-

Posts

867 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SaltyScot

-

You have made good progress, Phil. I commend you on being able to get all those tiny pieces looking the same!

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

Great to hear from you, Trevor! Yes, I will be following Phil's sound advice (I have already laid those two extra booms aside that I cut this morning). It is now my belief that one could take various tomes to hand and find conflicting ideas about any nautical subject in most of them. History is just like that.

- 257 replies

-

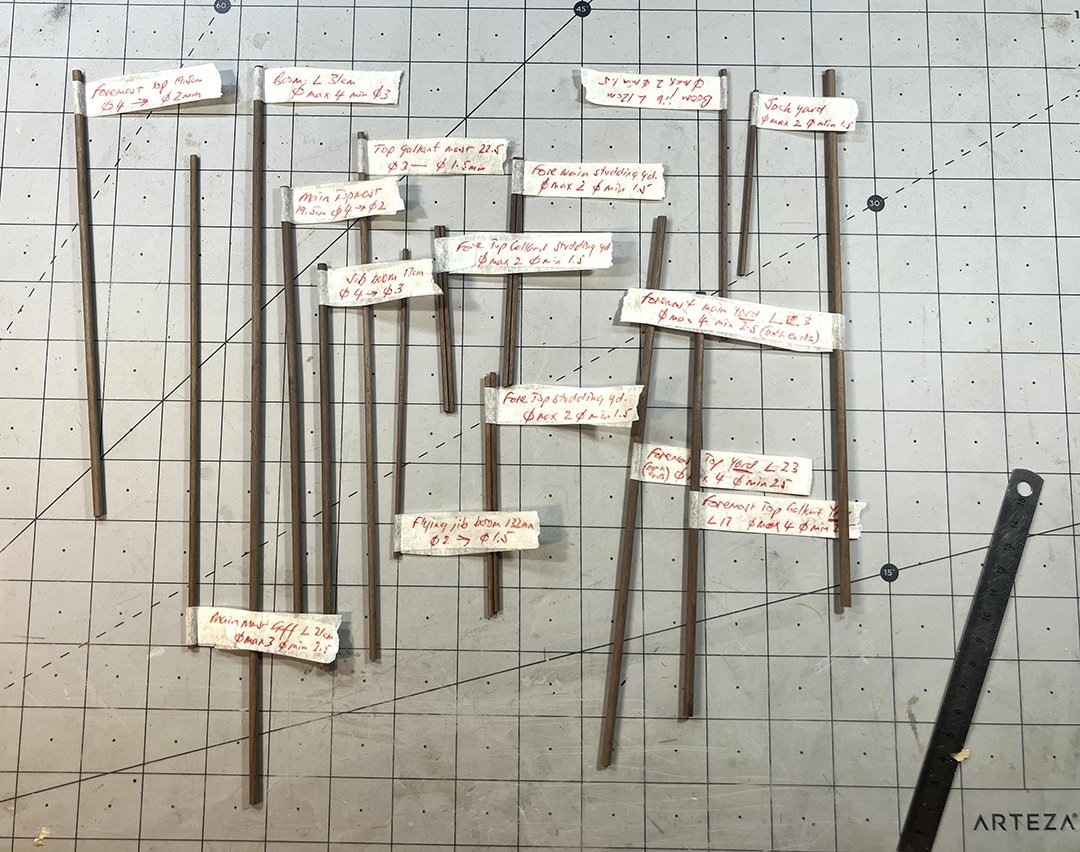

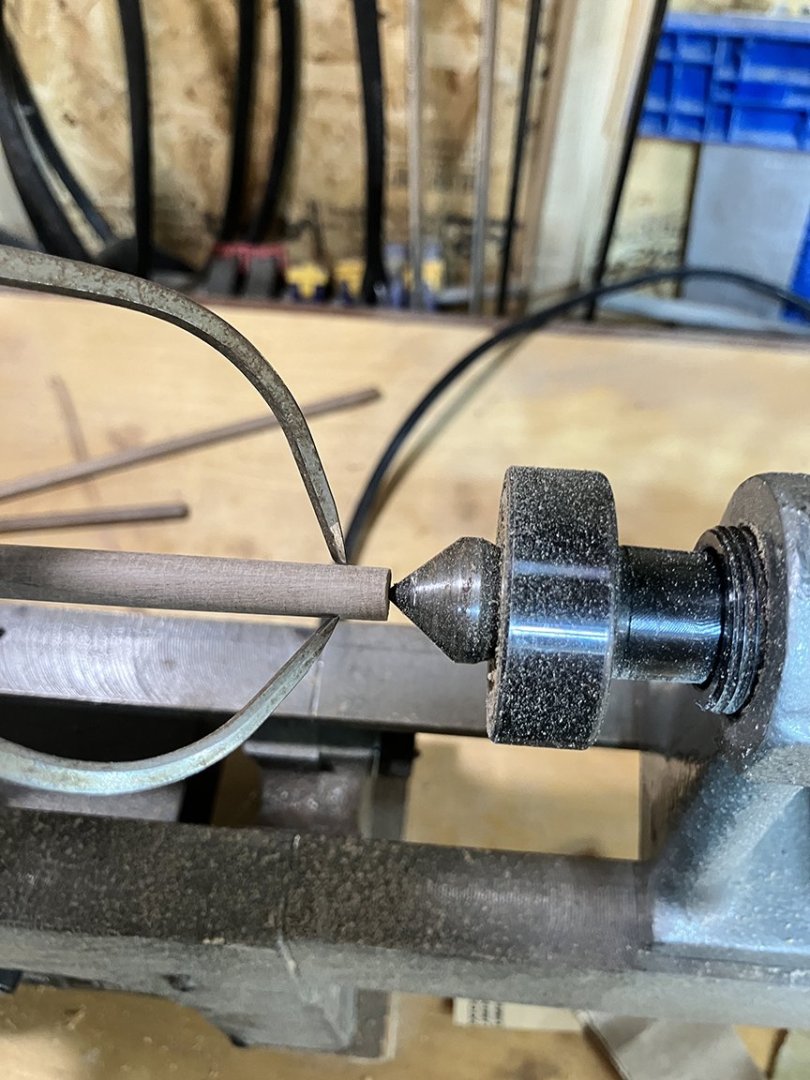

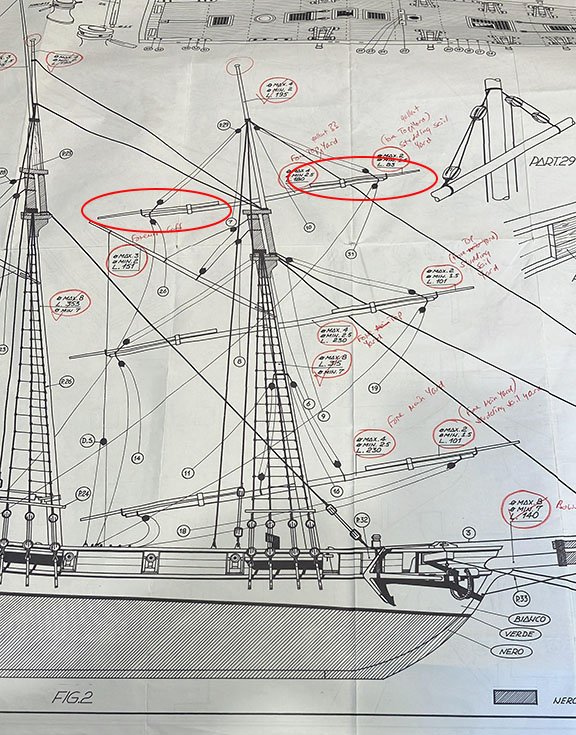

Today was mast and spar day. While it was still comparatively cool this morning (82F 🤨), I decided to sand down the masts and bowsprit on my lathe. I also wanted to sand down the yards and boom while I was over in the wood shop. After measuring, cutting and labeling the yards, I took them over to be worked on: The more astute amongst you will notice that some of the labels are not correctly named. I have since resolved that issue after talking to @Dr PR and clarifying the correct terminology for a few of the pieces (thank you again, Phil!). The masts and bowsprit were sanded down on my lathe: And checked with a set of calipers adjusted to the corresponding width: For the smaller yards I used a slightly different method that worked just as well as long as I did not let the wood "run free". I had to keep the sandpaper in contact with it so that it didn't flex: Once the temperature got just too unbearable and reached the forecasted 93F I shut down the shop (which has no a/c .... yet), and came back inside to the comfort of my shipyard to get on with other small tasks. Among other things I made the hawse hole covers that will be fitted to the hull tomorrow: A WORD OF WARNING TO THOSE FOLLOWING THIS AND BUILDING THE SAME KIT: The plans on the second sheet show the rigging for this model. @Dr PR was kind enough to point out a flaw in these plans when I shared them with him regarding a separate issue. Below is an image of the plans with the parts in question outlined with a red ellipse. Underneath the image is what Phil said about them: The drawing you posted has a peculiarity - probably a mistake. It shows studding sail booms at the ends of the upper yard. But these booms were fitted only on the yards at the bottom of the studding sail. Since there is not a fourth yard above the topgallant yard (the royal yard) there would not have been a studding sail above the topgallant yard. Therefore there would not be a studding sail boom on the topgallant yard. The foot of a studding sail was attached to the studding sail boom. The head of the studding sail was attached to the studding sail yard. This yard was raised with the studding sail halliard through a block on the end of the yard (yard arm) above. There was no studding sail boom on the highest yard. For your model there should be studding sail booms on only the lower two yards. I am truly grateful for his insight and willingness to help out us newbies

- 257 replies

-

Actually, I have two of them Steve. A friend of ours wanted a felled black walnut tree out of her yard and asked around if anyone wanted some. I have two bowl blanks like this and some more off-cut pieces. So yes, plenty of raw material. I just love the smell of black walnut sawdust when you are working the wood!

- 257 replies

-

Right? You can't shape it at all. it just falls apart. A lot of the fittings are the same and will be scratch built as well. Fun times!

- 257 replies

-

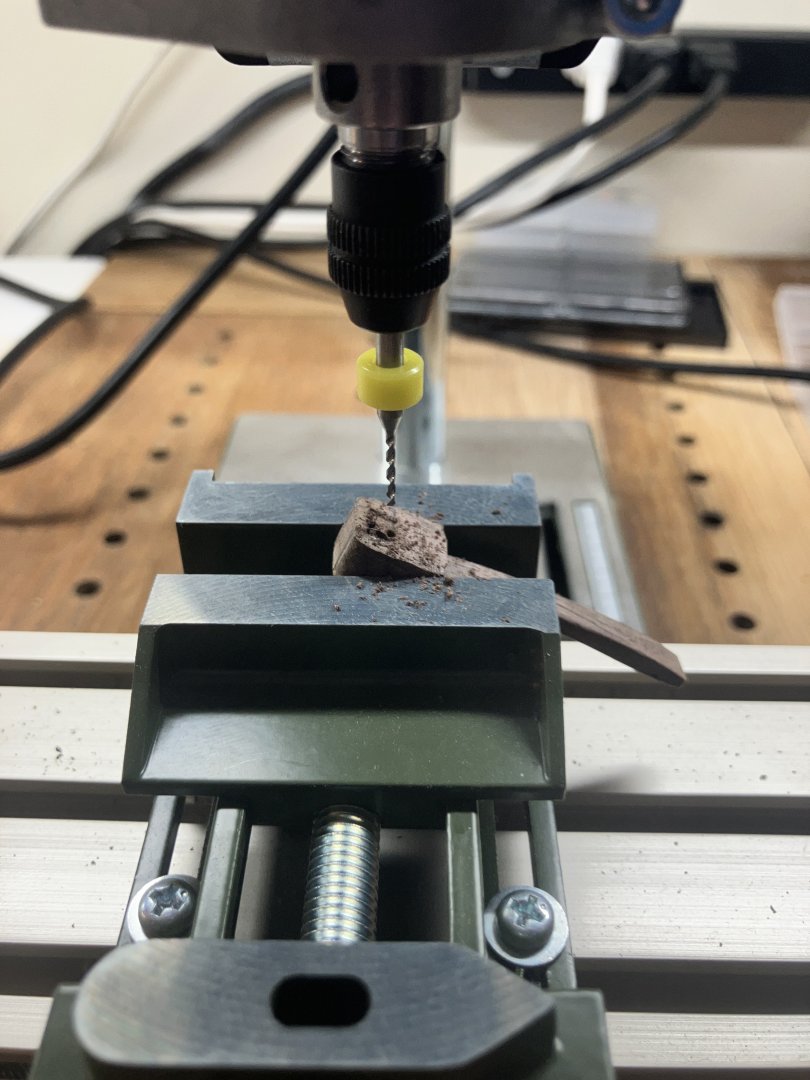

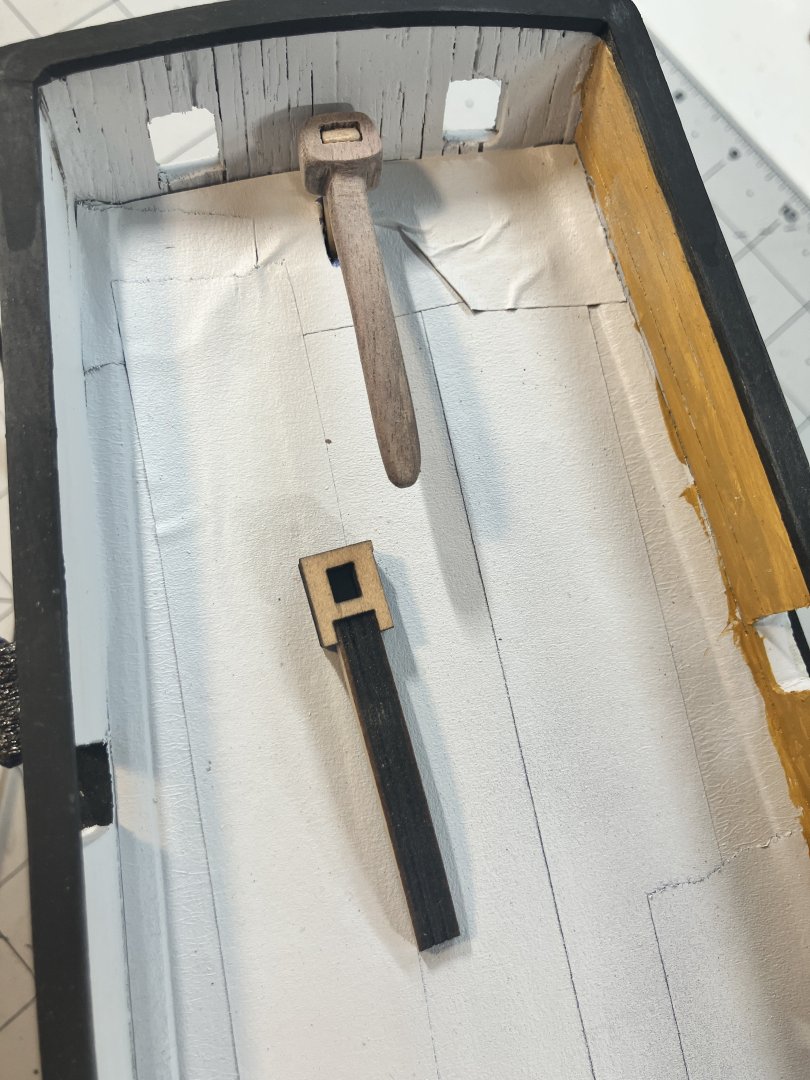

Tiller time. I wanted to make the tiller out of walnut. I had a piece of black walnut bowl stock I had turned down in the workshop that was no longer needed so I cut a piece off: The piece was cut down to size and shaped using the kit supplied plywood piece as a template: I then took it to my drill and drilled out the slanted hole for the rudder head: The remaining wood was removed with the Exacto knife and the tiller shaped to fit:

- 257 replies

-

I haven't looked in in a while, Phil but WOW is she looking good. Very nice job there, sir.

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

Your attention to detail is mind blowing, Phil. Even though this isn't the type of model I would build particularly (because I have ZERO knowledge of them), I am interested in how you tackle certain aspects of the build. It's fun to follow along for sure.

- 482 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

You should be proud of this, Gary. She is a fine looking vessel!

- 121 replies

-

- Lucia A Simpson

- AJ Fisher

-

(and 1 more)

Tagged with:

-

I agree, those CAD drawings are very good, Phil. In case I missed it, are these models going to be 3D or resin printed?

- 482 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

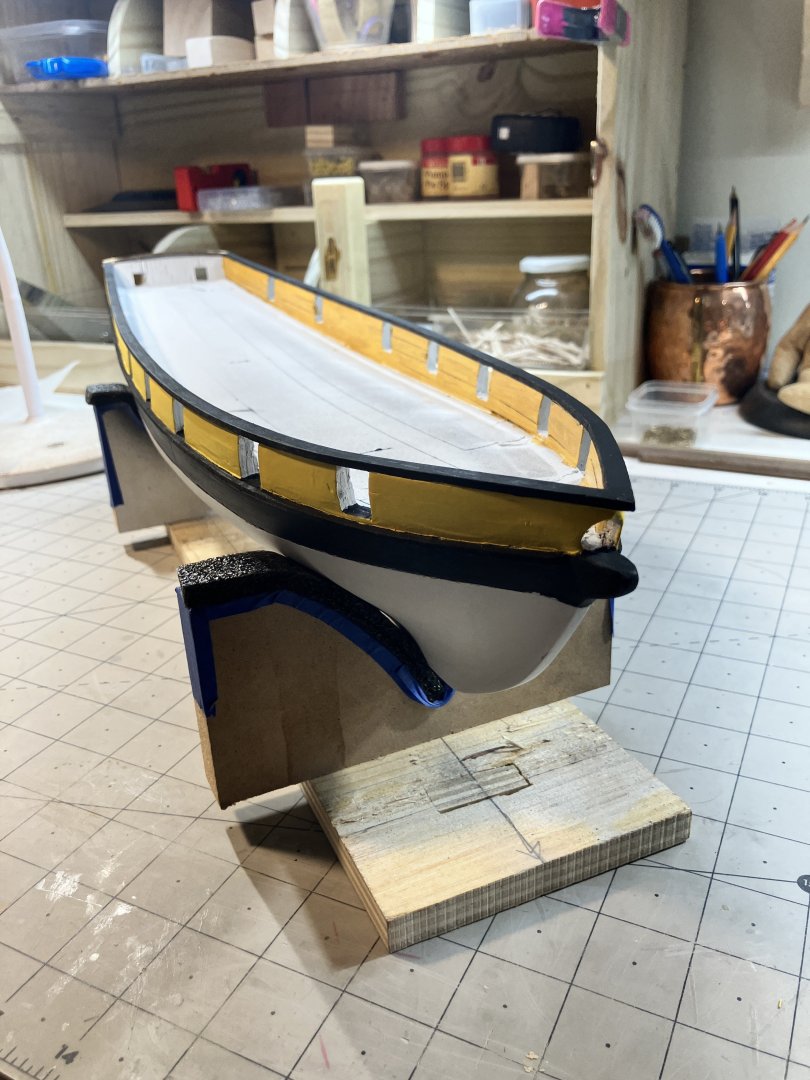

A small update. Because I have been hopping in and out of the shipyard in between my other activities this summer, I have made little progress and didn't really take the time to catalog that with a bunch of images. I was really only working on the hull and paintwork so there wasn't a lot to tell. I have given the build a lick of paint which still needs refining, added the cap and fender rails (as previously stated) and put a primer of yellow ochre on the interior bulwarks. I am still deciding if I like that color. This is how she looks at this point in time:

- 257 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.