-

Posts

157 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by John Maguire

-

-

-

- Duanelaker and mtaylor

-

2

2

-

I overlooked Chuck's plain warning to be sure to remove laser burn from the ends of the floors. I glued without reading that section of the instructions at the time I was working and forgot that I had read it on earlier studies. As Chuck says, if you don't do it, it creates a bit of a challenge later . . .

Fortunately, a tiny diamond stud file got me out of trouble in an hour. I have the keel attached to the rear section of frames and am ready to glue the forward end but have paused to RTFM again.

-

-

Wow, that is stunning . . .

-

- Ryland Craze, Rustyj, JeffT and 4 others

-

7

7

-

Additional tasking at the Cougar Mountain Shipyard . . .

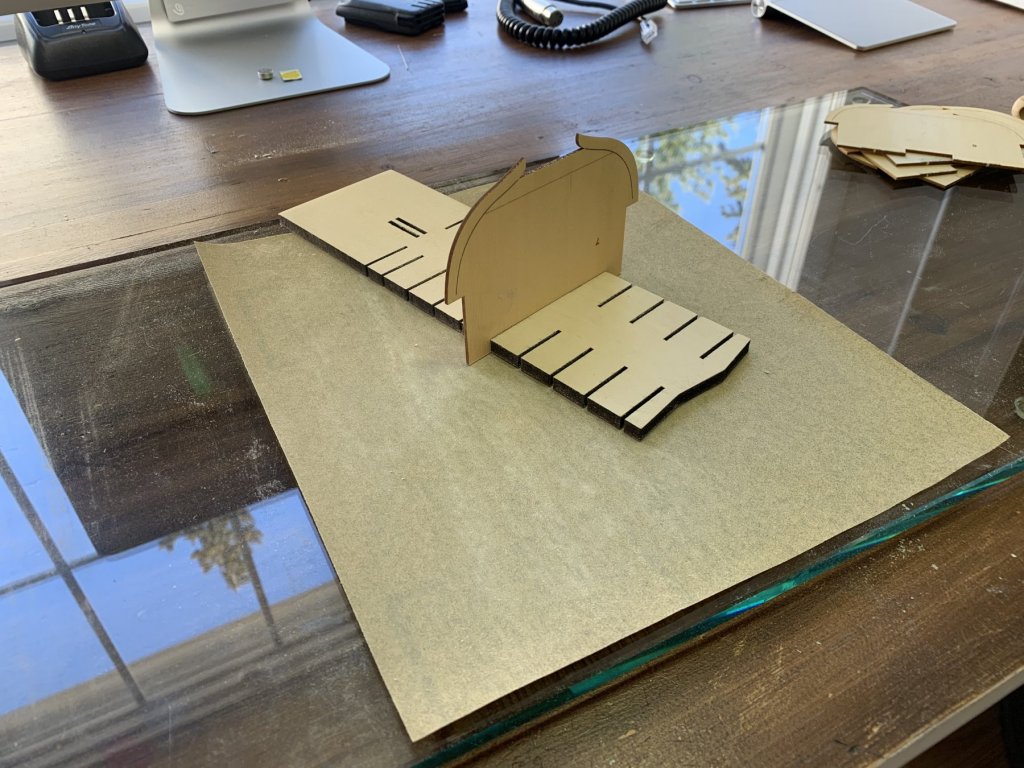

The bulkheads fit the building board with finished furniture tolerance. Eventual disassembly is going to be "fun". On a one by one basis I hold them to natural light looking for the lack of light seepage to be sure the bulkhead is flush with the building board.

When looking at the bottom of the building board most of the bulkheads are long by the thickness of a piece of paper or two . . .

I have a half inch thick slab of glass that I use as a "flat" surface with a piece of 220 to work off the bottom of each bulkhead, one at a time, in the actual location where it will eventually be placed.

And with happy hour approaching the two piece bulkheads were laid out with their respective floors, ready for glue.

-

Hi Griphos,

Thank you for looking in.

I thought it might be easier. I'll probably do the entire build this way.

-

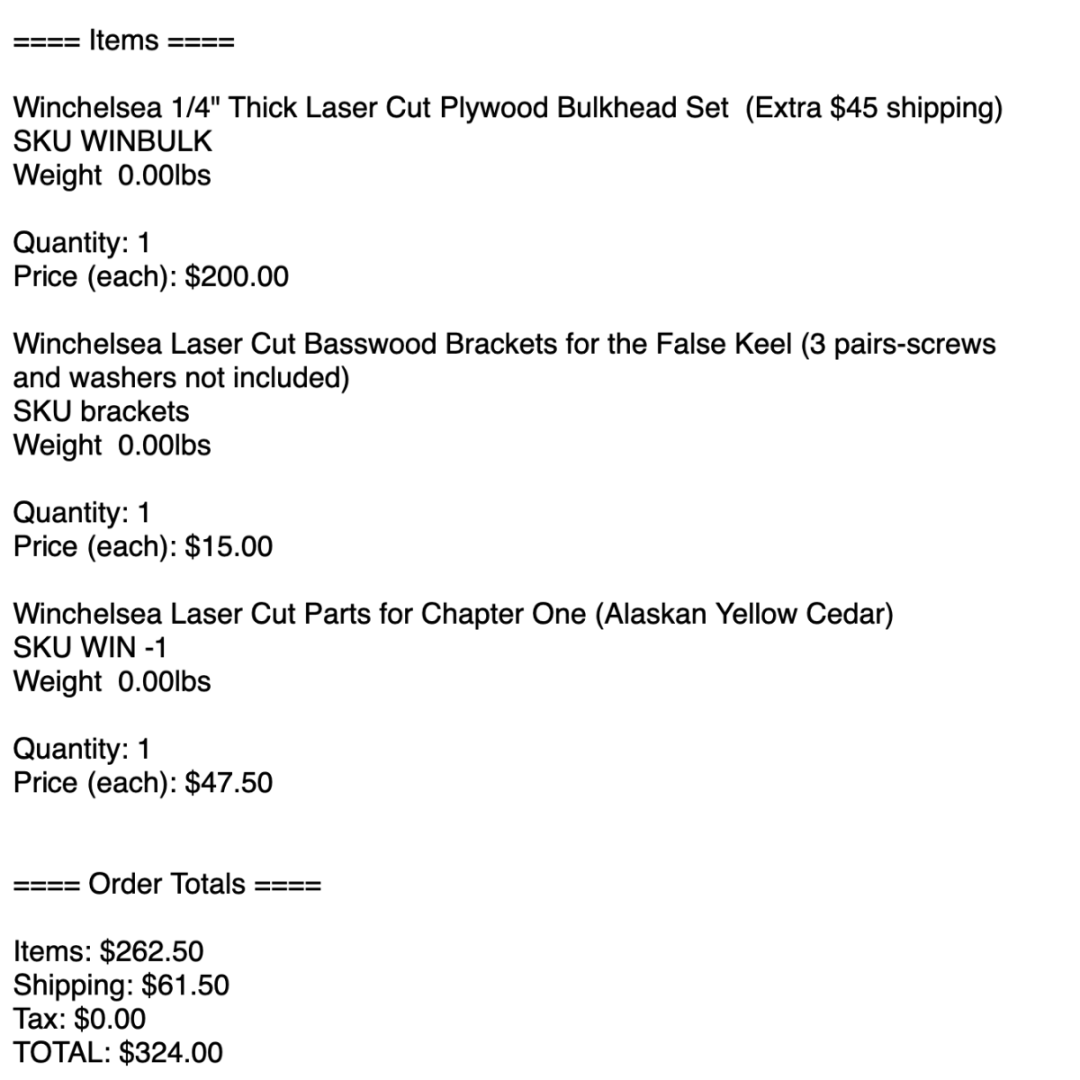

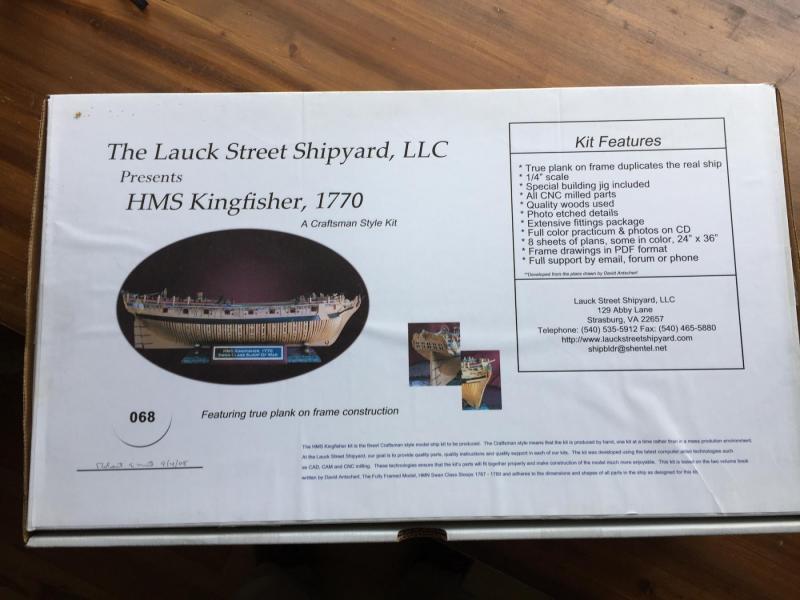

I have had my kit for a week during which time I have primarily been looking at what the rest of you have been doing to gain from your experiences and ideas. My comments about quick delivery, arriving in perfect condition and impression of high quality are the same as previously stated collectively by the group.

I fabricated the suggested spacers for installing the thinner pieces on top of the keel, stem and stern. I prefer the appearance of the scarfed keel and am building that way. It was impressive to see the notched piece fit snugly on top of the keel without need for any length adjustment.

I am using wipe on poly prior to releasing components. One coat is barely discernible, two as on the keel might be just about right.

I have seen one instance of waiting to attach the transom until the frames and keel are on the building board - I am inclined to follow that path myself.

Here is my beginning . . .

-

Rusty, that is spectacular - congratulations . . .

Respectfully,

John

-

-

Really nice, Steve . . .

Respectfully,

John

Seattle

-

Excellent. Well, Chuck has a new crop of happy campers . . .

-

-

Joining the list - hoping to be able to purchase a kit soon.

- Ryland Craze and JeffT

-

2

2

-

-

-

Thank for looking everybody. The kit found a happy new home 18 hours after I made the post . . .

Respectfully,

John

-

-

Don: I replied to this post incorrectly last night and it "bounced"! Let me PASTE it here:

It is GREAT to hear from you.

I have additional interests and have decided to attempt to liquidate some toys that I realistically don’t think I will use. I have hung on to those kits under the guise of pride of ownership. I see some directions in which I’d like to move and the sale of those kits would propel me.

All is well out here. I have simply been doing other things for awhile.

Respectfully,

JohnAdditionally, I have just photographed both kits and as soon as this is posted will go back to the two kit for sale offerings and add the photos.

- mtaylor, CaptainSteve and Elijah

-

3

3

-

-

-

Merry Christmas, dear friends . . .

Kurt, Mike, Denis, Joe & Doc, thank you for your kind comments. All is well at the Cougar Mtn Shipyard. We even had snow flurries on Christmas eve, unusual for Seattle. I am 900 feet up a 1400 foot hill and that helps.

I need to browse all of your posts and get caught up on what is going on. Denis, you can post a picture of one side of your house.

The fourth jongle was put in place and both edges of the uppermost jongle have been planked aft, port and stbd. The spell checker doesn't like some of these nautical terms!

Nothing exciting, just a strake section, glue, clamp, wait for it to set and then repeat the process.

All looks tight so hopefully it will sand out well. I need to experiment with a patch of this planking and see if I can use sanding sealer as well as poly or rubbed effect varnish. I still intend to use flat white for the under water hull area.

This is what I have on hand. I would appreciate comments on what would be appropriate as an undercoat for both the painted and the stain/varnish area.

Respectfully,

John

-

Over the past few months I drifted into other areas of interest. A couple of Raspberry Pi projects and some ham radio interests but all the while a plank here and a plank there - insufficient for a MSW post. During the process I have planked port & starboard at the same rate because I thought it would help me maintain symmetry at the stem and stern.

I am within about eight strakes of completion. Additionally, I see the possibility of a third and double length joggle and probably a couple of stealers. Today I did the four joggles. I'll run their four matching strakes tomorrow, probably a standard strake on each side of them and then decide on the advisability of an additional joggle.

So far I have done only a rough sanding. The plank seams are satisfactory - tight and no gaps.

Respectfully,

John

- capnharv2, Elijah, CaptainSteve and 10 others

-

13

13

San Bartolome galleon

in Wood ship model kits

Posted · Edited by John Maguire

forgotten option was added

My San Bartolome with the optional cradle, building slip, paint kit walnut wood and sails was shipped on October 9th and just cleared customs at JFK on Saturday. Pavel and Denis have been a joy to work with. I hold them in the highest regard . . ;.

Respectfully,

John