-

Posts

1,314 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MrBlueJacket

-

So we go to the next pair of deadeyes. Now the task is to make sure all the upper deadeyes are at the same level, which should be parallel to the waterline, not the deck.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

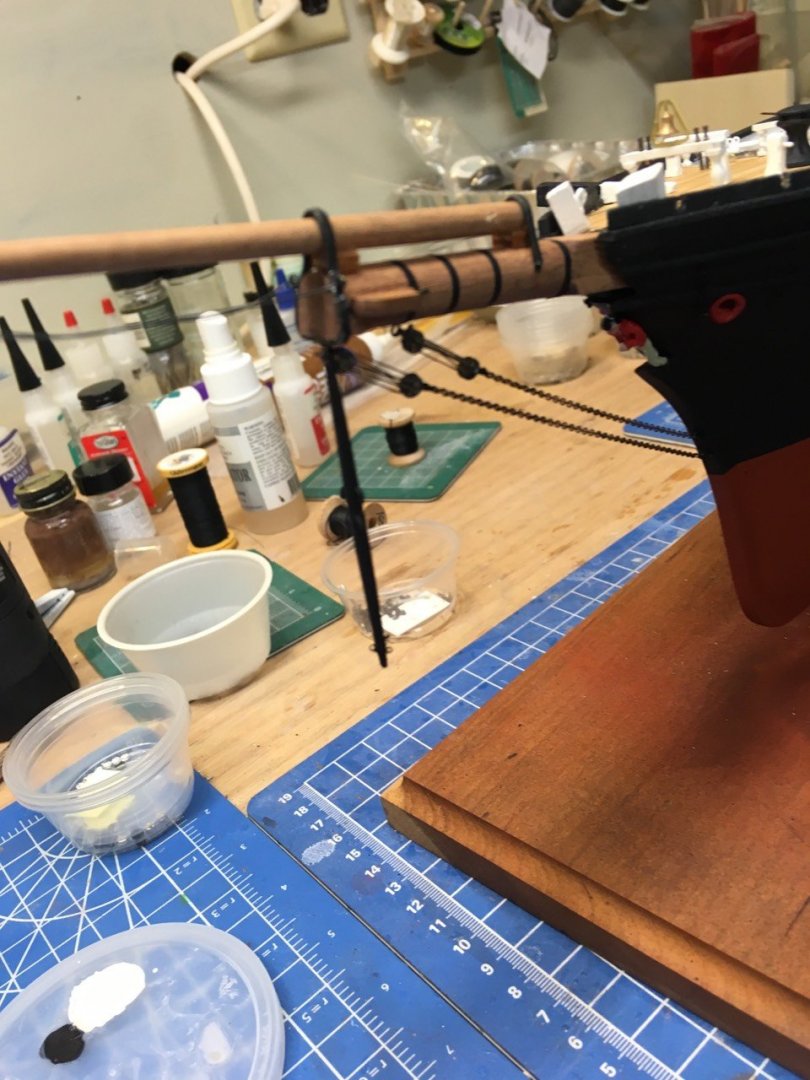

And so we begin the lower shrouds.The first shroud on each side, like the bowsprit, is critical to the alignment of the masts.Unless they are correct, the problems will mount later on. BTW, the masts are not glued in, they are held just by the rigging, like full-size practice. The lanyards on both sides are loose, then tightened up and adjusted to make the mast square before tying off.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Gift for 50th B Day

MrBlueJacket replied to ChrisLBren's topic in Modeling tools and Workshop Equipment

battery powered Dremel tool -

To avoid problems, we have to think ahead about what needs to go where before the other stuff gets in the way. For example, attaching the Mizzen stay would be nearly impossible after the main shrouds are installed.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Now starts the stepping of the masts. Here's the Mainmast being set up at the proper rake angle, as determined by the template provided in the kit.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Lead fittings are subject to corrosion (lead bloom) and decay, eventually turning to white powder. If they are perfectly sealed with paint, that doesn't become a problem for several decades. However, I suggest you replace them with Britannia metal fittings (lead-free pewter) - you can find probably everything you need from the fittings section of our website.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Mike, Since you are doing a build thread on the Notman, when it is done you will be getting 10% off your next kit you get from us. FOr the Red Jacket, that means a $63 savings. Nic

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

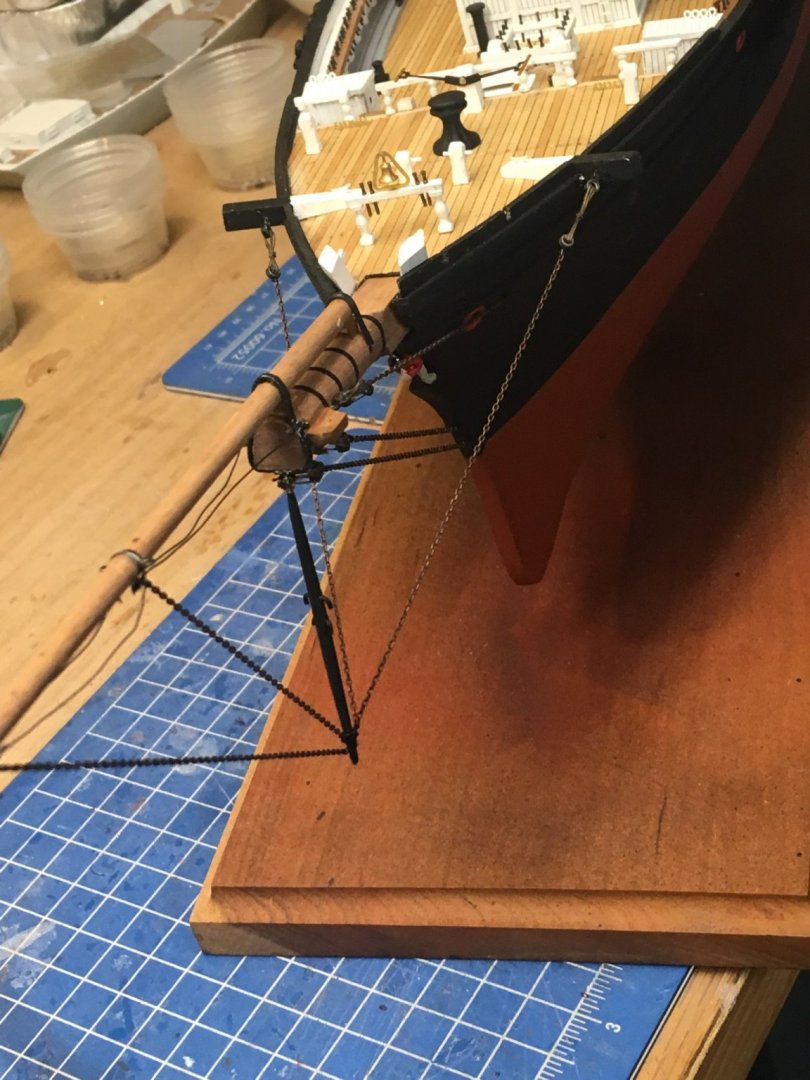

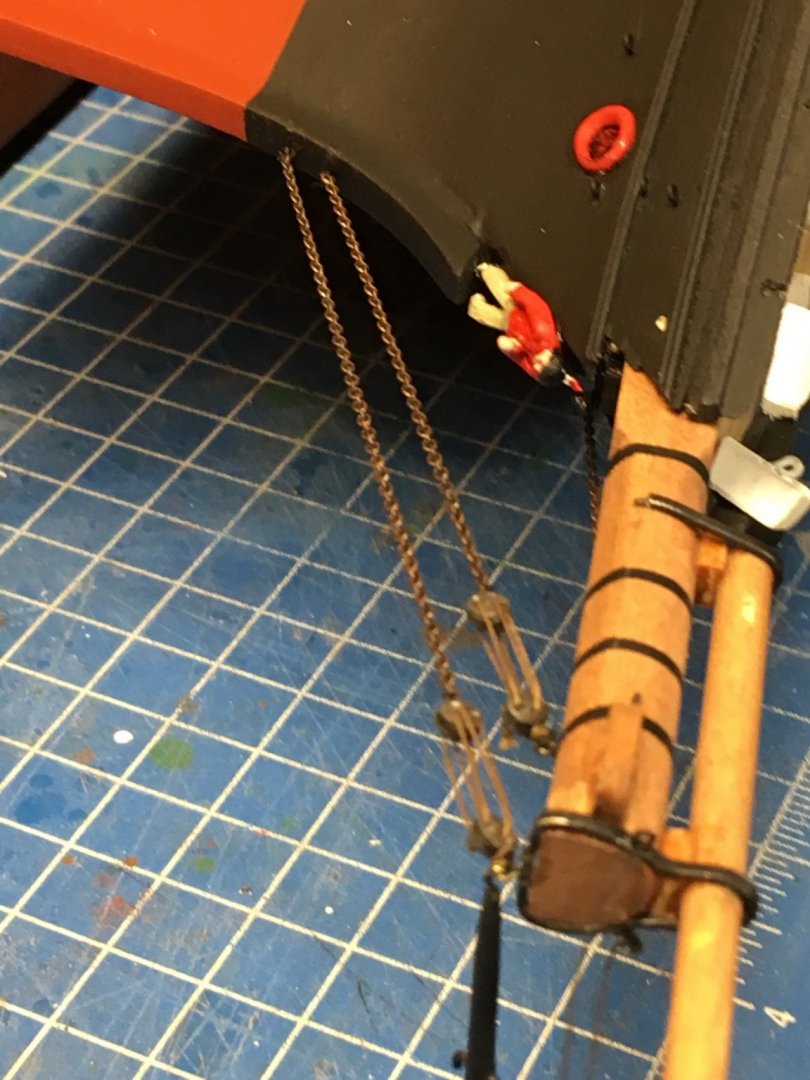

And this is the "money shot" - making sure everything is square and straight. Especially the martingale, it is balanced on both sides, and I had to play with the lanyards to get the tension just right.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

To make it easier to work on, I lay the ship on its side, with a foam rubber sheet under it for protection.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Luckily, back last February 25th, I put a stop block under the forecastle to position the bowsprit correctly. All I had to do was put some glue on the end and stick it in.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Getting the second boat tied down was a bit problematic because the rigging line had to go under the first boat.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Turns out there's 17 blocks and bullseyes on the main mast. Went back and decided to finish the ships boats. A little putty and sanding, then paint.Tie it down and its done.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Auto glazing putty is great stuff. It is lacquer-based, so even after it dries, a little lacquer thinner will soften it.

- 20 replies

-

- red baron

- lobster boat

-

(and 2 more)

Tagged with:

-

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

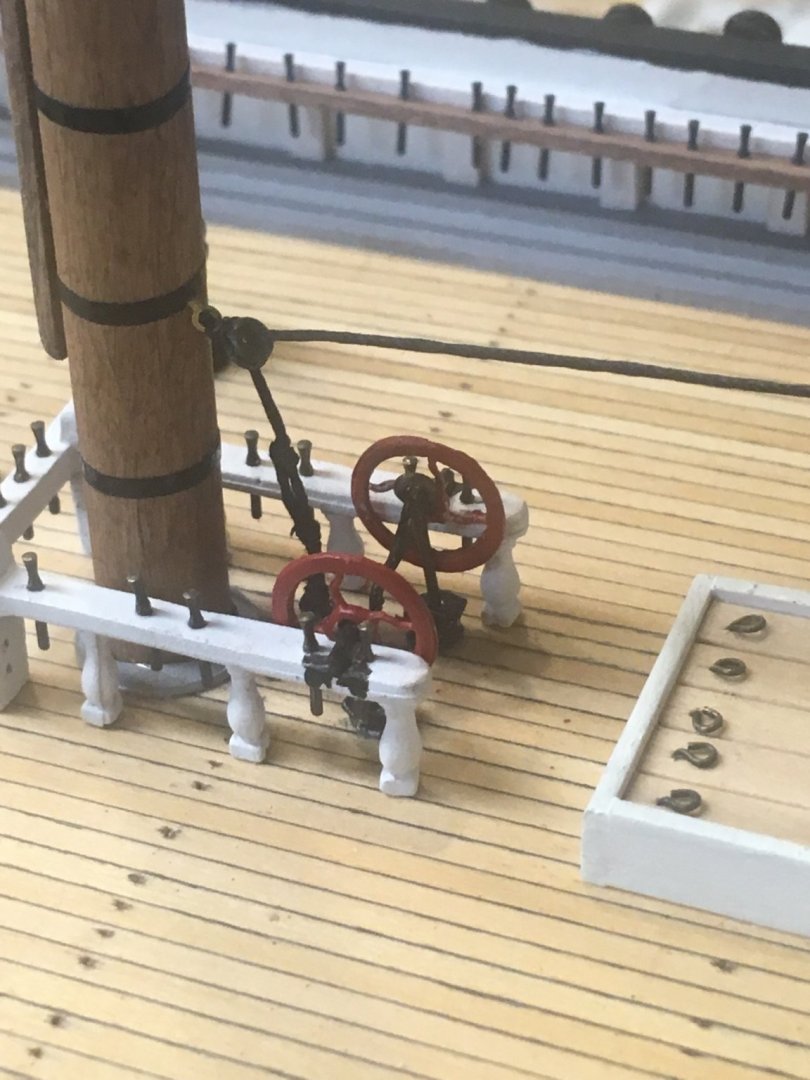

So I'm moving on to attaching the various blocks etc. to the mainmast. I decided to put each set of blocks into its own holding cup. That's quite a lot of cups!

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Nicely finished. Don't forget, you will get 10% off your next kit purchase. Nic

- 29 replies

-

- portland

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Hi Mike, I, of course am partial to the Smuggler. The hobby store Eskader in Stockholm may have one on the shelf. Nic

- 77 replies

-

- schooner

- solid hull

-

(and 4 more)

Tagged with:

-

Hi Mike, The kit comes with a sheet of scribed decking, but I substituted a sheet of glued-up decking instead. The glue is black, and makes a very realistic deck. My good wife sewed the sails for me. Nic

- 77 replies

-

- schooner

- solid hull

-

(and 4 more)

Tagged with:

-

Then I guess we have a mutual admiration society going here.........

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.