This plank is cut by the gunport. I started filing to fit before installation, and then it occurred to me that I ought to be using the gunport itself as a guide for filing the piece to final fit after it is glued in. This will be the same situation with all of the planking when it hits the sides of the ports. Are there any best practices for filing to the port without accidentally filing the side of the port itself? Masking tape on the inside faces of the ports? Mark

-

Hi Greg, I am like an aging film star; no closeups, soft filters on the lens required! But in a Hollywood-like expose, here to reveal all, is a closeup of the plank I just glued one, before sanding. You can see all my dark secrets. The re-drilling of the temporary batten, the stain on the hull that has been there for 10 years and I have no idea where it came from, and most important, the seams opening up between frames in places. These seams open up in the winter, with the lower humidity, and close in the summer. This is a classic problem of cross grain construction, where the wood expands and contracts much more at right angles to the grain than it does lengthwise. I measured this seasonal change at 3/16" to ¼" over the length of the hull. Good wood construction argues for avoiding this, or using slotted screw holes on wood at right angles to the grain; otherwise, the construction can tear itself apart. This is obviously not possible in this project, with deck clamps, wales, spirketting, planking all glued on at right angles to the frames. But several centuries of this construction methods seems to have worked, and I hope it will work for me. The humidity shifts are not nearly as severe here in Montana as they were in Colorado, so I see less annual movement already. And cross fingers, the planking above the wales still to come should cover up my other dark secrets... Best wishes, Mark

-

I am making steady progress on the wales. My old clamps are proving quite serviceable for this; I have started to run them through gunports as I get further astern and they no longer reach from below. The last photo shows why Gary's idea of a batten is such a good one. There are numerous little pieces around the pierced gunports, and I can see they will easily go astray without a constant guide from stem to stern including going over the gunports. Mark

-

Ed, Would the reason for this ingenious fixed yard and double topsail be that it would take fewer men to manage the sails (smaller surface to handle, more subtle adjustments possible)? Beautiful craftsmanship! Mark

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Gary, I did not think this through many years ago, when I got all exciting about putting in the gundeck before messing with the wales. I can see the value at this point of doing the wales first, since my framing system does not easily allow of clamps above the wales. But there is always a way, if only we stop to think about it a while! Mark

-

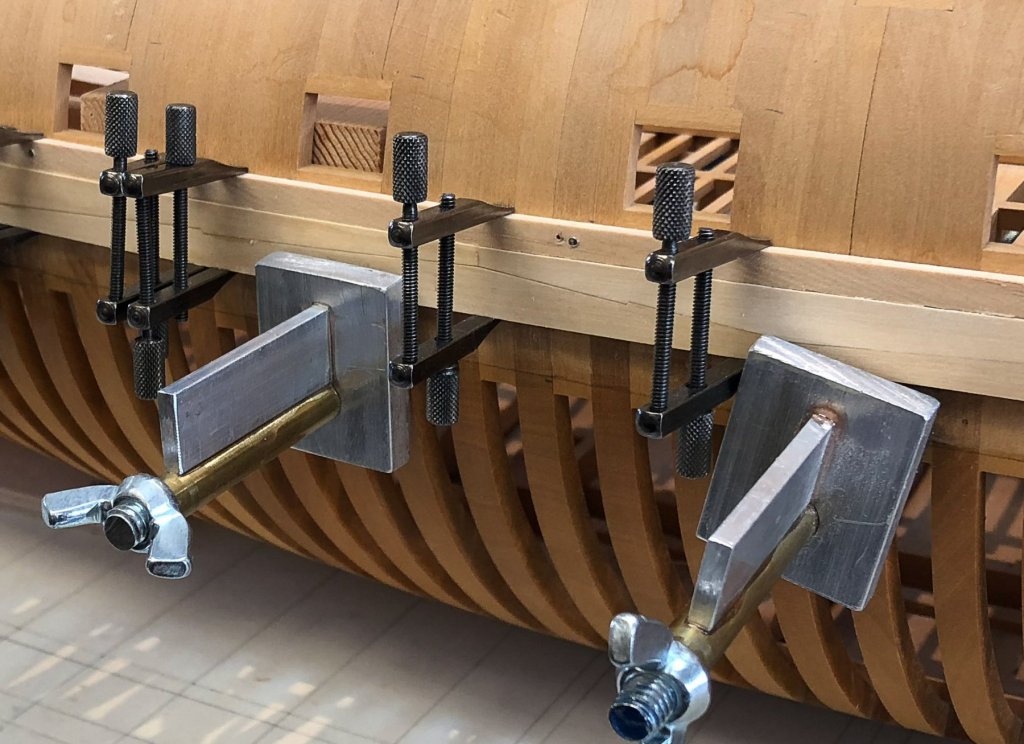

Thank you, Marc, for your words of encouragement, and I enjoyed your tag line of "we are all works in progress, all of the time." Applies to us and our models. Once I rounded the bows and began placing planks further aft, I realized that the wale dips below the lower gundeck at midships; and therefore, my clamps from above would no longer work. So I rummaged through my box of old tools, and recovered the clamps I had made almost 20 years ago to clamp up the growing sandwich of frames in the admiralty framing system. I ran these through the open frames athwartships, and they worked perfectly to clamp from below. I just have to be very careful not to nick the frames when I pass the threaded rod through. I wrapped them in tape to help avoid the worst damage. Mark

-

Hi Sailor, As John points out, the hooks give greater strength to the wales, preventing them from sliding fore and aft relative to each other. As I understand it, the ships tended to droop at the head and stern--this is called "hogging"--due to the greater buoyancy at midships relative to the two ends. The wale curves up to help counteract this hogging. The wales are in tension, pulled along their lengths, to resist the hogging. And so the hooks help keep the wales from pulling apart along their lengths when they are under strain. Even on the model, these provide surprisingly effective longitudinal strength. I understand the hooks were only used on larger ships, presumably due to the greater forces at play on a longer hull. Mark

-

Thanks, Mark, for the kind comment. I continue to be inspired by your phrase, "The shipwright is slow, but the wood is patient." That applies to me big time! Even with more time to commit to the project, it still seems to take me forever to get each piece on the hull. And thanks, Siggi, for the update on the collections in London. It sounds like they might finally do the right thing and put more of that priceless collection on display. And I look forward to seeing your new project, the 60 gun 1745 establishment. Will it be a full hull? Best, Mark

-

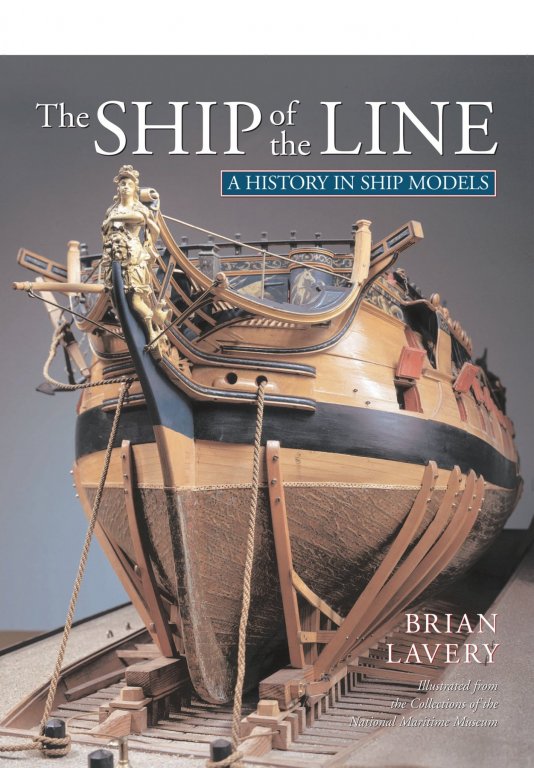

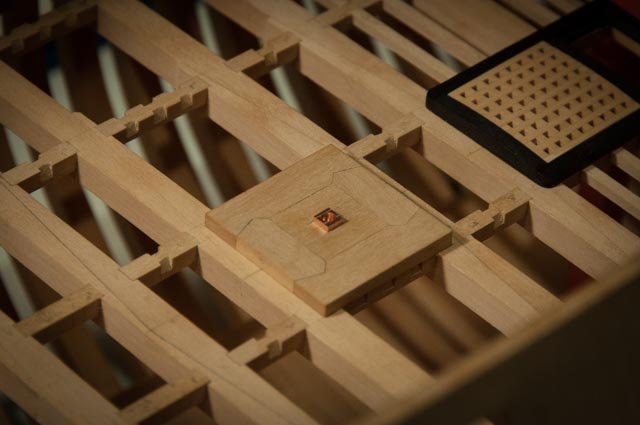

Thanks, Gary and druxey, you both helped me get this far! Håkan, although I am only a few months into retirement, I highly recommend it. A friend described retirement as this: "remember a sunny, summer day during your year between 8th and 9th grade (12-14 years old). That is retirement". Mike, good question about highlighting the joints. I have gone back and forth on this over the years, wanting to show off the joinery, but also thinking about the effect of scale. Looking at a model at 3/16"scale is like looking at the real ship from a good distance away, where joints would not show prominently, if at all. For the same reason, I have been using tinted colors so far, to keep it from looking too intense. At a little distance, a real ships colors are more muted due to the atmospheric effect. My boxing joint at the foot of the stem is an example of no highlighting (2nd photo). However, I did put some pencil graphite in the joints of the capstan step (3rd photo). I may do more of this. But for the wales, I think it will not show anyway. Looking at the 2nd model of the Bellona (shown on the cover of Brian Lavery's book below), the wales are pretty black and uniformly smooth, even with the more muted colors on the gunports and the fore bulkhead. I considered Ed Tosti's solution for his Naiad, which was a dark brown color, but I fancy staying closer to the 18th century model I am emulating. I am taking Ed's advice, and putting together a test panel to try the black stain on the joinery, to see how it looks before settling this altogether. So how will I feel if I put all this work into the joinery, and it does not show except very close up? It is a little like all of the great detail that many projects on this website put into lower decks, knowing that they will never be seen again. At least the ship modeler knows the details are there! I am open to thoughts about this. Best wishes, Mark The Lavery book it at: https://www.amazon.com/Ship-Line-History-Models/dp/1591141877/ref=sr_1_1?ie=UTF8&qid=1516232652&sr=8-1&keywords=The+Ship+of+the+Line%3A+A+History+in+Ship+Models

-

The first planks of the wales are on, so far, so good. They are a little oversize in thickness to allow for leveling later, but the hooked joints are tight. These were the most challenging pieces I have installed so far on this project, with compound curves and tight tolerances on the hooked joints. Mark

-

Gary, you are so right about doing things a couple of times to finally figure out what you are doing. Now if we had all had apprenticeships with a master model builder when we were young, we might have been able to avoid a few mistakes later in life, but not all... Mark

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.