-

Posts

1,694 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JesseLee

-

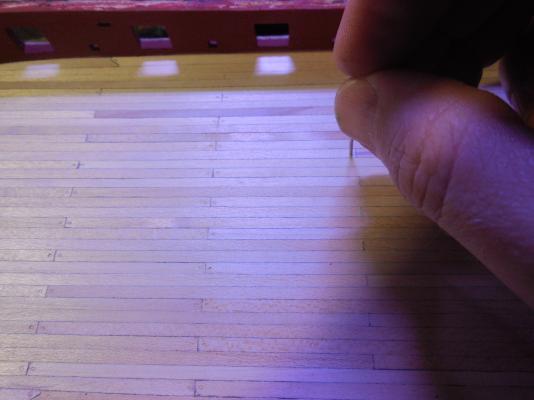

Thank you everyone for all the kind comments & for all the likes! I changed tree nailing methods. Instead of using toothpicks like I did on the outer hull I went with using a filed syringe needle. I didn't want the tree nails to stand out & look darker on the deck. It worked pretty well, got the results I wanted. I did have a problem with it actually pulling the plug out sometimes & I had to go back over it & fill in where that happened.

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Thank you Chuck, this is a great build! Scraped the deck with a razor blade. Got it all even & smooth but nicked the crap out of my bulwarks in the process! Got a lot of spots to fill & re-paint!

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Carl & George! Now the deck planking. Got the rest of the margin planks down. The thought of joggling had me joggled for a while but I finally decided to go for it. It wasn't as difficult as I thought it would be but did have some goof up's along the way. I studied the instructions & others build logs trying to figure out what butt shift to do. I settled with the one Chuck showed in the instruction manual because it made it much easier for me to have them always lay on the existing bulkheads ( a little confused as to which butt shift this actually is ). I did the caulking the same way I did the outer bulwarks, I used black paint- wiped on like stain to keep it thin. Was very unsure of how well I would get the planking spaced & keep it straight from front to back so I slowly cut it all out & dry fitted the whole deck before I glued anything down - holding a lot of planks in place with strips of masking tape to keep it from popping all out on me. This was the first step in this whole build where I got it right the first time. Didn't have to start over anywhere- it all fit right so I picked each piece back up & glued it back down. The glue must really swell the wood because the glued pieces all fitted tighter than the non-glued dry fitted pieces.

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Getting behind on my posting, got a lot of catching up to do. As I stated earlier, I'm going to wait on the cap rail right now but will work it in before too long. Got the inboard bulwarks painted red. Took a clearer shot of the transom molding- that first pic was pretty out of focus. Glued the forward margin planks down & did the companionway framing. My stupid computer wont load the pics in order again but you can tell what's what.

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

This was one of the many things about this kit & its instructions that I wasn't sure about. I often wondered as I did this build just how much of it was wrong. I should have stopped & asked more questions I guess. I wonder if maybe there should be a hook involved here? No one said anything about it when I posted the pictures.

- 389 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

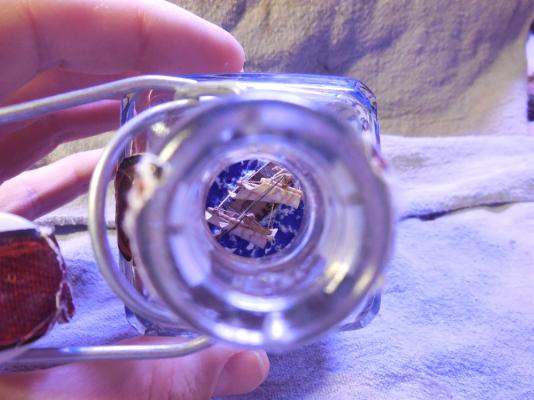

Thanks for the all the comments & likes! Marcus, yes I'm leaving both labels on so it is both one of my hot sauce bottle collection & a SIB. Pictures of the finished build.

- 71 replies

-

- pirate ship

- bottle

-

(and 1 more)

Tagged with:

-

- 71 replies

-

- pirate ship

- bottle

-

(and 1 more)

Tagged with:

-

I like the natural over the yellow but I know you will make it look good no matter what you go with!

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

- 71 replies

-

- pirate ship

- bottle

-

(and 1 more)

Tagged with:

-

Like George said, some don't glue them. I think this is so if you don't get them lined up perfectly you can pull it one way or another with rigging such as shroud lines and such. I have always glued mine but as George said again I wouldn't epoxy them just in case you have to undo it for some reason like not being lined up right after the glue dries. Full sails hide more rigging & blocks more open views of the deck from certain angles. No sails or furled sails show more of your other work. It a personal preference. I think with furled sails you kind of get the best of both worlds.

- 389 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Thinning down the inside bulwarks turned out to be way more involved than I expected. Took a long time & keeping them the same thickness was really fun . I ended up with notches in the bulkheads. Filled them in with wood filler. Planked the inside bulwarks.

- 1,306 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

- 71 replies

-

- pirate ship

- bottle

-

(and 1 more)

Tagged with:

-

Brushed the dust & stuff off the inside of the bottle. White painted the wave caps. Didn't trust that glue would hold hull down to putty when the rigging is pulled so I wedged wood sticks down in the putty to have something more solid to glue the ship to. Cut out sails. Stained them with coffee. I always do a wash or 2 in baking soda if I use tea of coffee to neutralize the acid in them.

- 71 replies

-

- pirate ship

- bottle

-

(and 1 more)

Tagged with:

-

They look ok to me too. Remember they need to be big enough for the sail material to take up its space & still be loose enough to easily slide up & down the mast.

- 389 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Robb, as for the number of bands I found that different builds had different numbers. So few records I think AL just guessed & whatever you decide to do will be fine. I saw one build that had 10 - 11 for each mast. I somehow ended up with 11 for one mast & 8 for the other. I cannot remember for the life of me why. Most of the details of the Scottish Maid are not really known because all the records were in one place & destroyed in a fire a long time ago in England.

- 389 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

- 71 replies

-

- pirate ship

- bottle

-

(and 1 more)

Tagged with:

-

- 71 replies

-

- pirate ship

- bottle

-

(and 1 more)

Tagged with:

-

Thank you Michael! When I first got done with them I thought I had over focused on them & messed them up. Turned out to be the best ones I've ever done. I definitely would use much thinner material next time.

- 607 replies

-

- scottish maid

- artesania latina

-

(and 1 more)

Tagged with:

-

Thanks Patrick & Bob! Yes Patrick, that's my Syren in the background

- 71 replies

-

- pirate ship

- bottle

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.