-

Posts

687 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Pete38

-

Sharpen #11 blades.....I thought you were supposed to break them before they got dull......been doing it wrong again.... Seriously though...I have not sharpened them...but I do have them saved back just in case....I can't remember if it was MSW1 or MSW2 where Dan Vadas had a thread where he went into detail on how to sharpen them (nice thread)

-

So Jim....have you made up your mind on what is next out of your shop....OSS....OSS......OSS

-

novice byrnes saw user--a couple questions

Pete38 replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

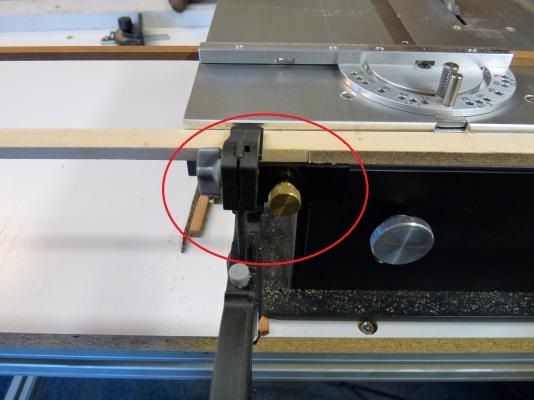

Here is my setup for longer repetitive cuts....crude but it works... The overall picture.... I am using the legos as the moment because they are very light and does not bend the wood down.... Clamp my long bar to the adjustment clamp where the rip fence goes and I can use this for moving the length just like you move the original rip fence If I ever get the time would like to make a more permanent type Maybe out of aluminum that would have a t-slot and nut for the adjustment and bold right to the rip fence adjustment.. Hope this helps someone..... -

novice byrnes saw user--a couple questions

Pete38 replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

If you are having trouble with tear out when crosscutting when the blade exits the wood....use a scrap piece behind to eliminate this...as seen in this picture I have used a couple of clamps and some wood to make a temporary installed stop that goes beyond the table...nothing fancy but it work...will try to set it up and post you a picture tomorrow.. Good Luck -

Warning points...

Pete38 replied to Torrens's topic in Using the MSW forum - **NO MODELING CONTENT IN THIS SUB-FORUM**

Look at this post...will explain it http://modelshipworl...warning +points -

Oscillating spindle sander with the option for a tilt table

-

Jim why don't you post some of your ideas from the drawing board here, as a survey and get votes for the most wanted....this may help stir up some new ideas and give you a better idea of what the market wants (just an idea) PS...a very happy customer of the Table Saw, Thickness Sander and Drawplate

-

Very nice and neat work "as usual" This will be a nice build to follow

- 421 replies

-

- granado

- bomb ketch

-

(and 2 more)

Tagged with:

-

What do you use your mill for ?

Pete38 replied to captainbob's topic in Modeling tools and Workshop Equipment

Richard..... I started the Sultan kit and never finished...moved to the Triton X-section I am working on now For the X-secion after the keel and keelson slot were cut have not used the mill much....but I have done other things with it...(making and repairing some broken metal parts around the house for me and my family) Using it for other things besides model ship building..... Would be hard to justify the cost for my model making alone.... It helps that there is no "Admiril" here to say "NO" to any purchased......or is that a bad thing.... -

What do you use your mill for ?

Pete38 replied to captainbob's topic in Modeling tools and Workshop Equipment

Here is a couple of pictures of a mill in use besides drilling. Used it to mill the keel and keelson slots in my frames for the Triton Cross Section Worked out really nice -

Small update.... I continues with the deck beams and started cutting the notches.... Then is when I realized I had fixed the problem with the wrong scaled plans 1/48 vs 1/32...but I guess I need to start reading the"BIG BOLD LETTERS" at the bottom of each page...... I was using the Gun Deck layout instead of the Lower Deck layout........This turned out okay because I am tossing all the beams and cross beams made so far and starting over with new ones....I did not like the way they were turning out....very sloppy work and the joints not looking good Here is an example of the offending joints Once I get more done I will hopefully post some pictures with better results Dain it.....Rusty and Rafine have set a very high bar for the x-section...Glad I have their build logs for reference...

-

Belt/disc sander questions

Pete38 replied to md1400cs's topic in Modeling tools and Workshop Equipment

I have had the Allwin for about a year. Not used the belt sander much and the disk if okay for what it is. If possible I would recommend saving up for a better grade sander. The Allwin will be okay till I can save up enough for the Byrnes disc sander....just my opinion -

You don't need the window open. This will just circulate the air in the room but it goes through the filter first. I had it sitting on the workbench with the window closed. Kinda of a poor man's air purifier.

-

I have my workshop in a upstairs spare bedroom, and when sanding do as Mark has said above....but also use a window box fan with filter material infront of it. Place it where I am working and it will get most of the sanding dust....plus just leave it running and it will clean the air. Here's a picture...you can see it in the background Works pretty well

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.