-

Posts

1,625 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Adrieke

-

hello Bill glad you have decided to rebuild your log however you can i think you inspire many on here with your beautiful carvings

- 382 replies

-

- sovereign of the seas

- carving

-

(and 1 more)

Tagged with:

-

apart from a cheap rotary tool and a corded drill i have no powertools at all as i would like to eventualy do scratch builds i want to slowly build up the necessary tools for it so after some thinking i tought the best would be a tool to cut wooden strips and dowels to the required length at the moment i am using a mini mitre block with saw but i have noticed that especialy on thicker parts the cuts are not straight what would be the best tool to do this more easily especialy if you need to cut a fair bit to the same length it takes a while

-

Thanks John i will try do the same. its a 4 day long weekend so i should haev some time for that and get a start on the windows

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

i am really strugling with getting the handrails on the stairs. thye have to bend and twist and it seems the ca glue is not holding probably due to the staining . i have tried being carefull but the whole construction of the stairs is starting to fall apart have put them aside for now i soaked and bended the rubbing fenders for the last 2 decks also lined the stair openings the reason why i wanted to finish that is that is the last i need of the 1x4 sapely strips i had planned to use the left over of these strips to scratch build the outside frames of the 24 windows i have calculated i need about 912 mm of them and i have about 990mm left so i better not mess them up too much

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

wel thats good customer service of them

- 432 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

you know all the shiny decorations could have been to blind the enemy so they could line up their guns adn knock them over with the cotton balls you know i have come to not worry about bad plans or instructions. just evealuate it maybe do a bit of research and then decide on how it probably would have looked and go with it

-

it starts with one deck the next thing you are scratch building a whole ship @Wim i havent dealt with AL themselves but always went through the store i bought the model and so far i have had everything replaced . just needed to keep reminding them.

- 432 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

going along well John i think you can get the right shape for that deck from the big plan

- 432 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

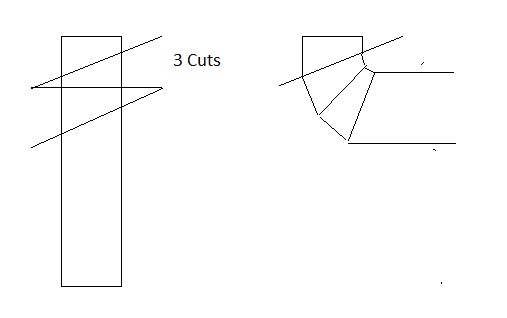

thanks Carl. my mom used to say : "haast en spoed is zelden goed" ( haste and speed are rarely good) and i keep to that and before i go ahead with the next step plan it didnt do anything tonight (birthday party for our youngest) but have been thinking about how to fix up the two smaller smoke stacks at the back. they seem to spring out of nowhere. on the second deck. i assume they go into the engine room compartment at an agnle of 90 degrees. my plan is to cut some left over dowel at about 27.5 degrees and glue 4 of these together creating a 90 degree 'elbow' .

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

lol Sjors i think we learn from eachother. although from now on he ll be steaming ahead in the lead so i can learn from him

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

thanks Sjors John has done his stairs before me Sjors i forgot to show you that i added a bit of height to the railings this makes it that the side of the stairs will not be visible through the gaps in the railing i need to smoothen that part a bit and paint it white like the rest

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

i think its his temporary case to protect his model augie

- 246 replies

-

- revell

- constitution

-

(and 2 more)

Tagged with:

-

Thanks Wim i had a look at your Mississippi and it looks great one of the reasons to show/share what techniques where used so future builders of the same model cna use and improve them.

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

a beautiful picture of her in baskign in the sunlight

- 246 replies

-

- revell

- constitution

-

(and 2 more)

Tagged with:

-

hi Carl yup a few holes a day keeps me going hi John i havent have much more prepared except the steering house also i need to see if i have enough left over wood to scratch build the windows and doors. my main concern now is making sure that i get the right curve in the ventilation window assembly as the idea is that it wil not be glued on to the 3rd deck for access to the wiring inside. once i got that right i can finish 3rd deck and steeringhouse but still lots to do before i get there

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

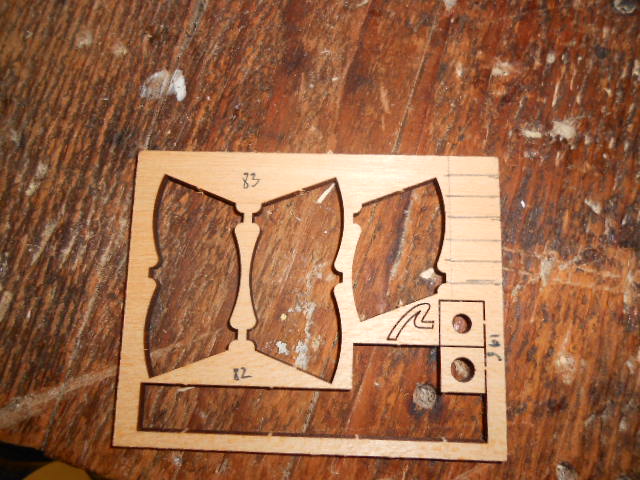

thanks John and Wim. yes this must be the hardest part on this model i actualy had more trouble with the straigth steps as each step holds on to the next only a little bit. so i had several times that a step came loose before i finaly had it done i have now added both the side railings on one of the stairs. i am going to let it dry over night just to be sure it stays together i am bending the top of the rails to prepare it for glueing it on. the other stairs need to long curvy rail to be glued on but waiting for the first one to come out alright first i had a bit of time left and drilled some more holes and glued the window framing parts on

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

thanks WIm. i thought it would be something like that

- 97 replies

-

- Turtle Ship;

- Korean Turtle War Ship

-

(and 1 more)

Tagged with:

-

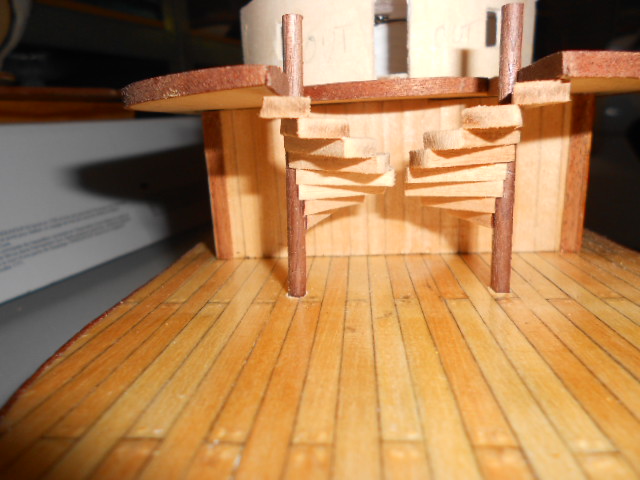

continued glued the first set to the dowel while it was on the base . the second set will easily fit on top using CA fitted them on to the ship. i previously drilled holes in the deck so that the dowels would fit the top of the rails need a bit of sanding so they dont look as square then a bit of stain . bit of fine sanding after will make them lighter finaly using the stairs themselves and the platform i assmebled the 2 straigth steps the 2 long curved railings are wrapped around a toothpick holder to curve them

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

this weekend has been all about the main stairs i have been pondering about it and lookign at how others tacled this construction they always say to cut things in bite size portions and thats what i did the curved part consist of 8 steps making 180 degrees or 2 times 4 steps making 90 degrees 4 steps seemed doable so i started preparing : i drilled some holes so that the dowels would be as deep as the point where the curved steps start from the left over from the sheet they came from i cut 6 small bits glueing them together to create a platform to rest the curved steps on while the glue dries at the base i glued a piece of strip against the middle of the dowel to push the first step against i used a metal angle bracket to measure the 90 degree angle i formed the platform a bit more so it would fit. all the elements are now ready the 4 curved steps glued in place after creating 2 sets of 4 steps i remembered i needed the others to curve the other way so i glued the base on the other side

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

very nice indeed can i ask what all the lines are on the deck ?

- 97 replies

-

- Turtle Ship;

- Korean Turtle War Ship

-

(and 1 more)

Tagged with:

-

Hi Carl no i dont have a drill standard. my workplace is pretty small so no room for tools. thank you Sjors and Wim.

- 1,038 replies

-

- King of the Mississippi

- Artesania Latina

-

(and 1 more)

Tagged with:

-

nice meeting you too John

- 432 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

i agree looks much better wiht a frame

- 432 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.