-

Posts

1,790 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ulises Victoria

-

Hello Casey. I have not used Hypo fabric glue in conjunction with beeswax, but I have used beeswax with diluted white glue. The glue just doesn't go through the wax. So my guess is that Hypo glue will not have any effect over beeswax to secure knots. In fact I stopped using beeswax at all for my rigging. I secure my knots with a mini drop of either Clear FLAT varnish or just diluted white glue. I NEVER use CA to secure my knots, by the way.

-

Do You enjoy Rigging your ship?

Ulises Victoria replied to bear's topic in Masting, rigging and sails

In reading all the posts in this thread, it is obvious that the vast majority of us ship builders do enjoy the part of the rigging. On a side thought, it is hard to believe that the whole operation and in some cases the life of such majestic man creations, was dependent almost totally upon the humble hemp rope. Cheers Ulises -

Do You enjoy Rigging your ship?

Ulises Victoria replied to bear's topic in Masting, rigging and sails

@RedDawg. I noticed in your Thermo you have all the central rigging but no shrouds. Did you do it in that order on purpose? I think this way is more likely that some of the rigging interferes with the correct laying of the shrouds. Just a thought. -

My opinion: I like ships of the pre-1800 era. Vasa, Soleil Royal, Sovereign of the Seas, etc you get the idea. Lots of ornamentation and bling. I would love to see well made ornamentation. No matter if wood, resin or metal. Only to be accurate. They can be painted anyway. I am still looking for a good POF kit of a ship of this style. Price range: I know quality comes with a price, so that would not matter much or in any case, would be understandable if priced high. Detailed instructions (or lack of) is something many builders complaint about too often. Accurate plans. Scale: A very tough question. The bigger the scale, the better the detail and the harder to find a place to build and display the ship. (The opposite for small scale.) Thank you Chuck for your interest!

-

Hello Hank. You don't need to respond to notifications. They are just informative so you know who has liked to your posts, etc... You can tun them off if you wish. Just click the "Options" button in your Notifications window.

- 187 replies

-

- new jersey

- trumpeter

-

(and 2 more)

Tagged with:

-

Writing that address directly in my browser window, takes me to a blank page with a hosting logo in the middle. Nothing else. Edit: However a search in Amazon for Vincenzo Lusci yields several items. https://www.amazon.com/s/ref=nb_sb_noss?url=search-alias%3Daps&field-keywords=vincenzo+lusci Edit II. Unfortunately, the book you mention is "Currently Unavailable"

-

Do You enjoy Rigging your ship?

Ulises Victoria replied to bear's topic in Masting, rigging and sails

Rigging is the best part of ship model building for me. (Well, except maybe starting a new project ) I find the rigging part to be extremely fun to do, (well, except tying several thousands of clove hitches on the ratlines ) And especially because that is the last step before finishing the project, (and start a new one ) Best regards Ulises -

Sjors! I was beginning to miss your likes! Thank you and Pat for your comments, and everyone who clicked the "like this" button. This encouragement is always welcome!!!

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

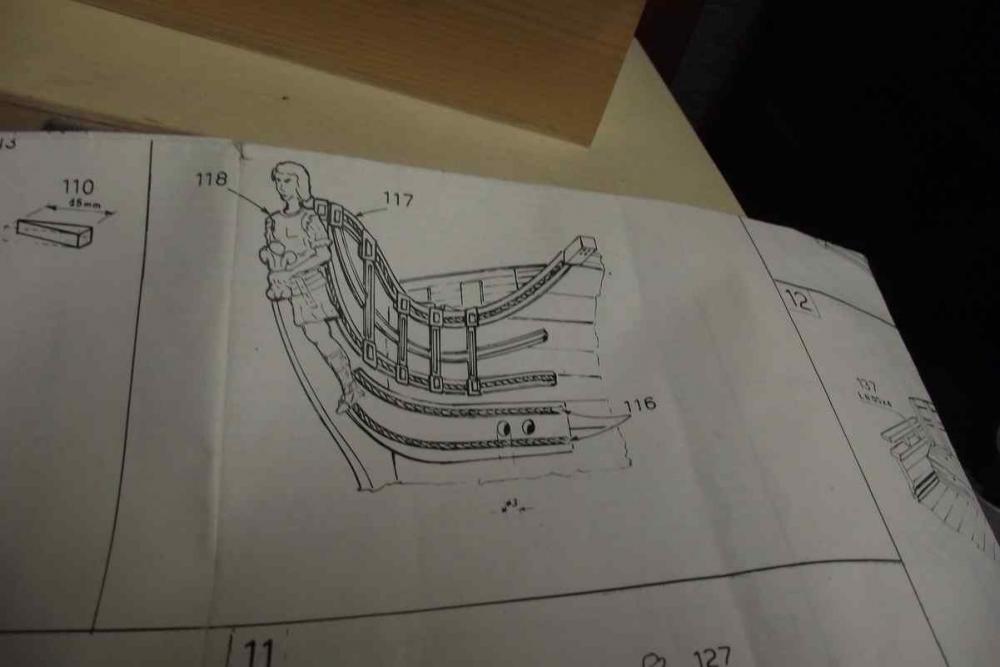

Hello all. Update. Worked the metallic parts in the bow. I fixed these parts like this. With thew upper part level with the top part of the keel. Then I realize they were too low. No room for the anchors holes. Then I looked more closely and saw that they should be higher: The top part in line with the back of the neck of the figure. I unglued them and fixed in their new position They look better now. I painted them black and then drybrushed the gold so that some of the black showed out. I like the "old" effect. Thanks for watching!!! Ulises

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Thank you all for the many likes. They really mean something to me. Hey Heinz (Karleop), are you coming to Monterrey for your niece's wedding?

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

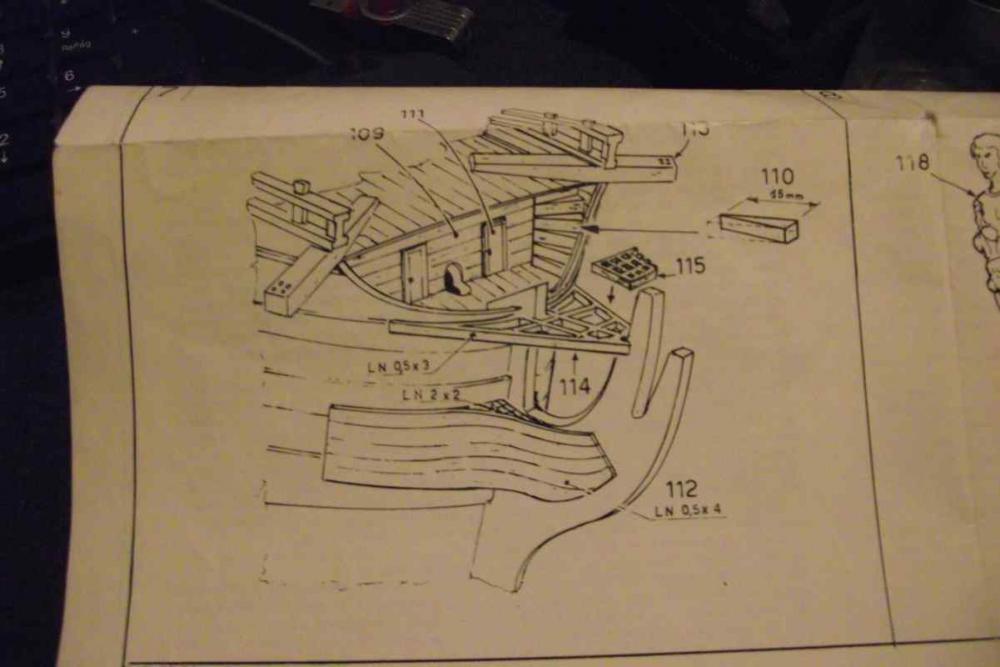

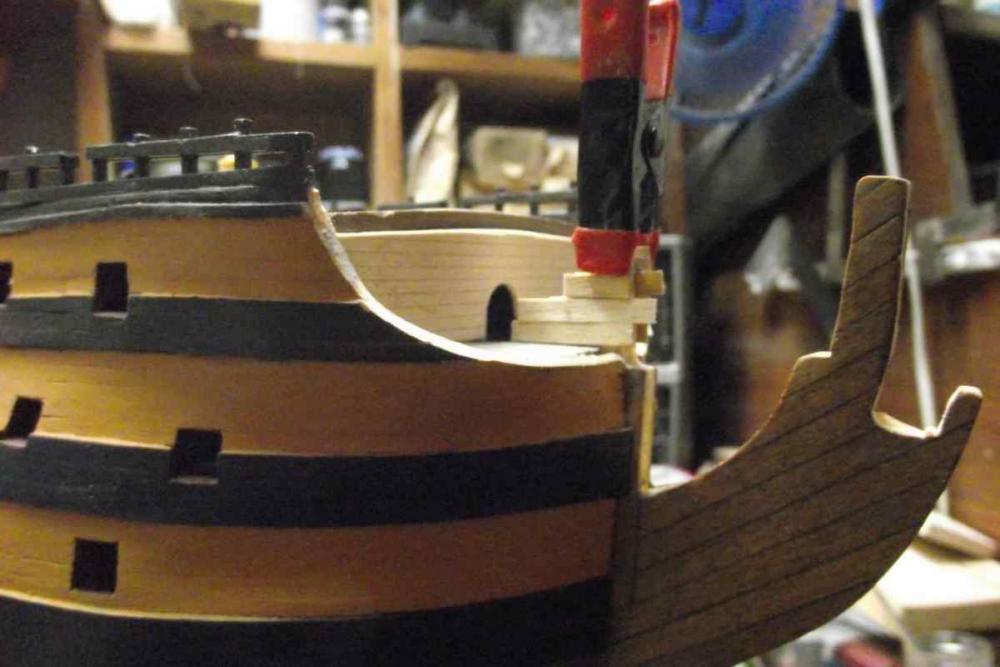

Hello all. Finally the dreaded part 112 is done!!! I am happy with it although it has its flaws. As you can see there is some unevenness here and there. I'm gonna' have to live with that. As you can see here, the instructions say to use several 2x2 woods to fill the space and then shape accordingly. I decided to use a piece of balsa instead. Here I am making a shape with cardboard of the profile. Planking starts. Due to the nature of the shape and the difficulty to properly clamp these planks, I decided to use contact cement to do this job. Worked wonderfully. I also changed the size of the planks from .5 x 4 mm to .5 x 3mm. Making sure both sides of that part will be at the same height. Both parts are finished and painted. Here is starboard When finished, I noticed some spots that were a bit bouncy, meaning they were not very well glued. And I was undecided about what color to use here. I decided to give a coat of CA to the entire area and then paint it black, to match the color of the wales. Unfortunately, the paint I used to paint the wales became unusable so I used a different paint, and it shows when looking closely. General view of the ship at this moment Thanks for watching, mates. All the best. PD We celebrate mother's day today. Best wishes to all moms here, either members or members' mom. Ulises

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Thank you so much for your detailed explanation, Pat. Just what I needed!!! Best regards Ulises

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Thank you all for your likes and comments! I was expecting some comments on my crude method of measuring the angle of the bowsprit. Perhaps a suggestion on how to do it more properly, or if what I did can be taken as a close enough method. Thanks again for visiting!!!

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Thank you all for your comments! Pollex... I specially appreciate your comment. So I went to check things and this is what I did and found: I measured the angle in the plans and it is 34º I don't know any method to actually measure the angle in the ship so this is what I came up with: Placed a bubble thingy on the deck to check for correct level. I then used the same 34º in my tool and checked by eye and hand how close the bowsprit angle was to 34º. against the waterline. In my opinion, it is very close, but as I said, this may be a very crude method for checking that. Any suggestion will be greatly appreciated. (If the ship looks not aligned, its because the camera is tilted. Thank you!

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

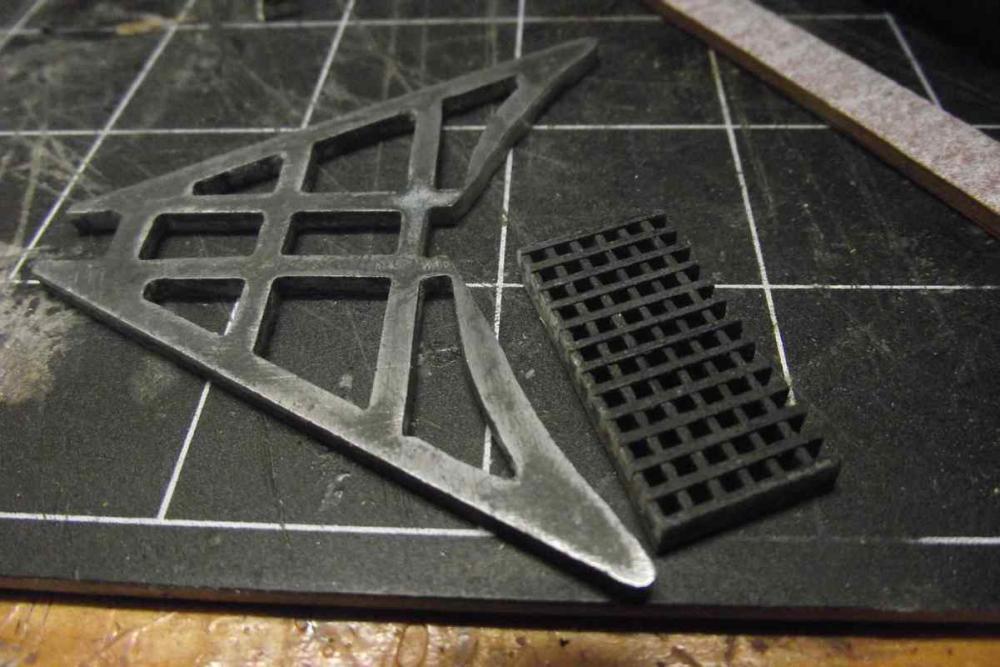

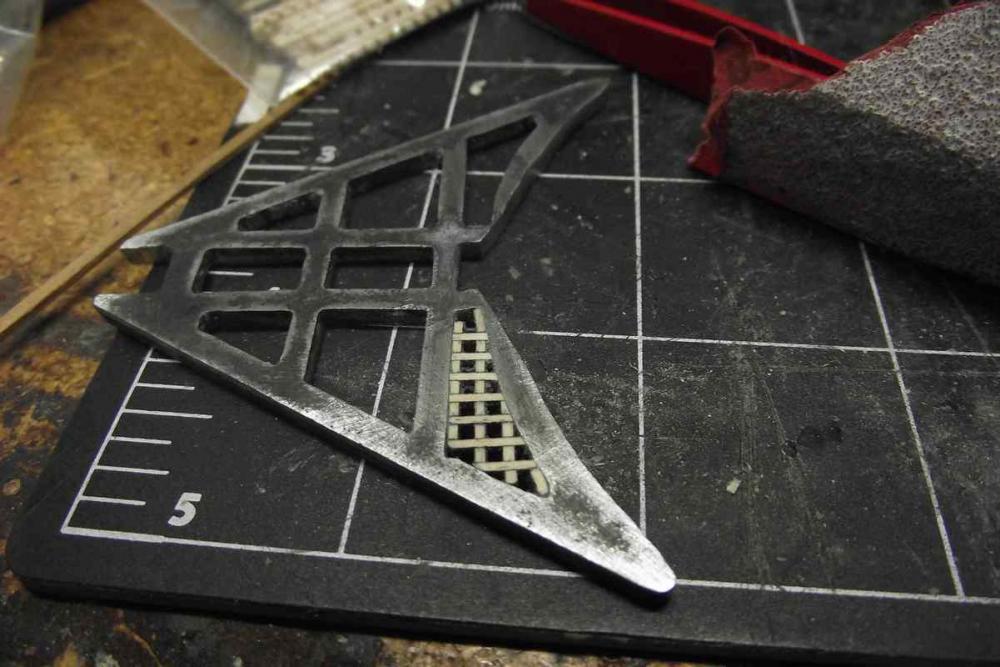

Hello there, mates! Another step I wasn't too excited about, was opening the sides of the bulwarks at the bow, so those large pieces of wood that support the anchors (English name, please?) could be fitted. Here they are These pieces taper a bit at the inner end. Thanks for visiting! Ulises

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Addendum to previous post. Completed the bow area with the steps. (I took some liberties here also. There was no way they could be fitted as per the drawings) Thanks again!!!

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

David... the second time I fitted the hole around the bowsprit before placing the wall in place. In fact, at the moment of the photos it is not definitely glued yet.

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Thank you Keith! The problem here was the wood. I opened a small hole with a file and then used a small sanding drum to widen it. The wood started to fly in splinters. Part of the problem was that it had no back support. As you can see in the photos, there were only a couple of columns behind it. Cheers!

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Hello again, mates! More than an update this is a recount of something I had to do again. After placing the doors in my last post, I tried to open the hole for the bowsprit to pass through. This is what happened. Ouch! It was a tough call, but it has to be re-done. Fortunately, I managed to save the doors. So I removed the old planking and start over. I am going to shamelessly confess that this time I am cheating. I will use again the pre-scribed balsa wood that I have in hand for this job. I am here gluing some business cards in the back for added strength. Actually, it was more work trying to fit exactly this part on all four sides plus the bowsprit opening. Here I am placing a mock bowsprit. Had to add a couple of wood pieces so the bp could make full contact with its support. Fixing that fix so that it looks good. Things start to look better. With doors attached. Which looks better....? This... ... or this? Thank you all for your continued support and encouragement. Badly needed!!! Best regards Ulises

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

-

Sjors: Your work is stunning. I admire and envy how clean your build looks. Excellent job, my friend. Ulises

- 1,616 replies

-

- caldercraft

- agamemnon

-

(and 1 more)

Tagged with:

-

Hello Don. Thank you and all who replied, for your kind words. Heller's Royal Louis in 1/200 if I remember correctly, was a pleasure to build. I gave that one to a very dear friend. To glue dissimilar materials I always use epoxy. I try to avoid CA (superglue) as much as possible and use it only for emergencies or desperate situations. Thanks for watching! Ulises

- 786 replies

-

- Royal Louis

- Finished

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.