-

Posts

376 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Boccherini

-

-

The octopus gave it the look of a sea going food truck. Not very piratical.

Regards,

Grant

- BLACK VIKING and mtaylor

-

1

1

-

1

1

-

That's looking good John.

What is the overall length at present?

Regards,

Grant.

- FriedClams and mtaylor

-

2

2

-

Steven,

just finished browsing through the build log, an interesting project well executed.

Regards,

Grant.

- Glen McGuire and mtaylor

-

2

2

-

I nearly forgot to add:

may your Christmas fowl be seasoned and cooked to perfection.

- Keith Black, GrandpaPhil, Canute and 2 others

-

4

4

-

1

1

-

Glen,

that is a well presented model, congratulations.

Looking forward to seeing the completed project.

Merry Christmas and a happy New Year.

Regards,

Grant.

- GrandpaPhil, Glen McGuire, Canute and 2 others

-

4

4

-

1

1

-

-

Off to a great start. They look good. The koa has a pleasing colour.

I thought we might be spared livestock and penguin references this time. You've let the longhorns in...........

Regards,

Grant.

- Keith Black, Canute and mtaylor

-

3

3

-

-

-

Thanks for the encouragement gentlemen.

Further progress, deadeyes and chainplates:

I'm not sure about the size of the blocks for the lower yard lifts, they look a little large......maybe? They are the correct size for the line that runs through them. It might be hard to pick up in the picture. Any opinions?

Grant.

-

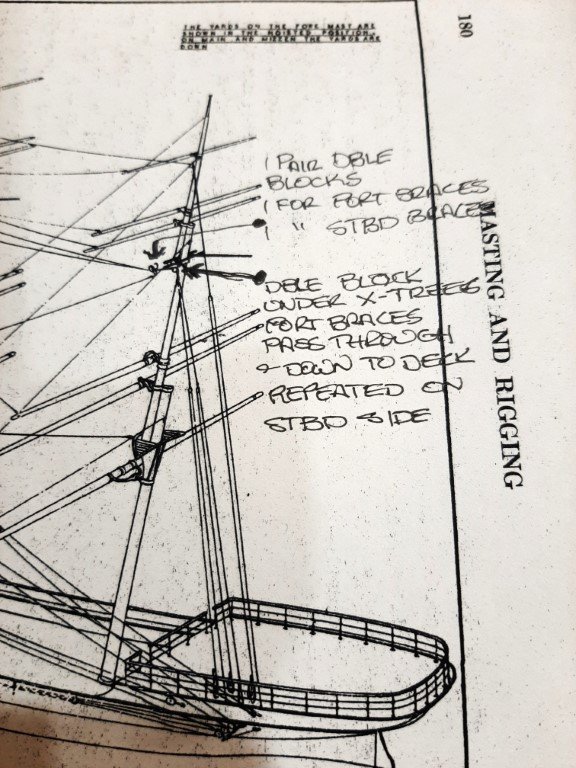

It's been a busy couple of months, heaps of progress.

Pin and cap rails installed, lower masts completed, lower yards shaped.

The steps up to the poop deck don't look right from some angles, very awkward to get right as the decks run off in different directions, nothing is nice and level or square.

The size of the lower yards surprised me. They extend past the rails 5-6m either side.

I've noticed a nasty problem with the 2 lower fore stays from the main mast. The rigging plan shows them running under cleats on the fore mast then to their deck fixing UNDER the forecastle deck. Just to complicate things, there is a windlass for the stays to go over. This is what happens when you start something with no real idea of what you're doing. Another "teaching moment".

Grant.

-

Pat,

thanks for taking the time to test and post your thoughts. I'll try Technoflux product with the oxy/acetylene torch and let you know how it goes.

Regards,

Grant.

- Glen McGuire, mtaylor, BANYAN and 1 other

-

4

4

-

Glen,

looks like Sweet Eileen dyes her hair, or possibly sports a wig/hair piece. Great pic.

Regards,

Grant.

- Keith Black, Glen McGuire, Canute and 1 other

-

2

2

-

2

2

-

Thanks. Take your time, it's not urgent.

Grant.

- mtaylor and Glen McGuire

-

2

2

-

0.2mm, impressive. I might try soldering some 0.27mm wire with my oxy acetylene Little torch to see if It's possible.

What's the heat gel you're using?

Grant.

- Keith Black, mtaylor and Glen McGuire

-

3

3

-

Pat,

Nice work.

Are you silver soldering the 0.3mm wire? If so, good heat control not melting the wire.

Regards,

Grant.

- Glen McGuire, mtaylor and Keith Black

-

3

3

-

Good to see you back in the workshop.

Grant.

-

Glen,

just caught up on your project, still enjoyable to see what you've been up to.

I was going to ask about the fate of the penguins........you anticipated my query.

Grant.

- mtaylor, Glen McGuire, Keith Black and 1 other

-

3

3

-

1

1

-

-

Where I'm currently at:

Note to self: stay focused while shaping masts.

This started a series of mistakes, it took 3 attempts to arrive at the finished items. The second pair were correct.....until I followed Underhill's advice to check the sizing of the mast above before committing yourself on the lower one. I'm becoming quite proficient at manufacturing masts from square stock as a result.

The "lug" on the cap for the crane caused some problems, snapping three 0.5mm bits or off centre holes on the underside while trying to drill holes for the crane pins. Drilling 1.04mm holes through the brass and brazing in 1mm tube sleeves with 0.5mm ID worked a treat.

Grant.

-

Kudos on the completion of an interesting project Dick.

Before setting foot on a vessel like that, I'd learn to swim, then secure a cast iron contract guaranteeing they would they venture no further than 100 metres offshore, at any time (including trips up and down rivers).

Grant.

- Ian_Grant, Ferrus Manus and mtaylor

-

3

3

-

Thanks Phil,

I've had a look at Wefalk's work, amazing stuff at that scale.

There is a "tipping point" with twisting. Too much and you end up with cable. I'll try using the rope walk, it may give more control over the process.

The copper "chain" blackens quite well after it has been annealed to remove the protective/insulating coating and soften the wire.

Grant.

-

-

Persistence has it's rewards. The book linked by Highwayman (Rudimentary treatise on masting, mast-making, and rigging of ships by Robert Kipping), if I've understood it correctly, provides sufficient information to work out the chain sizes.

This knowledge has created problem.....the smallest chain obtainable afaik is up to 42 links per inch, which works for the bobstays and jibboom shrouds, but not for the sheets etc.. These range from (if my reckoning is correct) 65 to 106 links per inch at 1:60.

Any suggestions on how to imitate chain at this scale?

Grant.

Mycenaean War Galley by Woodrat - 1:48 - Shell first Plank on Frame

in - Subjects built Up to and including 1500 AD

Posted

Dick,

I should've put a "😀" after "van". My apologies if you interpreted my light hearted comment as criticism. It was not intended as such.

Regards,

Grant.