cookster

Members-

Posts

416 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by cookster

-

Good going Rich, glad you're getting the hang of it!

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Looks good Augie! Ignore my words of sarcasm... Until you plank around those gunports (inside and out!)

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Enjoy framing your gunports Augie, I know I did... NOT!!

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

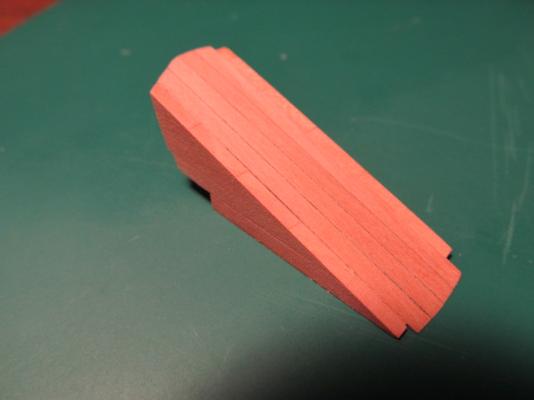

Here's the steps. I'm not sure how historically accurate this is, but it works for me and I like it And I LOVE working with this pear wood... If any of you that haven't tried hardwoods are on the fence about it, by all means do it!!! You'll love it,,, Here's what I'm after... Another dry dock shot...

-

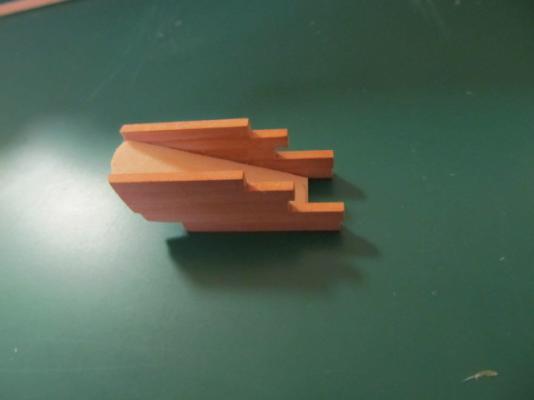

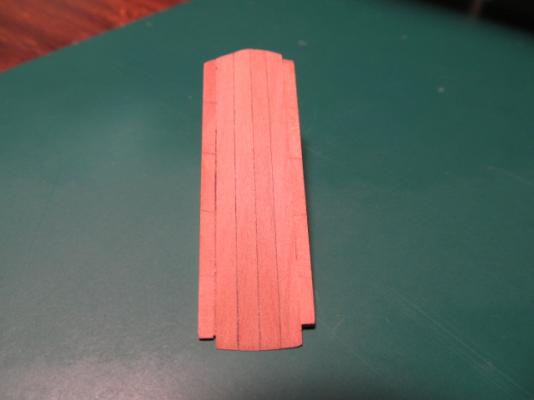

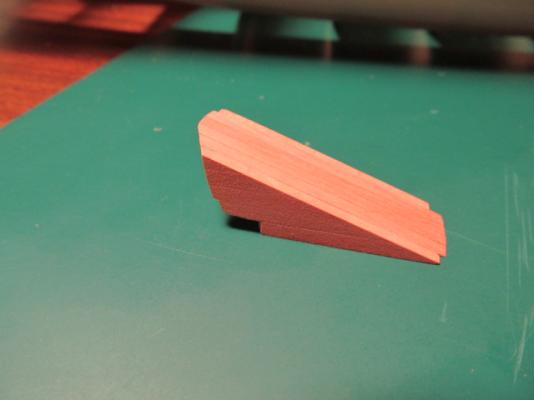

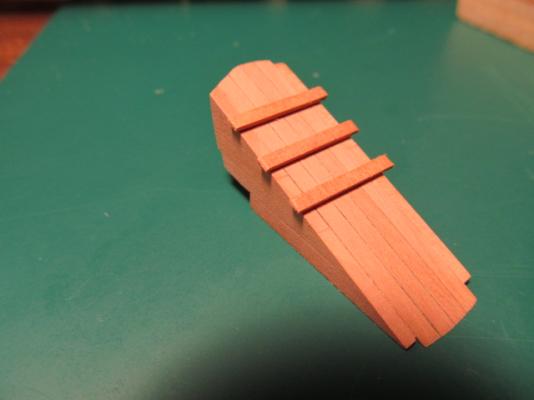

OK, here's the bowsprit steps Glued up the sides and trimed to fit the bow bullwarks I glued the sides together with a piece of basswood as a spacer to fit over the bowsprit Then added the planks Finished... Almost Still have to add the step treads, but I'm saving that for later until I get the bow rail on and make sure there's no fit issues

-

Wow, thanks for all the compliments! Not sure I deserve them though.... Patrick - Perfect?? not sure about that but thanks for saying! Guess I should've said steps TO the bowsprit. See the image from the Hull model. Any of you that have, or have built, the Revell Conny might remember them. I'm pretty sure they're accurate to 1812'ish, but were removed sometime later. I'm just "winging it" based on my old Revell model and making it fit. About halfway done at this point.... No pics yet

-

Jeff at Hobbymill had a wood package to replace the wood needed for deck furniture, planking etc. The last time I looked at his website it wasn't listed but if you contact him I bet he'd make one up for you! And of course you can buy anything else you need. I also bought some boxwood to replace the catheads and to try my hand a carving one of these days...

-

coming right along Augie! Looking good...

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

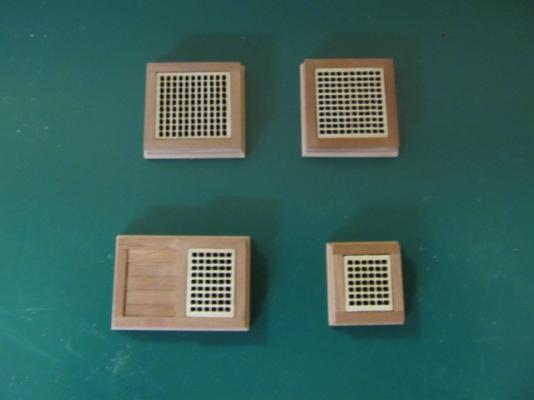

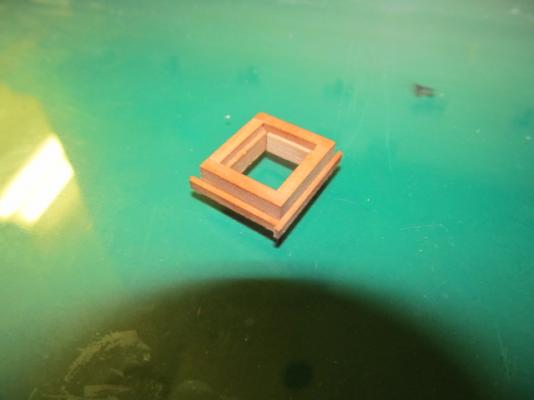

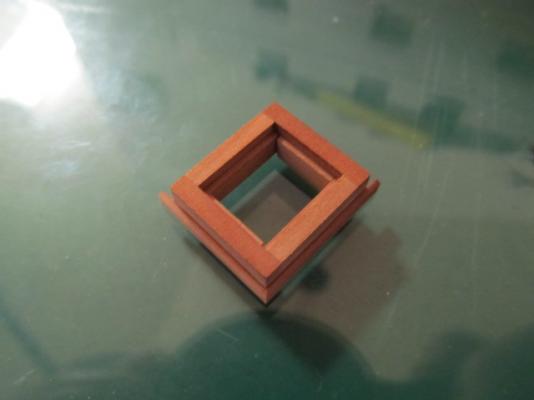

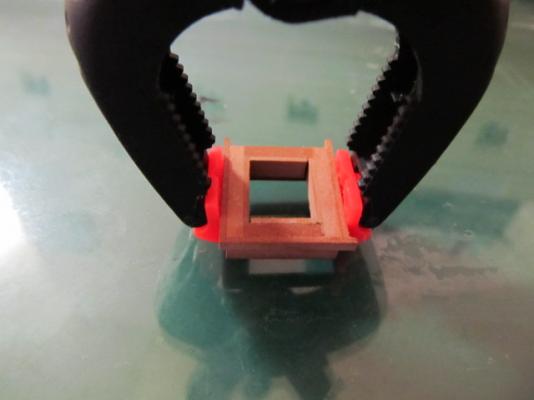

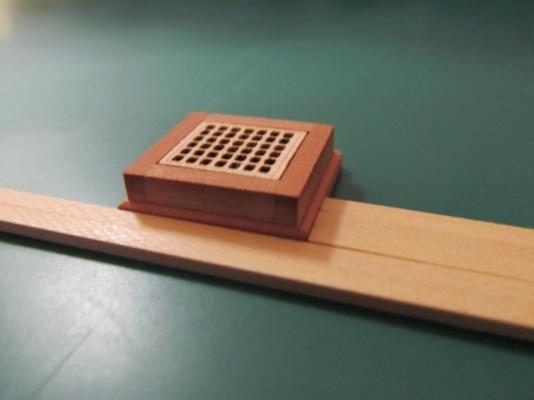

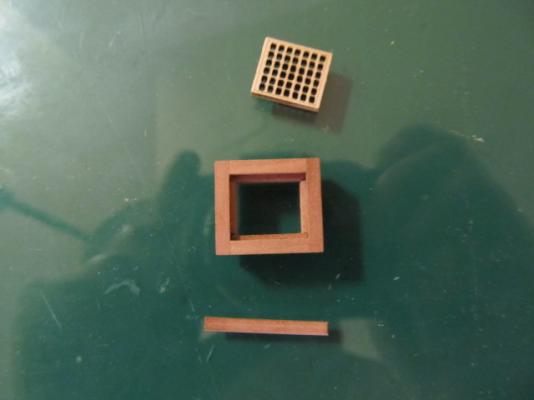

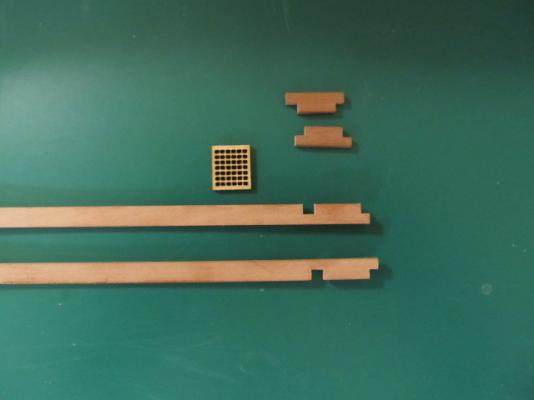

OK, got the first coaming done. (thanks to Lambsbk for reminding me of my ship's terminology!) I was worried about making these little rascals but this one really weren't that bad! Anyway, I added the trim pieces ran long to come back and trim down later. Trimmed and dressed the edge. glued the rest on And finished it up. Laid down some boxwood planking to see how the finished install will look, and of course couldn't resist setting in it's future home... Now on to the rest of the coamings....

-

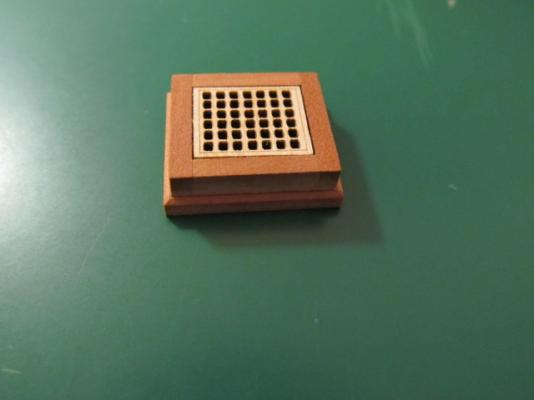

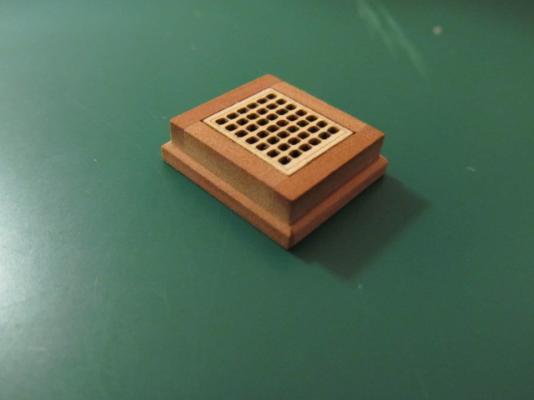

With planking temporarily put on hold to save my sanity, I moved to deck furniture. Finally get to use some pear wood, very nice stuff!! This is the first hatch cover, they"re all built basically the same as far as methods... I cut the half lap joints with my 10" table saw. Overkill? Yes, but I don't have a Jim Saw yet and I do love my power tools.... Once the half laps were cut I cut each piece to length (a little long) with a hobby miter box. Then I assembled the boxes and trimmed the excess with a knife blade, and added the support pieces on the inside for the grate. I still have to attach the small trim piece on each side. Will post pics of that when finished.

-

sander.... sander..... sander..... err wait, in my case it's Jim Saw... Jim Saw....Jim Saw....

- 2,191 replies

-

- confederacy

- Model Shipways

-

(and 1 more)

Tagged with:

-

Doing good Rich! Glad you enjoy a good challenge, you picked the right hobby for that!

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Thanks Augie, your Confed is coming along quickly. I had visions of starting mine and trying to keep pace with you - but not now! Rich, not sure what to tell you about your stem. I do know mounting the stem first with the rabbet it creates makes a great way to insert the planks at the stem. The three models I have are all Model Shipways and all share that feature. Maybe some of our more experienced builders can chime in and help you on that one!

-

Essex - Process and corrections to the new Model Expo Kit

cookster replied to samueljr's topic in Wood ship model kits

Thanks Sam! -

Hey, I'm a sub Lieutenant! Not much to report other that more planking. I finally got tired of it and decided to work on the deck, fitting masts etc. Thought I'd snap a couple pic while she's sitting in drydock on the bench. That odd bend at the first upper gunport is some kind of optical illusion, it doesn't actually look like that.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.