-

Posts

1,002 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Wintergreen

-

HMS Renard 1872 by Draque - 1/24 - POF

Wintergreen replied to Draque's topic in - Build logs for subjects built 1851 - 1900

Take your time and it will probably come out nicer. I also got the numbers wrong about room and space. It's the other way around, frames are 210 mm "sided" and space between is 240mm. Also, the moulded dimension would lessen going up from the keel so that the frame don't look top heavy. On Atlantica they go from ca 300 at the keel to 120mm at the deck line or sheer if you like. -

HMS Renard 1872 by Draque - 1/24 - POF

Wintergreen replied to Draque's topic in - Build logs for subjects built 1851 - 1900

Cheers Michael! Renard is quite similar in size to what I'm currently building. Even though Atlantica was build 1980 she is a direct descendant from Gratitude, built 1907. So not so far from 1872 when Renards was built. My point is that the discussion about framing pattern with room and space equal to each other is plausible. On Atlantica the frames are 240 and the space is 210 mm. -

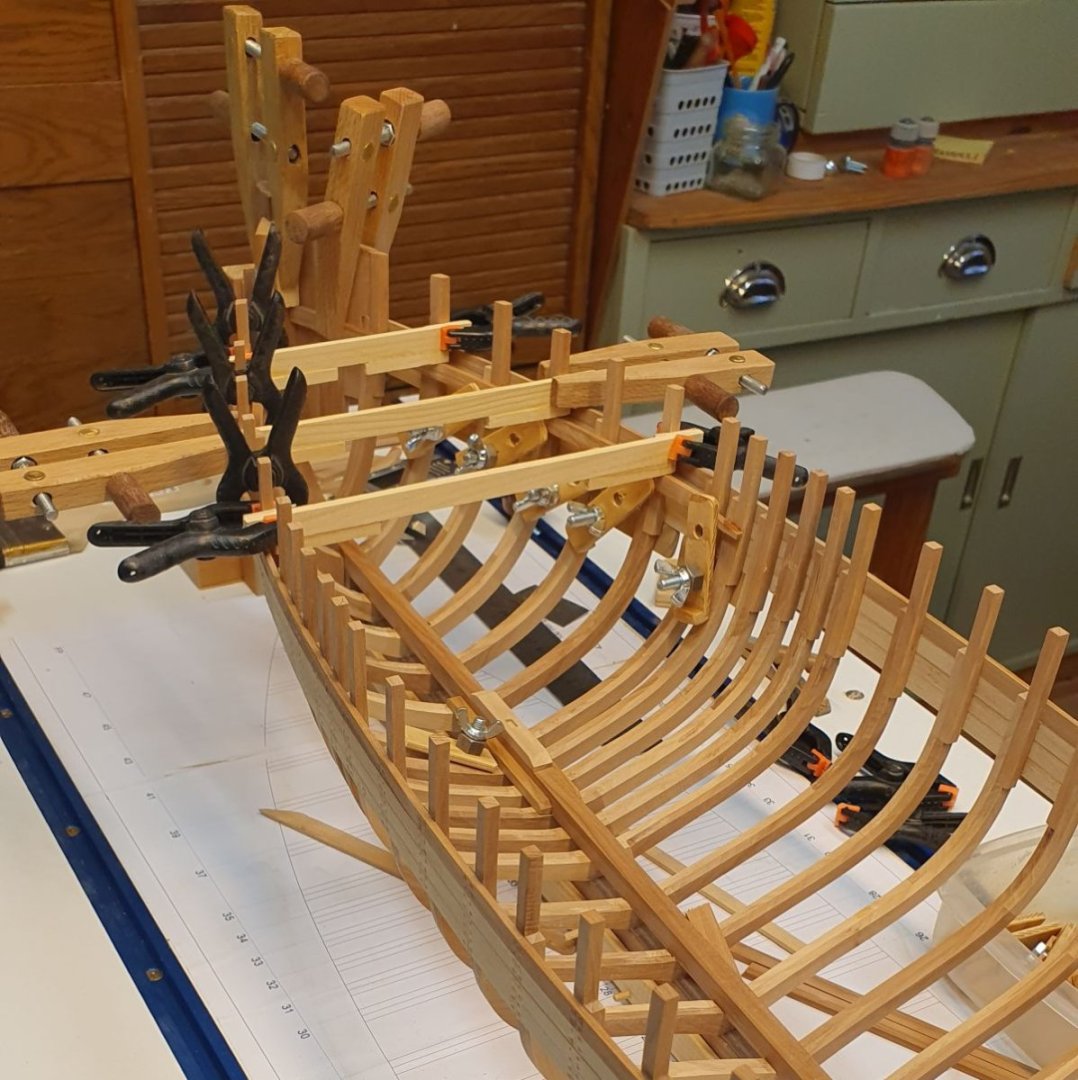

Thanks for likes and comments 🙂 And as promised, here are the last two pieces of the beam shelf. I didn't get the shape entirely correct on the starboard one, but it will be covered by the deck, so no big deal. Port side. and starboard side There is also a check seen, but since the piece didn't go "crack" when bent in place (steamed first) I let it be. And an overall shot as well. That will be all as far as the interior goes. Beam shelf and two stringers. On the real ship there were a couple of stringers at the turn of the bilge apart from the slats to cover the frames. Next up will be deck beams. But that is for another day. Cheers!

-

Thank you Keith! Yes, it turned out really neat. Probably 10 or so test fit for each scarph with minute filing in between. The last two joints came out decent, not more due to the acute curvature in the aft section. Pictures are coming soon. Thank you B.E! I'm glad to provide eye candy for you. 🙂 Better make the most of it since the hull will eventually be fully planked. 😉

-

Wow! I guess the crew was already used to be ruled by a "Frankenstein" even before they were selected for rowing duty 😄 What a little gem you have produced B.E. Hat or no hat, off should it be for your accomplishment 🙂

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thank you Tony and others that have "liked" 🙂 Work continued... not so much to read here today so I'll just treat the audience with some progress pictures. And here in the last photo are some cro-moly "treenails" that won't shear anytime soon... Yup, drill bits. It all went really well until.. Never mind, I'm quite well stocked with drill bits for the moment. Pax et bonum, friends!

-

Good choice having the crew to change from blue to off white shirts. The blue didn't blend well with the red lining. Lucky they had extras 😉 Yes, I've read that too, that the crew had to supply their own garments and clothing. Harsh, when you're already poor and called for duty by demand of the Admiralty.

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

EURYALUS 1803 by Peter6172 - 1:48

Wintergreen replied to Peter6172's topic in - Build logs for subjects built 1801 - 1850

Peter, hats off for undertaking such a project! I would be very reluctant if it was me. There are just so many different aspects of taking over/finishing someone else work. In fact I was approached one time with the prospect of inherit the work from a friends father, but the hull did not appeal to me at all so I gave it a pass. The Euryalus volumes sits in my library waiting ... so, in the meantime I'll tag along here. 🙂 Happy new year, mate! -

Agreed druxey. She was strong though and could separate herself from the disease. anyhow.. Happy new year to us all! Let me take a moment to explain what is going on in the above picture... I have come to realize that, to get a consistent and satisfying result when building from scratch jigs and fixtures are instrumental. Above the two first parts of the beam shelf are being worked on. The starboard side is glued and fixed and the port side await its turn. The beam shelf sits ca 160 mm beneath the sheer and the sheer is defined by the top outboard strake. As can be imagined the beam shelf needs to be edge bent as well with some degree of force. So, the pine boards (cross members) have a 5mm tab glued to them and also some double adhesive tape to make them unwilling to move. At the stem a stump of correct height is held in place by a large clamp in order to meet up with the front end of the beams. With this setup it was quite easy to force the beam in place up against the pine tabs. The keen eyed viewer can also see the mast step and supporting beams are glued in place. After trunnels and some cleaning it looks like below. A note on the tree nails. On the original the following bolt dimensions where used: entire keel structure - 1"/25mm other places of stress - 3/4"/19mm planks, beams aso - 5/8"/16mm For example, hull planks where fastened with 16mm, but I've used 0,8mm (24mm real world dimension). Mainly for two reasons, 1, drawing bamboo down to 0,8 mm is quite simple. Going the extra mile to get down to 0,53 mm (or 0,5mm to match drill bit size) adds quite some time and effort. 2, I think of it like simulating the bolt head, which of course is at least twice the bolt diameter in size. 3, inside won't be seen and outside will be painted... Then of course there is the discussion of with type of glue to use... For the hull planks I used medium CA and for the beams PVA. And the reasoning is that the outside will be sanded and painted and I therefore don't need to be bothered of residue. The interior will be hidden and not painted, but I still want it to look nice and PVA washes away easily with water.

-

Yep, looking good there, they are. Of course a lot of work and sore fingers, but worth it. Adding a crew makes the whole piece more alive, I like it.

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thank you @Jaager for a serious answer to a silly question. I was joking about the balsa as an option. Please don't put me on your s**t-list for not being totally clear about that. I am well aware of its shortcomings and its uses, which are few. Like you and John say - good for filler on POB builds but that's about it. And yes, I did put myself in the hurt-locker with the frames being a bit oversize. So I knew all along what I had coming to me. The outside of the hull was faired with power tools. Both my circular orbital sander and my orbital corner sander (sanding pad like a swollen triangle) made a somewhat quick job. The inside is another matter and I have opted out for using power tools there. It would be far to easy to char areas unintentionally. Hence manual labour instead. On a more philosophical level I try to balance my use of power tools for a couple of reasons. They are for the most part noisy. (yes I do use hearing protection extensively but I appreciate the silence in my shop) They produce a lot of dust and spreads it into the atmosphere (yes, I have a shop vac connected as far as possible, but still, it is not feasible at all times to connect a bulky hose) I like working with my hands and f.ex. a sharp chisel removes wood fast and clean. About sand paper or their alike. I agree there too with you Jaager. Grit 100-120 is for removal. The rest of the spectrum is more or less to get rid of the scratches from the previous step. Of course, smaller things can be sanded to spec using 150-180, or even 240. But in my current case with the frames, even 80 could be an option to start with. Thanks again for comments.

-

I hope that is expressed in a positive way, Keith 😉 (tongue in cheek). 😄 Thank you John, plodding along here. Been sanding away here since last time. Not much to show. Note to self - I need to learn how to build closer to specs or maybe it is my drafting skills that is lacking or maybe I should study the original plans more thoroughly. Or maybe it's all of the above. It is about the moulded widths of the frames at the sheer line. (Correct me if I'm wrong, but moulded isn't that the athwart-ships dimension, like from the station line inwards right?). After some measurements I've agreed on that dimension being 120 mm, or 4 mm to scale. The frame tops that the shipwrights roughly has hewn from the stock was closer to 180 mm or 6 mm to scale. Hence, Quite. a. Lot. Of. Sanding needed. Maybe I should have chosen balsa instead of apple? Any takers? The tree nails in the above picture is too prominent thanks to not being sanded flush. I've just chiseled them close at this stage. I think I'm satisfied with port side and as prophesied earlier, starboard will get another treatment with 100-120-150-180-240 and finally 320 grit paper. When the fingers needed a break from sanding I sat down and drew sticks of bamboo through the draw plate. Another mind boggling task (ha!). But lately I have been grateful for these mundane tasks since today was the funeral of a very dear, and close friend. We sang in the same choir since 2008 until she no longer could sing a couple of years ago. Taken away way too early by ALS (like Borje Salming if you know your NHL hall of fame). Pax et bonum!

-

I guess that you will paint the outside of the hull? If so, all those imperfections will be hidden which is also a blessing for a first/early build. 🙂 Oh, another though crossed my mind, if you need inspiration for detailing, I think there are other whaleboats here on MSW. Just use the search function and you will find.

-

Well, Christmas eve is passed and handled. Unfortunately only half of the family showed up. The other half, with the two small fairies had +39 degree of fever and stayed at home. We all live in the same village so there will other opportunities to meet. Progress on Atlantica has overall been decent. Last week the traditional Christmas concert was ticked off, and all the practices leading up to it did slow down the build a bit, but now there is more time since I have taken a couple of days off as well. As stated previously, after 4 strakes each side, focus turned to the inside of the hull. In the picture below starboard side is done and I also show all the various sanding blocks I used. Started off with 100 grit paper, then 150, 180 and finally 240. The block in the center of the picture, black, long rectangular shape is the preferred one. It is actually a rubber mat, ca 4 mm thick. It is stiff, but bends and therefore follows the shape of the hull. At the inside of the stern I used the Proxxon with a sanding drum attached. Attention then moved to the port side, but I will probably revisit the starboard side later on. Oh, and then I dived down a rabbit hole... One of the frames was a bit wiggly so I decided to practice some treenailing... The hull will be painted and I made a small test piece and was happy with the result. Marking the center line of each frame, the using an awl to indent where the "bolt" will go. Without the indentation the drill bit is prone to wander which leaves an ugly result. Finally drilling with my Proxxon and a 0.8 mm drill bit. I also made a small collar to fit on the drill bit, limiting its depth capacity to ca 5,5 mm. That was done after I drilled through on a couple of occasions. Tree nails are of bamboo and glued with CA. Thanks for likes and comments!

-

Never mind @druxey Keith, he is just jealous! I am too, that is some serious needlework there. Ever thought of turning to lace sewing? Merry Christmas to you and yours!

-

What a huge improvement regarding the support for the barge! I take it that the display case and baseboard still needs some finishing touches, but, very nice indeed.

- 106 replies

-

- Admirals Barge

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.