-

Posts

13,368 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by druxey

-

Don't post your e-address publicly - it's asking for spam! Send it by PM and delete it from this public forum.

- 1,132 replies

-

Nicely done roband there. For small scales, the simpler version is fine, but you'll impress folk by doing it correctly as you've shown.

-

It's more than likely that the beam layout varied between ships. The plan was specific to Pegasus rather than Atalanta. You've done the tight thing to be your own master shipwright. As for cumulative error, when the Admiralty inspectors come to see the work, the additional length means a larger tonnage. The contract says you are to be paid by tonnage, so you'll profit from this 'mistake'!

- 1,449 replies

-

Mid 18th Century glass

druxey replied to Mark P's topic in Building, Framing, Planking and plating a ships hull and deck

Yes, that's my understanding, Welfalk. 'Blown plate' is another name for 'cylinder glass'. There was also spun glass, which was disc-like, the pontil mark piece of the disc becoming the cheapest 'bulls-eye' seen in old panes. -

Mid 18th Century glass

druxey replied to Mark P's topic in Building, Framing, Planking and plating a ships hull and deck

This is in accord with what I've read elsewhere. Large 'blown plate' aka 'ground glass' was made by grinding and polishing 'broadsheet glass'. This accounts for its expense. Large pieces were principally used in coaches and for mirrors. Nice find, Mark! -

Frégate d'18 par Sané , la Cornélie

druxey replied to JohnE's topic in CAD and 3D Modelling/Drafting Plans with Software

Ca, c'est bon! Felicitations, John! -

They don't represent real dolphins, Siggi, but mythical ones. So - in a way - they are fantastical or imaginary.

- 58 replies

-

- barge

- ships boat

-

(and 1 more)

Tagged with:

-

Torsion would only occur if there are unequal forces acting on both sides of the shell. I've not had any issues of this nature by spiling the planking properly and pre-bending them, so that the shell is stress-free.

-

Yes, Pollex, that's the volume I was thinking of! Thanks for providing the information. hopefully, David, you can locate a copy. Try abebooks.com or Amazon. Oh, and the author is Jenson with an 'o'.

- 24 replies

-

- three sisters

- schooner

-

(and 1 more)

Tagged with:

-

I sit corrected, then! Replacing a knee of that type would involve removing decking to get at the bolts.... Thanks for an interesting exchange, everyone.

- 649 replies

-

- dunbrody

- famine ship

-

(and 2 more)

Tagged with:

-

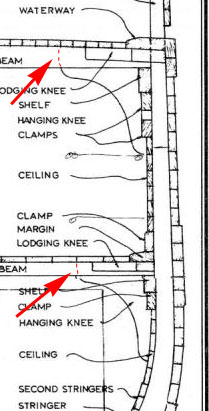

I've no wish to quibble, but the knees, fitted as shown, would be weak. My interpretation is that we are looking at the beam closer to the viewer and the athwartships arms of the knees are hidden. As modified, the illustration shows what was standard wooden ship practice. The bolts would run horizontally through the beam and the lodging knees would interlock with the hanging knees.

- 649 replies

-

- dunbrody

- famine ship

-

(and 2 more)

Tagged with:

-

Rivets imply iron or steel construction, Frank.

- 649 replies

-

- dunbrody

- famine ship

-

(and 2 more)

Tagged with:

-

Lovely work, but usually hanging knees attach to the sides of beams, not under them. Are you sure that this was not the case here?

- 649 replies

-

- dunbrody

- famine ship

-

(and 2 more)

Tagged with:

-

"Ve haf vays of keeping you vertical..." Those supports look like instruments of persuasion! However, they obviously do the job well. Good stuff!

- 525 replies

-

- anchor hoy

- hoy

-

(and 1 more)

Tagged with:

-

I guess I missed all your updates since April until now, Clare.How did you manage to fly under the radar? Anyway, catching up, your model looks terrific. Coming late to the table, I agree that, while Morope looks great, it has those major drawbacks discussed. Syren line behaves in a much more civilized way.

-

Pandora by marsalv - FINISHED - 1:52

druxey replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

Nice smithy work! I like the bolt heads and roves flanking the ports. -

Try starting with a small block, carved to shape and fitted to the model. You can then wrap paper around it to get the expanded view of the railing.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.