-

Posts

2,132 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by pete48

-

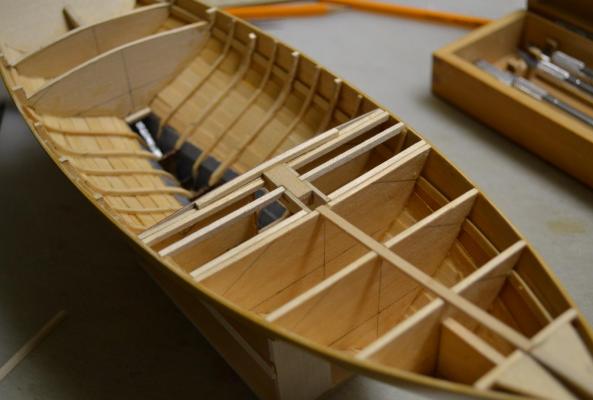

Thank's Bob, I was fortunate that today was a Snow Day from work, so I finished the Floor Framing and Decking. Next will be to start on the Seat framing. I am thinking about a removable grating for the bilge access. Here are the results

- 258 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

This morning, I started by installing the Birch ply to the rear Deck Bulkhead, I then finished the Keel Bolt Block framing, I then started on the Cockpit Floor framing. it was challenging part of the build that I had wanted to do on previous versions of the Buzzards Bay. Next will be to finish the Floor framing. Here are the results

- 258 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

Hi Crackers, I have never been there It looks Beautiful, I agree a full size replica would look good there ( or anywhere for that matter ) I live in North Idaho and Have done all of my Sailing on Lake Pend Oreille (for the last 7 years and before that Puget Sound ) is that your boat in the pic? ( and any chance I get to show a pic of my Boat I will ) Have a Merry Christmas and a Happy New Year Best Regards, Pete

- 258 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

Thank you, Cap'n'Bob, I am very pleased with how she is turning out. I am currently working on the Floor framing ( it's a lot more involved that I had originally envisioned ) however, I think by adding these details will set this build apart from the previous 2 boats. Have a Merry Christmas and Happy New Year Best Regards, Pete

- 258 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

Hello Matti, Beautiful Hull that you have built, I like your shop space, I will have to pull up a chair and follow along Best Regards, Pete

-

Last Night, Before I got to carried away, I decided to seal up the inside of the Hull with Titebond 3 ( Brushed on ). When I awoke this morning I decided to paint the Bilge ( Grey ). I then ( while the paint was drying ) turned my attention to finishing up the framing for the Mast step. I then glued the Birch on to the forward Bulkhead. Next will be to finish the floor framing in the Cockpit. Here are the results

- 258 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

HI Patrick, there is absolutely No trick, the Birch that covers the Bulkheads were stained before putting them in the boat. And they are just dry fit at this time, the Door trim was glued into position after the Stain was applied. You and everyone out there have a Merry Christmas and a Happy New Year Best Regards, Pete

- 258 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

Today, I started by laying out the bulkhead for the door, next I cut out the birch followed by the Bulkhead, I then cut out the Door moldings, I then Stained the Birch ply for the Cockpit section Cherry Red, I then turned my attention to finish making the Keel bolt blocks and stained them a provincial ( min wax ) I then stained the framing for the Keel bolt blocks Cherry Red. Only the Keel bolt blocks have been glued everything else is dry fit. Next will be to finish up the Keel bolt framing followed by the Floor framing, Here are the results

- 258 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

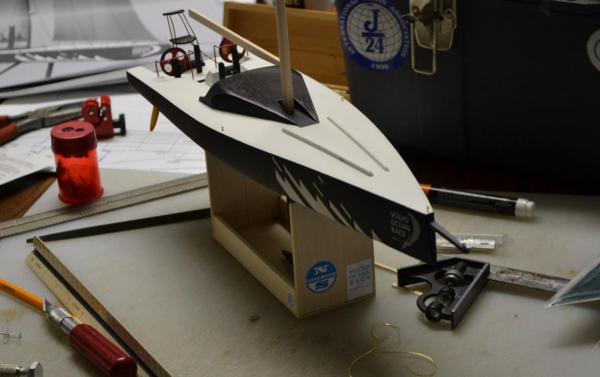

Michael, This is very tempting and I will build one at 1 1/2" = 1' - 0" scale, just not sure when Bob, I appreciate that everyone is waiting and I definitely would like to build one at that scale, However, I have been planning another build first Best Regards, Pete

- 258 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

Mark, thanks for all the useful information, this ( debonding) was something that I had no idea about Best Regards, Pete

- 258 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

Hi Patrick, The Mock up looks great, Mock up's are a very helpful tool Best Regards, Pete

- 1,083 replies

-

Wow, That is looking sharp Mark, I like the contrast in the planking, It looks more like the real deal Best Regards, Pete

-

That's a tough order there Patrick, ( pause ) so will there be a working bow thruster as well?( just kidding ) but seriously about the working engines .............Gasoline powered ??????????? Best Regards, Pete

- 1,083 replies

-

Hi Mark, I will do that ( in regards to the 90% Alcohol ) it makes perfect sense, less water less warpage. what do you use for de-bonding ( ungluing joints ) you brought up some fantastic points. much appreciated Best Regards, Pete

- 258 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

Very Nice, Bob, she's looking good, Beautiful work Best Regards, Pete

- 348 replies

-

- pequot

- cable ship

-

(and 1 more)

Tagged with:

-

Hi Druxey, The rubbing Alcohol that I use is 70% Isopropyl Alcohol, It is the kind that can be purchased in a Grocery Store ( as a First aid antiseptic ) and it does contain water Hello Michael, I am thinking that the same thing can be done at a larger scale, However, I would probably pre bend the Ribs and attach them to the frames ( after subtracting the thickness of the Ribs from the frames ) Kind of like how they do it on the full size versions, I have not tried this method on a Model. I do think on a larger Scale Model, that it would probably work out well Best Regards, Pete

- 258 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

Hi Piet, You are absolutely right, just depends on the situation, ( in model building ) I always grab the X-acto first ( for almost everything ) Best Regards, Pete

-

Thank you, Patrick, I am planning to make the Cockpit lockers open as well as access to the bilge. ( so visually it should look like the real deal when every thing is opened up ) Thank you, Piet, I am very pleased with how the Bent frames turned out, and using alcohol does work so much better than water Thank you, Druxey, The biggest advantage to using Alcohol is that it evaporates faster than water, giving you usable parts faster Thanks, Yves, It was a bit nerve-racking removing the frames, You just have to go slowly and take your time ( that's kinda the key for a lot of things ) Best Regards, Pete

- 258 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

Today, I decided to work on the Cockpit section, I started by cutting out the Birch ply for the rear Deck bulkhead, I then cut the rear Deck camber on the last 2 frames. I then turned my attention to carefully cutting away the 3 frames in the cockpit down to the height of the bent frames that were installed yesterday. I then started on cutting out parts for the floor framing. Nothing has been glued at this point, the Birch ply, Deck framing, and Floor timbers are just dry fit. Next will be to cut out the Door in the forward Bulkhead and finish up the Deck and Floor framing. Here are the results

- 258 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

Thank you, Patrick, It was not that complicated to get the compound curves. ( it helped that the soaked wood was very workable ) Thank You, Michael, I like to let the wood soak for about 2 hours, and its just standard 70% Isopropyl Alcohol ( purchased at the grocery store nothing fancy ) Best Regards, Pete

- 258 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

-

Hi Julie Mo, I think a block plane would work better than a spokeshave in this application, Thank you, Michael, I have used X-acto knives since I was a kid, I was about 10 years old when I got my first set for Christmas, ( I still use that wood box to house the knives, its 40 years old ) On the Mast tapering, I will have to try the trick you learned ( perhaps on the Buzzards Bay Mast ) Hello, Mark, There are Dagger boards ( port and starboard ) and the Keel swings and acts as a counter balance. its a very interesting design Best Regards, Pete

-

Today, I started by soaking 1/16" square Basswood in Rubbing Alcohol, These will become the bent Ribs for the exposed sections of the Boat, I then turned my attention to laying out and building the Mast Step, once glued in, I laid out the Forward bulkhead on 3/32" Birch ply and cut it out. Next I took the Basswood that had been soaking in Alcohol, bent them into Ribs then glued them into position. I then started on the Fore Deck framing. The framing and Birch ply are dry fit at this point. Next will be to finish the Deck framing and seal up the interior with Titebond 3. Here are the resuts

- 258 replies

-

- buzzards bay

- herreshoff

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.